Professional Documents

Culture Documents

Slide Plate Selection Chart

Uploaded by

Lovebin0 ratings0% found this document useful (0 votes)

3 views1 pageThis document provides specifications for PTFE filled with 25% glass, including mechanical, electrical, and thermal properties. Key properties include:

- Specific gravity of 2.1-2.3 and water absorption of 0.013%

- Tensile strength of 2000 PSI minimum and tensile elongation of 200-250%

- Flexural strength of 606 PSI and modulus of 2.39 x 105 PSI

- Coefficient of linear thermal expansion of 6.98 x 10-5 per °F and thermal conductivity of 3.12 Btu-In. hr-sq. (ft. °F)

- Continuous service temperature of 550°F and unaffected by weatherability

Original Description:

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis document provides specifications for PTFE filled with 25% glass, including mechanical, electrical, and thermal properties. Key properties include:

- Specific gravity of 2.1-2.3 and water absorption of 0.013%

- Tensile strength of 2000 PSI minimum and tensile elongation of 200-250%

- Flexural strength of 606 PSI and modulus of 2.39 x 105 PSI

- Coefficient of linear thermal expansion of 6.98 x 10-5 per °F and thermal conductivity of 3.12 Btu-In. hr-sq. (ft. °F)

- Continuous service temperature of 550°F and unaffected by weatherability

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

3 views1 pageSlide Plate Selection Chart

Uploaded by

LovebinThis document provides specifications for PTFE filled with 25% glass, including mechanical, electrical, and thermal properties. Key properties include:

- Specific gravity of 2.1-2.3 and water absorption of 0.013%

- Tensile strength of 2000 PSI minimum and tensile elongation of 200-250%

- Flexural strength of 606 PSI and modulus of 2.39 x 105 PSI

- Coefficient of linear thermal expansion of 6.98 x 10-5 per °F and thermal conductivity of 3.12 Btu-In. hr-sq. (ft. °F)

- Continuous service temperature of 550°F and unaffected by weatherability

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 1

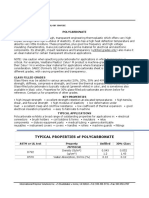

PTFE, 25% GLASS FILLED, SPECIFICATIONS

MECHANICAL PROPERTY VALUE ASTM TEST METHOD

Specific Gravity Measured 2.1 - 2.3 D638

Water Absorption (%) 0.013 D570-59T

Hardness, Shore D D2240

@ 78 °F 57

@ 300 °F 56

Wear Factor K less than 10 x 10-10

Tensile Strength (PSI) 2,000 min. D1457-56T

Tensile Elongation (%) 200 - 250 D1457-56T

Flexural Strength (PSI) 606 D790-59T

Modulus (PSI) 2.39 x 10 5

D638

Compressive Strength (PSI)

SLIDE PLATES

0.2% offset 1870 D695-54

Deformation at 78 °F, 2000 PSI

24 hr. 7.1

Permanent Deformation (%) 3.9 D621-59 (modified)

Deformation at 78 °F, 2000 PSI

100 hr. 8.9

Permanent Deformation (%) 4.4

Coefficient of Friction 0.06 for loads Modified

> 500 PSI static

ELECTRICAL PROPERTY VALUE ASTM TEST METHOD

Dielectrical Strength in air (v per mil) 327 D149A

Dielectrical Constant @ 60 cps 2.63 D150-54T

Volume Resistivity (ohm-cm) 1013

D257-57T

THERMAL PROPERTY VALUE ASTM TEST METHOD

Coefficient of Linear Thermal Expansion 6.98 x 10-5 D694-44

(per °F)

Coefficient of Thermal Conductivity 3.12 Cenco-Fitch

(Btu-In.) hr-sq. (ft. °F)

Continuous Service Temperature (°F) 550 Various

Weatherability Unaffected Physical exposure

194 www.pipingtech.com/slideplates

You might also like

- Hydrogen Attack A516 G70Document83 pagesHydrogen Attack A516 G70Kuppuraj ParamsivamNo ratings yet

- Quiz 1 Machine DesignDocument5 pagesQuiz 1 Machine DesignUsama Tariq50% (2)

- Is 4759 - 2006 - Hot-Dip Zinc Coatings On Structural Steel and Other Allied ProductsDocument9 pagesIs 4759 - 2006 - Hot-Dip Zinc Coatings On Structural Steel and Other Allied ProductsabhibmaneNo ratings yet

- Introduction To Materials EngineeringDocument53 pagesIntroduction To Materials EngineeringAlfred CallahanNo ratings yet

- Evaporation Rates EquationDocument3 pagesEvaporation Rates Equationmechmohsin4745100% (1)

- APPLIED PHYSICS Bonding in Solids by CHARIS ISRAEL ANCHADocument17 pagesAPPLIED PHYSICS Bonding in Solids by CHARIS ISRAEL ANCHACharis Israel Ancha100% (1)

- Ptfe SpecificationsDocument1 pagePtfe SpecificationsiN00bNo ratings yet

- PORON 4701-50 Firm - Supported MaterialsDocument2 pagesPORON 4701-50 Firm - Supported MaterialsLayeeq AhmedNo ratings yet

- Tecanat™ Tecanat™ Gf20 (Polycarbonate and Glass Filled Polycarbonate)Document1 pageTecanat™ Tecanat™ Gf20 (Polycarbonate and Glass Filled Polycarbonate)David Matthew Kurniawan BEngNo ratings yet

- CHRAFTECHIND Pai Bearing GradeDocument2 pagesCHRAFTECHIND Pai Bearing GradeZubair AamirNo ratings yet

- Kapton HN Data SheetDocument5 pagesKapton HN Data Sheet谢朋亨No ratings yet

- Poron 4701-30 Very SoftDocument2 pagesPoron 4701-30 Very SoftItzelMalagonVeraNo ratings yet

- Properties of PVC & CPVC PIPE Fitting: Item Test Method SI Unit Unit PVC CPVCDocument1 pageProperties of PVC & CPVC PIPE Fitting: Item Test Method SI Unit Unit PVC CPVCsidsaleemNo ratings yet

- Compound Specification Sheet: CSP-938 Diesel Grade, Vinyl Ester, Gray SMCDocument1 pageCompound Specification Sheet: CSP-938 Diesel Grade, Vinyl Ester, Gray SMCBrian García AguirreNo ratings yet

- TECAPET® PET and 1400® PET (Polyethylene Terephthalate) : Property ASTM Test Method Units Tecapet® PET 1400HI® PETDocument2 pagesTECAPET® PET and 1400® PET (Polyethylene Terephthalate) : Property ASTM Test Method Units Tecapet® PET 1400HI® PETFeby Shyntia AfirantiNo ratings yet

- Typical Properties of PVC and CPVC: Reference Information Supplied by Our SourcesDocument2 pagesTypical Properties of PVC and CPVC: Reference Information Supplied by Our SourcesAdnan KhanNo ratings yet

- Technical Data Sheet Polyimide: Benefits ApplicationsDocument3 pagesTechnical Data Sheet Polyimide: Benefits Applicationssanthosha rkNo ratings yet

- TecamidDocument2 pagesTecamidTejas HuddarNo ratings yet

- Technical Data Sheet PVC: (Polyvinyl Chloride)Document1 pageTechnical Data Sheet PVC: (Polyvinyl Chloride)Adnan KhanNo ratings yet

- Physical Properties of PVC CPVC PipeDocument1 pagePhysical Properties of PVC CPVC PipeBimal DeyNo ratings yet

- TECAPEEK Natural Polyetheretherketone 14Document2 pagesTECAPEEK Natural Polyetheretherketone 14kgrier8966No ratings yet

- PolystyreneDocument1 pagePolystyrenejoshkajasmineNo ratings yet

- PolycarbonateDocument2 pagesPolycarbonateAdnan KhanNo ratings yet

- PolycarbonateDocument2 pagesPolycarbonatepuvitta sudeshilaNo ratings yet

- PolycarbonateDocument2 pagesPolycarbonateROHIT SHARMANo ratings yet

- TECASINT 2011 Natural 14Document1 pageTECASINT 2011 Natural 14e.montgomeryNo ratings yet

- Craftechind PtfeDocument2 pagesCraftechind PtfeZubair AamirNo ratings yet

- CPVC PipesDocument24 pagesCPVC Pipeschaudhary osamaNo ratings yet

- Ptfe Data SheetDocument1 pagePtfe Data SheetEko PrastyoNo ratings yet

- TECAPEEK Natural Polyetheretherketone 14Document2 pagesTECAPEEK Natural Polyetheretherketone 14e.montgomeryNo ratings yet

- Pa 6 GF 30 (En)Document1 pagePa 6 GF 30 (En)Alessandro WeissNo ratings yet

- Technical Data Sheet Polycarbonate: Benefits ApplicationsDocument2 pagesTechnical Data Sheet Polycarbonate: Benefits ApplicationsjackNo ratings yet

- Pe-Uhmw Technical Data SheetDocument1 pagePe-Uhmw Technical Data SheetPrashant MalikNo ratings yet

- Polye PDocument2 pagesPolye PFranco Gabriel MercadoNo ratings yet

- Kocetal K700 Property DataDocument1 pageKocetal K700 Property DataRanjan GnanaoliNo ratings yet

- Wear Plate BrochureDocument2 pagesWear Plate Brochurec3512No ratings yet

- LdpeDocument1 pageLdpeArdy WiyogoNo ratings yet

- Durolon HFR 1910Document2 pagesDurolon HFR 1910elrolo3000No ratings yet

- Rigid PVCDocument1 pageRigid PVCRND KencanaNo ratings yet

- Tecasint 1011 Natural 0Document1 pageTecasint 1011 Natural 0Suraj_73No ratings yet

- Pc-Iso: Mechanical Properties Test Method ValueDocument2 pagesPc-Iso: Mechanical Properties Test Method ValuekaledioskoppNo ratings yet

- Nylon 6Document1 pageNylon 6luuiissNo ratings yet

- TECASINT 1011 Natural - Stock ShapesDocument2 pagesTECASINT 1011 Natural - Stock ShapesGreeshmaNo ratings yet

- Technical Data Sheet CPVC: (Chlorinated Polyvinyl Chloride)Document1 pageTechnical Data Sheet CPVC: (Chlorinated Polyvinyl Chloride)Nam NguyenNo ratings yet

- ULTRADUR B4300G6 (03p023)Document3 pagesULTRADUR B4300G6 (03p023)ayala castroNo ratings yet

- Acetal Natural Data SheetDocument1 pageAcetal Natural Data SheetvijayNo ratings yet

- Lexan™ 8010 Uncoated Polished Film DatasheetDocument3 pagesLexan™ 8010 Uncoated Polished Film DatasheetTeng Yan ChanNo ratings yet

- PORON 4790-92-25041 P Extra SoftSlow ReboundSupportedDocument2 pagesPORON 4790-92-25041 P Extra SoftSlow ReboundSupportedkarpagsNo ratings yet

- Technical Data Sheet Abs: (Acrylonitrile-Butadiene-Styrene)Document1 pageTechnical Data Sheet Abs: (Acrylonitrile-Butadiene-Styrene)Paulo RicardoNo ratings yet

- LNP™ THERMOCOMP™ Compound - DX11355 - Global - Technical - Data - SheetDocument2 pagesLNP™ THERMOCOMP™ Compound - DX11355 - Global - Technical - Data - SheetYJ WangNo ratings yet

- Technical Data Sheet Uhmw Polyethelyne (Uhmw Pe) : (Ultra High Molecular Weight Polyethylene)Document1 pageTechnical Data Sheet Uhmw Polyethelyne (Uhmw Pe) : (Ultra High Molecular Weight Polyethylene)HARSHA PNo ratings yet

- Ultraform N2320 003 BK120 Q600Document2 pagesUltraform N2320 003 BK120 Q600JoelNo ratings yet

- Acrylic PropertiesDocument1 pageAcrylic Propertiesmasood nazirNo ratings yet

- Kynar 370 Pellets TDS March 2014Document2 pagesKynar 370 Pellets TDS March 2014MelissaNo ratings yet

- POLYPROPYLENE Updated 281020Document1 pagePOLYPROPYLENE Updated 281020sribachaNo ratings yet

- TECAPEEK PVX Bearing Grade Data SheetDocument1 pageTECAPEEK PVX Bearing Grade Data SheetAaron LuoNo ratings yet

- Virgin Ptfe DatasheetDocument1 pageVirgin Ptfe DatasheetFelipe Zúñiga ParedesNo ratings yet

- 0001 - POLYFOAM Super (Gen) 09-30.11.2020Document1 page0001 - POLYFOAM Super (Gen) 09-30.11.2020Meeran MohamedNo ratings yet

- Technical Data Sheet High Density Polyethylene: Typical Properties of PolyethyleneDocument1 pageTechnical Data Sheet High Density Polyethylene: Typical Properties of PolyethyleneQuality teamNo ratings yet

- Polyester: Data SheetDocument1 pagePolyester: Data SheetñeNo ratings yet

- Styrolution PS 158N/L: General Purpose Polystyrene (GPPS)Document3 pagesStyrolution PS 158N/L: General Purpose Polystyrene (GPPS)scribdichigoNo ratings yet

- TECAPEEK Natural Polyetheretherketone 14Document2 pagesTECAPEEK Natural Polyetheretherketone 14nomeNo ratings yet

- Nylon 6.6 Data SheetDocument2 pagesNylon 6.6 Data SheetAshish Mohurle100% (1)

- Astm D4462-90Document2 pagesAstm D4462-90Priyadarshini KrishnaswamyNo ratings yet

- 933569Document138 pages933569rezaNo ratings yet

- Phase FieldDocument134 pagesPhase Field2021CEM013 AVINANDANMODAKNo ratings yet

- Sae J403 Uns G10050Document1 pageSae J403 Uns G10050Shrikar KuradeNo ratings yet

- Stresses and Deformation of Compressed Elastomeric O-Ring SealsDocument13 pagesStresses and Deformation of Compressed Elastomeric O-Ring SealsCarlosIkedaNo ratings yet

- CHAPTER 1 Formation and Structure of Foams Pressure in The Liquid and Gas 1998Document41 pagesCHAPTER 1 Formation and Structure of Foams Pressure in The Liquid and Gas 1998Anonymous UYDJtUnNo ratings yet

- Böhler HL 51 T-MC: Seamless Cored WireDocument2 pagesBöhler HL 51 T-MC: Seamless Cored WireFer VFNo ratings yet

- Turbulence and Inertia Effects in BearingsDocument7 pagesTurbulence and Inertia Effects in BearingsMourad TargaouiNo ratings yet

- 9-Introduction To Resistivity MeasurementsDocument24 pages9-Introduction To Resistivity Measurementsهيثم قاسم طاهر الميدمهNo ratings yet

- Full Download Test Bank For Conceptual Chemistry 5 E 5Th Edition John A Suchocki PDFDocument63 pagesFull Download Test Bank For Conceptual Chemistry 5 E 5Th Edition John A Suchocki PDFkimberly.levy818100% (15)

- Evaluation of Oral LiquidsDocument9 pagesEvaluation of Oral LiquidsAln Albin71% (7)

- Cu-XLPE-SWA - PVC 3X50 mm2Document1 pageCu-XLPE-SWA - PVC 3X50 mm2Jalal AlbadriNo ratings yet

- Amc Pac R PDS PDFDocument1 pageAmc Pac R PDS PDFFacehrezaNo ratings yet

- Trevor Pope. Stator Rubber Innovation Vs ApplicationDocument11 pagesTrevor Pope. Stator Rubber Innovation Vs ApplicationAkash YadavNo ratings yet

- Electrostatics: (Physics)Document72 pagesElectrostatics: (Physics)Vikrant BhanNo ratings yet

- Nptel - Lec32,33Document26 pagesNptel - Lec32,33Stupid FellowNo ratings yet

- Pultrusion of Glass Fibre Reinforced Maleated-PP Modified PP Matrix CompositesDocument10 pagesPultrusion of Glass Fibre Reinforced Maleated-PP Modified PP Matrix CompositesОлег ШибекоNo ratings yet

- British Steel Sections Datasheets PDFDocument18 pagesBritish Steel Sections Datasheets PDFhajabvgNo ratings yet

- Smart SoapsDocument8 pagesSmart SoapsAdi permadiNo ratings yet

- PHD Thesis On Gold NanoparticlesDocument6 pagesPHD Thesis On Gold Nanoparticlesdearneywartenbeesiouxfalls100% (2)

- Nanosheet Field Effect Transistors-A Next Generation Device To Keep Moore's Law Alive An Intensive StudyDocument12 pagesNanosheet Field Effect Transistors-A Next Generation Device To Keep Moore's Law Alive An Intensive StudyHung Lung ChienNo ratings yet

- Carnot Cycle For Mechanical Engineers.Document16 pagesCarnot Cycle For Mechanical Engineers.zega5394No ratings yet

- Diffraction Due To Grating Using HeDocument3 pagesDiffraction Due To Grating Using HeProfessor VoltNo ratings yet

- Synthesis of Carbon Quantum Dots From Food Products, Hydrothermal Carbonization MethodDocument5 pagesSynthesis of Carbon Quantum Dots From Food Products, Hydrothermal Carbonization MethodBunduc Burduhos Nergis DoruNo ratings yet

- IAS Mains Physics 2018 Paper 1Document11 pagesIAS Mains Physics 2018 Paper 1Shivam kumarNo ratings yet