Professional Documents

Culture Documents

Aramay-Tuazon BeamsAndColumnsFinal X

Uploaded by

aaronzaldivar29Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Aramay-Tuazon BeamsAndColumnsFinal X

Uploaded by

aaronzaldivar29Copyright:

Available Formats

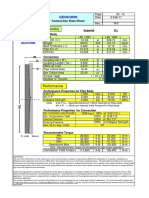

DESIGN OF REINFORCED BEAM

BEAM CODE: FLOOR LEVEL: GRID: GRID NO.

DESIGN PARAMETERS BEAM DESIGN PROCESS

b 300 mm fy 415 Mpa Moment Positive Reinforcement

H 560 mm f'c 30 Mpa Actual Mu 576 As 4193.844

d 490 mm d' 70 mm Maximum Steel Ratio (ρmax) 0.02200762233 Bar diameter No. of pcs

cc 40 mm β1 0.83571429 Maximum Nominal Moment (Mnmax) 540.05079375 16 21

db 25 mm Mu 576 kNm Reduction Factor (⌀) 0.81452991453 20 14

ds 10 mm Positive or Negative?Positive kNm ⌀Mnmax 439.887526875 25 9

⌀Mnt 436.887016084 32 6

LEGENDS SRB or DRB DRB! A's 994.6759

COLORS DESCRIPTION Required Steel Area (mm2) Bar diameter No. of pcs

CHANGEABLE As 4193.8442606 A's 994.675920378 16 5

NOT CHANGEABLE 20 4

CONDITION 25 3

ANSWER 32 2

BACK UP COMPUTATION

FOR POSITIVE MOMENT

If SRB govern IF DRB Govern Solver for value c

⌀Mnt 436.8870161 For Mu1 A IGNORE

C1 (Tension-Controlled) cmax 210 mm B IGNORE

⌀ 0.9 Mu1 439.88752688 kNm c2 IGNORE

Rn N/A Mu2 136.11247313 kNm c IGNORE

p N/A As fs 800 Mpa Constant IGNORE

pmin N/A N/A f's 400 MPa c1 IGNORE

preq N/A amax 175.5 mm c2 IGNORE

C2(Transition-Region)

c N/A COMPRESSION STEEL YIELDS COMPRESSION STEEL DOES NOT YIELD

fs N/A As1 3235.1204819 mm2 As1 3235.12048193 mm2

N/A N/A As2 958.72377868 mm2 As2 958.723778678 mm2

⌀ N/A Use As= As 4193.8442606 mm2 As 4193.84426061 mm2

As N/A N/A A's 958.72377868 mm2 A's 994.675920378 mm2

BEAM DETAILS

For As For A's

DESIRED REBAR DIAMETER 32 DESIRED REBAR DIAMETER 32

ONE LAYER SPACING 1.616 ONE LAYER SPACING 136

NOT OKAY IN ONE LAYER! TRY BUNDLE OR 2 LAYERS! ONE LAYER IS OKAY!

Note: When trying to do two layers, Note: When trying to do two layers,

it should have at least 25mm clear spacing between layers. it should have at least 25mm clear spacing between layers.

ARAMAY, ANA-MARIE F. TUAZON, AARON PHILIP BSCE 4A

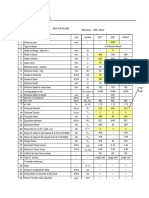

DESIGN OF SHEAR & TORSION REINFORCEMENT

PROVISIONS IN SHEAR DESIGN PARAMETERS (additional)

MAXIMUM SHEAR (STAAD Generated) Vu 250 kN ɸ 0.75

Nu 45 kN fyt 275 MPa

Tension or Compression? Compresion Legs 2

PROVISIONS IN TORSION DESIGN

Actual Tu (kNm) 10 DESIGN PROCESS

øTth 5.617340648 Acp (mm2) 168000 Tn 13.33333333

øTcr 22.46936259 Pcp (mm) 1720 At/s 0.28896149

TORSION REINFORCEMENT IS NECESSARY spacing 543.6005761

IF TORSION IS NECESSARY, smax 170

CHECK FOR CROSS-SECTIONAL LIMIT USE SPACING

CS1 1.889 170 mm

Calculate for Vc CS2 3.447 OR SAY 170 mm

SIMPLIFIED WITH AXIAL (Nu)

OKAY!

Vc 139.494665598613 kN

DETAILED WITH AXIAL (Nu) ADDITIONAL LONGITUDINAL AREA

For Compression For Tension Al 260.413488 mm Using 12 mm bars

a 144.251 kN a Al min1 670.846841 mm No. of bars 6.712909131

b 566.156 kN Al min2 759.212136 mm 7 PCS

N/A kN

c 242.393 kN Use 759.212136 mm

Final Vc Calculate for Vs NOTE: All Longitudinal bars for torsion must be distributed around the stirrups. Provide 2 pcs at

Vc 144.251 kN Vs 189.083 kN tension part and at least 1 pc at each leg and put the rest in the compression part.

ɸVc 108.188 kN Vsmax 536.768 kN

0.5ɸVc 54.094 kN Vsreq 268.384 kN

3

Stirrups are Required! Calculate Spacing

SPACING

S provided 112 mm Additional bars for torsion

arranged as shown

Smax 245 mm 2

REQUIRED SPACING (mm)

S 111.942968917978 mm 2

OR SAY 110 mm

SUMMARY

For 0mm diameter stirrups, use 111.9429689 mm spacing or say 100 mm.

BACK UP COMPUTATION

FOR SHEAR FOR TORSION

Area & Spacing Spacing For Minimum Stirrups x1 210

Av 157.080 mm2 S1 208 mm y1 470

S 111.943 mm S2 146 mm Ph 1360 mm

If Vs<Vsreq S 208 mm Aoh 98700 mm2

Smax1 245 mm Ao 83895 mm2

Smax2 600 mm

Smax 245 mm p 0.0285295527932354 mm2

If Vs>Vsreq

Smax1 122.5 mm FOR COMBINED SHEAR

Smax2 300 mm 1.494275394 for Ah at a distance of 2.33

Smax 122.5 mm 0.455314355 for Ah at a distance of 4.67

S 245 mm -0.246291267 for Ah at a distance of 5

PROVISIONS IN COMBINED SHEAR AND TORSION FINAL SPACING OF TRANSVERSE REINFORCEMENT AT

DESIGN CRITICAL POINT (Effective Depth Distance)

ARAMAY, ANA-MARIE F. TUAZON, AARON PHILIP BSCE 4A

IF TORSION IS NECESSARY,

For Shear: Av/s 1.403 mm2/mm

For Torsion: At/s 0.289 mm2/mm Spacing:

Combined: Ah 1.981 mm2/mm

35

Avmin 1 0.370 mm2/mm mm

Minimum Area per length

Avmin 2 0.382 mm2/mm

10 mm stirrups spaced @ 35

Use Ah 1.981 mm2/mm

mm OC

Use spacing 39.644 mm

or say 35

mm d 490 mm

MATRIX OF TRANVERSE REINFORCEMENT

At critical point (d= 490 mm), Combined Shear and Torsion 35

S

Considering Combined Shear and Torsion

Distance Ah

(m) Vu(KN) Tu(KN-m) (mm²/mm) smax (mm) S provided (mm) S (mm)

2.33 230 10 1.494 170 52.560 50

4.67 125 10 0.455 170 172.496 170

5 54.09 10 0.382 170 205.700 170

Considering this Shear Matrix if Torsion is not necessary

Distance

(m) Vu(KN) Vs (kN) sreq (mm) smax (mm) S provided (mm) S (mm)

2.33 230 162.42 130.323 245 130.323 125

4.67 125 22.42 944.256 245 245.000 225

5 54.09 -72.13 -293.468 245 -293.468 -300

FINAL DETAILING OF THE BEAM CONSIDERING FLEXURE

300

Flexure Torsion Total (mm2)

For A's

994.68 339.29 1333.968

Using 25 mm

Number of bars = 3 pcs of 25 mm bars

2-12mm Provide ONLY if Torsion requirement is necessary

560

Flexure Torsion Total

〖 (mm 〗 ^2)

For A's

4193.844 226.19 4420.039

Using 28 mm

Number of bars = 8 pcs of 28 mm bars

Critical

Point

10mm stirrups

10mm stirrups spaced 10mm stirrups 10mm stirrups No need

spaced @ 35 mm spaced @ 170 spaced @ 170

OC @ 50 mm OC mm OC mm OC stirrups

Point of zero shear

0.49 1.84 2.33 0.33 2

2.33 No need

4.67 stirrups

0.5ØVc

5

7

Supporting Data base from STAAD

Support Reaction 300 kN

0.5ØVc 54.09 kN

Point of 0.5ØVc 5 m

Point of Zero Shear 7 m

ARAMAY, ANA-MARIE F. TUAZON, AARON PHILIP BSCE 4A

DEVELOPMENT LENGTH

DESIGN PARAMETERS BACKUP COMPUTATION

Main db (tension) 25 mm Ψe 1 for Cb Standard 90° Hook

No. of bars 15 pcs. Ψc 1 (a) 75 Bend Bars

Main db (Compression) 25 mm Ψr 1 (b) 37.5 bar diameter

No. of bars 9 pcs. Ψt 1 For Straight: 10 to 25 mm 150

db (stirrups) 12 mm Ψs 1 Section 425.4.2.2 28 to 36 mm 200

No. of legs 2 pcs. Ψt Ψe 1 Ok! 20 mm Ø bars and 25 mm Ø bars and 40 to 58 mm 250

Spacing of Stirrups 45 mm Clear Concret Cover 50.5 smaller larger Standard 180° Hook

C-to-C Spacing 75 mm Beam Width 375 mm Case 1 714.404 882.499 Bend Bars

Column Width 400 mm Cb 37.5 Case 2 1071.606 1363.862 bar diameter

fy 275 MPa Atr 226.195 10 to 25 mm 150

f'c 21 MPa Ktr 13.404 Standard 180° Hook 28 to 36 mm 200

λ 1 CC 40 Straight Extension (Lext) 40 to 58 mm 250

NOTE: Do not input values to cells other than the blue cells under Design Parameters. bar diameter a b Standard 90° Hook

DESIGN PROCESS All bars 100 65 Straight Extension (Lext)

STRAIGHT (For Tension) bar diameter

Development Length (Ld) All bars 300

BAR Ø Section 425.4.2.2 Minimum DESIGN AND GEOMETRY

Case 1 Case 2 Section 425.4.2.3

400

25 882.499 1363.862 669.819 300

CC= 40

Case No. Case 1 Db= 20 330

BEAM COLUMN

Development Length (Ld) 882.499 mm

125

STRAIGHT (For Compression) Tie Dia= 10

Development Length (Ld)

200

Section 425.4.2.2

BAR Ø Case 1 Case 2 Minimum 330

25 295.625 360.060 200 100

225

125

Development Length (Ld) 360.060 mm

Point at which bar is being

WITH HOOKS (For Tension) developed

90° or 180° Hook Standards (90° Hook)Standards (180° Hook)475 350 180° Hook

Section 425.4.3.1 (mm) (mm)

a b c db 25 db 25

359.772 200 150 Ldh 359.772 Ldh 359.772

Hook Dev. Length Dia 150 Dia 150

359.772 mm

(Ldh) Lext 300 Lext 100 90° Hook

Lreq 330 Lreq 330

Excess 29.772 Excess 29.772

ARAMAY, ANA-MARIE F. TUAZON, AARON PHILIP BSCE 4A

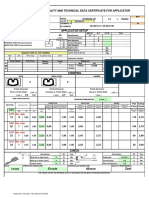

DESIGN OF REINFORCEMENT BEAM

FLOOR LEVEL 4 COLUMN CODE: C-2

PARAMETERS

Maximum axial load Pu 2500 kN

Column steel ratio ρ 2%

Compressive strength of steel fy 415 MPa

Compressive strength of f'c 21.0 MPa

Diameter of lateral ties dt 12 mm

Concrete Cover Cc 40 mm

Yield Strength of Ties fyt 275 mm

Reduction factor Φ 0.65

DESIGN PROCESS NSCP-2015

1. Express Ag in terms of Ast using the definition of steel ratio,ρg 4. Using equation 3 to solve for Area Gross, Ag

Ag = 186,395.24 mm²

Ast= Ag(ρg) (Eq.1)

5. Calculate the width/height of the square column.

2. Establish formula of Ultimate Load Pu √(Ag) = 431.7351 or say 450 mm

*Note: The minimum dimension w is rounded up to the nearest multiple of 50.*

Pu=ΦPn=Φ(0.80Po)

6. Using Equation 1 solve for the Steel Area(As), using the actual Ag

Ast = ρg(Ag) = 0.02Ag = 3,727.9 mm²

Pu=Φ(0.80)[0.85f'c(Ag-Ast)+fy(Ast)] (Eq.2)

7. Select the diameter of main bars to be use.

3. Substituting equation 1 to equation 2 Rebar diameter size 16 20 25 32

No. of rebar 20 12 8 6

Pu=Φ(0.80)[0.85f'c(Ag-Ag(ρg))+fy(Ag)(ρg)] (Eq.3)

*Note: The number of rebars is rounded up to the nearest even number.*

SPACING

SPACING OF LATERAL TIES (St) SPACING OF REINFORCEMENT

As per NSCP 2015, Section 425.7.2.1 Aggregate diameter size (dagg)

a. Smin = 4/3dagg = 4/3 (25) = 33.33 mm *diameter of aggregates is typically 25* a. Clear spacing shall be atleast the greates of:

b. Center-to-center spacing shall not exceed the least of: 1.5dbM 24.00 mm

16dbM 256.00 mm Governs! 40mm 40.00 mm Governs!

48dbT 576.00 mm (4/3)dagg 33.33 mm

Smallest dim. 450.00 mm Smin 40.00 mm

Stmax 256.00 mm

33.33< s <smax use s = 200.00 mm s>Smin

ANALYSIS OF THE DESIGN COLUMN COLUMN DETAILS

16

Input Desired Rebar Diameter Size

Area Gross of Concrete 225,000.00 mm² Parameters Value n (db) s(db)

Area of Steel 4,021.24 mm² Desired Rebar (db) 16 20

PuACTUAL 2,500.00 kN SMALLEST DIM 450 5 66.5

ARAMAY, ANA-MARIE F. TUAZON, AARON PHILIP BSCE 4A

You might also like

- Complete ComparisonDocument22 pagesComplete ComparisonMalcolm DadinaNo ratings yet

- Vav - 1Document10 pagesVav - 1perezismaelNo ratings yet

- Secant Pile DesignDocument7 pagesSecant Pile DesignINNOVATIVE ENGINEERNo ratings yet

- Design Principles of Metal-Cutting Machine ToolsFrom EverandDesign Principles of Metal-Cutting Machine ToolsRating: 4 out of 5 stars4/5 (4)

- RCC94 Two-Way Slabs (Tables)Document5 pagesRCC94 Two-Way Slabs (Tables)adelalwailyNo ratings yet

- ARAMCO DrawingDocument1 pageARAMCO DrawingLainhatanhNo ratings yet

- Reinforced Concrete Design As Per NSCP 2015.KLCDocument12 pagesReinforced Concrete Design As Per NSCP 2015.KLCKurt Laurhon CabahugNo ratings yet

- Seismic Slope StabilityDocument27 pagesSeismic Slope StabilityMUHAMMAD ALINo ratings yet

- Calculations: Project: of Section: File/ref No: Designed: Date: Checked: DateDocument6 pagesCalculations: Project: of Section: File/ref No: Designed: Date: Checked: DateWintun73No ratings yet

- HH 102Document100 pagesHH 102ROBERSON ROMERÒ100% (6)

- Mathcad - 05-Design of Doubly Reinforced BeamsDocument4 pagesMathcad - 05-Design of Doubly Reinforced BeamsMrAlittle Finger100% (1)

- 04 Barriers Parapets RailingsDocument36 pages04 Barriers Parapets RailingsTheDark Lord100% (1)

- RCDDocument7 pagesRCDRodel John AberiaNo ratings yet

- 13.375 Inch Geoconn 64-QDocument1 page13.375 Inch Geoconn 64-QBalkis FatihaNo ratings yet

- DEEP BEAM DesignDocument2 pagesDEEP BEAM DesignmangeshNo ratings yet

- Site-Investigation Site VisitDocument26 pagesSite-Investigation Site VisitNinie AzrinNo ratings yet

- Ventilation: MDM Nurul Aini/Qus 3206Document22 pagesVentilation: MDM Nurul Aini/Qus 3206Anisha NaiduNo ratings yet

- Rcc95 Continuous Beams (Tables)Document7 pagesRcc95 Continuous Beams (Tables)Eric Villenas100% (1)

- Code Case 2901 Nozzle S1 SL No Description Unit Value: Provided Nozzle Flange Is Safe For External LoadingsDocument1 pageCode Case 2901 Nozzle S1 SL No Description Unit Value: Provided Nozzle Flange Is Safe For External LoadingsguravdrNo ratings yet

- Mathcad - 21-Design of StairDocument3 pagesMathcad - 21-Design of StairMrAlittle FingerNo ratings yet

- Main Tunnel First CheckDocument9 pagesMain Tunnel First CheckDara HajebiNo ratings yet

- Foundation Pads - MPA - EC2Document1 pageFoundation Pads - MPA - EC2mayphyoNo ratings yet

- EC2-BE-dubble Reinforced Beams SLS-crackwidth Rev6Document7 pagesEC2-BE-dubble Reinforced Beams SLS-crackwidth Rev6Dong LINo ratings yet

- Weichai Engine PrintDocument52 pagesWeichai Engine PrintKo ZayNo ratings yet

- PC3 QmaxDocument1 pagePC3 QmaxCuong TranNo ratings yet

- RESIDENTIAL Beam Design - 1 PDFDocument3 pagesRESIDENTIAL Beam Design - 1 PDFWilbert ReuyanNo ratings yet

- Shear With TDocument2 pagesShear With Tkhaniskhan03No ratings yet

- RCD Beam DesignDocument8 pagesRCD Beam DesignMina MyoiNo ratings yet

- Community MarketDocument1 pageCommunity MarketAl-amin Kabiru YusufNo ratings yet

- ETABS 2016 Concrete Frame Design: ACI 318-14 Beam Section DesignDocument2 pagesETABS 2016 Concrete Frame Design: ACI 318-14 Beam Section DesignLulu Danur MayasinNo ratings yet

- ETABS 2016 Concrete Frame Design: ETABS 2016 16.2.1 License # 1G83KMAGR458AC8Document2 pagesETABS 2016 Concrete Frame Design: ETABS 2016 16.2.1 License # 1G83KMAGR458AC8Sandip BudhathokiNo ratings yet

- Erp-Reinf Shearwall R1Document6 pagesErp-Reinf Shearwall R1Gunawan Prc2020No ratings yet

- Input Data: Package: Bridge Name: Pier Name: 1. General Input DataDocument7 pagesInput Data: Package: Bridge Name: Pier Name: 1. General Input DataTuanNo ratings yet

- Concrete Deck Design1Document12 pagesConcrete Deck Design1Rin KutaruNo ratings yet

- Capstone Chapter 4Document108 pagesCapstone Chapter 4Calvin BaraquiaNo ratings yet

- Beam DesignDocument15 pagesBeam Designravi kumarNo ratings yet

- គំរបលូDocument4 pagesគំរបលូChhim RothyNo ratings yet

- Beam Design Beam Mark:B1 Similar Beams:: Sl. NoDocument3 pagesBeam Design Beam Mark:B1 Similar Beams:: Sl. NopandianNo ratings yet

- Critical Load Cases: L/C 44: 1.2DL + 1.2FL + 0.8LL (C+Z)Document3 pagesCritical Load Cases: L/C 44: 1.2DL + 1.2FL + 0.8LL (C+Z)John Carlo AmodiaNo ratings yet

- ETABS 2016 Concrete Frame Design: IS 456:2000 Column Section Design (Envelope)Document1 pageETABS 2016 Concrete Frame Design: IS 456:2000 Column Section Design (Envelope)Abdullah MohamedNo ratings yet

- Retaining Wall CGDDocument6 pagesRetaining Wall CGDGino CruzNo ratings yet

- Input Data: Package: Bridge Name: Pier Name: 1. General Input DataDocument7 pagesInput Data: Package: Bridge Name: Pier Name: 1. General Input DataTuanNo ratings yet

- ANNEX - A & B of IS 456-2000Document14 pagesANNEX - A & B of IS 456-2000Abrar AhmadNo ratings yet

- Design of Single Reinforced ConcreteDocument9 pagesDesign of Single Reinforced ConcreteCharlamagne MirandaNo ratings yet

- Design-of-Beam 350x600 - FinalDocument8 pagesDesign-of-Beam 350x600 - FinalJaycee Bareng PagadorNo ratings yet

- BS8110 Beam With DeflectionDocument3 pagesBS8110 Beam With DeflectionFrederick TanNo ratings yet

- Ampco 18Document1 pageAmpco 18Gloria TouguinhaNo ratings yet

- Beam (Flexure & Shear)Document9 pagesBeam (Flexure & Shear)DHYEY PARMARNo ratings yet

- 2B-21 (350x600) WSDDocument1 page2B-21 (350x600) WSDJaycee Bareng PagadorNo ratings yet

- A I y y y Z Z Z e e E' B: Nominal Width: 1200 MM Top Width (Calc) : 1161 MM Top Ange: 36 MMDocument6 pagesA I y y y Z Z Z e e E' B: Nominal Width: 1200 MM Top Width (Calc) : 1161 MM Top Ange: 36 MMskemitzarNo ratings yet

- Design of RC Plate Coupling BeamDocument5 pagesDesign of RC Plate Coupling BeamJai ThakkarNo ratings yet

- ETABS 2016 Concrete Frame Design: ETABS 2016 16.0.0 License # 18EMACAKL7JTANKDocument2 pagesETABS 2016 Concrete Frame Design: ETABS 2016 16.0.0 License # 18EMACAKL7JTANKSanjeev SanjeevNo ratings yet

- ETABS 2016 Concrete Frame Design: ETABS 2016 16.0.2 License # 1SVK7TR5A72FZP3Document2 pagesETABS 2016 Concrete Frame Design: ETABS 2016 16.0.2 License # 1SVK7TR5A72FZP3Roshan KejariwalNo ratings yet

- S355 610 X 305 UB 149: Flexural Beam Design To Eurocode 3Document17 pagesS355 610 X 305 UB 149: Flexural Beam Design To Eurocode 3Receb AgaNo ratings yet

- EC2-BE-shear and Torsion Rev 3Document10 pagesEC2-BE-shear and Torsion Rev 3Dong LINo ratings yet

- Beam Column CheckDocument78 pagesBeam Column Checkarunkumar.mgsNo ratings yet

- Quality and Technical Data Certificate For Applicator: L 105002 EVS0323-JBDocument7 pagesQuality and Technical Data Certificate For Applicator: L 105002 EVS0323-JBalexis cruz pradoNo ratings yet

- HWDP 3.5 03Document2 pagesHWDP 3.5 03km1790No ratings yet

- Mpa MM Mpa Mpa Mpa: 25 Nov 2020 14:23:41 - Endsection - Pedestal - SMDocument2 pagesMpa MM Mpa Mpa Mpa: 25 Nov 2020 14:23:41 - Endsection - Pedestal - SMgarysootetNo ratings yet

- Beam Design RCC 2020-02-19Document16 pagesBeam Design RCC 2020-02-19haicivilvinoNo ratings yet

- RCC94 Two-Way Slabs (Tables)Document3 pagesRCC94 Two-Way Slabs (Tables)Mohammad Twaha JaumbocusNo ratings yet

- ETABS 2016 Concrete Frame Design: ETABS 2016 16.2.0 License # 1UARYUV5QA3ALLSDocument2 pagesETABS 2016 Concrete Frame Design: ETABS 2016 16.2.0 License # 1UARYUV5QA3ALLSRakesh ShresthaNo ratings yet

- ETABS 2016 Concrete Frame Design: ETABS 2016 16.2.0 License # 1UR6WTN2QF4XGQ2Document2 pagesETABS 2016 Concrete Frame Design: ETABS 2016 16.2.0 License # 1UR6WTN2QF4XGQ2Samir RawatNo ratings yet

- 2B-22 (300x500) WSDDocument1 page2B-22 (300x500) WSDJaycee Bareng PagadorNo ratings yet

- SRR Beams (Economical)Document5 pagesSRR Beams (Economical)Isabella LimNo ratings yet

- Estimation of Marrige HallDocument57 pagesEstimation of Marrige HallRaghav SawantNo ratings yet

- AIM Forward Bin TipperDocument2 pagesAIM Forward Bin TipperRick DalzielNo ratings yet

- Mod MC Premium PM Installation Manual: Automatic Horizontal Sliding Car DoorDocument60 pagesMod MC Premium PM Installation Manual: Automatic Horizontal Sliding Car DoorCoil98No ratings yet

- Prefabrication ReportDocument8 pagesPrefabrication ReportSaparya AnejaNo ratings yet

- Analysis of Appartment BuildingDocument24 pagesAnalysis of Appartment BuildingJay BhavsarNo ratings yet

- A Guide To Ventilation Exhaust FansDocument4 pagesA Guide To Ventilation Exhaust FansLoter BelautNo ratings yet

- Mechanical Design of Transmission LinesDocument33 pagesMechanical Design of Transmission LinesKashif Hussain ShahNo ratings yet

- MCHW Vol 1 Series 400 Web PDFDocument23 pagesMCHW Vol 1 Series 400 Web PDFalejandraoy9No ratings yet

- Furniture Catalog For IDAp ProjectsDocument13 pagesFurniture Catalog For IDAp ProjectsSheik HassanNo ratings yet

- Lecture 23Document83 pagesLecture 23Robert Andy WoodNo ratings yet

- Liquefied Gas Pump Installation GuideDocument6 pagesLiquefied Gas Pump Installation GuideLuis Meza ArevaloNo ratings yet

- Compact Track Loader: Parts ManualDocument144 pagesCompact Track Loader: Parts ManualAleks BubaevNo ratings yet

- Ca With StairDocument10 pagesCa With Stairvamsi NathNo ratings yet

- Cable Profile For Box Girder DesignDocument2 pagesCable Profile For Box Girder DesignPunithan PunithanNo ratings yet

- HLX 5 Oms125 Yeni̇modelDocument17 pagesHLX 5 Oms125 Yeni̇modelroland100% (1)

- Company Profile: Hospital, Healthcare Planning & Management ConsultantsDocument34 pagesCompany Profile: Hospital, Healthcare Planning & Management ConsultantsVasco JosephNo ratings yet

- Analysis of Fatigue Fracture of Tank Wagon Railway Axles: Cosmin LocoveiDocument5 pagesAnalysis of Fatigue Fracture of Tank Wagon Railway Axles: Cosmin LocoveiZoser KalengayiNo ratings yet

- Finite Element Based Dynamic Analysis of Multilayer Fibre Composite Sandwich Plates With Interlayer DelaminationsDocument14 pagesFinite Element Based Dynamic Analysis of Multilayer Fibre Composite Sandwich Plates With Interlayer DelaminationsAhmet EcevitNo ratings yet

- 15 Intake and ExhaustDocument16 pages15 Intake and Exhaustwanderlei669085No ratings yet

- Dellorto Manual Features and TuningsDocument9 pagesDellorto Manual Features and TuningsvikerrsNo ratings yet

- Vidyasagar Setu Kolkata: Under The Guidance of Prof. Dibya Jivan PatiDocument7 pagesVidyasagar Setu Kolkata: Under The Guidance of Prof. Dibya Jivan PatisonakshiNo ratings yet