Professional Documents

Culture Documents

SIN00219

SIN00219

Uploaded by

Gaetano MuccioOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

SIN00219

SIN00219

Uploaded by

Gaetano MuccioCopyright:

Available Formats

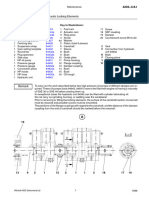

RTA58T-B Maintenance 4203–4/A2

Camshaft

Removing and Fitting of a Shrink fitted Flange Coupling

Tools: Key to Illustrations:

1 Withdrawing ring 94435a 1 Camshaft 8 2 Screw plugs

1 Withdrawing shaft 94435b 2 Flange coupling 9 O-ring

1 Stop plate 94436 3 Washer 10 O-ring

2 Connection pieces 94438 4 2 Screws M24x60 11 Support ring

1 HP oil pump 94931 4a 4 Screws M24x220

2 HP hoses 94935 4b 8 Screws M24x90

1 Hydraulic unit 94942 5 2 Threaded rods M24x350 E Venting bore

6 2 Nuts M24 M Mark

7 1 Cylindrical pin P Closing piece

Fitting of shrink fitted flange coupling

Clean flange coupling 2. Check if the bore in the flange coupling and the correspondent seat on camshaft 1 is clean

and undamaged.

Check if the bore diameter is smaller by 0.37– 0.42 mm than the correspondent camshaft diameter (shrinkage di-

mension).

Heat the flange coupling to a temperature of about 220 _C. Check before shrinking-on if the bore shows the required

oversize of 0.15 – 0.20 mm.

Shrink on the flange coupling, justify it with the end of the camshaft and let it cool down completely.

Remark Use a clean oil of SAE50 (cylinder lubricating oil) for the hydraulic tools!

The pressures for withdrawing ring and the flange coupling must not exceed 2000 bar.

Increase the pressures slowly!

Aligning of the flange coupling:

– Fasten the stop plate 94436 to the camshaft end with screws 4 and washers 3.

– Screw the connection piece 94438 into the mid oil connection of the flange coupling. Plug the connections

which are not used with screw plugs 8.

– Screw up the HP hose 94935 with hydraulic unit 94942 and connection piece 94438.

– Pump until oil sequeezes between the flange coupling and shaft so that the flange coupling can be moved.

– Press flange coupling against the stop plate and align the marks on the flange coupling with the mark on the

camshaft, then release pressure. Check if there is no clearance between stop plate and flange coupling.

– Dismantle the tool. Remove all screw plugs 8 and connection piece 94438.

8

A

8 94438

94935 M

3

4

94436

2

94942

98.7318

Wärtsilä NSD Switzerland Ltd 1 1999

4203–4/A2 Maintenance RTA58T-B

Removing and Fitting of a Shrink fitted Flange Coupling

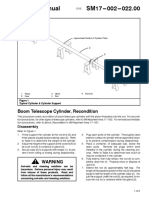

Removal of shrink fitted flange coupling

Before beginning with the removal of the flange coupling, clean the surfaces of camshaft 1 and withdrawing shaft

94435b and check them for damages.

Check O-rings 9 and 10 as well as support ring 11 for damages.

Check if the venting bore ’E’ in the withdrawing shaft is not fouled.

– Fit withdrawing shaft with pressed-in cylindrical pin 7 on camshaft end and tighten it slightly by means of screws

4a and washers 3.

– Lubricate O-ring 10, slide it on the withdrawing shaft and insert it in the groove. While doing this, it may be

necessary to slacken the withdrawing shaft a bit.

– Tighten screws 4a. Tightening angle 65_ to 70_.

– Screw both threaded rods 5 into the flange coupling 2, lubricate withdrawing shaft and withdrawing ring 94435a

with O-ring 9 and support ring 11, and with the use of nut 6 pull them carefully and evenly towards the flange

coupling up to the stop. Make sure that O-ring 9 remains in the groove (Fig. ‘B’).

94435a 3 6

B

5

4a

1

94435b

3

98.7319

10

11

9

– Dismantle the threaded rods and screw in screws 4b together with washers 3 (Fig. ‘C’).

– Tighten the screws 4b for the withdrawing ring. Tightening angle 20_ to 25_.

94438 8

C

3

8

4b

94438

98.7319

1999 2 Wärtsilä NSD Switzerland Ltd

RTA58T-B Maintenance 4203–4/A2

Removing and Fitting of a Shrink fitted Flange Coupling

– Screw the one connection piece 94438 in the withdrawing ring 94435a, the other in the mid oil connection of the

flange coupling.

Plug the oil connections which are not used with the screw plugs 8.

– Connect the withdrawing ring 94435a by HP hose 94935 with the HP oil pump 94931 as shown in Fig. ’D’.

– Connect hydraulic unit 94942 to the connection piece on the flange coupling, using HP hose 94935.

Remark During the following work secure the flange coupling against falling down by using a crane or a

chain block. However, make sure that the flange coupling can still be moved when slackening it.

– Increase the pressure in the flange coupling slowly by means of the hydraulic unit 94942, until oil sequeezes

between the flange coupling and the camshaft. The flange coupling should move in axial direction, otherwise

pressure must be provided on the withdrawing ring with the HP oil pump 94931 (Fig. ‘D’).

D

8

94935 94438

3

8

4b 94435b

4a

7

94935a

94438

94932

94942 94935

99.7131

94931 V

Wärtsilä NSD Switzerland Ltd 3 1999

4203–4/A2 Maintenance RTA58T-B

Removing and Fitting of a Shrink fitted Flange Coupling

– However, if the flange coupling still would not move in axial direction, discharge both pumps and screw the mid

connection piece in the first bore over the flange. Plug the mid bore with screw plug 8 (Fig. ‘E’).

– Provide pressure again in the sequence previously described.

– Now shift the flange coupling in axial direction. If it gets stuck again before being completely shifted over the

camshaft end, the connection piece on the flange coupling must be screwed once more in the following bore

above the oil groove, the other bores having to be plugged again, etc.

E

94935 94438

8

94438

94932

94942

94935

99.7130

94931 V

1999 4 Wärtsilä NSD Switzerland Ltd

RTA58T-B Maintenance 4203–4/A2

Removing and Fitting of a Shrink fitted Flange Coupling

After the mid oil groove of the flange coupling has been shifted over the camshaft end, the connection for the HP oil

pump can be removed, the hydraulic unit being sufficient for pumping (Fig. ‘F’).

F

94935 94438

98.7322

94942

– Once the total length of the flange coupling has been shifted over the camshaft end, the flange coupling can be

moved carefully over the withdrawing shaft, then removed, using a crane or a chain block (Fig. ‘G’).

– Unscrew the withdrawing ring, the withdrawing shaft, and all connection branches and screw plugs.

98.7322

Wärtsilä NSD Switzerland Ltd 5 u 1999

You might also like

- SCANIA Suspension BT200 Work DescDocument32 pagesSCANIA Suspension BT200 Work DescHeri Suryo0% (1)

- Plymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceFrom EverandPlymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceNo ratings yet

- SUMITOMO R450LC-7 EXCAVATOR Service Repair Manual PDFDocument18 pagesSUMITOMO R450LC-7 EXCAVATOR Service Repair Manual PDFsekfsekmddde100% (4)

- MODEL 84980 Hydraulic Vent Valve Series "B": Section Form 402085 DEC - 2005Document4 pagesMODEL 84980 Hydraulic Vent Valve Series "B": Section Form 402085 DEC - 2005Putro 10100% (1)

- Lit2323 r7 Ch400b Parts ListDocument28 pagesLit2323 r7 Ch400b Parts ListRoman cupulNo ratings yet

- TSB Porsche 944 Brembo Brake Improved Piston SealsDocument6 pagesTSB Porsche 944 Brembo Brake Improved Piston Seals9TECHNIKNo ratings yet

- Instalación ch330Document4 pagesInstalación ch330Edwing GuerreroNo ratings yet

- G3406 Connecting Rod BearingsDocument4 pagesG3406 Connecting Rod BearingsnobodymagdesignNo ratings yet

- CPA Syllabus 2016Document188 pagesCPA Syllabus 2016athancox5837100% (1)

- Recycling of FRP BoatsDocument9 pagesRecycling of FRP Boatsjayaramsomarajan1975No ratings yet

- Don Casey's Complete Illustrated Sailboat Maintenance Manual: Including Inspecting the Aging Sailboat, Sailboat Hull and Deck Repair, Sailboat Refinishing, SailboFrom EverandDon Casey's Complete Illustrated Sailboat Maintenance Manual: Including Inspecting the Aging Sailboat, Sailboat Hull and Deck Repair, Sailboat Refinishing, SailboRating: 4.5 out of 5 stars4.5/5 (12)

- Drilling Fluids Processing HandbookFrom EverandDrilling Fluids Processing HandbookRating: 4.5 out of 5 stars4.5/5 (4)

- Hist C12 Indian History 3Document190 pagesHist C12 Indian History 3kane21232874No ratings yet

- Malabar: Read AND SaveDocument8 pagesMalabar: Read AND SavedairucNo ratings yet

- Service Manual #27Document631 pagesService Manual #27CharlesWhiteNo ratings yet

- WP Fork SXS ManualDocument143 pagesWP Fork SXS ManuallubisNo ratings yet

- WheelHorse 36 Inch Rear Discharge Mower Deck Parts ListDocument8 pagesWheelHorse 36 Inch Rear Discharge Mower Deck Parts ListKevins Small Engine and Tractor Service100% (1)

- Modal AnalysisDocument21 pagesModal AnalysisemreNo ratings yet

- Industech Exhibitor List 2020Document5 pagesIndustech Exhibitor List 2020kuldeepNo ratings yet

- DM45 Spur1Document60 pagesDM45 Spur1lalo11715100% (3)

- Service Bulletin A - 14: Technical Information To All The Owners of Sulzer AS25 and AT25 Type Diesel Engines 18.10.96Document3 pagesService Bulletin A - 14: Technical Information To All The Owners of Sulzer AS25 and AT25 Type Diesel Engines 18.10.96Gaetano MuccioNo ratings yet

- hc158 Workshop ManualDocument72 pageshc158 Workshop ManualJorge David Martínez100% (2)

- Parts Catalog Cummins, 6LTAA8.9G2 - ESN 82312099 - CPL 3079-55Document1 pageParts Catalog Cummins, 6LTAA8.9G2 - ESN 82312099 - CPL 3079-55Hardiansyah Simarmata100% (1)

- คู่มือบำรุงรักษา root blowerDocument17 pagesคู่มือบำรุงรักษา root blowervarayutjNo ratings yet

- Manual de Partes Correcto - para El Serial Del EquipoDocument90 pagesManual de Partes Correcto - para El Serial Del Equipojordy valverdeNo ratings yet

- Parts Catalog: 850J TIER 3 Crawler Dozer (SN 130886-)Document567 pagesParts Catalog: 850J TIER 3 Crawler Dozer (SN 130886-)Castro FernandoNo ratings yet

- 2020 Loss Control For TradersDocument8 pages2020 Loss Control For TraderskoushkiNo ratings yet

- M451-M453C HarDocument81 pagesM451-M453C HarRizky AS100% (4)

- SIN00217Document12 pagesSIN00217Gaetano MuccioNo ratings yet

- Piston Assembly, Skirt and Ring RTA-72Document6 pagesPiston Assembly, Skirt and Ring RTA-72rafaelNo ratings yet

- T50y IpbDocument4 pagesT50y IpbMarcelo ArayaNo ratings yet

- Set, Upper Engine Gasket PDFDocument2 pagesSet, Upper Engine Gasket PDFDavid NguyenNo ratings yet

- PCT 1575773Document12 pagesPCT 1575773Marisabel Barrientos carreraNo ratings yet

- Valvula Contravalance HTC 8670LBDocument6 pagesValvula Contravalance HTC 8670LBJorge YuniorNo ratings yet

- SIN00218Document3 pagesSIN00218Gaetano MuccioNo ratings yet

- Reglage Allumage 70 CV MercDocument5 pagesReglage Allumage 70 CV MercasursNo ratings yet

- Air Starter MotorsDocument3 pagesAir Starter MotorsCadeco ZamoraNo ratings yet

- Section 4A - Powerhead: Special ToolsDocument26 pagesSection 4A - Powerhead: Special ToolsRandall PettersonNo ratings yet

- SmontaggioTMA PDFDocument24 pagesSmontaggioTMA PDFHishamSayedNo ratings yet

- Procedures For Rebuilding The PQ100/200 Sampling Pump: Maintenance ManualDocument14 pagesProcedures For Rebuilding The PQ100/200 Sampling Pump: Maintenance ManualDaniel MasiasNo ratings yet

- Technical Service Bulletin: 210-2418 Ed. 4 April 2006 AllDocument7 pagesTechnical Service Bulletin: 210-2418 Ed. 4 April 2006 AllPyro KDNo ratings yet

- Removing and Installing Toothed BeltDocument12 pagesRemoving and Installing Toothed BeltJulien VasilevNo ratings yet

- Ripper Lift Cylinder R&RDocument8 pagesRipper Lift Cylinder R&Rconnor.millsNo ratings yet

- Toro 38180 Snowthrower Parts CatalogDocument16 pagesToro 38180 Snowthrower Parts CatalogDanNo ratings yet

- 4 Kul 94Document9 pages4 Kul 94Saeid MirNo ratings yet

- T50P PartsDocument5 pagesT50P Partsdanigo1977No ratings yet

- John Deere 450CLC Excavator Service Repair Technical Manual (TM1925)Document14 pagesJohn Deere 450CLC Excavator Service Repair Technical Manual (TM1925)laopaodunNo ratings yet

- BALEROSDocument17 pagesBALEROSjulio cesarNo ratings yet

- CSL1013Document7 pagesCSL1013Asep HidayatNo ratings yet

- Grundfosliterature 2616Document22 pagesGrundfosliterature 2616Sal MendezNo ratings yet

- Vane MotorsDocument4 pagesVane MotorsJosueNo ratings yet

- Tdi T: T50-P Air Starter PackageDocument7 pagesTdi T: T50-P Air Starter PackageΜερκουρηςκαπαNo ratings yet

- Greddy SBD ManualDocument22 pagesGreddy SBD ManualKenneth ChanNo ratings yet

- Duc256 WWDocument32 pagesDuc256 WWalexNo ratings yet

- 04 - Clutch - Gearshift Linkage - Kick Starter - AbwtDocument8 pages04 - Clutch - Gearshift Linkage - Kick Starter - Abwtcarlos melendez morenoNo ratings yet

- TDI T30-P Air Starter Illustrated Parts Breakdown T30-P-716 - 6701234 - 01Document4 pagesTDI T30-P Air Starter Illustrated Parts Breakdown T30-P-716 - 6701234 - 01Rogelio PerezNo ratings yet

- Media Search - SENR3594 - 3612 and 3616 EnginesDocument24 pagesMedia Search - SENR3594 - 3612 and 3616 EnginesLUIZ GUSTAVONo ratings yet

- Toyota 4Y Motor Spec - MotorpowerDocument1 pageToyota 4Y Motor Spec - MotorpowerClaudio BustosNo ratings yet

- Screenshot 2022-11-16 at 13.24.00Document2 pagesScreenshot 2022-11-16 at 13.24.00Andres Valencia BNo ratings yet

- 2752 HGB ServiceDocument4 pages2752 HGB ServiceJorge CabreraNo ratings yet

- Connecting Rod BearingsDocument4 pagesConnecting Rod Bearingsma.powersourceNo ratings yet

- Orbitrol Repairing 2Document25 pagesOrbitrol Repairing 2Islam ShoukryNo ratings yet

- Despiece Trasero Parte 2Document2 pagesDespiece Trasero Parte 2leogerguzNo ratings yet

- Drive Unit Compl For Roller Screen: Drawing-No. Name Revision Assembly Group Format Part-NoDocument2 pagesDrive Unit Compl For Roller Screen: Drawing-No. Name Revision Assembly Group Format Part-Nokev YNo ratings yet

- Volvo 244Document104 pagesVolvo 244Hadida MedlaminNo ratings yet

- Desplazador Doble Tipo 55D Serie 55D-SW-054Document5 pagesDesplazador Doble Tipo 55D Serie 55D-SW-054SARAMQRNo ratings yet

- MercjetDocument30 pagesMercjetBaxter LoachNo ratings yet

- ATV320 IS UL Type1 Kit NVE60199 03Document12 pagesATV320 IS UL Type1 Kit NVE60199 03cannabispernambucoNo ratings yet

- Service Bulletin A-7.2: 19.12.97 Technical Information To All The Owners of Sulzer A/AS/AT25 Type Diesel EnginesDocument5 pagesService Bulletin A-7.2: 19.12.97 Technical Information To All The Owners of Sulzer A/AS/AT25 Type Diesel EnginesGaetano MuccioNo ratings yet

- Service Bulletin A - 8: Technical Information To All The Owners of Sulzer A - Type Diesel Engines 15.08.94Document5 pagesService Bulletin A - 8: Technical Information To All The Owners of Sulzer A - Type Diesel Engines 15.08.94Gaetano MuccioNo ratings yet

- SIN00344Document4 pagesSIN00344Gaetano MuccioNo ratings yet

- SIN00341Document1 pageSIN00341Gaetano MuccioNo ratings yet

- SIN00231Document2 pagesSIN00231Gaetano MuccioNo ratings yet

- Framo Pump by BL-23Oct.02Document16 pagesFramo Pump by BL-23Oct.02Gaetano MuccioNo ratings yet

- SIN00216Document1 pageSIN00216Gaetano MuccioNo ratings yet

- LogcatDocument14 pagesLogcatprathmeshmarathe240No ratings yet

- Creative Accounting Full EditDocument11 pagesCreative Accounting Full EditHabib MohdNo ratings yet

- PTS 925 PTS 2000 User Manual USDocument249 pagesPTS 925 PTS 2000 User Manual USjoaquin mellaNo ratings yet

- Factors Affecting The Intention To Use Digital Banking in VietnamDocument8 pagesFactors Affecting The Intention To Use Digital Banking in VietnamRania barabaNo ratings yet

- Quick Sizer Guide For SAPDocument76 pagesQuick Sizer Guide For SAPpkv001No ratings yet

- Component Based Software EngineeringDocument21 pagesComponent Based Software Engineeringkarishma10No ratings yet

- Format Laporan Praktikum Citra DigitalDocument8 pagesFormat Laporan Praktikum Citra DigitalThomas C. YudhaNo ratings yet

- Forms DC BarDocument7 pagesForms DC BarEldy Quintanilla de RochéNo ratings yet

- SzlendakGryniewicz-FEMmodel Diaphragmactioneffectsv 0 95Document9 pagesSzlendakGryniewicz-FEMmodel Diaphragmactioneffectsv 0 95Ivan BurtovoyNo ratings yet

- Joint and Solidary Obligations Lecture Discussions in BaclawDocument5 pagesJoint and Solidary Obligations Lecture Discussions in BaclawRhos Bernadette SuicoNo ratings yet

- Department of Electronics &telecommunication Engineering Sem:VIII Question Bank of Satellite CommunicationDocument4 pagesDepartment of Electronics &telecommunication Engineering Sem:VIII Question Bank of Satellite CommunicationPavan WaseNo ratings yet

- 1 Where Were Wal Mart S Questionable Payments Made and WhereDocument1 page1 Where Were Wal Mart S Questionable Payments Made and WhereAmit PandeyNo ratings yet

- Chapter-1 COMPUTER SECURITYDocument48 pagesChapter-1 COMPUTER SECURITYLemi TuroNo ratings yet

- CASE SCENARIO ON Chronic BronchitisDocument2 pagesCASE SCENARIO ON Chronic BronchitisMacy AbellaNo ratings yet

- Draw Section CutsDocument1 pageDraw Section CutsFernando PizarroNo ratings yet

- Mathematics: Profit, Loss, Discount and AverageDocument9 pagesMathematics: Profit, Loss, Discount and AverageVishal JainNo ratings yet

- AutoTechnology - Article - 2003 (ChampCar) PDFDocument4 pagesAutoTechnology - Article - 2003 (ChampCar) PDFDavid DominguezNo ratings yet

- FW-V20 NivomerDocument8 pagesFW-V20 NivomersxasxNo ratings yet

- TOI Full Page - Dehradun Edition - May 2023Document1 pageTOI Full Page - Dehradun Edition - May 2023SakshamNo ratings yet

- Paul Samuelson PHD DissertationDocument6 pagesPaul Samuelson PHD DissertationIDon'TWantToWriteMyPaperCanada100% (1)

- Threaded Mechanical FastenersDocument32 pagesThreaded Mechanical FastenersfahkingmoronNo ratings yet

- Summer Internship ReportDocument28 pagesSummer Internship ReportKumar Rishikesh100% (1)

- 19180525RCDocument12 pages19180525RCPedja MetlicNo ratings yet