Professional Documents

Culture Documents

Jig and Fixtures 1

Uploaded by

pjpatel5999Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Jig and Fixtures 1

Uploaded by

pjpatel5999Copyright:

Available Formats

What is the universal distinction between a Jig and a Fixture?

Jigs are made to guide the cutting tool while the workpiece remains stationary,

and fixtures are made to guide the workpiece while the machining tool remains

in place.

How are Jigs identified?

Jigs are further identified by their basic construction. The two common forms of

jigs are open and closed. Open jigs carry out operations on only one, or

sometimes two, sides of a workpiece. Closed jigs, on the other hand, operate

on two or more sides.

How are fixtures most often identified?

Fixtures are most often identified by the machine tool where they are used.

Examples include mill fixtures or lathe fixtures. However, the function of the

fixture and/or basic construction of the tool can also identify a fixture type.

What are the two meanings of “tool”; why is important to make the distinction?

The term "tool" encompasses both jigs and fixtures. Essentially, it is a generic term describing a

work holder, which is identified with a part or machine. Sometimes "tool" is used to refer to a

cutting tool or a machine tool, so it is important to make clear distinctions

Production tools

Cutting tools

Hands tools.

What is a broader term used for jigs and fixtures?

Work holders is a broad term that refers to both jigs and fixtures. A work holder is any device that

holds, supports, and locates a workpiece.

What is the major separation of permanent and temporary work holders?

The major difference between the various types of work holders, from permanent, to flexible, to

modular and general-purpose work holders is the cost/benefit relationship between the

workholder and the process.

Give two examples of a general purpose work holder

General-purpose work holders include machine vises, self-centering vises, collet chucks, collet

vises, and chucks. They usually hold regular or symmetrically shaped workpieces; squares,

rectangles, cylinders, hexagons, and similar part shapes.

What are the three main groups of stakeholders?

The major difference between the various types of work holders, from permanent, to flexible, to

modular and general-purpose work holders is the cost/benefit relationship between the work

holder and the process.

Give applications for jigs and fixtures aside from machining.

Welding fixtures.

Mechanical-assembly fixtures (Riveting, stapling, stitching, pinning, etc.)

Soldering fixtures.

Where should locators contact the part?

Whenever practical, position the locators so they contact the workpiece on a machined surface.

The machined surface not only provides repeatability but usually offers a more stable form of

location. The workpiece itself determines the areas of the machined surface used for location.

Explain the six-point locational method.

3-2-1 principle of location definition The 3-2-1 principle of location, also called the six-point

positioning principle, the 3-2-1 principle of location means that the workpiece has six degrees of

freedom in space, i.e., the freedom of movement along the three right-angle axes of x, y, and z

and the freedom of rotation

3. What is repeatability?

the variation in successive measurements of the same variable taken under the same conditions (e.g.,

same observer, location, instrument, and procedure) in a short period.

“Repeatability” is the ability of the work holder to consistently produce parts within tolerance limits, and is

directly related to the referencing capability of the tool

4. What is meant by the term referencing?

“Referencing” is a dual process of positioning the workpiece relative to the work holder, and the work holder

relative to the cutting tool. Referencing the work holder to the cutting tool is performed by the guiding or setting

devices.

5. What percentage of part tolerance is applied to the tool?

20 - 50% of the part tolerance

6. What is the purpose of foolproofing the tool?

The main purpose of foolproofing is to ensure the workpiece is loaded the correct way each time.

7. What is duplicate locating?

using more than one parallel surface to

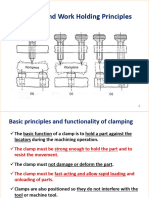

8. Where should the clamp contact the part?

At the end of the corner or surface. Above the support

9. What will happen if clamped areas aren’t supported?

It can damage the profile of the workpiece

10. What causes tool forces and how can they be used as an advantage?

Tool forces are used to hold the workpiece preventing part damage.

11. What determines the type and amount of necessary clamping force?

The amount of cutting force calculated

12. Where should the bulk of the tool thrust be directed?

Locater for a solid portion

400%

Bushings, Construction, and Workholders

1. How thick should the jig plate be to support bushing?

Bushing length

2. How much chip clearance should be allowed between the bushing and workpiece when

drilling and reaming?

Half to one and half

3. Drill bushings are identified by letters and numbers, identify the following

P-20-16-.1250?

Press fit bhushing od=20/64” l=16/16” id=.1250”

4. What are the three general categories of drill bushings and define each?

Fixed (or Solid) Drill Bushings:

Fixed drill bushings are permanent fixtures that are pressed or otherwise fixed into a jig or fixture.

Removable (or Renewable) Drill Bushings:

Removable drill bushings are designed to be inserted into and removed from a jig or fixture as needed

Floating (or Slip) Drill Bushings:

Floating drill bushings are designed to allow for slight movement or "float" during the drilling process.

5. What is the purpose of liner bushings?

primarily related to guiding and supporting linear motion

6. How much interference is ideal when installing a bushing in the mounting hole, what other

factors affect the size of the mounting hole?

The amount of interference required when installing a bushing into a mounting hole depends on several

factors, including the material properties of the bushing and the mounting hole, the intended application,

and the desired fit characteristics. In general, a small amount of interference is preferred to ensure a snug fit

between the bushing and the mounting hole, providing stability, proper alignment, and resistance to

loosening or movement during operation.

7. What is the main function of a tool body?

Housing of workpiece

Mounting base for all components.

8. What are the three general categories of tool bodies and what are the main advantages,

disadvantages of each?

Bolting

Welding

Casting

9. Name 3 categories of jigs.

Plate

Angular

welding

10. Name 3 categories of fixtures.

Painting

Welding

assembly

11. Name 3 general purpose work holders.

Vice chuck collars

You might also like

- Tool Design #2Document3 pagesTool Design #2api-26046805No ratings yet

- F Tool EngineeringDocument23 pagesF Tool EngineeringGiduthuri Es Prakasa RaoNo ratings yet

- Jig & FitDocument49 pagesJig & FitRavi Arjun KumarNo ratings yet

- Introduction To Work HoldingDocument29 pagesIntroduction To Work HoldingAndres Fitria FarrelNo ratings yet

- Introduction To Workholding: HistoryDocument36 pagesIntroduction To Workholding: HistoryramptechNo ratings yet

- Introduction To Workholding: HistoryDocument16 pagesIntroduction To Workholding: HistoryRavi Arjun KumarNo ratings yet

- Jig and FixturesDocument25 pagesJig and FixturesFadhli LieNo ratings yet

- Design of FixtureDocument4 pagesDesign of Fixtureapi-26046805No ratings yet

- FixturesDocument12 pagesFixturesakshay2761No ratings yet

- ME411-Workholding Device - 10.4.21Document71 pagesME411-Workholding Device - 10.4.21Albert VillarosaNo ratings yet

- Manufacturing Process Assignment 1Document10 pagesManufacturing Process Assignment 1abhishek chibNo ratings yet

- Jig and FixturesDocument38 pagesJig and FixturesrajatjainkkjNo ratings yet

- BIW Welding Fixture ProcessDocument31 pagesBIW Welding Fixture ProcessAnonymous 9q5GEfm8I50% (4)

- MT Ii 2 Marks PDFDocument19 pagesMT Ii 2 Marks PDFParamasivam Veerappan100% (1)

- DFM Lecture NotesDocument30 pagesDFM Lecture NotesShreya UppuNo ratings yet

- DJFP-PART A Q&ANS - FullDocument30 pagesDJFP-PART A Q&ANS - FullGunasekaranNo ratings yet

- QB - ME5635-Design of Jigs, Fixtures and Press Tools-Jan-May.2014Document27 pagesQB - ME5635-Design of Jigs, Fixtures and Press Tools-Jan-May.2014Carlos WilliamsonNo ratings yet

- I. Repetitive Nesting of Workpiece in A Jig/FixtureDocument8 pagesI. Repetitive Nesting of Workpiece in A Jig/FixtureJeremy NicanorNo ratings yet

- Lathes and Lathe Machining OperationsDocument18 pagesLathes and Lathe Machining Operationssarasrisam100% (1)

- Pipe JigsDocument26 pagesPipe Jigsarvind565No ratings yet

- Jigs Mini Project PDFDocument32 pagesJigs Mini Project PDFZahid PocieNo ratings yet

- Broaching FixtureDocument6 pagesBroaching Fixturemahmoudelsayad01013No ratings yet

- Jigs and FixtureDocument9 pagesJigs and FixtureJobin GeorgeNo ratings yet

- LV02 - Foundation Skills - Issue 1Document61 pagesLV02 - Foundation Skills - Issue 1Valentin Silvan Valentin SilvanNo ratings yet

- Jig and Fixtures LMDocument9 pagesJig and Fixtures LMJames AcquahNo ratings yet

- 2nd Chapter Continioues 17.12.2022Document12 pages2nd Chapter Continioues 17.12.2022Shiva Sankar BeharaNo ratings yet

- Locating and Clamping Principles: The Mechanics of LocatingDocument4 pagesLocating and Clamping Principles: The Mechanics of Locatingniloy_67No ratings yet

- Jigs & FixturesDocument124 pagesJigs & Fixturespaul chandra100% (1)

- Jigs & FixtureDocument33 pagesJigs & FixtureramtwinsmeNo ratings yet

- DJFP QUESTION BANK 23rd NovDocument6 pagesDJFP QUESTION BANK 23rd NovGunasekaranNo ratings yet

- DJFP-Important UT-1 CT-1 Q ADocument14 pagesDJFP-Important UT-1 CT-1 Q AGunasekaranNo ratings yet

- MT Ii 2 MarksDocument19 pagesMT Ii 2 MarksprasanthprpNo ratings yet

- Work 13Document17 pagesWork 13engineeradel2No ratings yet

- Unit I Locating and Clamping PrinciplesDocument15 pagesUnit I Locating and Clamping PrinciplesMECHANICAL DESIGNSNo ratings yet

- Dawit SolomonDocument24 pagesDawit Solomondawit solomonNo ratings yet

- Fixture Lecture 3 1Document32 pagesFixture Lecture 3 1Shubham BhagwatNo ratings yet

- Quiz1 ReviewerDocument17 pagesQuiz1 ReviewerJag MasterNo ratings yet

- Jig and Fixture Design AnnaDocument22 pagesJig and Fixture Design AnnaZemariyam BizuayehuNo ratings yet

- Title: - Clamping Systems EXP No.: - 5: Prepared By: V G Chhaya 1Document6 pagesTitle: - Clamping Systems EXP No.: - 5: Prepared By: V G Chhaya 1vishallchhayaNo ratings yet

- DG - 1147313041 - Body in White 2Document19 pagesDG - 1147313041 - Body in White 2K S RANJITH ランジットNo ratings yet

- Jigs and FixturesDocument73 pagesJigs and Fixturesashish Raut100% (1)

- Jigs and FixturesDocument26 pagesJigs and FixturesAumNo ratings yet

- Locating Principles and DevicesDocument154 pagesLocating Principles and DevicessrutiiNo ratings yet

- 2.1 Jigs and Fixtures - Principles of Location and Principles of ClampingDocument141 pages2.1 Jigs and Fixtures - Principles of Location and Principles of Clamping727721eumc020No ratings yet

- English Color VersionDocument165 pagesEnglish Color VersionVlad CiorteaNo ratings yet

- 1.1 Types of FixturesDocument19 pages1.1 Types of FixturesSrinivas DsNo ratings yet

- Experiment No. 1: AIM: To Study Single Point Cutting ToolDocument40 pagesExperiment No. 1: AIM: To Study Single Point Cutting ToolShreyas GajapureNo ratings yet

- Unit 6 Jigs and FixturesDocument53 pagesUnit 6 Jigs and FixturesNaresh kumar100% (2)

- Sindhi Board of Technical Education Karachi: Diploma of Associate Engineer Technology:MechanicalDocument8 pagesSindhi Board of Technical Education Karachi: Diploma of Associate Engineer Technology:MechanicalMmmNo ratings yet

- Manufacturing Engineering-1 - DPME-304Document27 pagesManufacturing Engineering-1 - DPME-304Vikas YadavNo ratings yet

- MT 2 MarksDocument11 pagesMT 2 MarksVimala Nalisetty0% (1)

- Jigs and FixturesDocument13 pagesJigs and FixturesTashoo KritNo ratings yet

- What Are Limits and FitsDocument9 pagesWhat Are Limits and FitsKashif RasheedNo ratings yet

- DFM Lecture NotesDocument20 pagesDFM Lecture NotesShreya UppuNo ratings yet

- Off-Road Welding: Advanced Techniques on How to Become a True Off-Road WelderFrom EverandOff-Road Welding: Advanced Techniques on How to Become a True Off-Road WelderRating: 5 out of 5 stars5/5 (2)

- Geometrical Dimensioning and Tolerancing for Design, Manufacturing and Inspection: A Handbook for Geometrical Product Specification Using ISO and ASME StandardsFrom EverandGeometrical Dimensioning and Tolerancing for Design, Manufacturing and Inspection: A Handbook for Geometrical Product Specification Using ISO and ASME StandardsRating: 4.5 out of 5 stars4.5/5 (3)

- CHAPTER 25 Testing and Inspection Activity HWDocument3 pagesCHAPTER 25 Testing and Inspection Activity HWpjpatel5999No ratings yet

- WeldingDocument2 pagesWeldingpjpatel5999No ratings yet

- Fire Drill Disaster Assignment No 4Document5 pagesFire Drill Disaster Assignment No 4pjpatel5999No ratings yet

- Week 3 HomeworkDocument3 pagesWeek 3 Homeworkpjpatel5999No ratings yet

- CNC Group ProjectDocument16 pagesCNC Group Projectpjpatel5999No ratings yet

- Assiginment No. 3 EiDocument7 pagesAssiginment No. 3 Eipjpatel5999No ratings yet

- S.No Process Description Fixture Requirement Instruments and Gauges Inspection Criteria RecordsDocument5 pagesS.No Process Description Fixture Requirement Instruments and Gauges Inspection Criteria RecordsRavi BabaladiNo ratings yet

- Wing Box AssemblyDocument7 pagesWing Box AssemblyDennis Padec BwochengoNo ratings yet

- MGPG 41Document97 pagesMGPG 41Douglas YamanakaNo ratings yet

- The Chopper Builders Handbook Notch-O-Matic' Tube Notcher The DesignDocument26 pagesThe Chopper Builders Handbook Notch-O-Matic' Tube Notcher The Designgww25100% (2)

- Jigs ElementsDocument14 pagesJigs ElementsNur Nabila HudaNo ratings yet

- Machine Tool Question Paper Jntuh Mt-1-1Document2 pagesMachine Tool Question Paper Jntuh Mt-1-1sudhakarNo ratings yet

- Work Holding Principles: Tool and Die DesignDocument29 pagesWork Holding Principles: Tool and Die DesignRey Niño GarciaNo ratings yet

- Study of Magnetorheological Fluid Based Flexible Work Holding FixtureDocument5 pagesStudy of Magnetorheological Fluid Based Flexible Work Holding FixtureAjith KrishnanNo ratings yet

- Hot and Cold WorkingDocument5 pagesHot and Cold Workingmuhammad al afiqNo ratings yet

- Brochure RZ 410Document8 pagesBrochure RZ 410Harris ChackoNo ratings yet

- LatheDocument74 pagesLatheChandrakantha K100% (1)

- Failure of Jigs & FixtureDocument27 pagesFailure of Jigs & FixtureTooling ganeshNo ratings yet

- Ts2400 Table Saw ManualDocument52 pagesTs2400 Table Saw Manualwill heiseNo ratings yet

- Jigs and Fixture Theory & Design: Fill in The BlanksDocument11 pagesJigs and Fixture Theory & Design: Fill in The BlanksGIRIDHAR CHIKKAMATHNo ratings yet

- Catalog Menghine TOOLEXDocument44 pagesCatalog Menghine TOOLEXMihai FilipNo ratings yet

- VMC 1300P - SINUMERIK 802D Operating ManualDocument130 pagesVMC 1300P - SINUMERIK 802D Operating ManualcipilanNo ratings yet

- Jigs and Fixtures - Mechanical Engineering (MCQ) Questions and AnswersDocument2 pagesJigs and Fixtures - Mechanical Engineering (MCQ) Questions and AnswersPrashant SinghNo ratings yet

- Standardized OperationsDocument38 pagesStandardized OperationsMurat TerziNo ratings yet

- JIG AND FIXTURE DESIGN MANUL Eric K HenriksenDocument160 pagesJIG AND FIXTURE DESIGN MANUL Eric K HenriksenPrakashmech4028No ratings yet

- JP Balancer Catalog 2022-LDocument19 pagesJP Balancer Catalog 2022-Lisidromundarain67No ratings yet

- Improving Gear Box 15006Document8 pagesImproving Gear Box 15006ivan platiniNo ratings yet

- NIKKEN NC303L - E - 220221-30mbDocument340 pagesNIKKEN NC303L - E - 220221-30mbGilberto XavierNo ratings yet

- 1.1 Types of FixturesDocument19 pages1.1 Types of FixturesSrinivas DsNo ratings yet

- Jigs and FixturesDocument85 pagesJigs and FixturesMudassar KhanNo ratings yet

- University of Engineering and Technology Lahore Machine Tool & Machining Lab AssignmentDocument5 pagesUniversity of Engineering and Technology Lahore Machine Tool & Machining Lab AssignmentTauQeer ShahNo ratings yet

- PSTC 5Document4 pagesPSTC 5Soo SeoNo ratings yet

- Getting The Most From The MFT Multifunction TableDocument52 pagesGetting The Most From The MFT Multifunction TableamayarNo ratings yet

- Kennametal Technical Data MetricDocument35 pagesKennametal Technical Data MetricVimaher Vila-realNo ratings yet

- Drilling ProcessDocument15 pagesDrilling ProcessAl Fredo95% (21)

- Manual, Craftsman Table Saw, Model 113-298720 and 750Document52 pagesManual, Craftsman Table Saw, Model 113-298720 and 750Eng-JR80% (5)