Professional Documents

Culture Documents

Exp 01

Uploaded by

Saleem KhanCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Exp 01

Uploaded by

Saleem KhanCopyright:

Available Formats

NUST COLLEGE OF ELECTRICAL & MECHANICAL ENGINEERING

DEPARTMENT OF MECHANICAL ENGINEERING

Experiment no.1 Charging of a Refrigeration System

Objective:

1. To evacuate a refrigeration system.

2. To charge a refrigeration system.

Apparatus:

Portable charging station, Refrigerant cylinder, System to be charged, Gauge manifold set,

Spanner set, Leak detector / Soapy Water

Introduction:

This system can be used to fully service any short / leak of refrigeration system. Firstly the

refrigeration system is evacuated in order to get rid of air or any short of fluid in the system. Then

refrigerant is transferred from the cylinder to the refrigerant tube in the charging station and

finally the refrigerant is charged in the required system.

Procedure:

First of all connect one line of gauge manifold with the charging port of refrigeration system and

other line to the cylinder. Open the gauge valve and pressurize the system for leak testing. Test the

system for all joints with leak detector or soapy water. Keep the pressure between 50 psi to 100 psi

for one or two hours to ensure no leakage in the system. Disconnect the line from the cylinder and

open the gauge valve to release the pressure from the system. Connect one side of the gauge with

the system and the other line to the vacuum pump. Use the lower side of the gauge for vacuum.

Start the vacuum pump. When the compound gauge reading is 29.92 Hg the vacuum is complete.

Turn the vacuum pump "Off" and disconnect the line. Connect the line with refrigerant cylinder for

charging of refrigerant. Open the cylinder valve and purge down the line with gas pressure. Open

the gauge valve slowly and enter the refrigerant into the system. When the pressure is about to 0

psi to 25 psi start charging the refrigeration system. Check the full load ampere of the system,

cooling temperature and site glass. Ensure that the site glass has shown completely liquid form

refrigerant in the system, required cooling temperature is achieved and rating current of system is

normal. When the charging is complete and system is in working condition, turn "Off" the system

and disconnect the gauge manifold with the system. Close the charging port with service valve or

punching tools.

Precautions

1. Before starting ensures all service valves of compressor are open.

2. During evacuation and filling process disconnect the electrical supply to the system to be

charged.

General Questions

1. What are the indications of the full charged system.

2. What will happen if some atmospheric air is left in the system.

3. What will be position of the sustain service valve after charging is complete.

4. Why the system is drawing more current then its rated value.

5. Explain the different positions of suction service valve.

You might also like

- PNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGFrom EverandPNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGNo ratings yet

- Refrigerant ChargingDocument10 pagesRefrigerant ChargingsrybsantosNo ratings yet

- Charging Refrigerants Into HVACDocument12 pagesCharging Refrigerants Into HVACRay NamuNo ratings yet

- Marvel Carbureter and Heat Control: As Used on Series 691 Nash Sixes Booklet SFrom EverandMarvel Carbureter and Heat Control: As Used on Series 691 Nash Sixes Booklet SNo ratings yet

- Pre Action System Testing and Commissioning Method Statement - Method Statement HQ PDFDocument5 pagesPre Action System Testing and Commissioning Method Statement - Method Statement HQ PDFjajaka100% (2)

- Troubleshooting Process Plant Control: A Practical Guide to Avoiding and Correcting MistakesFrom EverandTroubleshooting Process Plant Control: A Practical Guide to Avoiding and Correcting MistakesRating: 1 out of 5 stars1/5 (2)

- Performance Test On Vapour Compression Refrigeration SystemDocument5 pagesPerformance Test On Vapour Compression Refrigeration SystemBala Murali0% (1)

- Collin Test and Commissioning ProcedureDocument7 pagesCollin Test and Commissioning ProcedureSamuelJrManatadNo ratings yet

- Air Conditioning, Heating and Ventilation: Air Conditioning System Safety Precautions For Working With RefrigerantDocument26 pagesAir Conditioning, Heating and Ventilation: Air Conditioning System Safety Precautions For Working With Refrigerantvidurav@gmail.comNo ratings yet

- Midterm - Unit OpsDocument19 pagesMidterm - Unit OpsKrizzia Anne ShengNo ratings yet

- P&IDDocument7 pagesP&IDTagabo AliNo ratings yet

- Plan54 IOMDocument11 pagesPlan54 IOMAnonymous AS1lUJLNo ratings yet

- Manual For Starting PlantDocument2 pagesManual For Starting PlantShau WilliamNo ratings yet

- Water Fire Protection SystemsDocument190 pagesWater Fire Protection SystemsAnonymous qOBFvI100% (1)

- Pump Down Procedure PDFDocument1 pagePump Down Procedure PDFTTaanNo ratings yet

- Chiller T & C - TextDocument4 pagesChiller T & C - TextRajarajan KNo ratings yet

- Automatic Isolation Valves Test ProceduresDocument4 pagesAutomatic Isolation Valves Test ProceduresRahul ChandrawarNo ratings yet

- Refrigerant Leakage and Detection - Charging of Refrigerant - System ControlsDocument22 pagesRefrigerant Leakage and Detection - Charging of Refrigerant - System ControlsS R Akhil KrishnanNo ratings yet

- Ammonia Systems: Testing, Charging and SafetyDocument3 pagesAmmonia Systems: Testing, Charging and SafetyCorrosion FactoryNo ratings yet

- Title:Perform Charging of Refrigerant in Air Conditioning SystemDocument3 pagesTitle:Perform Charging of Refrigerant in Air Conditioning Systemcpt.ghostNo ratings yet

- Environmental Control SystemDocument16 pagesEnvironmental Control SystemAlaye AkpanaNo ratings yet

- Charging and Discharging RefrigeratorDocument1 pageCharging and Discharging RefrigeratorMateo, Dale Vincent A.No ratings yet

- Ash Handling System Operetaion and Maintenance InstructionDocument162 pagesAsh Handling System Operetaion and Maintenance InstructionHari PrasadNo ratings yet

- Plant Startup Shutdown Sequence Description ForReleaseDocument65 pagesPlant Startup Shutdown Sequence Description ForReleaseAnkurNo ratings yet

- Method Statement For Testing & Commissioning of Foam SystemDocument3 pagesMethod Statement For Testing & Commissioning of Foam SystemDong Vanra100% (1)

- Information Sheet M2-6Document20 pagesInformation Sheet M2-6Chamile BrionesNo ratings yet

- STEP 1 Install The Gage Manifold Compound Gage To The Suction LineDocument3 pagesSTEP 1 Install The Gage Manifold Compound Gage To The Suction LineFLORENDO Christael Angelique D.No ratings yet

- Deluge SystemDocument13 pagesDeluge SystemAnuj GuptaNo ratings yet

- Tutorial Guide To Manifold GaugesDocument2 pagesTutorial Guide To Manifold GaugesJames MockNo ratings yet

- Fire Sprinkler SystemsDocument83 pagesFire Sprinkler Systemsrams789No ratings yet

- Ac IntroductionDocument28 pagesAc Introductionthermopolis3012No ratings yet

- 120-50 Ultrasonic Cement AnalyzerDocument7 pages120-50 Ultrasonic Cement AnalyzerJadeja GirirajsinhNo ratings yet

- A Report On Boiler Feed WaterDocument11 pagesA Report On Boiler Feed WaterAustin UdofiaNo ratings yet

- Experiment 5 6Document14 pagesExperiment 5 6Rizwan SaeedNo ratings yet

- Boiler Operation and MaintenanceDocument69 pagesBoiler Operation and MaintenanceGloria Hamilton100% (4)

- Turbine Startup ProcedureDocument8 pagesTurbine Startup ProcedureBrijesh Srivastav0% (1)

- Air Conditioner ChargingDocument2 pagesAir Conditioner ChargingNorienelle Peñaranda AlasNo ratings yet

- I.P.C LeqDocument9 pagesI.P.C LeqnileshNo ratings yet

- Fire Sprinkler SystemsDocument83 pagesFire Sprinkler SystemsJaime Alberto Villarreal100% (1)

- Charging of RefrigerantDocument14 pagesCharging of RefrigerantMARIO BULANADINo ratings yet

- DTAC Charging System ProceduresDocument2 pagesDTAC Charging System ProceduresGerald BoyNo ratings yet

- Refrigerant Recovery and Recharge of A Room Air Conditioner 170280VDocument9 pagesRefrigerant Recovery and Recharge of A Room Air Conditioner 170280VMathiNo ratings yet

- Automatic Operation of BoilerDocument23 pagesAutomatic Operation of BoilerSuhas KassaNo ratings yet

- Draining, Flushing and Charging A Heat Transfer SystemDocument2 pagesDraining, Flushing and Charging A Heat Transfer SystemDipak ChandwaniNo ratings yet

- BSEE Test ProcedureDocument35 pagesBSEE Test ProcedureNatraji100% (2)

- CH.4 A.C. System Control DevicesDocument10 pagesCH.4 A.C. System Control Devicescpt.ghostNo ratings yet

- Calibration and Leak-By Test ProceduresDocument2 pagesCalibration and Leak-By Test Proceduresromi_hamdaniNo ratings yet

- Heating System DesignDocument19 pagesHeating System Designmarkbrennan1No ratings yet

- How To Recharge Air Conditioner: Purpose, Do's and Don'ts, and Some AdviceDocument11 pagesHow To Recharge Air Conditioner: Purpose, Do's and Don'ts, and Some AdviceSanjay OhriNo ratings yet

- Control Loops: An Open Loop Control SystemDocument17 pagesControl Loops: An Open Loop Control Systemget_engineer05No ratings yet

- API 682 Short Guide Most Common Plans and Operational InformationDocument40 pagesAPI 682 Short Guide Most Common Plans and Operational InformationFarhan TalibNo ratings yet

- NFPA 13 PRESSURE TEST PROCEDURES (Fire Pro)Document2 pagesNFPA 13 PRESSURE TEST PROCEDURES (Fire Pro)Mechanical Engineer50% (2)

- 5L Glass Fermenter 5GJ-Manual使用说明书Document61 pages5L Glass Fermenter 5GJ-Manual使用说明书mustaf mohamedNo ratings yet

- Unit Cold Start: 1. Start Service Water Pump 2. Start Auxiliary Cooling Water SystemDocument13 pagesUnit Cold Start: 1. Start Service Water Pump 2. Start Auxiliary Cooling Water SystemMuhammad luqman100% (1)

- SOP Gas AbsorptionDocument19 pagesSOP Gas AbsorptionKevin EsmunaldoNo ratings yet

- Refrigerant Charging ProcedureDocument3 pagesRefrigerant Charging Procedurenagarajasarma78% (9)

- Testing Fire-ProtectionDocument2 pagesTesting Fire-Protectionmia murciaNo ratings yet

- Operation and MaintenanceDocument76 pagesOperation and Maintenancesaie_1No ratings yet

- HPLDocument10 pagesHPLJoy KumarNo ratings yet

- Number Synthesis Isomers Linkage TransformationDocument14 pagesNumber Synthesis Isomers Linkage TransformationSaleem KhanNo ratings yet

- Topic 2 - Vapor Compression and Air, Refrigeration CyclesDocument77 pagesTopic 2 - Vapor Compression and Air, Refrigeration CyclesOk SokNo ratings yet

- Lecture 17Document27 pagesLecture 17Saleem KhanNo ratings yet

- Lecture 9Document12 pagesLecture 9Saleem KhanNo ratings yet

- Technological University (Maubin) Department of Mechanical Engineering Mini One Door RefrigeratorDocument13 pagesTechnological University (Maubin) Department of Mechanical Engineering Mini One Door RefrigeratorLin Yi100% (1)

- CIH EXAM Equations Simply Explained and With Examples: October 2019Document37 pagesCIH EXAM Equations Simply Explained and With Examples: October 2019AnandhuNo ratings yet

- GP 15-09-01 Control ValvesDocument23 pagesGP 15-09-01 Control ValvesAllia-Europe100% (1)

- Nissan Teana J32 2008-2013 Heater and Air Conditioning SystemDocument59 pagesNissan Teana J32 2008-2013 Heater and Air Conditioning SystemIchsan Kurniawan0% (1)

- Surge TankDocument2 pagesSurge TankBilel MarkosNo ratings yet

- H V P, I .: Y AC Roducts NCDocument2 pagesH V P, I .: Y AC Roducts NCJose Miguel Romero SevillaNo ratings yet

- 4.11.4 Steam Pipe Sizing and DesignDocument3 pages4.11.4 Steam Pipe Sizing and DesignSaurabh VijNo ratings yet

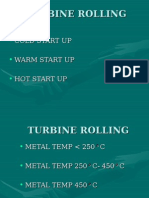

- Turbine RollingDocument39 pagesTurbine RollingSarah Frazier100% (2)

- Pro ValveDocument2 pagesPro ValvedonyaNo ratings yet

- IFV Safety Aspects Relating To The Use of Hydrogen in Confined SpacesDocument58 pagesIFV Safety Aspects Relating To The Use of Hydrogen in Confined SpacesNafees VakilNo ratings yet

- Wa0001Document18 pagesWa0001Talal IhsanNo ratings yet

- 1.0 Severn Glocon CV Sizing Selection ManualDocument104 pages1.0 Severn Glocon CV Sizing Selection Manualkoushik420000% (1)

- Balanced Cement Plug Example Calculations - Cement Plugs - CementingDocument3 pagesBalanced Cement Plug Example Calculations - Cement Plugs - Cementingazareiforoush100% (1)

- Handout - 4 Normal Shock WavesDocument18 pagesHandout - 4 Normal Shock WavesBrijal PatelNo ratings yet

- Momentum TransferDocument12 pagesMomentum TransfermohitreddyNo ratings yet

- Kinetic Theory of Gases +thermodynamics (Xii 2022-24) (Ans) 15 06 23Document2 pagesKinetic Theory of Gases +thermodynamics (Xii 2022-24) (Ans) 15 06 23Piyush Student Acc JEENo ratings yet

- Appendix A: Pipe and Duct SystemsDocument25 pagesAppendix A: Pipe and Duct SystemsUM'mer FarooqNo ratings yet

- A Complete Analysis of Your Reformer: Bill Cotton and Barry FisherDocument9 pagesA Complete Analysis of Your Reformer: Bill Cotton and Barry Fishersalvatore raffaNo ratings yet

- 575 0300 WET ScrubberDocument8 pages575 0300 WET Scrubberzhigang dingNo ratings yet

- 2017 Gas Lift CatalogDocument28 pages2017 Gas Lift CatalogHìnhxămNơigóckhuấtTimAnhNo ratings yet

- Balaji FormalinDocument14 pagesBalaji Formalinbhavesh moorjaniNo ratings yet

- BASF PSV Documentation RequirementsDocument12 pagesBASF PSV Documentation RequirementsMEGAN ASBROCKNo ratings yet

- DLM142EDocument28 pagesDLM142Eseaqu3stNo ratings yet

- División Académica de Ingeniería y Arquitectura: Dimensional ConsistencyDocument11 pagesDivisión Académica de Ingeniería y Arquitectura: Dimensional ConsistencyTano TGNo ratings yet

- Standards Publication: DOC NO: QP-GDL-S-031 Revision 1Document10 pagesStandards Publication: DOC NO: QP-GDL-S-031 Revision 1Deepak Kannan100% (1)

- Basic Refrigeration CycleDocument9 pagesBasic Refrigeration Cyclekhushal bhanderiNo ratings yet

- FI01 2008 en Kap04 PDFDocument388 pagesFI01 2008 en Kap04 PDFRandy LangleyNo ratings yet

- Analysis On Risks and Hazards of The Sloshing Liquid Cargo Tank in Oil TankerDocument5 pagesAnalysis On Risks and Hazards of The Sloshing Liquid Cargo Tank in Oil TankerAmalia IstighfarahNo ratings yet

- Hydraulics III PumpsDocument15 pagesHydraulics III Pumpsbub1ll4No ratings yet

- Hand PumpDocument4 pagesHand PumpMagdalena Belen Sepulveda LavanchyNo ratings yet

- The ISO 45001:2018 Implementation Handbook: Guidance on Building an Occupational Health and Safety Management SystemFrom EverandThe ISO 45001:2018 Implementation Handbook: Guidance on Building an Occupational Health and Safety Management SystemNo ratings yet

- Chemical Process Safety: Learning from Case HistoriesFrom EverandChemical Process Safety: Learning from Case HistoriesRating: 4 out of 5 stars4/5 (14)

- Workbook to Accompany Maintenance & Reliability Best PracticesFrom EverandWorkbook to Accompany Maintenance & Reliability Best PracticesRating: 3.5 out of 5 stars3.5/5 (3)

- Guidelines for Auditing Process Safety Management SystemsFrom EverandGuidelines for Auditing Process Safety Management SystemsNo ratings yet

- A Complete Guide to Safety Officer Interview Questions and AnswersFrom EverandA Complete Guide to Safety Officer Interview Questions and AnswersRating: 4 out of 5 stars4/5 (1)

- Introduction to Petroleum Process SafetyFrom EverandIntroduction to Petroleum Process SafetyRating: 3 out of 5 stars3/5 (2)

- Functional Safety from Scratch: A Practical Guide to Process Industry ApplicationsFrom EverandFunctional Safety from Scratch: A Practical Guide to Process Industry ApplicationsNo ratings yet

- Nutritional and Therapeutic Interventions for Diabetes and Metabolic SyndromeFrom EverandNutritional and Therapeutic Interventions for Diabetes and Metabolic SyndromeNo ratings yet

- Guidelines for Initiating Events and Independent Protection Layers in Layer of Protection AnalysisFrom EverandGuidelines for Initiating Events and Independent Protection Layers in Layer of Protection AnalysisRating: 5 out of 5 stars5/5 (1)

- Practical Industrial Safety, Risk Assessment and Shutdown SystemsFrom EverandPractical Industrial Safety, Risk Assessment and Shutdown SystemsRating: 4 out of 5 stars4/5 (11)

- Rules of Thumb for Maintenance and Reliability EngineersFrom EverandRules of Thumb for Maintenance and Reliability EngineersRating: 4.5 out of 5 stars4.5/5 (12)

- The Invisible Rainbow: A History of Electricity and LifeFrom EverandThe Invisible Rainbow: A History of Electricity and LifeRating: 4.5 out of 5 stars4.5/5 (21)

- Handbook of Fire and Explosion Protection Engineering Principles: for Oil, Gas, Chemical and Related FacilitiesFrom EverandHandbook of Fire and Explosion Protection Engineering Principles: for Oil, Gas, Chemical and Related FacilitiesRating: 4.5 out of 5 stars4.5/5 (2)

- Tensor Technology Guide: Tensor Ring Benefits and UsesFrom EverandTensor Technology Guide: Tensor Ring Benefits and UsesRating: 5 out of 5 stars5/5 (2)

- General Orders for Security Personnel: A Guide to Maintaining Discipline and ProfessionalismFrom EverandGeneral Orders for Security Personnel: A Guide to Maintaining Discipline and ProfessionalismNo ratings yet

- Redefining Work Health and Safety: Systems, Strategies, and Progressive ApproachesFrom EverandRedefining Work Health and Safety: Systems, Strategies, and Progressive ApproachesNo ratings yet

- Autophagy in Health and DiseaseFrom EverandAutophagy in Health and DiseaseBeverly RothermelNo ratings yet

- Guidelines for Implementing Process Safety ManagementFrom EverandGuidelines for Implementing Process Safety ManagementNo ratings yet

- A Poison Like No Other: How Microplastics Corrupted Our Planet and Our BodiesFrom EverandA Poison Like No Other: How Microplastics Corrupted Our Planet and Our BodiesRating: 5 out of 5 stars5/5 (1)

- Trevor Kletz Compendium: His Process Safety Wisdom Updated for a New GenerationFrom EverandTrevor Kletz Compendium: His Process Safety Wisdom Updated for a New GenerationNo ratings yet

- Handbook of Hazardous Chemical PropertiesFrom EverandHandbook of Hazardous Chemical PropertiesRating: 5 out of 5 stars5/5 (1)

- Environmental and Health and Safety Management: A Guide to ComplianceFrom EverandEnvironmental and Health and Safety Management: A Guide to ComplianceRating: 4 out of 5 stars4/5 (2)