Professional Documents

Culture Documents

Design of Multi-Crop - Thresher-Case - Study

Uploaded by

teddiyfentawOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Design of Multi-Crop - Thresher-Case - Study

Uploaded by

teddiyfentawCopyright:

Available Formats

GIAN-North

Innovation Incubation at Grassroots

Multi crop Thresher

Madanlal Kumawat, Rajasthan, India

A Case Study

By

Rajeev Singhal

Grassroots Innovations Augmentation Network – North (GIAN - North)

Science Park, Shastri Nagar, Jaipur, Rajasthan, India

Madanlal-Case Study2.doc Page 1 of 11

GIAN-North

Executive Summary

Madanlal Kumawat of Rajasthan, India is a grassroots innovator who could get

formal education only till class fourth. The circumstances forced him to stay back

at home and learn how to work. He was born and brought up in a village of

Rajasthan and has four sisters and one brother. His father was a carpenter and

gave him initial education at home only. At 15 he trained himself as a tailor,

shifted to carpentry profession after a few years and finally got some satisfaction

at a metal engineering workshop. There he learned engineering skills on various

farm machineries and also developed an improved multi-crop thresher. This

thresher had the output much cleaner than the existing threshers and after this

development Madanlal started gaining popularity among the local mechanics of his

region.

He setup his own workshop in 1997 and further modified his thresher to improve its

efficiency, low power consumption, use for other crops for which it was not used

and different models to suit the requirement of the users. Most of the

improvements carried out by Madanlal were based on the feedback and

requirement of the users. It took about 7-8 years for him to come to this stage

after setting his own unit. During this phase he also got introduced to Honey Bee

Network, which gave him recognition, market linkages, financial support, formal

evaluation of his work and social fame.

Today his threshers are tested by Rajasthan Agriculture University, India and he

has four different models varying in size, capacity and features. His is the only

thresher which is claimed to be used on almost all kinds of crops including

groundnuts and switching over from one crop to other takes minimum time and

efforts. His work not only gained recognition by National Innovation Foundation

and support by GIAN-North but also got appreciation by the scientist involved for

the formal testing. He was so impressed by the work that he wrote a formal paper

for a scientific journal, keeping Madanlal a co-author. Madanlal also gained a

patent for his innovative work and today is doing well in his business in some areas

of Rajasthan with a vision to spread it all over India.

His objective of life is to keep working with honesty and hardwork and never cheat

anyone. He often says “imandaari aur mehnat se apna kaam karte raho…..

musibat main usse chodo nahin, accaha samay aayegaa….. kisi ka bura mat socho,

ant accaha hoga…”

Madanlal-Case Study2.doc Page 2 of 11

GIAN-North

Background

The innovator Madanlal Kumawat was born in 1964 in a village called Gopalpura in

Distt. Churu of Rajasthan, India. His father was a carpenter and use to earn his

livelihood by working on daily wages in the village. The innovator had his initial

education at home till he was 10 years and was admitted to a village school in

class first. After studying for 10-15 days in class first and second his teacher

realized that Madanlal can be promoted to next class and he was shifted to class

third. He was a good student but could not continue his studies after class fourth

due to a major accident. After the accident he was quite weak physically and thus

decided to learn tailoring which would not involve much physical labour.

Simultaneously, he also learned carpentry from his father and contributed a little

in that too. After engaging himself in work he started gaining physical strength

and he full time shifted to carpentry profession. He and his father were so good in

their profession that there was a demand of their work in other villages too. Once

Madanlal was invited by a known from other village called Rampura for carpentry

work which took about 15-20 days to execute. During those 15-20 days he became

popular for his work and noticed a great demand of his work in that village. He

shifted to Rampura and started his work there. After about three years he got

inclined towards the metal engineering work and got himself associated with a

workshop in village Bagru through a villager to learn the skills. He learnt almost

all the technicalities of agriculture implements manufactured there and soon

gained the confidence of the owner. He spent about 9 years in that workshop and

improvised a few agriculture implements there.

He than setup his own workshop at Danta in 1997 and started manufacturing

threshers and other agriculture machinery.

Madanlal has one brother younger to him and is engaged with him in his workshop.

Madanlal is staying with his wife and three children who are currently studying. He

wants to support them for studying till they want to study. Madanlal works about

Madanlal-Case Study2.doc Page 3 of 11

GIAN-North

15-18 hours a day. When his wife was asked that his so much involvement in work

effects his social life, she said dhando phele mean work is the first priority !

Genesis and details of present innovation

During 80ies and early 90ties manufacturers and dealers of agriculture implements

in Rajasthan use to bring threshers from Punjab and sell. The workshop owners

mainly use to conduct repair work as per demand. Once Madanlal realized, why

not to manufacture the same at his facilities and the thought process began. He

started developing the first thresher at the workshop he was working. After about

20-30 days of efforts he could develop a thresher whose performance was

comparable with the existing ones. During the development phase he found that

there is tremendous scope of improvement in the performance of the thresher and

started working on the ideas generated during the development.

He observed that the grains coming out of the threshers were not so clean and

needed to be cleaned before bagging. He developed a mechanism of cleaning the

grains while threshing by incorporating a blower and canalizing the air in such a

way that the straw mixed with grains gets separated before reaching the outlet.

The flow and speed of blower needed optimization for various crops and that was

achieved by incorporating a set of gears & pulley mechanism.

Madanlal-Case Study2.doc Page 4 of 11

GIAN-North

Development stages

- 1991 - Incorporation of blowers to get much cleaner output : The need was

felt to develop a thresher of his own in Rajasthan

and developed a thresher based on the basic

design of existing threshers. During the

development it was observed that there is

tremendous scope of improvement to get the

better output. The various moving parts in the

thresher generated flow of air and Madanlal

modified it into a built-in blower and canalized

the air to clean the grains. A cutting mechanism was also introduced at the

first stage to simplify the threshing mechanism.

- 1991-93 – Covering the remaining crops : Till now

the multicrop threshers were unable to thresh

the crops which were quite heavy or quite light.

Madanlal made modifications in the beating

mechanism and optimized the blower speed etc.

to the extent that it became suitable to use for

these crops also.

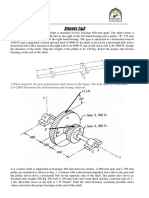

- 1997 – Optimized the size of the drum and the

beater and increased the length of the thresher

to reduce the load on the prime mover. He again

optimized the design to reduce the changeover

time of the fitments. Thresher needs to be

modified to make it suitable to different crops.

This changeover in conventional threshers takes

about 2-3 hours. Madanlal made the fitments in

such a way that minimum needs to be changes and it takes only 10-15

minutes to make it suitable for other crops.

- 2005 – By this time also the threshing of

groundnuts was done using a separate thresher.

Madanlal modified this thresher to be used as a

groundnut thresher. The only difference was

that the modifications took about 2-2.5 hours to

convert it into a groundnut thresher.

- 2006 – Different Models : Till now Madanlal was

manufacturing only one model of thresher with

high capacity (about 20-22 Q/hr) but than he

noticed that farmers with lesser requirements

are not preferring his thresher. He than came

out with two more intermediate models with

lesser capacity (about 7-15 Q/hr) which gave him

more market.

Madanlal-Case Study2.doc Page 5 of 11

GIAN-North

Introduction with Honey Bee Network

After Madanlal setup his own workshop at Danta, he became more popular for his

work and was noticed by Sundaram Verma, a Honey Bee Collaborator and scout

from the same place in 2000. When the scout first approached him to know details

about his work, he was not entertained by Madanlal for the reason that he might

get into some trouble. But in second or third meeting he got convinced and shared

the details about his work . Madanlal was thus linked with Honey Bee Network and

his innovation was nominated in the First National Competition on Grassroots

Innovations and TK.

Recognition & Award

He was recognized by National Innovation Foundation under the consolation

category in the above said competition in the year 2001.

He has also been awarded first by the State Government for the same innovation in

November 2004.

Madanlal-Case Study2.doc Page 6 of 11

GIAN-North

Extension of support in further development by network partners

- After the work of Madanlal got recognition, it was supported by GIAN-North

for getting formally evaluated by organized sector. The details were

submitted by Maharana Pratap University of Agriculture and Technology,

Rajasthan. They appreciated the work and suggested a few areas which

may be improved upon.

- Further the innovator was supported financially to incorporate the feature

of groundnut threshing in this multi-crop thresher in 2002.

- The patent for the innovation was applied in the year 2002 and has been

granted.

- This prototype was developed and submitted to Rajasthan Agriculture

University for further evaluation. The detailed formal testing and

evaluation has been conducted and this innovation has been found much

better than the existing ones.

- The expert involved has also co-authored himself with the innovator to

write a paper for a National Journal.

- Market inputs have been provided through business linkages for the need of

low capacity and low cost threshers. As a results three different models

ranging from 6-7 Q/ hr. capacity to 22 Q/hr capacity to meet the

requirement of various farmers.

Madanlal-Case Study2.doc Page 7 of 11

GIAN-North

The product

Abstract

The multi-crop thresher developed by Madanlal Kumawat of India is a unique

device which can be used for threshing almost all the kinds of crops by changing a

few fitments in the minimum time. The device as compared with the existing

alternatives given much cleaner grains which can be bagged directly and at a

lesser expense.

Features

The only multicrop thresher, having the provision of Groundnut Threshing

Minimum effort to switchover to other crops.

It uses 35 to 45 HP. (26.1 to 33.6 kilowatt) diesel engine.

The feed mechanism of the “improved thresher” has a gearbox, which is used

to rotate five cylinders of the feed mechanism with different speeds to enable

effective feeding to different crops requiring different rate of feed.

It is a machine in which both cutting and threshing can be done in succession.

It has different feeding arrangement for different crops.

It has variable blower speed to blow off the chaffs of different crops.

It is high capacity thresher and its output is higher than standard threshers.

Due to optimized design it consumes lesser fuel as compared to other

threshers.

Madanlal-Case Study2.doc Page 8 of 11

GIAN-North

Advantages

1. More efficient and consumes less power for same output

2. Grains are cleaner and do not need further cleaning before bagging up. Thus

can be directly bagged and save time, energy and cost.

3. Easy to operate for Multiple crops: Rearrangement time for fitments for

different crops is very less as compares to the other multicrop threshers. This

takes only 10-15 minutes to replace the necessary accessories while the others

take about 2 – 3 hours.

4. Has the added feature of Groundnut threshing for which the design and concept

is being made and new improved prototype is proposed.

Comparison with available alternatives

Innovation Madan Lal Kumawat’s Semi Axial Flow thresher Other Multi-crop

threshers

Source NIF database CIAE Bhopal http://www.agridept.g

ov.lk/FCRDI/FM_imple.

htm#thresher1

Summary It is Spike tooth type, high It is a spike tooth type It is a throw-in type

capacity thresher, which thresher. It has provision of high capacity thresher

can handle multiple crops adjustment of thresher to with blower fan

including groundnuts with achieve better cleaning for winnowing and can

minimum machine all crops over other thresh paddy, maize,

adjustments, it can be run commercial threshers. sunflower and soybean

by the tractor engine with minute

power. adjustment.

Components Threshing drum, concave, Threshing drum, concave, Threshing cylinder,

feeding chute, blower, feeding chute, blower unit, concave, belt and

aspirator , belt and pulley belt and pulley drive and pulley drive, feeding

drive for shaft and power source chute and power

aspirator and chain and (tractor/engine). source (power tiller /

sprocket for varying stationary engine)

speed.

Material of Mild steel and cast iron Mild steel and cast iron Mild steel and cast iron

construction

Principle of By cutting, rubbing and By rubbing and beating By rubbing action

threshing beating action action.

Power Tractor (35-40HP) 7.5 hp electric motor 7.5 hp power

source tiller/electric motor

capacity 1500-2200 kg of dry crop 350 kg of dry crop per hour 700-1000 kg of dry crop

per hour depending on depending upon the

crop crop.

Changeover 10-15 minutes (except Not known 2-3 Hours

time groundnut )

Labour 3 labours are required. 4 labours are required 3 labours are required.

requirement

Madanlal-Case Study2.doc Page 9 of 11

GIAN-North

Cost 1. Rs. 165,000/- NA Rs. 65,000/- per unit

2. Rs. 135,000/- excluding the cost of

3. Rs. 110,000/- power source

4. Rs. 65,000/-

Applications Useful for threshing maize, Useful for threshing pigron Useful for threshing

pea, gram, sunflower, pea, gram, wheat, soybean, maize, sunflower,

soybean, paddy, wheat, maize sorghum, etc. soybean, paddy, etc.

groundnut and other crops

Photo

Ergonomics One of the model is One has to step up to come One has to step up to

designed in such a way up to the level of feed in come up to the level of

that it can be fed in at section feed in section

ground level with ease.

Business Development

- Market Research has been conducted with the help of a group of students

from a management institute. The report showed the potential of the

innovation and confidence to support further.

- Business Planning was done by National Innovation Foundation and GIAN-N

and Madanlal has been supported with venture funds to expend the

business. He also enhanced his manufacturing facilities and today he has a

capacity to produce 10-15 units each day.

- Madanlal has also been given the opportunity by GIAN-N and NIF to showcase

his work in various National and International Exhibitions and Trade Fairs to

create new opportunities.

Madanlal-Case Study2.doc Page 10 of 11

GIAN-North

Future plans

Madanlal is a dedicated innovator with creative brain but lacks in entrepreneurial

skills. He worked with many partners but could not succeed much in business. In

spite of owning a unique technology which he sells at almost 1.5 times (and

people prefers) he has not made much profit.

He has plans to make his thresher popular all over India after covering his own

state and also to launch a few more innovative products. He is currently working

on a unique weeder which is expected to be developed in another 4-5 month.

Madanlal has seen many ups and downs in his life but is very determined. His

philosophy of life is very simple “Never leave Honesty and Hard work, and the

success will be achieved one day. This path may take long to get the success but

the end will be better.”

Madanlal-Case Study2.doc Page 11 of 11

You might also like

- Desing and Fabrication of Sugar Cane Planting MachineDocument16 pagesDesing and Fabrication of Sugar Cane Planting Machinevenkatesaperumal eNo ratings yet

- Design, Development and Fabrication of Mini Cultivator and TillerDocument4 pagesDesign, Development and Fabrication of Mini Cultivator and TillerShrineevasan RNo ratings yet

- An Introduction To Design ThinkingDocument59 pagesAn Introduction To Design ThinkingVinay MurgodNo ratings yet

- Untitled DocumentDocument16 pagesUntitled DocumentBharath MahendrakarNo ratings yet

- Untitled DocumentDocument16 pagesUntitled DocumentBharath MahendrakarNo ratings yet

- NFL Training ReportDocument28 pagesNFL Training ReportjbjassibansalNo ratings yet

- Coconut-DehuskersdocDocument5 pagesCoconut-DehuskersdocManga DeviNo ratings yet

- Gajanan Rice Mill ReportDocument68 pagesGajanan Rice Mill ReportChannu Arjun100% (1)

- Assignment I&EDocument8 pagesAssignment I&ESUFIYAN KHANNo ratings yet

- 3 Wheel TractorDocument14 pages3 Wheel TractorJeevan Landge Patil100% (1)

- Sarvaay Solutions Team Name - Corporate Pirates Team MembersDocument6 pagesSarvaay Solutions Team Name - Corporate Pirates Team Memberstanya guptaNo ratings yet

- Summer Training Project PrportDocument30 pagesSummer Training Project PrportSwapnil KhartadNo ratings yet

- Aim & Objective: Modelling and Fabrication of Paddy Planting MachineDocument16 pagesAim & Objective: Modelling and Fabrication of Paddy Planting MachineAYAZ AHMADNo ratings yet

- Kerala Agro Machinery Corporation Ltd. (KAMCO) Was Established in The YearDocument52 pagesKerala Agro Machinery Corporation Ltd. (KAMCO) Was Established in The YearSudarsan Mv100% (5)

- A Case Study On Cotton Stripper MachineDocument23 pagesA Case Study On Cotton Stripper Machineavinashmunnu100% (1)

- Jugaad Innovation:: Mic PresentationDocument26 pagesJugaad Innovation:: Mic PresentationSooraj KNo ratings yet

- Multipurpose Agriculture MachineDocument8 pagesMultipurpose Agriculture MachinesudheeshNo ratings yet

- Summer Trrainng ProjectDocument52 pagesSummer Trrainng ProjectAnjay PandeyNo ratings yet

- Final ProjectDocument55 pagesFinal ProjectArpita BiswalNo ratings yet

- Ganesh Project OriginalDocument31 pagesGanesh Project OriginalAshutosh JadhavNo ratings yet

- NFL Summer Internship ReportDocument54 pagesNFL Summer Internship ReportIsha Chhabra100% (1)

- A Pedal Operatedpedal Operated Coconut de HuskerDocument3 pagesA Pedal Operatedpedal Operated Coconut de HuskerDr.Eswara Reddy SiddareddyNo ratings yet

- Fabrication of Low-Cost Manualcrop Harvesting MachineDocument9 pagesFabrication of Low-Cost Manualcrop Harvesting Machinepratik g100% (1)

- A Study On Gur (Jaggery) Industry in India (Research - Outline)Document4 pagesA Study On Gur (Jaggery) Industry in India (Research - Outline)prgunjalNo ratings yet

- Rutvik Walde - Bullet SantiDocument3 pagesRutvik Walde - Bullet SantiRUTVIK WALDENo ratings yet

- Mansukhbhai Jagani Developed A MotorcycleDocument10 pagesMansukhbhai Jagani Developed A MotorcycleJennz MontyNo ratings yet

- Sibi SEED SOWING MACHINE Plowing Leaveling 2Document25 pagesSibi SEED SOWING MACHINE Plowing Leaveling 2Sergio PugazhNo ratings yet

- Sugarcane Financial ProjectDocument49 pagesSugarcane Financial Projectkannan100% (1)

- Development and Testing of Self-Propelled Cono-Weeder For Mechanized Rice CultivationDocument5 pagesDevelopment and Testing of Self-Propelled Cono-Weeder For Mechanized Rice CultivationSapuniiNo ratings yet

- Guided By: Submitted By:: Mr. Piyush Patel Megha Shah Sarika Shah Nisha Nair Akruti RajputDocument74 pagesGuided By: Submitted By:: Mr. Piyush Patel Megha Shah Sarika Shah Nisha Nair Akruti RajputNichu@No ratings yet

- Mrketing MixDocument90 pagesMrketing Mixsvjrao100% (1)

- NFCLDocument19 pagesNFCLSunil Varma Agrico100% (1)

- Training Report: Submitted in Requirement For Six Weeks Industrial TrainingDocument31 pagesTraining Report: Submitted in Requirement For Six Weeks Industrial TrainingAshutosh GuptaNo ratings yet

- Modeling and Manufacturing of Versatile Agriculture MachineDocument7 pagesModeling and Manufacturing of Versatile Agriculture Machinesai jathinNo ratings yet

- AssignmentDocument1 pageAssignmentHannan KhattakNo ratings yet

- Entrepreneurship AsssignmentDocument7 pagesEntrepreneurship AsssignmentamitcmsNo ratings yet

- Marketing Strategies (Prince ReportDocument75 pagesMarketing Strategies (Prince ReportDeepali Thakur100% (1)

- Halimaw MachineDocument21 pagesHalimaw MachineJoana Doray100% (1)

- 2 Pomegranate de SeederDocument3 pages2 Pomegranate de SeederloomzakhaevNo ratings yet

- Design, Development and Fabrication of A Compact Harvester: December 2014Document8 pagesDesign, Development and Fabrication of A Compact Harvester: December 2014akashmanavalan0911No ratings yet

- 8 Rural InnovationDocument16 pages8 Rural InnovationRanga ReddyNo ratings yet

- Project - FinalDocument85 pagesProject - FinalAbhishek ChopraNo ratings yet

- Project Report PDFDocument21 pagesProject Report PDFnagaraju b 334No ratings yet

- Vinayak PDFDocument5 pagesVinayak PDFrajput sunilNo ratings yet

- An andDocument45 pagesAn andRakesh Burly100% (1)

- Design & Fabrication of Solar Powered Groundnut Sheller MachineDocument1 pageDesign & Fabrication of Solar Powered Groundnut Sheller MachineVinay MuleyNo ratings yet

- Personal Learning PaperDocument7 pagesPersonal Learning PaperSomnath KejriwalNo ratings yet

- Huller MachineDocument5 pagesHuller MachineshahrukhNo ratings yet

- Retail ProductDocument90 pagesRetail Productanil4770100% (2)

- Irjet V5i6410Document4 pagesIrjet V5i6410Flip ItNo ratings yet

- Transformational Leadership in India TheDocument29 pagesTransformational Leadership in India TheDoc TuberNo ratings yet

- Background of InnovationsDocument7 pagesBackground of InnovationsdpparkheNo ratings yet

- Kerala 3Document22 pagesKerala 3engage4u2020No ratings yet

- Swaraj Training ReportDocument91 pagesSwaraj Training ReportAmrit PaddaNo ratings yet

- TKP 3501 - Practical 7Document4 pagesTKP 3501 - Practical 7shafiqbal1996No ratings yet

- Summer Internship Project Report ON: "A Study On Working of H.R. Function " ATDocument33 pagesSummer Internship Project Report ON: "A Study On Working of H.R. Function " ATShrey KashyapNo ratings yet

- The Two-Wheel Tractor Handbook: Small-Scale Equipment and Innovative Techniques for Boosting ProductivityFrom EverandThe Two-Wheel Tractor Handbook: Small-Scale Equipment and Innovative Techniques for Boosting ProductivityNo ratings yet

- Chapter-4 Centrifugal PumpDocument20 pagesChapter-4 Centrifugal PumpteddiyfentawNo ratings yet

- Turbo For ExitDocument72 pagesTurbo For ExitteddiyfentawNo ratings yet

- Turbomachinery Exit Exam TutorialsDocument22 pagesTurbomachinery Exit Exam TutorialsteddiyfentawNo ratings yet

- Heat Transfer Chapter Two PDFDocument86 pagesHeat Transfer Chapter Two PDFteddiyfentawNo ratings yet

- 3rd Round - 2015 - Mock Nationa Exit ExamDocument20 pages3rd Round - 2015 - Mock Nationa Exit ExamteddiyfentawNo ratings yet

- Maintenance of Machinery Blue Print ObjectDocument10 pagesMaintenance of Machinery Blue Print ObjectteddiyfentawNo ratings yet

- Fluid Power System, CHAPTER-2Document26 pagesFluid Power System, CHAPTER-2teddiyfentawNo ratings yet

- General Church History 1 MR GetachewDocument59 pagesGeneral Church History 1 MR Getachewzerubabel AbebeNo ratings yet

- Fluid Power System, CHAPTER-2Document26 pagesFluid Power System, CHAPTER-2teddiyfentawNo ratings yet

- Living With Simple MachinesDocument54 pagesLiving With Simple MachinesJulie Ann GernaNo ratings yet

- F56/F53 Bill Dispenser Unit Maintenance Training Summary: Document No. / File Name Check Document NameDocument25 pagesF56/F53 Bill Dispenser Unit Maintenance Training Summary: Document No. / File Name Check Document Namearmando hNo ratings yet

- S-18 20Document2 pagesS-18 20Raghavendra MurthyNo ratings yet

- Power Jib Crane DesignDocument64 pagesPower Jib Crane Designhalder.kalyan100% (4)

- Part I. Multiple Choice Questions: Prepared By: Engr. Jose R. Francisco, PMEDocument6 pagesPart I. Multiple Choice Questions: Prepared By: Engr. Jose R. Francisco, PMEMarcial MilitanteNo ratings yet

- Timingbelts PDFDocument45 pagesTimingbelts PDFIndra DamarNo ratings yet

- Oil Skimmer Belt Selection: The World Leader in Oil Skimming TechnologiesDocument6 pagesOil Skimmer Belt Selection: The World Leader in Oil Skimming TechnologieshungntNo ratings yet

- China Vehicle Parts & Auto Accessories Suppliers ListDocument41 pagesChina Vehicle Parts & Auto Accessories Suppliers ListinfoNo ratings yet

- Piaggio X7 125 (EN)Document297 pagesPiaggio X7 125 (EN)ManuallesNo ratings yet

- Development of A Modified Palm-Nut Cracker: March 2020Document12 pagesDevelopment of A Modified Palm-Nut Cracker: March 2020Adri YasperNo ratings yet

- SPX-Plenty Mixer PDFDocument24 pagesSPX-Plenty Mixer PDFkingathur26681100% (1)

- Tool Post GrinderDocument28 pagesTool Post GrinderBoopathi KalaiNo ratings yet

- PM-25MV ManualDocument24 pagesPM-25MV ManualAlan KarasNo ratings yet

- NOTICE - ATEX - Gaz - Anglais Rev.012012 - 02ENDocument32 pagesNOTICE - ATEX - Gaz - Anglais Rev.012012 - 02ENGorch MarrokoNo ratings yet

- Nissan GTR R32 Service ManualDocument804 pagesNissan GTR R32 Service ManualGorkandMork67% (6)

- Cat C4.4 ACERT™: Engine Sales ManualDocument193 pagesCat C4.4 ACERT™: Engine Sales ManualAlberto PA100% (1)

- Tb2 SDC - vp101 00hfb M M1a Man 9033 Rev0 (Even Error Trang 200)Document512 pagesTb2 SDC - vp101 00hfb M M1a Man 9033 Rev0 (Even Error Trang 200)nguyễn hữu trườngNo ratings yet

- Rosta Motor BasesDocument15 pagesRosta Motor BasesDIANA ROSENDONo ratings yet

- Camshaft Sprocket Timing BeltDocument3 pagesCamshaft Sprocket Timing BeltnafNo ratings yet

- ME463 Plate2 BALDEZAMODocument12 pagesME463 Plate2 BALDEZAMOAdriane BaldezamoNo ratings yet

- Belt Sway Control PDFDocument29 pagesBelt Sway Control PDFSrinivasa Rao Venkumahanthi0% (1)

- R8 Nov-Dec-2015Document3 pagesR8 Nov-Dec-2015Hari VenkitNo ratings yet

- DM100iDM200i SeriesDocument64 pagesDM100iDM200i SeriesstevanreljicNo ratings yet

- TM 5-3222 Tractor T-9Document298 pagesTM 5-3222 Tractor T-9AdvocateNo ratings yet

- Ww65h5200ew Se SMDocument54 pagesWw65h5200ew Se SMAlham Tetra Cesario83% (6)

- Design of Machine Members Short Questions 1. Desgin of BearingsDocument3 pagesDesign of Machine Members Short Questions 1. Desgin of BearingsAraveetiCSReddyNo ratings yet

- Preventive Maintenance Manual - DRFDocument115 pagesPreventive Maintenance Manual - DRFmliugong100% (8)

- Taif Sheet 2&3 Shaft Design and BearingsDocument2 pagesTaif Sheet 2&3 Shaft Design and BearingsBen Ahmed100% (1)

- Engines Awy, Azq, BMD, BmeDocument94 pagesEngines Awy, Azq, BMD, BmeAlina Teodora100% (2)

- BE Manual Operation and Maintenance Fans Ceiling Cabinet PDFDocument12 pagesBE Manual Operation and Maintenance Fans Ceiling Cabinet PDFAbdulSattarNo ratings yet