Professional Documents

Culture Documents

Flexijoint Datasheet

Uploaded by

novtomy0 ratings0% found this document useful (0 votes)

3 views2 pagesFlexi-joints are flexible pipe couplings that allow for misalignments and movement. They can be used to temporarily or permanently join pipe sections together without welding or threading. Flexi-joints are quick to assemble, even in tight spaces, and they prevent vibration and noise transmission while allowing movement. They are available in sizes from 0.675 to 6.38 inches to accommodate different pipe diameters. Standard flexi-joints have a mild steel sleeve, but non-standard options include coated steel or copper sleeves. They have working pressures up to 300 PSI with external restraint or 100 PSI without. Flexi-joints see wide use in industrial, marine, locomotive, and process applications for oils, water, steam, and gases

Original Description:

Teconnex

Original Title

flexijoint Datasheet

Copyright

© © All Rights Reserved

Available Formats

DOC, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentFlexi-joints are flexible pipe couplings that allow for misalignments and movement. They can be used to temporarily or permanently join pipe sections together without welding or threading. Flexi-joints are quick to assemble, even in tight spaces, and they prevent vibration and noise transmission while allowing movement. They are available in sizes from 0.675 to 6.38 inches to accommodate different pipe diameters. Standard flexi-joints have a mild steel sleeve, but non-standard options include coated steel or copper sleeves. They have working pressures up to 300 PSI with external restraint or 100 PSI without. Flexi-joints see wide use in industrial, marine, locomotive, and process applications for oils, water, steam, and gases

Copyright:

© All Rights Reserved

Available Formats

Download as DOC, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

3 views2 pagesFlexijoint Datasheet

Uploaded by

novtomyFlexi-joints are flexible pipe couplings that allow for misalignments and movement. They can be used to temporarily or permanently join pipe sections together without welding or threading. Flexi-joints are quick to assemble, even in tight spaces, and they prevent vibration and noise transmission while allowing movement. They are available in sizes from 0.675 to 6.38 inches to accommodate different pipe diameters. Standard flexi-joints have a mild steel sleeve, but non-standard options include coated steel or copper sleeves. They have working pressures up to 300 PSI with external restraint or 100 PSI without. Flexi-joints see wide use in industrial, marine, locomotive, and process applications for oils, water, steam, and gases

Copyright:

© All Rights Reserved

Available Formats

Download as DOC, PDF, TXT or read online from Scribd

You are on page 1of 2

INTRODUCTION TYPICAL FLEXI – JOINT

Flexi-joint coupled pipe-work may be

temporary or permanent and will

prevent the transmission of vibration

and noise and allow flexibility in length

and alignment.

Our Flexi-joints enable pipe work that

has been cut to approximate length to

be coupled together with only the aid

of a spanner. This negates the need to

weld, flange groove or thread in order

to extend, repair or create pipe work

for moderate system pressures.

It is also possible to assemble the

flexi-joint in cramped locations and still

retain a uniform leak-proof loading on

the seal. Many years of successful

application to thousands of pipe-work

systems coupled with a progressive

product development programme,

enable us to offer this popular fitting

for an ever-increasing range of

applications.

FEATURES AND BENEFITS

Generates a positive seal

even with angular

misalignments of up to 4º.

Quickly assembled in cramped

locations.

Dampens vibration and noise

transmission.

Allows close grouping of pipe-

work with no rotational

constraint.

SIZES

To fit standard schedule tube or pipe

outside diameters of 0.675 inches or

17.15mm up to 4.500 inches or GASKETS AVAILABLE

114.30mm.

We are able to offer you a choice of

MATERIALS four types of gasket to suit specific

temperature requirements.

Standard - Mild steel sleeve

zinc plated

Non-standard – Mild steel

sleeve coated in either

Cupronickel or Durogard.

Non-standard – Copper sleeve

APPLICATIONS

Gasket Min Max

Material Operating Operating Flexi-joints are used in a wide variety

Temperature Temperature of industrial marine locomotive and

NITRILE -30ºC 120ºC

process applications for fast efficient

VITON A -20ºC 210ºC

installation of pipe-work carrying oil,

SILICON -60ºC 200ºC

EPDM -50ºC 130ºC

water, solvents, steam and other

gases. Many hose pipe couplings with

EPDM gaskets have been introduced wire or clip fastenings can be replaced

as the softer material improves sealing with this protected seal joint which is

on certain applications whilst preferred by many operators of power

maintaining wear resistance. equipment and compressors, etc, also

by heating, ventilating and air

conditioning engineers. Agricultural

HOW IT WORKS

workers, laying temporary irrigation or

liquid insecticides systems prefer

The principle of a compression joint is flexi-joint couplings to other forms of

well proven, the resilient seal is attachments. Applications are almost

constrained to contract onto the pipe unlimited for this universal joint.

diameter when the clamp is tightened

and will seal on all normal pipe

surfaces that are free from deep WHAT TO DO NEXT

scratches gouges and dents. The

friction grip will prevent slip at low Our Sales Department will be pleased

pressures but will require external to quote you for flexi-joints to suit your

restraint at high pressure (see table application. If you require assistance

Below). our Technical Department with its long

experience of connection solution

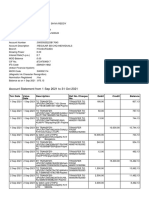

Flexi- Flexi- Flexi- Self Externally design will be only too happy to advise

joint joint joint restrained restrained you.

outside overall overall pressure pressure

diameter width length rating rating

1.78 2.48 2.25 100 PSI 300PSI

1.98 3.75 2.25 100 PSI 300PSI

2.16 4.00 2.50 100 PSI 300PSI

2.16 4.00 2.50 100 PSI 300PSI

2.36 4.12 2.88 100 PSI 300PSI

2.42 4.25 2.88 100 PSI 300PSI

2.42 4.25 3.00 100 PSI 300PSI

2.61 4.37 3.00 100 PSI 300PSI

2.61 4.37 4.00 100 PSI 300PSI

2.77 4.62 3.25 80PSI 200PSI

2.88 4.75 3.25 80PSI 200PSI

3.11 4.93 3.50 80PSI 200PSI

3.48 5.43 4.00 80PSI 200PSI

3.61 5.56 4.00 80PSI 200PSI

4.88 6.87 4.50 80PSI 200PSI

4.52 6.50 6.50 80PSI 200PSI

4.88 6.87 5.00 80PSI 200PSI

5.13 7.12 5.00 60PSI 150PSI

5.13 7.12 6.25 60PSI 150PSI

5.38 7.43 5.00 60PSI 150PSI

5.38 7.43 6.50 60PSI 150PSI

5.63 7.68 5.00 60PSI 150PSI

6.38 8.43 6.50 60PSI 150PSI

You might also like

- CHP 4 Project MGT Problems QuestionsDocument4 pagesCHP 4 Project MGT Problems QuestionsSunil Shaw0% (1)

- 2012 Chevrolet Sonic 1.8L Motor LUWDocument612 pages2012 Chevrolet Sonic 1.8L Motor LUWPatricio ValenciaNo ratings yet

- Adc01-Doc-195 Advc Configurable Ioex r00 WebDocument16 pagesAdc01-Doc-195 Advc Configurable Ioex r00 WeblucinaldoNo ratings yet

- Technical Specifications With SaddlesDocument6 pagesTechnical Specifications With Saddlesmihaidanpan791No ratings yet

- Protect and Preserve The Integrity of Electronic Components: Gore Automotive Vents For Adhesive InstallationDocument4 pagesProtect and Preserve The Integrity of Electronic Components: Gore Automotive Vents For Adhesive InstallationBurak YILMAZNo ratings yet

- FMC Weco Wing Union CatalogDocument16 pagesFMC Weco Wing Union CatalogSargunam Sankaravadivel100% (2)

- Jain PE Gas Piping SystemDocument4 pagesJain PE Gas Piping Systemkishore@scribdNo ratings yet

- Ps1520 Fit Metal DataDocument15 pagesPs1520 Fit Metal DataAir PumpingNo ratings yet

- Gulf-O-Flex Insulation Tube & Coil: Dimensions of Box: 50x50x20 CmsDocument6 pagesGulf-O-Flex Insulation Tube & Coil: Dimensions of Box: 50x50x20 CmsRiyas UdheenNo ratings yet

- Ball Valves: For SteamDocument8 pagesBall Valves: For SteamcontorrresjulianNo ratings yet

- Spacelabs Blease Datum BrochureDocument6 pagesSpacelabs Blease Datum BrochureA. A.G.No ratings yet

- 2020 Style 600 CatDocument8 pages2020 Style 600 CatdiamsamNo ratings yet

- Spirax Ball ValveDocument8 pagesSpirax Ball ValvetitieNo ratings yet

- Oem Manual p800-Px800 Advance MetalDocument43 pagesOem Manual p800-Px800 Advance MetalenriqueNo ratings yet

- 462 CatDocument2 pages462 Catanoop9079No ratings yet

- Global Core PARKERDocument12 pagesGlobal Core PARKERRodrigo Pessoa VespaNo ratings yet

- Advanced Series PLASTIC Pumps: Advance Your ProcessDocument35 pagesAdvanced Series PLASTIC Pumps: Advance Your ProcessJuan Mac LeanNo ratings yet

- Oilfield Hoses Fittings AccembliesDocument29 pagesOilfield Hoses Fittings Accembliesthapa786mNo ratings yet

- Product Overview: Valves Actuators Automation TechnologyDocument36 pagesProduct Overview: Valves Actuators Automation TechnologyBrion Bara IndonesiaNo ratings yet

- Brochure - PP-V Backing FlangeDocument2 pagesBrochure - PP-V Backing FlangeJean FrazierNo ratings yet

- Drawing 80H30Document3 pagesDrawing 80H30kpranjal15No ratings yet

- ActuationDocument12 pagesActuationZeeshan KhanNo ratings yet

- Baker Onyx - Overview HiResDocument2 pagesBaker Onyx - Overview HiResBruce100% (1)

- TESEO Triptico PDFDocument5 pagesTESEO Triptico PDFLuis Felipe ZuñigaNo ratings yet

- Gas Springs and Dampers For Industrial Applications: STABILUS Technology Gives ComfortDocument25 pagesGas Springs and Dampers For Industrial Applications: STABILUS Technology Gives Comfortjose prudencioNo ratings yet

- 3.2. Flowstrong Yellowbox - Product SpecsDocument16 pages3.2. Flowstrong Yellowbox - Product SpecsHussain Al SanonaNo ratings yet

- 200 SeriesDocument4 pages200 Serieslacsmm982No ratings yet

- Hose, Tube & Connection Fittings Catalogue: JSG Industrial SystemsDocument20 pagesHose, Tube & Connection Fittings Catalogue: JSG Industrial Systemsagung wijayaNo ratings yet

- Disc Diffuser Assembly, Operating and Maintenance InstructionDocument10 pagesDisc Diffuser Assembly, Operating and Maintenance InstructionMohamed TallyNo ratings yet

- Catalog F84L F88Document16 pagesCatalog F84L F88lix0123No ratings yet

- Technip Drilling BrochureDocument12 pagesTechnip Drilling Brochurenedumaran.sNo ratings yet

- Codeline Drawing 80E30Document2 pagesCodeline Drawing 80E30hargote_2No ratings yet

- Nitrogen PurgeDocument4 pagesNitrogen Purgejawwad kabirNo ratings yet

- Vespel: Shapes: SP Polyimide Machining StockDocument8 pagesVespel: Shapes: SP Polyimide Machining StockFriedrich GaussNo ratings yet

- Advanced Series PLASTIC Pumps: Advance Your ProcessDocument31 pagesAdvanced Series PLASTIC Pumps: Advance Your ProcessJuan Mac LeanNo ratings yet

- P Pv8 Org MTL Eom 02Document35 pagesP Pv8 Org MTL Eom 02powder18No ratings yet

- TERA Joint-Floor Joint System PDFDocument16 pagesTERA Joint-Floor Joint System PDFClaudioNo ratings yet

- Fisher Valve EzDocument28 pagesFisher Valve EzGrant BloxomNo ratings yet

- GPT 1-3 PGE Tech SpecificationsDocument4 pagesGPT 1-3 PGE Tech SpecificationsEhtisham AndrAbiNo ratings yet

- Multifan Galvanized Slant Wall Fan USA 01-17Document4 pagesMultifan Galvanized Slant Wall Fan USA 01-17Julio Cesar BorasinNo ratings yet

- SpecDocument2 pagesSpecneversigNo ratings yet

- WK Cooling ElementDocument4 pagesWK Cooling ElementNathanNo ratings yet

- Gfps Us 1334 Datasheet Type 244 Data Sheet enDocument6 pagesGfps Us 1334 Datasheet Type 244 Data Sheet enOmar GuillenNo ratings yet

- TechukDocument8 pagesTechukMiguel LopezNo ratings yet

- COOK Moppet Valve BrochureDocument2 pagesCOOK Moppet Valve BrochureYurizki LhzNo ratings yet

- ERIKS - Simrit Merkel Omegat Stangafdichtingen (OMS-SPR)Document6 pagesERIKS - Simrit Merkel Omegat Stangafdichtingen (OMS-SPR)Sérgio GomesNo ratings yet

- 3-6 Quad BopDocument29 pages3-6 Quad Bopsambhaji100% (1)

- Codeline, 150 PSI, Drawing - 80S15Document3 pagesCodeline, 150 PSI, Drawing - 80S15RamanNegiNo ratings yet

- Wilden Pump p8Document47 pagesWilden Pump p8RUBERTH ALEXANDER OCHOANo ratings yet

- 2022 ASTEC Cond CatalogueDocument28 pages2022 ASTEC Cond CatalogueRoo FaNo ratings yet

- SPO Webversion HighDocument6 pagesSPO Webversion HighchadNo ratings yet

- Hydroseal Series 3500 Pilot Operated Relief ValvesDocument8 pagesHydroseal Series 3500 Pilot Operated Relief Valvesprihartono_diasNo ratings yet

- NBR Piston Cup Seal: General Cylinders Pneumatic CylindersDocument10 pagesNBR Piston Cup Seal: General Cylinders Pneumatic CylindersSHANENo ratings yet

- Ajuste en Bridas Plásticas REV - 01Document3 pagesAjuste en Bridas Plásticas REV - 01jose mesereNo ratings yet

- PDS Na GTS65 PDFDocument2 pagesPDS Na GTS65 PDFMoaatazz NouisriNo ratings yet

- Mos3200 Bs 2000m FP Product DataDocument4 pagesMos3200 Bs 2000m FP Product DataJeromeNo ratings yet

- Two Three Way Ball ValvesDocument6 pagesTwo Three Way Ball ValvesUzair AnsariNo ratings yet

- Yoke Style Closure Double Single Bolt BrochureDocument14 pagesYoke Style Closure Double Single Bolt Brochureandreshuertascalderon02No ratings yet

- Double Pipe Heat ExchangerDocument8 pagesDouble Pipe Heat ExchangerSami ThirunavukkarasuNo ratings yet

- IN2065-07-01 MPreC enDocument6 pagesIN2065-07-01 MPreC enknsbNo ratings yet

- Ancon 25-14 Restraint SystemDocument4 pagesAncon 25-14 Restraint SystemmcbluedNo ratings yet

- Cuplaje ElasticeDocument27 pagesCuplaje ElasticeAndrei VictorasNo ratings yet

- Installation and Assembly InstructionsDocument3 pagesInstallation and Assembly InstructionsSamir IskricNo ratings yet

- Business Partner Objects in SAP HCM Talent Management - SAP BlogsDocument11 pagesBusiness Partner Objects in SAP HCM Talent Management - SAP BlogsParadise 2026No ratings yet

- T8 Yi FTS8 UFC7 DNF XDocument15 pagesT8 Yi FTS8 UFC7 DNF XShiva reddy KalluriNo ratings yet

- Instruction Manual ELOTOP 502-EnDocument46 pagesInstruction Manual ELOTOP 502-EnEmigdio PoloNo ratings yet

- EE-313L CEP LabDocument4 pagesEE-313L CEP LabSyed AsfandyarNo ratings yet

- Online Sales and InventoryDocumentationDocument122 pagesOnline Sales and InventoryDocumentationJahiruddin AhamedNo ratings yet

- Errores M4580Document58 pagesErrores M4580joseNo ratings yet

- Block Diagram of Infrared Remote Control SwitchDocument4 pagesBlock Diagram of Infrared Remote Control SwitchminthooNo ratings yet

- 2012-03-06 082320 Rachel Sundusky Is The Manager of The SouthDocument4 pages2012-03-06 082320 Rachel Sundusky Is The Manager of The SouthHiten PatelNo ratings yet

- Documentation PDFDocument21 pagesDocumentation PDFMick SousaNo ratings yet

- 3com MSR Router CommandDocument12 pages3com MSR Router CommandSaurrabh Nanda100% (1)

- Installation Manual: Enclosed Type Switching Power Supply (Families: G3, NE, LRS, SE, PFC, HSP, SPV, USP, RST, G5, MSP)Document2 pagesInstallation Manual: Enclosed Type Switching Power Supply (Families: G3, NE, LRS, SE, PFC, HSP, SPV, USP, RST, G5, MSP)Aicky IkrackNo ratings yet

- Block Mine Welcomes You The World of Digital Platforms..!Document29 pagesBlock Mine Welcomes You The World of Digital Platforms..!heartvadorNo ratings yet

- IMI Herion Valve CatalogDocument12 pagesIMI Herion Valve CatalogjbkimNo ratings yet

- User's Manual: Digital Brush DC Servo DriverDocument12 pagesUser's Manual: Digital Brush DC Servo DriverDario AcostaNo ratings yet

- Salesforce Lab AssignmentDocument2 pagesSalesforce Lab Assignmentapi-541116146No ratings yet

- A 112-Gb S PAM-4 Long-Reach Wireline Transceiver Using A 36-Way Time-Interleaved SAR ADC and Inverter-Based RX Analog Front-End in 7-nm FinFETDocument12 pagesA 112-Gb S PAM-4 Long-Reach Wireline Transceiver Using A 36-Way Time-Interleaved SAR ADC and Inverter-Based RX Analog Front-End in 7-nm FinFET王国庆No ratings yet

- Data IMS Email 310123 (BRG Akan Diambil TGL 010223)Document2 pagesData IMS Email 310123 (BRG Akan Diambil TGL 010223)apriani stNo ratings yet

- Balluff EthernetIPwithIOL - To - FanuControllerDocument6 pagesBalluff EthernetIPwithIOL - To - FanuControllerChristian AldrinNo ratings yet

- An Introduction To Vdsl2 and Vdsl2 Deployment Options: - Zyxel White PaperDocument20 pagesAn Introduction To Vdsl2 and Vdsl2 Deployment Options: - Zyxel White PaperMichael Tollund NielsenNo ratings yet

- PICA Breakdown Unit (TGL 05 December'17)Document4 pagesPICA Breakdown Unit (TGL 05 December'17)Tuluss Kosonq TiigaNo ratings yet

- Digital Darwinism: Driving Digital Transformation With Devops and Continuous DeliveryDocument14 pagesDigital Darwinism: Driving Digital Transformation With Devops and Continuous Deliveryप्रफुलताम्राकारNo ratings yet

- Mitsubishi Manuals 1053Document188 pagesMitsubishi Manuals 1053mrtansNo ratings yet

- Common Input Optomos Relay: Lcc110 UnitsDocument8 pagesCommon Input Optomos Relay: Lcc110 UnitsmoocomNo ratings yet

- Syllabus Intro PDFDocument17 pagesSyllabus Intro PDFKarima BabaNo ratings yet

- Fabrication Work Risk AssessmentDocument11 pagesFabrication Work Risk Assessmentstansilous100% (1)

- WBS Task Prevention Current Cost of QualityDocument4 pagesWBS Task Prevention Current Cost of QualityP ENo ratings yet