Professional Documents

Culture Documents

ZFR 75 - Industrial Three Phase: Suction Unit

Uploaded by

Siddiqui ovaisOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

ZFR 75 - Industrial Three Phase: Suction Unit

Uploaded by

Siddiqui ovaisCopyright:

Available Formats

INDUSTRIAL VACUUM CLEANERS

ZFR 75 - INDUSTRIAL THREE PHASE SUCTION UNIT

Voltage V - Hz 400 - 50

Power kW 3

Electrical protection IP 65

CHEMICAL-PHARMACEUTICAL Max water lift mmH₂O 3000-2300

Max air flow m³/h 318

Suction inlet mm 80

ELECTRONICS Noise level (EN ISO 3744) dB(A) 75

FILTER UNIT

Filter Type Star

Surface - Diameter cm²-mm 30.000 - 500

Material - Efficiency IEC 60335-2-69 Polyester - ANT M

Air load on filter m³/m²/h 123

Cleaning system Manual

COLLECTION UNIT

Capacity l 100

Side channel blower motor , powerful and Vacuum gauge to detect filter clogging

silent, totally maintenance free, suitable for

continuous duty Low noise level VOLUME

Largest surface filter in its category Compact and mobile

Dimensions cm 79x66x170h

Integrated filter cleaning system Easy filter replacement

Weight kg 95

Complete steel construction Reduced downtime of machine tools

Extractable collection container with optional

use of disposable bags

SUCTION UNIT OPTIONALS

The suction unit is a side channel blower, with direct coupling between the motor and the ABSOLUTE HEPA FILTER /H14

impeller fan. It designed without any transmission system, and is therefore silent, totally

PTFE COATED FILTER CLASS M

maintenance free and suitable for continuous duty operations.

EARTH GROUNDING

A pressure relief valve protects the motor, providing additional air for cooling.

CYCLONE FOR FILTER PROTECTION

FILTER UNIT PRESSURE RELIEF VALVE

OTHER VOLTAGES AND FREQUENCIES AVAILABLE UPON REQUEST

The large surface star filter, located inside the filter stainsteel chamber, is made of

REMOTE CONTROL

polyester and provides high resistance against clogging and passage of fine dust.

ENDLESS BAG BAGGING SYSTEM

It is possible to clean the filter using an integrated mechanical system: an external lever

shakes the filter vertically and enables to clean the filter thoroughly and safely, maintaining

constant suction performance and preventing any dispersion of dust in the environment.

A vacuum gauge enables to check constantly the state of the filter and detect possible

clogging, warning the operator that the filter must be cleaned.

COLLECTION UNIT

The vacuumed material is collected into a wheeled steel container, which can be extracted

for easy disposal and can be used with optional disposable bags, for safer and handier

disposal

You might also like

- Special Tools D2840 & D2842Document12 pagesSpecial Tools D2840 & D2842abdul muslimNo ratings yet

- Forklift Safety TrainingDocument22 pagesForklift Safety TrainingSteve DonardNo ratings yet

- Fleetguard OptiairDocument28 pagesFleetguard OptiairDaniel CasillasNo ratings yet

- 16 Samss 506Document40 pages16 Samss 506HatemS.MashaGbehNo ratings yet

- Geotextiles and Geomembranes HandbookFrom EverandGeotextiles and Geomembranes HandbookT.S. IngoldRating: 5 out of 5 stars5/5 (1)

- Ultrasound Analysis for Condition Monitoring: Applications of Ultrasound Detection for Various Industrial EquipmentFrom EverandUltrasound Analysis for Condition Monitoring: Applications of Ultrasound Detection for Various Industrial EquipmentRating: 4.5 out of 5 stars4.5/5 (3)

- Yaskawa A1000 CatalogueDocument20 pagesYaskawa A1000 CatalogueCare AutomationNo ratings yet

- BODOR User Manual of Fiber Metal Cutting MachineDocument50 pagesBODOR User Manual of Fiber Metal Cutting Machinesebastian carreño100% (2)

- CAT Product Line NewDocument40 pagesCAT Product Line NewFaisal SaleemNo ratings yet

- Rcms2901-120fe (Rev.a) User Manual 201110Document27 pagesRcms2901-120fe (Rev.a) User Manual 201110ciro_svNo ratings yet

- F175(M)021 Bag Filter User Manual袋收尘操作说明书Document96 pagesF175(M)021 Bag Filter User Manual袋收尘操作说明书Ali AlatasNo ratings yet

- Brochure MVRT 2015 ENDocument8 pagesBrochure MVRT 2015 ENم.حسين العامريNo ratings yet

- Plasmair: Hepa-Md Mobile Air Decontamination UnitDocument2 pagesPlasmair: Hepa-Md Mobile Air Decontamination UnitValentin MalihinNo ratings yet

- 202 Ds Eco T - Industrial Three Phase: Suction UnitDocument2 pages202 Ds Eco T - Industrial Three Phase: Suction UnitPentolNo ratings yet

- Aspirateur MTL300BL-001Document2 pagesAspirateur MTL300BL-001volganoteNo ratings yet

- DG VL 150 SeDocument1 pageDG VL 150 SevinodhharshiNo ratings yet

- DM40 SGA BT Battery OperatedDocument2 pagesDM40 SGA BT Battery OperatedZayNo ratings yet

- Andritz Combi-Zone Dryer For Extruded PelletsDocument8 pagesAndritz Combi-Zone Dryer For Extruded Pelletssarah ahmedNo ratings yet

- Sebf-I: The Art of Powerful Cleaning..Document3 pagesSebf-I: The Art of Powerful Cleaning..Pn ThanhNo ratings yet

- Menred Central Vacuum Cleaner&Ventilation ProductsDocument16 pagesMenred Central Vacuum Cleaner&Ventilation ProductsbjainnNo ratings yet

- 1 Disab Uk Bagvac Tech SpecDocument2 pages1 Disab Uk Bagvac Tech SpecJhon SanfraNo ratings yet

- 1cgde09jv 337626Document4 pages1cgde09jv 337626Fati ZoraNo ratings yet

- WFF 1800 PetDocument1 pageWFF 1800 Petqwaz7No ratings yet

- 001a-AstroPure 450 Brochure - NewDocument2 pages001a-AstroPure 450 Brochure - NewDesiana PermataNo ratings yet

- Biological Safety Cabinet AC1 Brochure A4 VC LR 012419Document4 pagesBiological Safety Cabinet AC1 Brochure A4 VC LR 012419Luis GutierrezNo ratings yet

- Biological Safety Cabinet - AC2-G3 - Brochure - A4 - VG - LRDocument8 pagesBiological Safety Cabinet - AC2-G3 - Brochure - A4 - VG - LRhüseyin vururNo ratings yet

- Dispensing and Sampling BoothDocument1 pageDispensing and Sampling BoothAhlada Group of CompaniesNo ratings yet

- Silotop Zero en 0217 EditDocument4 pagesSilotop Zero en 0217 EditJulio Vega AngelesNo ratings yet

- Airway Heat & Moisture Exchange Filters (HMEF) : Manufacturer Part # CommentsDocument1 pageAirway Heat & Moisture Exchange Filters (HMEF) : Manufacturer Part # CommentsnmmMJKJNo ratings yet

- AstroPure 550C Catalogue Rev 1Document3 pagesAstroPure 550C Catalogue Rev 1m.indrajayaNo ratings yet

- Centralised Compressed Air Supply SystemDocument48 pagesCentralised Compressed Air Supply Systemshahrul aimanNo ratings yet

- Fehlerfrei Mpj250 300-1Document4 pagesFehlerfrei Mpj250 300-1Sam BestNo ratings yet

- Cabines de Segurança BiológicaDocument8 pagesCabines de Segurança BiológicadrycabsbNo ratings yet

- Cleaning SystemDocument12 pagesCleaning SystemThe GamingspyNo ratings yet

- RFT 043 RFT 072: Return Filters - LightlineDocument5 pagesRFT 043 RFT 072: Return Filters - LightlineYazad DoctorrNo ratings yet

- CatalogueDocument6 pagesCatalogueRakesh RanjanNo ratings yet

- 2018 The Latest Arrival Catalog DecemberDocument16 pages2018 The Latest Arrival Catalog Decemberbernardardi1No ratings yet

- Silotop Zero en 0219 EditDocument4 pagesSilotop Zero en 0219 EditademgsNo ratings yet

- Laminar Airflow (Horizontal) PDFDocument2 pagesLaminar Airflow (Horizontal) PDFNeeraj YadavNo ratings yet

- Scheuch Folder Ligno Impulsfilter E 20150522 02Document6 pagesScheuch Folder Ligno Impulsfilter E 20150522 02MagdalenaNo ratings yet

- 2016 PI Zero Smog EL GBDocument2 pages2016 PI Zero Smog EL GBh_878236333No ratings yet

- Filtercart W3: Filtercart+ W3 Mobile Filter Unit For Intermittent To Light Duty Welding and Extraction ApplicationsDocument4 pagesFiltercart W3: Filtercart+ W3 Mobile Filter Unit For Intermittent To Light Duty Welding and Extraction ApplicationsTsogjargal JambalNo ratings yet

- Metasys CompresorDocument8 pagesMetasys CompresorPlatigue ClangNo ratings yet

- SC Ims10.sc01.00 Ultraceco - SC - Bro - enDocument4 pagesSC Ims10.sc01.00 Ultraceco - SC - Bro - enHEINER_PNo ratings yet

- Ote Fp-S Filter Press Eng Web PDFDocument8 pagesOte Fp-S Filter Press Eng Web PDFRegina Choque HuallpaNo ratings yet

- Mini Pascal CatalogueDocument4 pagesMini Pascal CatalogueoriginatepowerNo ratings yet

- DS FlourMilling WAMFLO 0115 ENGDocument2 pagesDS FlourMilling WAMFLO 0115 ENGsixto pepitoNo ratings yet

- 04 Vacuum Pump With Filter Data SheetDocument2 pages04 Vacuum Pump With Filter Data SheetMuhammad Syafiq Faiz TamanNo ratings yet

- MC55W - Product Flyer - ECPEN20-702 - EnglishDocument2 pagesMC55W - Product Flyer - ECPEN20-702 - EnglishvukNo ratings yet

- Ultrasonic Cleaner S-3300 - HM, 440VDocument2 pagesUltrasonic Cleaner S-3300 - HM, 440Vankarthik11No ratings yet

- Ronningen-Petter F-Series: Backwashing Pressure Filter SystemDocument2 pagesRonningen-Petter F-Series: Backwashing Pressure Filter Systemck19654840No ratings yet

- Data-Sheet PDFDocument4 pagesData-Sheet PDFCarlos ChisanNo ratings yet

- AW240 190 Gaggenau Specifications SheetDocument2 pagesAW240 190 Gaggenau Specifications SheetFrederick CooryNo ratings yet

- Biologolical CabinetsDocument8 pagesBiologolical CabinetsFernz EspantoNo ratings yet

- AstroPure 1700V BrochureDocument2 pagesAstroPure 1700V Brochurem.indrajayaNo ratings yet

- 9837 2-3-12 91005 577E Adsorption Dryers Classical SystemDocument8 pages9837 2-3-12 91005 577E Adsorption Dryers Classical SystemLeonardo Tommy DacuNo ratings yet

- NEDERMAN FilterMax C25Document4 pagesNEDERMAN FilterMax C25deibymendez93No ratings yet

- Laminar Vertical Cabinet: Basic CharacteristicsDocument2 pagesLaminar Vertical Cabinet: Basic CharacteristicsBoris KozjanNo ratings yet

- Zhuowei Catalog 2016 - Fan Filter Units SeriesDocument3 pagesZhuowei Catalog 2016 - Fan Filter Units Seriesinnovameq.ingenieriaNo ratings yet

- Bio Safety SpecsDocument3 pagesBio Safety Specsmikky.mythuNo ratings yet

- Treated Fresh Air SystemDocument4 pagesTreated Fresh Air SystemNitish YadavNo ratings yet

- Class II Biosafety Cabinet Catalog BiolabDocument8 pagesClass II Biosafety Cabinet Catalog BiolabVivek HamseNo ratings yet

- EX-TRACK Table & Filtration ESDocument2 pagesEX-TRACK Table & Filtration ESHernan GhibaudoNo ratings yet

- Product Group Industrial Vacuum Cleaners, 0415-156Document8 pagesProduct Group Industrial Vacuum Cleaners, 0415-156هبال حمزةNo ratings yet

- Fine Dust-AircubeDocument12 pagesFine Dust-Aircubesparthiban89No ratings yet

- CS 1225 H Vacuum - HEPADocument1 pageCS 1225 H Vacuum - HEPAEric CastilloNo ratings yet

- Datasheet ES094 1040 ENDocument6 pagesDatasheet ES094 1040 ENPhamvandong TincayNo ratings yet

- GSH GHH Operation and Maintenance Manual - Copy-1Document37 pagesGSH GHH Operation and Maintenance Manual - Copy-1Navarro NayraNo ratings yet

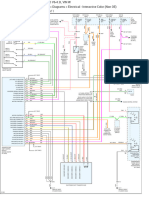

- Blazer 96 Diagram TransmisiónDocument1 pageBlazer 96 Diagram Transmisióntallercuervo2100% (1)

- Tronxy X5SA-400 Installation GuideV6.2Document22 pagesTronxy X5SA-400 Installation GuideV6.2Leonardus Tonny75% (4)

- Product Catalog Wartsila JOVYATLASDocument17 pagesProduct Catalog Wartsila JOVYATLASa.elwahabNo ratings yet

- Foreign DMND Comm DivDocument2 pagesForeign DMND Comm Divapi-26741788No ratings yet

- 142 PDFDocument38 pages142 PDFsoklongsrengNo ratings yet

- Bottle Jack - NewDocument9 pagesBottle Jack - NewWaseneh MuluNo ratings yet

- S12 Optimine For DD-DS210LDocument34 pagesS12 Optimine For DD-DS210LrolandNo ratings yet

- Ins. Overhead CraneDocument4 pagesIns. Overhead CranePetrusNo ratings yet

- ECE5545 Lecture0 Spring24 2Document38 pagesECE5545 Lecture0 Spring24 2eshwar_worldNo ratings yet

- RegO Pop-Action ValveDocument1 pageRegO Pop-Action ValveSwapnil JawaleNo ratings yet

- Renr9561renr9561-02 SisDocument2 pagesRenr9561renr9561-02 Sistommy lanyonNo ratings yet

- FM 30Document36 pagesFM 30Ender RamirezNo ratings yet

- Pump - Model Hurlcon CTX SeriesDocument2 pagesPump - Model Hurlcon CTX SeriesMechanicalLatestNo ratings yet

- Argus 707 - Service ManualDocument38 pagesArgus 707 - Service Manualluc1902100% (1)

- Adapter AC-DC Power Block Diagram 2013.03.29 V1.1 PDFDocument13 pagesAdapter AC-DC Power Block Diagram 2013.03.29 V1.1 PDFblassNo ratings yet

- Dac 606Document2 pagesDac 606amirin_kingNo ratings yet

- Install Process Instrumentation and Control Cabling and TubingDocument9 pagesInstall Process Instrumentation and Control Cabling and TubingAbela DrrsNo ratings yet

- Section - 17 Pneumatic Tool - EbookDocument14 pagesSection - 17 Pneumatic Tool - EbookandraNo ratings yet

- System Maintenance of Machine Computer Numerically ControlDocument14 pagesSystem Maintenance of Machine Computer Numerically ControlMuhammadRidhaAliKadirNo ratings yet

- Rs20 Wiring DiagramDocument5 pagesRs20 Wiring Diagramthanhhai31No ratings yet

- Maintenance Instructions, Parts Identification & Seal Kits For Series 2H / 2HD / 2HB & 3H / 3HD / 3HBDocument10 pagesMaintenance Instructions, Parts Identification & Seal Kits For Series 2H / 2HD / 2HB & 3H / 3HD / 3HBAtaa AssaadNo ratings yet

- DWG Rev. ADocument1 pageDWG Rev. AAlex SilvaNo ratings yet