Professional Documents

Culture Documents

Edge Cam

Edge Cam

Uploaded by

2005kowshikOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Edge Cam

Edge Cam

Uploaded by

2005kowshikCopyright:

Available Formats

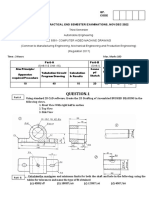

PART B: CNC PROGRAMMING USING CAM SOFTWARE

Introduction – Selecting the work mode and environment – tool bars and windows – construction plan

– Milling : face milling operation – Roughing operation – profiling operation – drill operation - create

2D design in cam software – create stock – change to manufacturing mode –simulate machining – NC

code generation – Turning :turning operation – grooving operation –hole and thread operation - create

2D design in cam software – create stock – change to manufacturing mode – simulate machining –

NC code generation.

CNC Turning Machine

1. Generate a part programming for the given drawing – using stock removal cycle in cam

software.

Ø30

Ø26

55 5

2. Generate a part programming for the given drawing – using canned cycle in cam

software.

M24

Ø18

Ø26

Ø30

100

35

Page 124 of 135

CNC Milling Machine:

1. Generate a part programming for the given drawing – using linear and circular

interpolation in cam software.

40 20

10

100

60

40

100

2. Generate a part programming for the given drawing – using canned cycle in cam

software.

50

10

100

DETAILED ALLOCATION OF MARKS

Sl. Performance Indicator Marks

No.

Part A – Manual Part programming and Machining

1 Program writing 15

2 Editing and Machining 15

3 Component Finishing 05

Part B – CNC programming using CAM software

4 2D design and stock creation 15

5 Program simulation and NC code generation 20

6 Viva voce 05

Total 75

Page 125 of 135

You might also like

- Cad CamDocument28 pagesCad CamAyush SainiNo ratings yet

- Manual GuideDocument6 pagesManual GuideDeysi CardenasNo ratings yet

- SAT 250 SCALA - General BasicsDocument9 pagesSAT 250 SCALA - General BasicsyeferdalNo ratings yet

- SolidCAM 2020 2.5D Milling Training Course PDFDocument318 pagesSolidCAM 2020 2.5D Milling Training Course PDFEko SiswonoNo ratings yet

- SolidCAM 2020 Imachining Getting Started PDFDocument45 pagesSolidCAM 2020 Imachining Getting Started PDFDejan Stamenković100% (1)

- NX CAM ISV Introduction TrainingDocument11 pagesNX CAM ISV Introduction TrainingRudra DasNo ratings yet

- SolidCAM IMachining 2D A Simulation StudDocument12 pagesSolidCAM IMachining 2D A Simulation StudzzNo ratings yet

- Grafcet Step 7Document34 pagesGrafcet Step 7Mazarel AurelNo ratings yet

- CAM - Training (CNC Simulator)Document110 pagesCAM - Training (CNC Simulator)farid_a_dzNo ratings yet

- Genie Z 60-34 Manual de PeçasDocument205 pagesGenie Z 60-34 Manual de PeçasHelio100% (2)

- Cad-Cam Lab ManualDocument41 pagesCad-Cam Lab ManualAnonymous CFkk91INo ratings yet

- CADCAM 3D Machining Lab Sheet PDFDocument2 pagesCADCAM 3D Machining Lab Sheet PDFnurhazwaniNo ratings yet

- Cadlab Manual For r15Document54 pagesCadlab Manual For r15Guru MaheshNo ratings yet

- WinCam ManualDocument159 pagesWinCam ManualBui TrungTuyen (Beo)100% (1)

- CAMConcept Turn EN 1829 C PDFDocument186 pagesCAMConcept Turn EN 1829 C PDFDavis JazminNo ratings yet

- FeatureCAM Project Final YearDocument21 pagesFeatureCAM Project Final YearDhruvit PatelNo ratings yet

- Case-Study 2 Fall2018 r1Document2 pagesCase-Study 2 Fall2018 r1reginaldo joseNo ratings yet

- Me 2309 - Cad / Cam Lab Allocation of MarksDocument21 pagesMe 2309 - Cad / Cam Lab Allocation of MarksM Vinoth kumarNo ratings yet

- V. S. B Engineering College, Karur - 639 111: Department of Mechanical EngineeringDocument121 pagesV. S. B Engineering College, Karur - 639 111: Department of Mechanical EngineeringvinodkumarNo ratings yet

- B&R Automation Studio Target For SimulinkDocument76 pagesB&R Automation Studio Target For SimulinkAdrian MeleroNo ratings yet

- CNC ManualDocument14 pagesCNC ManualsuswagatNo ratings yet

- Expt 08Document3 pagesExpt 08Raja GoshNo ratings yet

- Cad Cam - 22.12.15-1 PDFDocument87 pagesCad Cam - 22.12.15-1 PDFGuru MaheshNo ratings yet

- Ae6312 Set1Document10 pagesAe6312 Set1Tomble BravoNo ratings yet

- Solidcam Imachining (2D) : A Simulation Study of A Spur Gear Machining and G-Code Generation For CNC MachineDocument9 pagesSolidcam Imachining (2D) : A Simulation Study of A Spur Gear Machining and G-Code Generation For CNC MachineTamanna KamalNo ratings yet

- Cim Lab Exam Q SDocument17 pagesCim Lab Exam Q SMohammed ImranNo ratings yet

- ME1355-CAD / CAM Laboratory: Lab ManualDocument42 pagesME1355-CAD / CAM Laboratory: Lab ManualVeeria Chandran S100% (1)

- CAMConcept Turn EN 1829 C PDFDocument186 pagesCAMConcept Turn EN 1829 C PDFManuel García HernándezNo ratings yet

- Report CadcamDocument9 pagesReport CadcamAmirul ZulfadhliNo ratings yet

- CAMConcept - Turn - EN 1829 - DDocument196 pagesCAMConcept - Turn - EN 1829 - DGianfranco capellinoNo ratings yet

- Vertical Machining Center: CNC (Computer Numerical Control)Document23 pagesVertical Machining Center: CNC (Computer Numerical Control)Rohith BayyaNo ratings yet

- Cadcam Report SHAH f1172Document8 pagesCadcam Report SHAH f1172Arif DanialNo ratings yet

- Using Standard CAD SoftwareDocument6 pagesUsing Standard CAD SoftwarePratheesh JpNo ratings yet

- CAMConcept - Mill - EN 1828 - D PDFDocument204 pagesCAMConcept - Mill - EN 1828 - D PDFLuis Alarcon CastroNo ratings yet

- 2018 SW CAM PlaycardDocument2 pages2018 SW CAM PlaycardCrea mundoNo ratings yet

- Manufacturing Technology (As Degree S0918) : Required CoursesDocument1 pageManufacturing Technology (As Degree S0918) : Required CoursesMFNo ratings yet

- Batam Expert Automation TeamDocument8 pagesBatam Expert Automation Teamchea nisterNo ratings yet

- Cad/Cam Integration: Significantly Improve Your Product Development ProcessDocument10 pagesCad/Cam Integration: Significantly Improve Your Product Development ProcessBiswajit PatraNo ratings yet

- PLM - Indishtech PVT Ltd-Corporate ProfileDocument16 pagesPLM - Indishtech PVT Ltd-Corporate ProfileMounesh7No ratings yet

- Introduction To CAD/CAMDocument31 pagesIntroduction To CAD/CAMJOHN RICHMOND DIZONNo ratings yet

- Practical No1Document8 pagesPractical No1Dept. Of Mechanical Engg.No ratings yet

- En Simit-Sce v7 ManualDocument45 pagesEn Simit-Sce v7 ManualxendikaNo ratings yet

- CNC Lab Manual 2023 Med 3102Document66 pagesCNC Lab Manual 2023 Med 3102G. RajeshNo ratings yet

- Lecture 8 CADCAMDocument31 pagesLecture 8 CADCAMAnand P DwivediNo ratings yet

- Sinumerik 840C Graphic 1997Document25 pagesSinumerik 840C Graphic 1997enamicul50No ratings yet

- Using Advanced CAM System in Modern Machining: The 7 International Conference On Engineering and Technology ICET-2015Document4 pagesUsing Advanced CAM System in Modern Machining: The 7 International Conference On Engineering and Technology ICET-2015Moez BellamineNo ratings yet

- Delcam - PowerMILL 2012R2 Whats New EN - 2012Document82 pagesDelcam - PowerMILL 2012R2 Whats New EN - 2012phạm minh hùngNo ratings yet

- SIMIT-SCE V7 Manual PDFDocument45 pagesSIMIT-SCE V7 Manual PDFCarlos MusellaNo ratings yet

- Delcam - PowerMILL 2012 Whats New EN - 2011Document100 pagesDelcam - PowerMILL 2012 Whats New EN - 2011phạm minh hùngNo ratings yet

- Data Sheet SolidcamDocument2 pagesData Sheet SolidcamCrea mundoNo ratings yet

- Cimco Edit 7brochureDocument2 pagesCimco Edit 7brochureMx SanookNo ratings yet

- 22 EngDocument6 pages22 EngAnis SuissiNo ratings yet

- Me8381 CadDocument20 pagesMe8381 CadSiva RamanNo ratings yet

- CamDocument9 pagesCamhemaf85No ratings yet

- Delcam - PowerMILL 2014 R2 Whats New EN - 2014Document109 pagesDelcam - PowerMILL 2014 R2 Whats New EN - 2014phạm minh hùngNo ratings yet

- INSTRUKSI KERJA DESAIN TATA LETAK SCHEMATIC DIAGRAM-UPDATE - Id.enDocument8 pagesINSTRUKSI KERJA DESAIN TATA LETAK SCHEMATIC DIAGRAM-UPDATE - Id.enDzulfikri PrabowoNo ratings yet

- MTS Prospekt 2013 ENGDocument2 pagesMTS Prospekt 2013 ENGfefegoNo ratings yet

- Bro Blow Mold 5 Axis Cam Software Hypermill enDocument6 pagesBro Blow Mold 5 Axis Cam Software Hypermill enVinicius Sabrina PedroNo ratings yet

- Experiment CNC and 3D - Uday Kumar PaliwalDocument20 pagesExperiment CNC and 3D - Uday Kumar PaliwalHarsh VatreNo ratings yet

- Pava ApplicationDocument1 pagePava ApplicationChs PavaNo ratings yet

- An Analysis Method For IPv6 Firewall PolicyDocument6 pagesAn Analysis Method For IPv6 Firewall PolicyAdrian O.MoraNo ratings yet

- SS018 - Painting & Texture CoatingDocument19 pagesSS018 - Painting & Texture CoatingFandy PratamaNo ratings yet

- Gsic Toyota Corolla Altis 2011 2012 Nze141 Zze1142 Zre141 143 Ce140 Workshop ManualDocument22 pagesGsic Toyota Corolla Altis 2011 2012 Nze141 Zze1142 Zre141 143 Ce140 Workshop Manualdavidmiller030201igj100% (102)

- Analytical Analysis of Steel Reinforced Concrete Transfer BeamDocument4 pagesAnalytical Analysis of Steel Reinforced Concrete Transfer BeamChime MornNo ratings yet

- CLD 20202 Exp 1-Control ValveDocument15 pagesCLD 20202 Exp 1-Control ValveAbu RectifyNo ratings yet

- Experiment No 7 CMTDocument5 pagesExperiment No 7 CMTFrancis ArcillaNo ratings yet

- P5 ML ICT LessonDocument3 pagesP5 ML ICT LessonNorsena NorseNo ratings yet

- ML QP Problem Solutions Dec 18 - Jan 19 PDFDocument7 pagesML QP Problem Solutions Dec 18 - Jan 19 PDFM. Muntasir RahmanNo ratings yet

- Commercial Catalogue: All of Your Electrical Needs in One Book!Document44 pagesCommercial Catalogue: All of Your Electrical Needs in One Book!rhap_0925060No ratings yet

- Lupo 1.2 Tdi 3lDocument53 pagesLupo 1.2 Tdi 3lgoopejko100% (2)

- Recode 4 DhsDocument139 pagesRecode 4 DhsAyu IndriNo ratings yet

- A Review of Subdomain Modeling Techniques in Electrical Machines Performances and ApplicationsDocument7 pagesA Review of Subdomain Modeling Techniques in Electrical Machines Performances and ApplicationsFaiza OuiddirNo ratings yet

- Final Reflection Letter EnglishDocument2 pagesFinal Reflection Letter EnglishChelsea Roehl100% (1)

- University of Engineering & Technology Peshawar, Pakistan: TranscriptDocument1 pageUniversity of Engineering & Technology Peshawar, Pakistan: TranscriptaliNo ratings yet

- AE6022 Cp4Document31 pagesAE6022 Cp4Osman PekmutluNo ratings yet

- Case Study - PaytmDocument23 pagesCase Study - PaytmGitanjoli BorahNo ratings yet

- Grade 4 DLL English 4 q4 Week 8Document6 pagesGrade 4 DLL English 4 q4 Week 8Cristina SingsingNo ratings yet

- SmartTrials Clinical Data Review - Suggested Review Process - v1.0Document17 pagesSmartTrials Clinical Data Review - Suggested Review Process - v1.0SurajNo ratings yet

- Time Shared Architecture Time Shared Architecture: CH 9: DR Shoab CH 8,10: Stephen Brown CH 8,10: Stephen BrownDocument65 pagesTime Shared Architecture Time Shared Architecture: CH 9: DR Shoab CH 8,10: Stephen Brown CH 8,10: Stephen BrownRabeea AhmadNo ratings yet

- Center of Gravity and EquilibriumDocument2 pagesCenter of Gravity and EquilibriumHarrison Cabreros100% (1)

- Rivulis R5000 English Metric 20190507 WebDocument8 pagesRivulis R5000 English Metric 20190507 WebAnddrixNo ratings yet

- Tab 06 - SubSurface Safety ValvesDocument59 pagesTab 06 - SubSurface Safety ValvesAbboud KingNo ratings yet

- A Practice Theory Perspective On Learning Beyond A Standard ViewDocument17 pagesA Practice Theory Perspective On Learning Beyond A Standard Viewasskeeper153No ratings yet

- Rozee Academy - Daily Duties Checklist (Example)Document3 pagesRozee Academy - Daily Duties Checklist (Example)Kickz CribNo ratings yet

- I. Is Photography Over?: Trevor PaglenDocument3 pagesI. Is Photography Over?: Trevor PaglenMarin Marius RaicaNo ratings yet

- Project Management - Process Groups and PhasesDocument19 pagesProject Management - Process Groups and Phasesaishwarya sanapNo ratings yet

- Event Venue: Literature Review Case Study - TAAJ PLACE Banquet & Event VenueDocument5 pagesEvent Venue: Literature Review Case Study - TAAJ PLACE Banquet & Event VenueSagar Mahat100% (1)

- Aquamax Basecoat Series 500: Waterborne Basecoat For 2-3 Stage FinishesDocument3 pagesAquamax Basecoat Series 500: Waterborne Basecoat For 2-3 Stage FinishesYoussef LfarissiNo ratings yet