Professional Documents

Culture Documents

Rickenmann 1991 Hyperconcentrated Flow and Sediment Transport at Steep Slopes

Uploaded by

rohanOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Rickenmann 1991 Hyperconcentrated Flow and Sediment Transport at Steep Slopes

Uploaded by

rohanCopyright:

Available Formats

HYPERCONCENTRATED F L O W AND SEDIMENT

TRANSPORT AT STEEP SLOPES

Downloaded from ascelibrary.org by "Indian Institute of Technology, Guwahati" on 03/06/24. Copyright ASCE. For personal use only; all rights reserved.

By Dieter Rickenmann1

ABSTRACT: In order to simulate a fine-material slurry of a debris flow, a clay

suspension of various concentrations was recirculated in a steep flume. The effect

of an increasing fluid density and viscosity on the flow behavior and the bed-load

transport capacity of the flow was examined. Viscous effects were found to become

important below a limiting particle Reynolds number of about 10. Above this

limiting value, density effects cause an increase in the bed-load transport rates as

compared to similar conditions with clear water as transporting fluid. The exper-

imental data in this range can be described with conventional (Newtonian) formulas

and is analyzed together with other bed-load transport data. Two different calcu-

lation schemes are proposed for the steep slope range (S >~ 10%) where the bed-

load concentration is significant with respect to the total flow depth. Below the

critical particle Reynolds number of 10, the bed-load transport rates decreased

strongly.

INTRODUCTION

In a torrent catchment, different sediment transport processes may occur.

During a flood event, increasing discharges can destroy the armor layer of

the torrent bed and fluvial transport of bed material will start. In addition

there may be sediment supply to the channel from slope failures (slides and

undercutting of banks) and thus, sediment availability could be sufficient

for the flow to move sediment in rates close to its transport capacity. In

steep reaches of the channel, saturated parts of loose material may be set

in motion rather suddenly and a debris flow can form. Then the flow of this

sediment-water mixture is highly unsteady; debris flows usually consist of

one or several pulses or waves. At the front of the flow, the particles are

more or less uniformly distributed over the flow depth, while the mixture

behind the front becomes more and more diluted, and at the end, the coarser

particles are concentrated near the bed as in fluvial sediment transport (e.g.,

Costa 1984; Davies 1988).

The water and the suspended fine sediment may be considered as a new

fluid matrix that can have a different rheological behavior than that of a

Newtonian fluid like clear water (Johnson 1970; Costa 1984). In the tran-

sition region between normal streamflow (with fluvial sediment transport)

and a debris flow, increasing amounts of fine material form a hypercon-

centrated slurry. These conditions may also be present in the rear, more

diluted part of a debris-flow wave.

Here a hyperconcentrated flow is defined as a still more or less uniform

flow with a high suspended fine-material concentration and a viscosity larger

than that of water; coarse sediment may be transported as bed load. The

term debris flow is restricted here for an unsteady, pulsing flow of a mixture

of water and both coarse and fine sediment. To distinguish between these

•Hydr. Engr., Amt fur Gewasserschutz und Wasserbau des Kantons Zurich,

Walchetor, 8090 Zurich, Switzerland.

Note. Discussion open until April 1, 1992. To extend the closing date one month,

a written request must be filed with the ASCE Manager of Journals. The manuscript

for this paper was submitted for review and possible publication on December 13,

1990. This paper is part of the Journal of Hydraulic Engineering, Vol. 117, No. 11,

November, 1991. ©ASCE, ISSN 0733-9429/91/0011-1419/$1.00 + $.15 per page.

Paper No. 26320.

1419

J. Hydraul. Eng., 1991, 117(11): 1419-1439

two flow types, a sediment concentration by volume between about 30%

and 60% was proposed by various researchers; a comparison of different

classification schemes including such limiting values is given by Bradley

(1986).

Downloaded from ascelibrary.org by "Indian Institute of Technology, Guwahati" on 03/06/24. Copyright ASCE. For personal use only; all rights reserved.

In the past, studies on sediment transport in rivers and flumes were mainly

concerned with bed slopes up to a few percent. It is only recently that

interest on sediment-transport processes in steep channels has grown. Such

studies, including flume slopes in excess of 10%, were performed by Mi-

zuyama (1977), Mizuyama and Shimohigashi (1985), and Smart and Jaeggi

(1983). The transporting fluid used in these flume tests was clear water. In

torrents where debris flows also occur, the influence of large amounts of

suspended fine particles may become important. Accordingly, the objective

of the present study was to examine the effect of an increasing density and

viscosity of the fluid on the flow and the sediment-transport behavior. A

series of steep flume tests was performed using a clay suspension to represent

the fine slurry of a debris flow, and the flow resistance and the sediment-

transport capacity were determined for various clay concentrations. The

experiments of Smart and Jaeggi (1983) [see also Smart (1984)], which were

carried out at the same hydraulic laboratory, served as a reference condition

for the clear-water case.

EFFECT OF HIGH FINE MATERIAL CONCENTRATIONS

In the past, two principally different debris-flow theories have been de-

veloped. One of them is the viscoplastic model that was applied to flows

containing a lot of fine material in a viscous slurry. It is based on the

approach by Bingham (1922) to describe a particular type of non-Newtonian

flow. The Bingham model also applies to clay suspension flows as used in

this study and it can be written as:

T = T + T1 (1)

* *(!)

where T = the shear stress in the fluid; iB = the (Bingham) yield stress;

r\B = the Bingham viscosity; and dvldy = the velocity gradient perpendic-

ular to the flow direction.

Considering mainly the interaction between the coarser particles in a

debris flow, Takahashi (1978) proposed an alternative model based on Bag-

nold's (1954) concept of dispersive pressure. Combining these two basic

approaches, more complex models were formulated, for example, Chen

(1988a, 1988b) and Julien and Lan (1991). A detailed discussion on debris-

flow models can be found elsewhere (Bradley 1986; Rickenmann 1990).

Many hyperconcentrated slurries of fine particles suspended in water

behave like a Bingham fluid (Costa 1984; Chen 1986). The flow resistance

of these fluids can be analyzed either by a set of equations in terms of the

Bingham parameters (Johnson 1970; Naik 1983) or by defining an effective

viscosity (xe2 and using conventional Newtonian formulas (Quian et al. 1980;

Wan 1982):

(xe2 = T)B + -^ (2)

where h = the flow depth; and V = the mean fluid velocity.

Several studies were concerned with the effect of hyperconcentrated flows

1420

J. Hydraul. Eng., 1991, 117(11): 1419-1439

on sediment transport, but they are mainly confined to flatter slopes. There

seems to be general agreement that in turbulent hyperconcentrated flows,

the suspended load transport rates increase with increasing fine-material

concentration; this was concluded both from field observations (Beverage

Downloaded from ascelibrary.org by "Indian Institute of Technology, Guwahati" on 03/06/24. Copyright ASCE. For personal use only; all rights reserved.

and Culbertson 1964; Bradley 1986) and from laboratory experiments (up-

per-regime tests of Simons et al. 1963; Kikkawa and Fukuoka 1969; Wan

1982; Bradley 1986; Wan and Song 1987). With regard to the effect on bed-

load transport rates qB, an increase in qB due to an increase of the fluid

density is predicted from experimental results by Shields (1936), by Meyer-

Peter and Mueller (1948), and by Luque and van Beek (1976), and from

theoretical considerations by Yalin (1977) and by Woo (1985). However,

Wan and Song's (1987) theory predicts a decrease in the dimensionless bed-

load transport rates Q>B for an increasing fluid density at higher shear stresses.

Low (1989) found that many bed-load transport formulas adequately ac-

count for a change in the solid/fluid density ratio, but that the Smart and

Jaeggi (1983) equation should be modified. Information on the effect of an

increasing viscosity alone on qB in open-channel flow is less conclusive (Hong

et al. 1984; Woo 1985; Lau 1987). Wan (1982) concluded from his experi-

ments that <$>B was smaller in the bentonite suspension flows than in the

corresponding clear-water flows, particularly in the low flow-intensity

region.

There is not yet much information available on sediment transport in

laminar flow. In their experiments, both Wan and Song (1987) and Bradley

(1986) observed an increase in the total bed-material discharge; in Bradley's

study the transport rates in laminar flow were about an order of magnitude

higher than in the corresponding turbulent flow (with the same fluid dis-

charge). Pipe flow tests reported by Thomas (1979b) may suggest that the

bed-load transport rates decrease in laminar flow, assuming that bed load

is the predominant mode of transport at a velocity slightly above depositional

conditions. Negative lift forces for particles near the bed (Coleman 1967;

Davies and Samad 1978) and theoretical considerations by Bagnold (1956)

also seem to indicate that bed-load transport should be smaller in laminar

flow than in turbulent flow.

EXPERIMENTS

In the experiments, a clay suspension of various concentrations was re-

circulated in a 20.1-cm-wide and 5-m-long flume. Commercially available

Opalinus clay was added to the water system so as to obtain different clay

concentration levels. After settling of the larger components, the concen-

tration of the flowing clay suspension could be kept approximately constant.

At a given concentration level, a series of tests was performed with different

slopes and flow rates. The clay suspension showed increasingly non-New-

tonian characteristics with increasing concentration. The maximum density

of the suspension was about 1.36 g/cm3 (corresponding to a volume con-

centration of 22%), and the maximum effective viscosity |xe2 (defined as

analogous to the Newtonian viscosity) reached 1,800 cps.

At each clay concentration level, two different kinds of experiments were

performed. In the first series of tests (case A), a fixed rough bed made of

gravel was installed to measure the flow resistance of the clay suspension

flows without any bed-load transport. In the second series (case B) a mov-

able bed of gravel was used, and the same particles were also fed at the

flume entrance in order to determine the equilibrium bed-load transport

1421

J. Hydraul. Eng., 1991, 117(11): 1419-1439

rate for a preset slope and flow rate. A rather uniform gravel mixture with

a mean diameter d,„ = 1 cm was used as bed material; for this material,

d9i) = f .2 cm where dgn is the grain size at which 90% of the material by

weight are finer. In the case B tests the bed slope S was varied between

Downloaded from ascelibrary.org by "Indian Institute of Technology, Guwahati" on 03/06/24. Copyright ASCE. For personal use only; all rights reserved.

7% and 20%, and the fluid flow rate Q between 10 and 30 1/s. Experiments

were performed at five different clay concentration levels; the corresponding

fluid properties are summarized in Table 1. The measured flow parameters

are given in Table 2 for the experiments without sediment transport (case

A). The fixed rough bed in these experiments had the same grain-size

characteristics as the bed material used in the sediment. The data of clay

suspension flows with bed-load transport (case B) is shown in Table 3. The

experimental results labeled H z O were taken from Smart and Jaeggi (1983).

(See section on bed-load transport for distinction between case Bl and case

B2 experiments.

The Bingham parameters iH and r\B were measured with a rotational

viscometer, and the effective viscosity |x(>2 was determined according to (2).

The salt tracer technique was used to measure the mean fluid velocity; at

the highest concentrations this method was not reliable because of insuffi-

cient mixing of the salt solution in the clay suspension (see also remarks in

Tables 2 and 3). The flow depth was inferred from a flow surface level

determined by ultrasonic distance measuring devices and information about

the bed level. In the case B tests, the boundary between nonmoving grains

of the bed and the transport layer was detected by electric conductivity

readings at different levels across the flume width, since no visual obser-

vation was possible in the muddy suspension. All measurement methods

are described in more detail in Rickenmann (1990).

In the analysis of both the case A and the case B experiments, a correction

for sidewall friction effects was applied. A procedure used by Smart and

Jaeggi (1983) was adapted; the method is based on the approach by Einstein

(1934) who postulated equal velocities in flow sections with different rough-

ness. Thus the reduced flow depth, hr, and the reduced flow rate per unit

width, qn were determined from the measured flow depth, H, and the

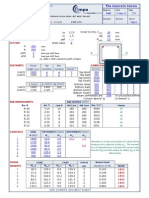

TABLE 1. Clay Concentration Levels, Ci, and Fluid Properties

a P (g/cm3) Cr (%) T« (N/m2) f\B (cps) fx,2 (cps)

(D (2) (3) (4) (5) (6)

(a) Case A Experiments (No Bed-Load Transport)

H,0 0.998 0.0 0.0 1.02 1

CI 1.078 4.7 0.44 1.93 5-10

C2 1.165 10.0 2.82 3.60 25-55

C3 1.238 14.4 7.29 5.92 60-140

C4 1.324 19.6 23.6 20.0 180-400

C5 1.365 22.1 40.8 34.3 250-1800

(b) Case B Experiments (with Bed-Load Transport)

H,0 0.998 0.0 0.0 1.02 1

CI 1.072-1.096 4.4-5.8 0.43-0.67 1.87-2.17 10-15

C2 1.141-1.160 8.6-9.7 2.20-2.77 3.00-3.33 35-65

C3 1.201-1.246 12.2-14.9 4.31-8.55 4.35-6.74 100-200

C4 1.257-1.293 15.6-17.8 12.8-20.1 11.2-16.2 200-450

C5 1.356-1.363 21.6-22.0 33.6-40.8 28.8-34.3 800-1000

1422

J. Hydraul. Eng., 1991, 117(11): 1419-1439

measured flow rate per unit width, g, as follows (Rickenmann 1990): hr =

H - 2 • [V/(kh\/S)Y5 • (HIB) and qr = q - V • (H - ft,.), where /c,„ is

the Striekler value characterizing the flume wall (Ar,v = 110 m1/3/s was used

for the perspex side walls) and B denotes the flume width.

Downloaded from ascelibrary.org by "Indian Institute of Technology, Guwahati" on 03/06/24. Copyright ASCE. For personal use only; all rights reserved.

FLOW RESISTANCE

Flow resistance measurements were performed for both cases A and B

experiments. The case A test series allowed an analysis of the clay suspen-

sion flows alone, without any interference of a two-phase flow as in experi-

ments B.

The flow resistance data was plotted on a Moody-type diagram in terms

of the Darcy-Weisbach friction factor/ = 8T„/(pV2) and the Reynolds num-

ber R2 = 4V77,.p/m2, defined with the effective viscosity (jie2. Here T0 =

pgh,S = the bed shear stress; p = the fluid density; g = the gravitational

acceleration; and S = the bed slope. Some of the clay suspension flows

without bed-load transport (case A) were in the laminar region, and the

corresponding data points lie close to the relation for laminar Newtonian

flow, / = 96/R2 [Fig. 1(a)]. This confirmed the findings of other studies

(Quian et al. 1980; Wan 1982) that by using the effective viscosity \x.e2, the

flow resistance may be described by conventional Newtonian formulas.

The data was also analyzed by using a Colebrook-type flow resistance

equation:

$!•*»{$+* <3>

where ks = the equivalent sand roughness; (3 = a coefficient depending to

some extent on the relative flow depth; and A is constant in the hydraulically

fully turbulent region where no viscous effects are present (Yalin 1977). In

Fig. 2, the data is plotted in terms of A' = [1/V/ — 2 • \og(hrld9Q)] and

RJ, and R2 = v*dp/\ie2 is the particle Reynolds number, with v* = (gh,.S)0-5

and d = dgo. It is seen that viscous effects only become important for

R2 :£ 10. Above this critical value, A' is approximately constant with an

average of 2.4; from a comparison with (3) it can be concluded that a value

of ks = 0.76 • d90 would best describe the clay suspension experiments in

the turbulent region.

In the experiments with bed-load transport (case B), no flows in the

laminar region were observed. The analysis of the flow resistance data shows

only a very slight increase of the friction factor / for some of the C2 and

C3 tests [Fig. 1(b)]. This minor change is associated with an increase in bed-

load concentration and thus, flow depth, and is not a direct effect of altered

fluid properties.

In further analysis, a search was made for a prediction equation for the

fluid velocity that would apply to both the bed-load transport experiments

in the fully turbulent clay suspension flows (for which R* > 10, case Bl,

see also section on bed-load transport) and the bed-load transport tests of

Smart and Jaeggi (1983).

Jaeggi (1983) proposed a modified flow resistance equation for a sediment

transporting flow over a movable bed at smaller relative depths hldgo, be-

cause many conventional formulas tend to overpredict the velocities in the

range 5 < h/d9n < 20. His equation is given as:

1423

J. Hydraul. Eng., 1991, 117(11): 1419-1439

TABLE 2. Case A Experiments, No Bed-Load Transport

Q V H Tfl •<\B P

a S (l/s) (m) (cm) (N/m2) (ops) (g/cm3

Downloaded from ascelibrary.org by "Indian Institute of Technology, Guwahati" on 03/06/24. Copyright ASCE. For personal use only; all rights reserved.

0) (2) (3) (4) (5) (6) (7) (8)

H20 0.05 10.0 1.20 4.01 0.00 1.02 0.998

H20 0.05 20.0 1.62 6.02 0.00 1.02 0.998

H20 0.05 40.0 2.13 9.38 0.00 1.02 0.998

H20 0.10 10.0 1.46 3.19 0.00 1.02 0.998

H20 0.10 20.0 1.95 5.04 0.00 1.02 0.998

H20 0.10 30.0 2.27 6.44 0.00 1.02 0.998

H20 0.15 10.0 1.63 2.83 0.00 1.02 0.998

H20 0.15 15.0 1.95 3.63 0.00 1.02 0.998

H20 0.15 30.0 2.63 5.83 0.00 1.02 0.998

H20 0.20 10.0 1.76 2.58 0.00 1.02 0.998

H20 0.20 20.0 2.35 4.24 0.00 1.02 0.998

H,0 0.20 40.0 3.18 6.29 0.00 1.02 0.998

CI 0.05 10.0 1.18 3.98 0.47 1.92 1.079

CI 0.05 20.0 1.69 5.86 0.47 1.92 1.079

CI 0.05 40.0 2.35 8.45 0.47 1.92 1.079

CI 0.10 10.0 1.42 3.08 0.47 1.92 1.079

CI 0.10 20.0 1.98 4.79 0.47 1.92 1.079

CI 0.10 30.0 2.41 6.03 0.47 1.92 1.079

CI 0.15 10.0 1.60 2.72 0.47 1.92 1.079

CI 0.15 15.0 1.90 3.44 0.47 1.92 1.079

CI 0.15 30.0 2.65 5.38 0.47 1.92 1.079

CI 0.20 10.0 1.77 2.44 0.47 1.92 1.079

CI 0.20 20.0 2.39 3.78 0.47 1.92 1.079

CI 0.20 40.0 3.36 5.90 0.47 1.92 1.079

C2 0.05 10.0 1.15 3.99 2.92 3.62 1.165

C2 0.05 20.0 1.64 5.87 2.92 3.62 1.165

C2 0.05 40.0 2.18 9.10 2.92 3.62 1.165

C2 0.10 10.0 1.19 3.09 2.51 3.55 1.163

C2 0.10 20.0 • 1.97 4.76 2.51 3.55 1.163

C2 0.10 30.0 2.42 6.02 2.51 3.55 1.163

C2 0.15 10.0 1.54 2.70 2.92 3.62 1.165

C2 0.15 15.0 1.87 3.42 2.92 3.62 1.165

C2 0.15 30.0 2.61 5.36 2.92 3.62 1.165

C2 0.20 10.0 1.69 2.36 2.92 3.62 1.165

C2 0.20 20.0 2.38 3.68 2.92 3.62 1.165

C2 0.20 40.0 3.24 5.82 2.92 3.62 1.165

C3 0.05 10.0 1.22" 3.59 8.65 6.70 1.250

C3 0.05 20.0 1.66a 5.90 8.65 6.70 1.250

C3 0.05 40.0 2.23 a 8.89 8.65 6.70 1.250

C3 0.10 10.0 1.43 3.09 6.60 5.46 1.227

C3 0.10 20.0 1.90 4.84 6.60 5.46 1.227

C3 0.10 30.0 2.30 6.00 6.60 5.46 1.227

C3 0.15 10.0 1.58 2.89 6.95 5.75 1.237

C3 0.15 15.0 1.85 3.66 6.95 5.75 1.237

C3 0.15 30.0 2.51 5.56 6.95 5.75 1.237

C3 0.20 10.0 1.73 2.53 6.95 5.75 1.237

C3 0.20 20.0 2.28 3.79 6.95 5.75 1.237

C3 0.20 40.0 3.16 5.68 6.95 ' 5.75 1.237

1424

J. Hydraul. Eng., 1991, 117(11): 1419-1439

TABLE 2. Continued

Q V H Tfl 1)B P

a S (l/s) (m) (cm) (N/m2) (cps) (g/cm3)

Downloaded from ascelibrary.org by "Indian Institute of Technology, Guwahati" on 03/06/24. Copyright ASCE. For personal use only; all rights reserved.

(D (2) (3) (4) (5) (6) (7) (8)

C4 0.05 10.0 1.18° 4.20 23.60 20.00 1.324

C4 0.05 20.0 1.78" 5.58 23.60 20.00 1.324

C4 0.05 40.0 2.41" 8.27 23.60 20.00 1.324

C4 0.10 10.0 1.50" 3.31 23.60 20.00 1.324

C4 0.10 15.0 1.87" 4.00 23.60 20.00 1.324

C4 0.10 30.0 2.46" 6.06 23.60 20.00 1.324

C4 0.15 10.0 1.73" 2.87 23.60 20.00 1.324

C4 0.15 15.0 2.00" 3.73 23.60 20.00 1.324

C4 0.15 30.0 2.66" 5.62 23.60 20.00 1.324

C4 0.20 10.0 1.82" 2.74 23.60 20.00 1.324

C4 0.20 20.0 2.40" 4.14 23.60 20.00 1.324

C4 0.20 40.0 3.36" 5.92 23.60 20.00 1.324

C5 0.05 10.0 0.75" 6.69 40.80 34.30 1.365

C5 0.05 15.0 1.14" 6.53 40.80 34.30 1.365

C5 0.05 20.0 1.46" 6.83 40.80 34.30 1.365

C5 0.10 10.0 1.13" 4.43 40.80 34.30 1.365

C5 0.10 15.0 1.54" 4.85 40.80 34.30 1.365

C5 0.10 20.0 1.86" 5.37 40.80 34.30 1.365

C5 0.15 10.0 1.42" 3.50 40.80 34.30 1.365

C5 0.15 15.0 1.77" 4.21 40.80 34.30 1.365

C5 0.15 20.0 2.07" 4.80 40.80 34.30 1.365

C5 0.20 10.0 1.74" 2.87 30.00 26.00 1.340

C5 0.20 20.0 2.27" 4.39 30.00 26.00 1.340

C5 0.20 30.0 2.76" 5.41 30.00 26.00 1.340

"In these tests, velocity measurement by salt tracer technique was not reliable (C3,

C4), or not possible at all (C5); the velocity determined as V = Q [B • H) was used here.

12.27ft

2 1 exp In (4)

7 =" L - U^V M9o

where the coefficients (^ and ax depend on the grain-size distribution and

the packing and the shape of the bed material. For their steep channel bed-

load transport tests, Smart and Jaeggi (1983) determined o^ = 0.05 and Bt

= 15. Using the same coefficients, the performance of (4) is shown in Fig.

3 for the steep flume data sets of Smart and Jaeggi and of the writer. It is

observed that (4) tends to slightly overpredict the velocities of the clay

suspension tests. It may be noted that (4) was developed from experimental

data with flatter slopes; for large relative flow depths and small slopes, the

correction factor in square brackets of (4) approaches unity and the formula

becomes similar to a Nikuradse-type equation.

Based on the concept of dispersive stresses between the moving grains,

Takahashi (1978) proposed an equation for the mean velocity of a quasi-

steadily moving debris-flow front. Replacing concentration and density terms

together with grain-shearing coefficients by one single parameter A*, the

following expression is obtained (Takahashi 1978):

1425

J. Hydraul. Eng., 1991, 117(11): 1419-1439

TABLE 3. Case B Experiments with Bed-Load Transport

Q V H O fl f« T}B P

a s (l/s) (m/s) (cm) (kg/s) (N/m2) (cps) (g/cm3)

Downloaded from ascelibrary.org by "Indian Institute of Technology, Guwahati" on 03/06/24. Copyright ASCE. For personal use only; all rights reserved.

(D (2) (3) (4) (5) (6) (7) (8) (9)

(a) Case Bl Experiments

H20 0.07 15.0 " 1.28 5.90 0.68 0.00 1.02 0.998

H20 0.07 25.0 1.55 8.20 1.42 0.00 1.02 0.998

H20 0.10 10.0 1.07 5.00 0.84 0.00 1.02 0.998

H20 0.10 15.0 1.38 6.30 1.60 0.00 1.02 0.998

H20 0.10 30.0 2.06 6.00 3.53 0.00 1.02 0.998

H20 0.15 10.0 1.18 4.80 2.30 0,00 1.02 0.998

H20 0.15 15.0 1.57 6.00 4.08 0.00 1.02 0.998

H20 0.15 ' 30.0 2.52 8.00 9.49 0.00 1.02 0.998

H20 0.20 10.0 1.26 6.00 4.80 0.00 1.02 0.998

H20 0.20 15.0 1.74 6.80 8.84 0.00 1.02 0.998

H20 0.20 20.0 2.44 7.60 10.30 0.00 1.02 0.998

H,0 0.20 30.0 2.59" 8.50 14.91 0.00 1.02 0.998

CI 0.07 15.0 1.16 5.19 0.88 0.67 2.17 1.092

CI 0.07 25.0 1.57 7.31 1.49 0.61 2.09 1.084

CI 0.10 10.0 1.11 4.61 1.49 0.43 1.93 1.075

CI 0.10 15.0 1.35 5.25 2.31 0.60 2.13 1.084

CI 0.10 30.0 2.01 7.69 4.34 0.63 2.13 1.087

CI 0.15 10.0 1.18 4.82 3.52 0.59 2.05 1.091

CI 0.15 15.0 1.52 6.01 5.29 0.52 1.93 1.072

CI 0.15 30.0 2.03 8.12 9.08 0.63 2.13 1.088

CI 0.20 10.0 1.25 5.62 7.05 0.59 2.17 1.086

CI 0.20 15.0 1.60 6.89 10.58 0.58 2.03 1.096

CI 0.20 20.0 1.90 7.77 12.88 0.43 1.93 1.077

CI 0.20 30.0 2.47 9.07 17.63 0.63 2.13 1.088

C2 0.07 15.0 1.27 5.83 1.15 2.70 3.33 1.152

C2 0.07 25.0 1.46 7.80 1.97 2.56 3.22 1.149

C2 0.10 10.0 1.12 4.80 2.03 2.50 3.32 1.160

C2 0.10 15.0 1.40 5.96 3.12 2.77 3.33 1.153

C2 0.10 30.0 2.18 8.54 5.08 2.26 3.06 1.145

C2 0.15 10.0 1.18 4.95 4.75 2.20 3.16 1.153

C2 0.15 15.0 1.58 6.30 7.05 2.20 3.16 1.152

C2 0.15 30.0 2.22 8.52 10.85 2.41 3.19 1.147

C2 0.20 10.0 1.29 6.58 9.63 2.50 3.32 1.158

C2 0.20 15.0 1.83 7.70 14.37 2.38 3.22 1.159

C2 0.20 20,0 2.19 8.25 16.27 2.26 3.00 1.141

C2 0.20 30.0 2.75 9.79 20.74 2.26 3.06 1.145

C3 0.07 15.0 1.21 5.62 1.49 8.06 6.27 1.245

C3 0.07 25.0 1.60 8.11 2.24 4.31 4.35 1.201

C3 0.10 10.0 1.15 4.50 2.58 8.07 6.43 1.243

C3 0.10 15.0 1.41 5.91 3.91 8.07 6.43 1.243

C3 0.10 30.0 1.93 8.72 4.95 7.35 6.00 1.223

C3 0.15 10.0 1.23 5.44 5.97 6.95 5.75 1.240

C3 0.15 15.0 1.61 6.70 9.01 8.14 6.74 1.241

C3 0.15 30.0 2.34 9.04 12.20 7.75 6.37 1.228

C3 0.20 10.0 1.58 7.46 13.56 8.55 6.10 1.246

C3 0.20 15.0 1.73 8.69 17.55 8.14 6.74 1.236

1426

J. Hydraul. Eng., 1991, 117(11): 1419-1439

TABLE 3. Continued

Q V H GB T/J Tie P

a .V (l/s) (m/s) (cm) (kg/s) (N/m2) (cps) (g/cm3)

Downloaded from ascelibrary.org by "Indian Institute of Technology, Guwahati" on 03/06/24. Copyright ASCE. For personal use only; all rights reserved.

(1) (2) (3) (4) (5) (6) (7) (8) 0)

(a) Case Bl Experiments-Continued

C4 0.07 25.0 1.69 7.06 2.39 18.60 16.20 1.286

C4 0.10 30.0 2.08 8.15 7.18 17.60 15.70 1.275

C4 0.15 10.0 1.32 6.21 6.38 20.10 17.50 1.266

C4 0.15 30.0 2.49 8.53 13.32 16.20 14.80 1.257

(b) Case B2 Experiments

C4 0.07 15.0 1.36 5.83 1.20 18.60 16.20 1.287

C4 0.10 10.0 1.16 4.90 1.76 20.10 17.50 1.293

C4 0.10 15.0 1.43 6.00 3.35 16.20 14.80 1.275

C5 0.07 15.0 1.36b 6.85 0.59 40.80 34.30 1.363

C5 0.10 10.0 1.16" 5.75 0.81 40.80 34.30 1.363

C5 0.10 15.0 1.43b 6.50 2.17 40.80 34.30 1.363

C5 0.15 10.0 1.32b 6.60 3.06 33.60 28.80 1.356

C5 0.20 10.0 1.58b 7.80 7.65 33.60 28.80 1.356

"No velocity was measured in this experiment; velocity calculated by Smart and Jaeggi

(1983) was used here.

b

In these tests, velocity measurement by salt tracer technique was not reliable (C5);

as approximation, velocity of corresponding flow at next lower concentration level (C4

or C3) was used here.

U

(gdf ^5 = A*(sin a)" 2

(5)

3L

gd3

where U = the mean velocity of the moving grains; q = the fluid discharge

per unit flume with; and a = the bed slope angle. Takahashi plotted his

experimental results in terms of the nondimensional velocity [given by the

left-hand side of (5)] versus the bed slope tan a. As predicted by (5), there

is only a slight dependence on tan a in his figure. From his diagram (Tak-

ahashi 1978), it can be determined that A* ~ 1.3. Using this experimental

value for the parameter A*, (5) can be transformed into:

(sin af-2q°-6g0-2

U = 1.3 (6)

d0A

Interestingly a regression analysis with the two steep flume data sets dis-

cussed previously results in an empirical relation very similar to (6). In fact,

Fig. 4 shows good agreement for the steep flume data between measured

and calculated fluid velocities; putting sin a ~ tan a = S, d = d9Q and U

= V, (6) becomes:

6

'0.2„0.6 n 0.2

13S^q°- g

V 0 (7)

d'

«Q<)

1427

J. Hydraul. Eng., 1991, 117(11): 1419-1439

T

* + 0

* *

I c, [% 22.1 19.6 14.4 10.0 4.7 0.0

\ 11 f S = 20°/c1

0.40 ^ . 96 J-~\

Downloaded from ascelibrary.org by "Indian Institute of Technology, Guwahati" on 03/06/24. Copyright ASCE. For personal use only; all rights reserved.

\ \ ]S=15%f.

0.30

f

" Re ->!

1-

\

0.20

f

0.10

\

i .l^*--^

\I

% V

fS = 5%] ^

"

i Sl~A

0.08

\ ^ * s X, ^

•>. N <\»\ \ * \ ~^

0.06 \ \ N , \ -tr~ X

* «<\ r

\ \V \ \

• »

0.04 N \

0.03 \

102 10 3 10" 10 5 10s

Re2

C, [%]

0.80 96 1 S = I5%[ | | |

\

\ '/ |

0.60

x \ |s-m%l\ nL5^20%]

0.40 \ -r

^ \ \L-

\ n• "—

I

^r-

V \ \ \ ^ V V

0.30 kv

0.20

\\

A

4.

X +

^ \ -N \ \

^\

\

\

^ \

\ xa

f

0.10

\

V

1

s?

*

\

^ \ | S = 5°/ V

•u ft

• *

0.08 2

10 3

\ 10 4 105 „ 106

10

Re 2

FIG. 1. Flow Resistance Data of (a) Clay Suspension Flows over Fixed Rough

Bed; and (b) Experiments with Bed Load Transport. Data Points with Equal Slope

are Connected by Straight Lines

The correlation coefficient squared is r2 = 0.79 and the standard error is

SE = 14% of the mean measured velocity. It is remarkable that the fluid

velocity of a bed-load transporting flow at slopes 0.05 < = S < = 0.20 may

be predicted by the same formula as the velocity of the front of a debris

flow. The corresponding debris-flow experiments of Takahashi (1978) cover

a slope range 0.17 < = S < = 0.47.

BED-LOAD TRANSPORT

In the case of bed-load transport in the clay suspension (case B), each

experiment was performed with the same preset slope and flow rate as for

the clear-water tests by Smart and Jaeggi (1983), which served as a reference

condition. The ratio of the corresponding bed-load transport rates per unit

width, qB/qB,Hicn w a s found to increase with increasing clay concentration

of the suspension (and thus, fluid density) up to a limiting value, above

which transport rates decreased strongly. This change in bed-load transport

capacity can also be plotted against the particle Reynolds number R* (Fig.

5), which represents the effect of a changing fluid viscosity; here RJ is

determined with the mean grain size dm. It can be concluded from Fig. 5

1428

J. Hydraul. Eng., 1991, 117(11): 1419-1439

1 hr

A ' = T p -2 log d90

T

rl * +

^

« I C, [%]| 22.1 19.6 14.4 10.0 4.7 0.0

Downloaded from ascelibrary.org by "Indian Institute of Technology, Guwahati" on 03/06/24. Copyright ASCE. For personal use only; all rights reserved.

ft

"++ «

t-

[» * *

+ i+ * *** A A<£ .A

Y

r i 0

T

1

Y 1

1

r 1

1

_|~Re 2 * = 10[]Re 2 * = 5a •

1

1

0 1 2 3 4

log (Re2*)

FIG. 2. Flow Resistance Data of Clay Suspension Flows over Fixed Rough Bed,

Shown in Terms of Parameters A' = [l/(Vf - 2 • log(hJdmi)] and K

that the strong decrease in transport rates occurs for values of R* below

about 10-15.

For open-channel flow, the thickness of the laminar (viscous) sublayer,

k, is given as (Yalin 1977): X = 11.6Wu* = 11.6(T|/p)/w*, where v is the

kinematic and T| is the dynamic (Newtonian) viscosity. This implies that in

a flow with R* ~ 12, the laminar sublayer is of the same magnitude as the

equivalent sand roughness ks. It is assumed that the relationship for X is

also valid in the case of the clay suspension, using the effective viscosity

|xe2. With regard to the critical value of R* shown in Fig. 5, this implies

that the thickness of the laminar sublayer is of the order of the grain size

of the transported bed material. Thus it appears that once the flow around

the grains becomes laminar, the bed-load transport capacity starts to de-

crease, for otherwise equal flow conditions.

Interestingly, also for the clay suspension flows over fixed rough bed (case

A), a limiting value of RJ = 10 was found below which viscous effects

become important. It is therefore concluded that in the bed-load transport

experiments, the decrease in qB for RJ <~ 10 (case B2) is due to the

increasing viscosity while viscous effects are negligible in the region R* > ~

10 (case Bl).

Transport Equation, Steep Slopes

In the following analysis, only those clay-suspension bed-load transport

experiments with negligible viscous effects (case Bl) are considered. It was

found that the transport rate qB can be described by a simple relationship

including the (corrected) fluid flow rate qr, the bed slope S, and the param-

eter (s — 1), where s = cr/p is the ratio of the grain density to the fluid

density.

A bed-load transport equation of a similar form was already proposed by

Smart and Jaeggi (1983) from their steep flume tests (slope range 3% < S

< 20%) in which clear water was used as transporting fluid:

1429

J. Hydraul. Eng., 1991, 117(11): 1419-1439

V co ic.[m/sl

Downloaded from ascelibrary.org by "Indian Institute of Technology, Guwahati" on 03/06/24. Copyright ASCE. For personal use only; all rights reserved.

Vmeas.[m/S]

FIG. 3. Comparison between Measured Fluid Velocities, V„„m, and those Calcu-

lated with (4), V„k, for Two Steep Flume Data Sets

-^fePM-fc) ; <»

where d30 = the grain size at which 30% by weight of the material is finer;

6„ = the critical Shields stress at initiation of motion; and 9„, = hrjn • SI

[{s — 1) • dm] — the dimensionless bed shear stress determined with the

mixture flow depth hrm (including the space occupied by the transported

solids but corrected for sidewall friction) and the mean grain size d,„. It is

noted that (8) was developed in order to predict also the bed-load transport

rates of the Meyer-Peter and Mueller (1948) experiments covering a slope

range of 0.04% < S < 2% [data given by Smart and Jaeggi (1983)].

The data of the clay-suspension experiments (case Bl) was analyzed to-

gether with the Smart and Jaeggi tests, and a regression calculation yielded

the following transport equation, valid for the slope range 5% < X < 20%:

(9)

' • - < r r ^ (£)"<''"'-^

where qcr = the critical discharge at initiation of motion. The correlation

coefficient squared is r2 = 0.95 and the standard error is SE = 20% of the

1430

J. Hydraul. Eng., 1991, 117(11): 1419-1439

Vcalc.[m/S]

X A

X ./

Downloaded from ascelibrary.org by "Indian Institute of Technology, Guwahati" on 03/06/24. Copyright ASCE. For personal use only; all rights reserved.

2.5 4 " / *

ft

A * / *

A &

2.0 A /

A / X

«

A^ Oy/ x

1.5

* "

£

Uniform

1.0 Data set

grain size Mixture -

J *X

Smart/Jaggi A x

Rickenmann *

0.5 I

0.5 1.0 1.5 2.0 2.5 3.0

Vmeas.[m/S]

FIG. 4. Comparison between Measured Fluid Velocities, Vmem, and those Calcu-

lated with (7), V,.„,c, for Steep Flume Data

qB

qB,H20

3.2

-i 1 1

c, [%]

2.8 T 21.6-22.0

"-••-J

ft 15.6-17.8

+ 12.2-14.9

2.4

« 8.6-9.7

s V-':" < * 4.4-5.8

2.0

+ 0

1

0

ft <5

1.6 *

* **

1.2

"f >

+ " * + /

>

0.8

T *

n J5

1.0 10.0 100.0 1000.0

Re 2 *

FIG. 5. Ratio of Bed Load Transport Rate Measured in Clay Suspension to Value

Obtained in Clear Water, qBlqBM20, as Function of Grain Reynolds Number R*

1431

J. Hydraul. Eng., 1991, 117(11): 1419-1439

1

mean measured transport rate. The critical discharge qcr is expressed by a

relationship proposed by Bathurst et al. (1987), which was slightly modified

to include also the density factor (s - 1) (Rickenmann 1990):

Downloaded from ascelibrary.org by "Indian Institute of Technology, Guwahati" on 03/06/24. Copyright ASCE. For personal use only; all rights reserved.

q„ = 0.065(5 - l)1-67g°-srfi6S'S-1-12 (10)

where d50 = the grain size at which 50% by weight of the material is finer.

By comparing (8) and (9), some differences can be observed. First, the

exponent of the density factor (s - 1) is larger in the second formula. This

is not surprising since no variation of the density ratio was included in the

Smart and Jaeggi (1983) tests. Apart from the clay-suspension data of this

study there is other evidence that the exponent of (s - 1) should be larger

than in (8). Low (1989) conducted a large number of experiments with

lightweight sediments to investigate the effect of a change in the density

ratio s on bed-load transport rates. He used water as transporting fluid, and

thus, no possible viscous effects were involved as in this study. He examined

his results in terms of the parameters used by Smart and Jaeggi (1983) and

concluded that the exponent of the density factor (s - 1) in (8) should be

increased to 1.5 (and the constant adjusted) to obtain best agreement with

his data. An improved version of the Smart/Jaeggi equation (Rickenmann

1990) also better predicts some data of Meyer-Peter and Mueller (1948)

which included transport tests with coal (s = 1.25) and barite (s = 4.22)

as bed load.

A second difference concerns the influence of the slope parameter. In

the analysis of this study, it was found that the exponent of S should be

larger for the steep flume tests than for the flatter slope conditions of the

Meyer-Peter and Mueller experiments. In the development of (8), the num-

ber of tests with a slope S s 5% was considerably larger than the number

of tests for the steeper slope range. This may explain why the exponent 1.6

in (8) is close to the exponent of 1.5, which results from a regression analysis

of the Meyer-Peter and Mueller experiments alone (Rickenmann 1990). It

is interesting that both Mizuyama (1981) and Mizuyama and Shimohigashi

(1985) also proposed a dependency of qB on S2, based on steep flume

experiments in a similar slope range as in this study.

To describe the critical conditions at initiation of motion, the use of (10)

has the advantage that no information of the flow depth is needed to de-

termine the critical discharge qcr. The bed-load transport rate is given as a

function of the flow rate (q) in both (9) and (8). With (9), only the slope,

bed material, and fluid characteristics are needed as further input parameters

whereas (8) requires in addition the use of a flow resistance relationship in

order to determine 0m.

Transport Equation, Steep and Flat Slopes

As an alternative form to (8) or (9), an analysis was made of both the

steep flume experiments (clay-suspension data of the author and clear-water

tests of Smart and Jaeggi) and the low slope data of Meyer-Peter and Mueller

in terms of the dimensionless parameters $>B and 8,„, where the dimension-

less bed-load transport rate is defined as $ B = qB/[g(s - l)^,] 1 - 2 . In this

study, the following equation was determined by regression analysis to give

best agreement between measured and predicted transport rates for the

entire slope range of 0.1% < = S < = 20%:

*° = j^{tY^-«')F1A ' (11

>

1432

J. Hydraul. Eng., 1991, 117(11): 1419-1439

where F = V7(g • /?,..,„) = the Froude number, determined with the mixture

flow depth /(,.,„. The critical Shields stress at initiation of motion was taken

as 0.047 for the Meyer-Peter and Mueller experiments, while for the steep

flume tests this value was somewhat reduced by a slope correction according

Downloaded from ascelibrary.org by "Indian Institute of Technology, Guwahati" on 03/06/24. Copyright ASCE. For personal use only; all rights reserved.

to Stevens et al. (1976). With (11), the correlation coefficient squared is r2

= 0.96 and the standard error SE = 35%, for a total number of 252 ex-

periments. It is interesting that (11) predicts both the steep and low slope

data almost as well as do separate formulas valid only over a limited slope

range. Considering the steep flume data only (115 experiments), as used in

the development of (9), the correlation parameters for (11) are: r2 — 0.96

and SE = 25%. The performance of (11) over the entire slope range can

also be judged from Fig. 6, where calculated transport rates are shown

against measured values on a log scale. It is seen that the scatter is consid-

erably larger in the low slope region (data of Meyer-Peter and Mueller); in

this region the flow conditions are much closer to the critical conditions at

incipient motion, which makes prediction of transport rates much more

difficult.

In comparison, an improved version of the Smart and Jaeggi transport

equation [(8)], with the exponent 1.5 instead of 1.0 for the density factor

(s — 1), gives a similar correlation (r2 = 0.96) and a slightly greater standard

error (SE = 44%) when applied to the entire data set (252 experiments).

If the whole slope range could be as well described by a single formula in

the form of (8) as in the form of (11), the standard error should rather be

smaller since the flow rate could be much more accurately measured in the

experiments than the flow depth. However, by the use of hrm in (11) (con-

l°g(qB,caic.[m3/s m])

,«*/

4m

f

I'rf

o

e

/i*

s°

i*

• !&

J

43: 1

s>

Uniform

' , y< i

Data set grain size

Mixture

i

/ I

Smart/Jaggi * *

Rickenmann *

o

Mtiller

C I r~

X

1 1

-0.7 -0.6 -0.5 -0.4 -0.3 -0.2 -0.1

3

l°g(qB,meas.[m /s m])

FIG. 6. Comparison between Measured Bed Load Transport Rates, <7B,mcas., and

those Predicted by (11), qB,mlc_, for Three Data Sets Covering Slope Range 0.1%

< = 5 < = 20%

1433

J. Hydraul. Eng., 1991, 117(11): 1419-1439

tained in the parameters 0,„ and F), there is also some information included

on the flow resistance. With (8) and (9), on the contrary, the parameter qr

= V • hrf contains only the fictitious flow depth hrf, thus not taking into

account the increased flow depth due to high bed-load concentrations at

Downloaded from ascelibrary.org by "Indian Institute of Technology, Guwahati" on 03/06/24. Copyright ASCE. For personal use only; all rights reserved.

steep slopes. These findings are consistent with the aforementioned con-

clusion that in the form of (8) and (9) the exponent of the slope factor

should be different in the steep and low slope region. To distinguish between

the two regions, a limiting slope of about 10% may be assumed above which

the space occupied by moving grains is significant with respect to the total

flow depth.

DISCUSSION

Increasingly clay concentrations in the clay-suspension experiments of the

author produced an interesting result: For a given slope and flow rate, the

bed-load transport rates increased considerably with increasing fluid density,

particularly at steeper slopes. This change was associated with only a minor

increase in flow depth and in flow velocity, implying that the flow resistance

did not significantly change [Fig. 1(b)]. It can be concluded that the fluid

velocity is largely determined by the slope and the flow rate. Since these

two parameters also determine the bed-load transport rates [see (9)], any

effects of bed load on the fluid velocity could be implicitly accounted for

by q and S. This may explain the rather good performance of (7), in which

the fluid velocity is related to the slope, the flow rate, and a characteristic

grain size.

As a rough approximation, it is proposed that the turbulent flow in a

steep rough channel is mainly governed by the slope, the flow rate, and the

fluid density. For a given q and 5, larger depths were observed for the flows

over a movable bed than for the flows over a fixed bed, while the fluid

velocities were only slightly higher in the latter case. These larger flow depths

(or shear velocities) are mainly associated with the space required for the

transported grains. The only minor difference in fluid velocity suggests that

the adjustment of the (mixture) flow depth could be the primary mechanism

by which the flow supplies the energy required for grain movement. It may

be hypothesized therefore that the fluid-grain mixture is a self-regulating

system, adjusting flow depth and transport rates in such a way that the fluid

velocity is not greatly affected, but instead is largely determined by the slope

and flow rate.

At clay concentrations Q above about 17% (p > = 1.28 g/cm3), a decrease

in the bed-load transport rates was observed with further increasing de-

values. This decrease was found to be associated with a grain Reynolds

number R2 below about 10 (Fig. 5), which implies that the thickness of

the laminar sublayer, \ , is greater than the grain size, d. A similar conclusion

can be drawn based on a study about the hydraulic transport of solids in

pipes (Thomas 1979a, 1979b) in which the transport capacity can be expected

to decrease if \ > ~ d. Negative lift forces may be an explanation for this

decrease. Based on experiments, Davies and Samad (1979) found the lift

forces to decrease with decreasing particle Reynolds numbers; they meas-

ured negative values for R* < ~ 5. Similar experimental results were re-

ported by Coleman (1967).

It is noted that the case B2 experiments of this study were in the hy-

draulically smooth turbulent regime. For a given pressure gradient in pipe

flow, Thomas (1979b) concluded that the transport capacity should be smaller

in laminar than in turbulent flow. Since the flow resistance increases strongly

1434

J. Hydraul. Eng., 1991, 117(11): 1419-1439

in laminar flow with increasing viscosity, larger flow depths will occur in

open channel flows (for a given flow rate), implying an increase in shear

stress. With increasing viscosity, the bed-load transport rate is expected to

decrease; however, a part of the grains may then be transported in suspen-

Downloaded from ascelibrary.org by "Indian Institute of Technology, Guwahati" on 03/06/24. Copyright ASCE. For personal use only; all rights reserved.

sion (not supported by turbulence but due to a very small settling velocity).

It is difficult to predict what the combined effect will be on the bed-load

transport capacity in laminar open-channel flow. Experimental evidence

(Bradley 1986; Wan and Song 1987) suggests that the total transport capacity

may be considerably higher in laminar flow.

Three mechanisms were proposed by Takahashi (1981) for the initiation

of a debris flow: (1) A landslide from a hill slope may transform into a

debris flow; (2) at sufficiently steep slopes ( > ~ 27%) and with large bed

shear stresses, material deposited in a channel bed may be mobilized and

eventually form a debris flow; and (3) accumulation of debris material from

the side slopes can cause a temporary blockage of material to be built up

in the channel, and a debris flow may be initiated when this material starts

to move.

It was noted by Davies (1988) that a temporary blockage of large grains

can occur in a uniform flow of a grain-fluid mixture in a steep, narrow

channel. He further pointed out that the development of roll waves may

cause the pulsing of a debris flow; the critical Froude number for the oc-

currence of roll waves is much smaller in laminar than in turbulent flow.

Based on field data, Davies showed that the limiting conditions developed

for clear-water flows also apply generally for debris-flow conditions. Re-

cently, Savage (1989) demonstrated theoretically that the critical Froude

number for the occurrence of roll waves decreases with increasing cohesion

(Bingham yield stress), viscosity and particle interaction.

In the light of the experimental results of this study, the pronounced

decrease of the bed-load transport rate in macroviscous flow (i.e., having

R2 s 10) may also be seen as an element enhancing the instability of a

uniform flow, and thus offer a possible explanation for the pulsing behavior

of debris flows. In the experiments, macroviscous flow occurred at clay

concentrations Cf above about 17%. Scaling considerations suggest that a

higher critical value of Cf can be expected in the field (Rickenmann 1990).

In the range of fine-material concentrations Cf between 20% and 50%, the

Bingham yield stress TB increases strongly with Cf (Chen 1986; O'Brien and

Julien 1986). According to field data compiled by Davies (1988), the tran-

sition to macroviscous flow may be expected to occur in this concentration

range. For a given flow rate in a torrent, a local input of fine material might

thus cause a sudden decrease in bed-load transport capacity (at R* — 10),

causing a part of the grains to be deposited. If such events are frequent and/

or large enough, the deposited material could form a temporary dam. In

contrast to direct deposition of material from the side slopes, a partial or

full blockage to the flow might therefore also be caused by a change in flow

properties.

CONCLUSIONS

To study the effect of the increasing non-Newtonian properties with in-

creasing fine-material concentration (i.e., increasing Bingham yield stress

and Bingham viscosity) on the flow, experiments were performed with a

clay suspension flowing over a fixed rough bed in a steep channel without

any sediment transport (case A). The flow resistance analysis indicated that

Newtonian formulas can still be used if an adequate viscosity is defined,

1435

J. Hydraul. Eng., 1991, 117(11): 1419-1439

such as the effective viscosity \xe2. No viscous effects could be detected in

the hydraufieally transitional region [10 £ R* < 54, (Fig. 7)]. This is in

agreement with the analysis of the bed-load transport tests (Fig. 5). It is

interesting that a semitheoretical equation can be applied to both the ex-

Downloaded from ascelibrary.org by "Indian Institute of Technology, Guwahati" on 03/06/24. Copyright ASCE. For personal use only; all rights reserved.

perimental flows with intense bed-load transport (with slopes up to 20%)

and experimental debris flows (with slopes up to 47%).

The case A experiments with R? ^ 10 were in the laminar region, and

the corresponding data points lie close to the relation for laminar Newtonian

flow [Fig. 1(a)]. It appears that the hydraulically smooth turbulent regime

(RJ :S 10) is obscured by the formation of a plug flow in a Bingham fluid.

This is a zone with no shearing between adjacent fluid layers, extending

from the flow surface downwards; with increasing Bingham yield stress of

the fluid, this zone occupies increasing proportions of the flow cross section.

When it merges with the viscous sublayer, the flow becomes laminar.

Also bed-load transport experiments were performed with clay-suspen-

sion flows in a steep channel (case B). With increasing clay concentration,

the bed-load transport capacity increased due to the decreasing solid/fluid

ratio s. Once the effect of the increasing viscosity of the fluid becomes

important (at R| s 10) and the flow around the grains is laminar, the trans-

port capacity decreases markedly with further increasing clay concentration.

The bed-load transport experiments in the turbulent region (RJ < 10)

were analyzed together with the data sets of Smart and Jaeggi (1983) and

of Meyer-Peter and Mueller (1948). It was found that in the g^-form [such

as (9)] the equations for the steep and the lower slope range should have

a different exponent in the slope factor. In the $B-form [such as (11)],

however, a single equation may be used for the whole slope range since the

dimensionless bed shear stress 6,„ also contains some information on the

flow resistance increase due to significant bed-load concentrations at steep

slopes. As a result of the interaction between bed-load transport and flow

resistance in the steep slope range (S >~ 10%), two different calculation

procedures are proposed. Since (4) predicts the flow velocity as a function

of the flow depth, it may be used in connection with the bed-load transport

equation [(11)]. This calculation procedure can be applied over a slope range

0.1% <~ S < ~ 20%. If, however, the flow rate is used as input parameter

instead of the flow depth, it is recommended that (7) and (9) are used to

calculate the other parameters of the two-phase flow. These formulas should,

however, only be applied in the steep flume range, i.e., 5% < ~ S <~ 20%.

The two proposed calculation schemes are discussed in more detail by Rick-

enmann (1990).

ACKNOWLEDGMENTS

The presented study was performed at the Laboratory of Hydraulics,

Hydrology and Glaciology of the ETH in Zurich where the writer worked

as a research engineer.

APPENDIX I. REFERENCES

Bagnold, R. A. (1956). "The flow of cohesionless grains in fluids." Phil. Trans.

Royal Soc, 249A, 235-297.

Bathurst, J. C, Graf, W. H., and Cao, H. H. (1987). "Bed load discharge equations

for steep mountain rivers." Sediment transport in gravel bed rivers, Thorne, Ba-

thurst, and Hey, eds., John Wiley and Sons, New York, N.Y., 453-477.

Beverage, J. P., and Culbertson, J. K. (1964). "Hyperconcentrations of suspended

sediment."/. Hydr. Div., ASCE, 90(6), 117-126.

1436

J. Hydraul. Eng., 1991, 117(11): 1419-1439

Bingham, E. C. (1922). Fluidity and plasticity, McGraw-Hill, New York, N.Y.

Bradley, J. B. (1986). "Hydraulics and bed material transport at high fine suspended

sediment concentrations," thesis presented to Colorado State Univ., at Fort Col-

lins, Colorado, in partial fulfillment of the requirements for the degree of Doctor

Downloaded from ascelibrary.org by "Indian Institute of Technology, Guwahati" on 03/06/24. Copyright ASCE. For personal use only; all rights reserved.

of Philosophy.

Chen, C. (1986). "Chinese concepts of modeling hyperconcentrated streamflow and

debris flow." Proc. 3rd Int. Symp. on River Sedimentation, Univ. of Mississippi,

1647-1657.

Chen, C. (1988a). "Generalized viscoplastic modeling of debris flow." /. Hydr.

Engrg., ASCE, 114(3), 237-258.

Chen, C. (1988b). "Generalized solutions for viscoplastic debris flow." /. Hydr.

Engrg., ASCE, 114(3), 259-282.

Coleman, N. L. (1967). "A theoretical and experimental study of drag and lift forces

acting on a sphere resting on a hypothetical stream bed." Proc. 12th IAHR Con-

gress, Fort Collins, Vol. 3, 184-192.

Costa, J. E. (1984). "Physical geomorphology of debris flows." Developments and

applications of geomorphology Costa and Fleisher, eds., Springer-Verlag, Berlin,

Germany, 268-317.

Davies, T. R. H. (1988). "Debris flow surges—A laboratory investigation." Mitt.

Nr. 96 der Versuchsanstalt fur Wasserbau, Hydrologie und Glaziologie, ETH

Zurich.

Davies, T. R. H., andSamad, M. F. A. (1978). "Fluid dynamic lift on a bed particle."

/. Hydr. Div., ASCE, 104(8), 1171-1182.

Einstein, H. A. (1934). "Der hydraulische oder Profilradius." Schweiz. Bauzeitting, 8.

Hong, R.-J., Karim, M. R., and Kennedy, J. F. (1984). "Low-temperature effects

on flow in sand-bed streams." J. Hydr. Engrg., ASCE, 110(2), 109-125.

Jaeggi, M. N. R. (1983). "Alternierende Kiesbanke," Diss. ETH Nr. 7208, Ziirich

Mitt. Nr. 62 der Versuchsanstalt fur Wasserbau, Hydrologie und Glaziologie der

ETH Zurich.

Johnson, A. M. (1970). Physical processes in geology. Freeman Cooper and Co.,

San Francisco, Calif.

Julien, P. Y., and Lan, Y. (1991). "Rheology of hyperconcentrations." /. Hydr.

Engrg., ASCE, 117(3), 346-353.

Kikkawa, W., and Fukuoka, S. (1969). "The characteristics of flow with wash load."

Proc. 13th IAHR Congress, Kyoto, Japan, Vol. 2, 233-240.

Lau, Y. L. (1987). Discussion of "Low temperature effects on flow in sand-bed

streams," by Hong et al. (1984). J. Hydr. Engrg., ASCE, 113(1), 111-115.

Low, H. S. (1989). "Effect of sediment density on bed-load transport." /. Hydr.

Engrg., ASCE, 115(1), 124-137.

Luque, R. F., and van Beek, R. (1976). "Erosion and transport of bed-load sedi-

ment."/. Hydr. Res., 14(2), 127-144.

Meyer-Peter, E., and Mueller, R. (1948). "Formulas for bed-load transport." Proc.

2nd meeting IAHSR, Stockholm, Sweden, 39-64.

Mizuyama, T. (1977). "Bedload transport in steep channels." thesis presented to

Kyoto Univ., at Kyoto, Japan, in partial fulfillment of the requirements for the

degree of Doctor of Philosophy.

Mizuyama, T. (1981). "An intermediate phenomenon between debris flow and bed

load transport." Proc. Symp. on Erosion and Sed. Transp., IAHS Publication No.

132, Int. Association of Hydrol. Sci., 212-224.

Mizuyama, T. and Shimohigashi, H. (1985). "Influence of fine sediment concentra-

tion on sediment transport rates." Jpn. Civ. Engrg. J., 27(1), 46-49 (in Japanese).

Naik, B. (1983). "Mechanics of mudflow treated as the flow of a Bingham fluid,"

thesis presented to Washington State Univ., at in partial fulfillment of the re-

quirements for the degree of Doctor of Philosophy.

O'Brien, J. S., and Julien, P. Y. (1986). "Rheology of non-Newtonian fine sediment

mixtures." Proc. Speciality Conference on Advances in Aerodynamics, Fluid Me-

chanics, and Hydraulics, ASCE, New York, N.Y., 989-996.

Quian, Y., Yang, W., Zhao W., Cheng X., Zhang L., and Xu W. (1980). "Basic

1437

J. Hydraul. Eng., 1991, 117(11): 1419-1439

characteristics of flow with hyperconcentration of sediment." Proc. Int. Symp. on

River Sedimentation, Beijing, China, 183-184.

Rickenmann, D. (1990). "Bedload transport capacity of slurry flows at steep slopes."

Diss. ETH Nr. 9065. Zurich Mitt. Nr. 103 der Versuchsanstalt fur Wasserbau,

Hydrologie und Glaziologie der ETH Zurich.

Downloaded from ascelibrary.org by "Indian Institute of Technology, Guwahati" on 03/06/24. Copyright ASCE. For personal use only; all rights reserved.

Savage, S. B. (1989). "Flow of granular materials." Theoretical and applied me-

chanics. Germain, Piau, and Caillerie, eds., Elsevier, Amsterdam, The Nether-

lands, 241-266.

Shields, A. (1936). "Anwendung der Aehnlichkeitsmechanik und der Turbulenz-

forschung auf die Geschiebebewegung," Mitt. d. Preuss. Vers. anst. fur Wasserbau

und Schiffbau, Berlin, Nr. 26.

Simons, D. B., Richardson, E. V., and Haushild, W. L. (1963). "Some effects of

fine sediment on flow phenomena." Water-Supply Paper 1498-G, U.S. Geological

Survey.

Smart, G. M. (1984). "Sediment transport formula for steep channels." J. Hydr.

Engrg., ASCE, 110(3), 267-276.

Smart, G. M., and Jaeggi, M. (1983). "Sediment transport on steep slopes," Mitt.

Nr. 64 der Versuchsanstalt fur Wasserbau, Hydrologie und Glaziologie, ETH

Zurich.

Stevens, M. A., Simons, D. B., and Lewis, G. L. (1976). "Safety factors for riprap

protection." J. Hydr. Div., ASCE. 102(5), 637-655.

Takahashi, T. (1978). "Mechanical characteristics of debris flow." J. Hvdr. Div.,

ASCE, 104(8), 1153-1169.

Takahashi, T. (1981). "Debris flow." Ann. Rev. Fluid Mech., 13, 57-77.

Thomas, A. D. (1979a). "Predicting the deposit velocity for horizontal turbulent

pipe flow of slurries." Int. J. Multiphase Flow. 5, 113-129.

Thomas, A. D. (1979b). "The role of laminar/turbulent transition in determining

the critical deposit velocity and the operating pressure gradient for long distance

slurry pipelines." Proc. 6th Int. Conf. on the Hydraulic Transport of Solids in

Pipes, BHRA Fluid Engineering, Cranfield, Bedford. England, 13-27.

Wan, Z. (1982). "Bed material movement in hyperconcentrated flow." Ser. Paper

31, Inst. Hydrodyn., Tech. Univ. of Denmark, Lyngby, Denmark.

Wan, Z., and Song, T. (1987). "The effect of fine particles on vertical concentration

distribution and transport rate of coarse particles." Proc. 22nd IAHR Congress,

Lausanne, Switzerland. 80-85.

Woo, H. (1985). "Sediment transport in hyperconcentrated flows." thesis presented

to Colorado State Univ., at Fort Collins, Colo., in partial fulfillment of the re-

quirements for the degree'of Doctor of Philosophy.

Yalin, M. S. (1977). Mechanics of sediment transport, 2nd Ed., Pergamon Press,

Oxford, England.

APPENDIX ! l . NOTATION

The following symbols are used hi this paper:

A = constant in flow resistance equation;

A* = parameter in velocity equation for debris-flow front;

B = flume width;

Cf = volume concentration of fine material;

Ci = clay-concentration level;

d = grain size;

d,„ = mean grain size;

d30 = characteristic grain size, 30% of the material by weight is finer;

d5tt = characteristic grain size, 50% of the material by weight is finer;

d90 = characteristic grain size, 90% of the material by weight is finer;

(dv/dy) = fluid velocity gradient (shear rate) perpendicular to flow direc-

tion;

1438

J. Hydraul. Eng., 1991, 117(11): 1419-1439

Froude number = (V/(g/hy-2);

Darcy-Weisbach friction facioi = (8-iy'pV2);

sediment-feeding rate;

acceleration due to gravity;

Downloaded from ascelibrary.org by "Indian Institute of Technology, Guwahati" on 03/06/24. Copyright ASCE. For personal use only; all rights reserved.

measured flow depth;

flow depth;

(reduced) flow depth corrected for sidewall influence;

fictitious fluid flow depth in flow of grain-fluid mixture = (qj

V), corrected for sidewall influence;

mixture flow depth (including space occupied by moving grains),

corrected for sidewall influence;

Strickler coefficient for flume walls;

equivalent sand roughness;

flow rate in flume;

volumetric water or fluid discharge per unit width;

reduced fluid discharge per unit width, corrected for sidewall

influence;

critical flow discharge at beginning of bed-load transport;

volumetric bed-load transport rate per unit width;

Reynolds number defined with effective viscosity |x(,2 = {AVhpl

particle Reynolds number defined with effective viscosity \x.L,2 =

(T<*rfp/u,(,,);

correlation coefficient (between measured and calculated val-

ues);

slope (= tan (3);

standard error;

ratio between grain and fluid density = (cr/p);

mean velocity of debris-flow front;

average fluid velocity;

shear velocity = (ghS)U2\

bed slope angle;

coefficient in flow resistance formula of Smart and Jaeggi (1983);

coefficient in flow resistance equation;

coefficient in flow resistance formula of Smart and Jaeggi (1983);

dynamic fluid viscosity;

Bingham viscosity;

dimensionless bed shear stress = (T„/pg(s — l)d,„) = (hSI(s ~

i)4,);

critical value of 9 at initiation of motion;

dimensionless bed shear stress in grain-fluid mixture; = {hrmSI

{s - 1)4,);

thickness of laminar (viscous) sublayer;

effective viscosity = (T| S + iBh/2V);

kinematic viscosity;

fluid density;

grain density;

shear stress in fluid;

fluid shear stress at bed = (gpSh);

Bingham (yield) stress; and

dimensionless bed-load transport rate = qB/[g(s ~ l ) ^ ] 1 ' 2 -

1439

J. Hydraul. Eng., 1991, 117(11): 1419-1439

You might also like

- Two-Dimensional Shear-Layer Entrainment, DimotakisDocument6 pagesTwo-Dimensional Shear-Layer Entrainment, DimotakisAmbara BernabeuNo ratings yet

- TubiditasDocument9 pagesTubiditasDrugis CatarsisNo ratings yet

- Ó Náraigh2010JNNFMDocument20 pagesÓ Náraigh2010JNNFMRafael SalgadoNo ratings yet

- Journal of Non-Newtonian Fluid Mechanics: Guilherme Henrique Fiorot, Geraldo de Freitas MacielDocument7 pagesJournal of Non-Newtonian Fluid Mechanics: Guilherme Henrique Fiorot, Geraldo de Freitas MacielEnijad ArnautNo ratings yet

- Settling VelocityDocument10 pagesSettling VelocityMunhu Wakanaka100% (1)

- Data 10Document38 pagesData 10Mauro hernandezNo ratings yet

- H The Foundation May Be Used For Cases of Horizontal Permeability 10 To 100 TimesDocument9 pagesH The Foundation May Be Used For Cases of Horizontal Permeability 10 To 100 Timesomed muhammadNo ratings yet

- Mode of TransportDocument6 pagesMode of TransportZulisNo ratings yet

- Water 13 01460 v2Document16 pagesWater 13 01460 v2Angga SyahputraNo ratings yet

- Active Control of A Backward Facing Step Flow With Plasma ActuatorsDocument9 pagesActive Control of A Backward Facing Step Flow With Plasma ActuatorsGopi KrishnaNo ratings yet

- Eddy Viscosity: Adoc 4060/5060 Spring 2013 Chris JenkinsDocument17 pagesEddy Viscosity: Adoc 4060/5060 Spring 2013 Chris JenkinsGiovannaNo ratings yet

- Sludge Handling Characteristics in Piped SystemsDocument6 pagesSludge Handling Characteristics in Piped Systemschouli8No ratings yet

- 28asce 290733 9429 282002 29128 3A12 281060 29Document9 pages28asce 290733 9429 282002 29128 3A12 281060 29Basem MohamedNo ratings yet

- 05 Muhammad KhurramDocument9 pages05 Muhammad KhurramDavid SamudraNo ratings yet

- DR Neguse T Hydralic Structure 1 2Document34 pagesDR Neguse T Hydralic Structure 1 2Ahmed AmanNo ratings yet

- A High Resolution Seismic Study in The Gulf of MexicoDocument11 pagesA High Resolution Seismic Study in The Gulf of MexicoAlan CherryNo ratings yet

- By M. Salih Kirkgoz ABSTRACT: Velocity Measurements, Using A Laser-Doppler Anemometer, Are CarDocument19 pagesBy M. Salih Kirkgoz ABSTRACT: Velocity Measurements, Using A Laser-Doppler Anemometer, Are CarBiman KalitaNo ratings yet

- Bed-Load Transport Equation For Sheet Flow: Technical NotesDocument5 pagesBed-Load Transport Equation For Sheet Flow: Technical Notesomed muhammadNo ratings yet

- Bedload Transport in Alluvial Channels: Miguel Bravo-Espinosa W. R. Osterkamp and Vicente L. LopesDocument13 pagesBedload Transport in Alluvial Channels: Miguel Bravo-Espinosa W. R. Osterkamp and Vicente L. Lopesomed muhammadNo ratings yet

- Chapter 15 Dewatering - 2016 - Wills Mineral Processing Technology Eighth EditionDocument22 pagesChapter 15 Dewatering - 2016 - Wills Mineral Processing Technology Eighth EditionSAYEENo ratings yet

- VanGent 1995 JWPCOE ASCE PorousFlowThroughRubbleMoundMaterialDocument7 pagesVanGent 1995 JWPCOE ASCE PorousFlowThroughRubbleMoundMaterialputhenkulamNo ratings yet

- Spe 147 PaDocument8 pagesSpe 147 PaJagerstacey JagerNo ratings yet

- Abstract:: by Alain G. Faure and Jos D. Viana Da Mata 2Document14 pagesAbstract:: by Alain G. Faure and Jos D. Viana Da Mata 2Bhaskar RanjanNo ratings yet

- Global Stability of A Lid-Driven Cavity With Throughflow: Flow Visualization StudiesDocument12 pagesGlobal Stability of A Lid-Driven Cavity With Throughflow: Flow Visualization StudiesDebendra Nath SarkarNo ratings yet

- (Asce) Hy 1943-7900 0001261Document11 pages(Asce) Hy 1943-7900 0001261Andres CalderonNo ratings yet

- Mass Transfer TheoriesDocument4 pagesMass Transfer TheoriespandianvijaybharathiNo ratings yet

- Progress in Debris Flow Modeling: Tamotsu TakahashiDocument2 pagesProgress in Debris Flow Modeling: Tamotsu TakahashiadikusumaNo ratings yet

- Wave Interaction With A Flexible Porous Breakwater in A Two-Layer FluidDocument8 pagesWave Interaction With A Flexible Porous Breakwater in A Two-Layer FluidShyam TPNo ratings yet

- Fluid Flow Through Randomly Packed Columns and Fluidized BedsDocument6 pagesFluid Flow Through Randomly Packed Columns and Fluidized BedsKyriacos ZygourakisNo ratings yet

- Computational Dam-Break Hydraulics Over Erodible Sediment BedDocument15 pagesComputational Dam-Break Hydraulics Over Erodible Sediment BedZurab JikiaNo ratings yet

- 6.sedimentation and Erosion HydraulicsDocument102 pages6.sedimentation and Erosion HydraulicsPuerto Parra Plan Aguas SantanderNo ratings yet

- On Prediction and Unified Correlation For Decay of Vertical Buoyant JetsDocument6 pagesOn Prediction and Unified Correlation For Decay of Vertical Buoyant JetsHahaNo ratings yet

- Abramian Et Al. 2020 - Laboratory Rivers Adjust Their Shape To Sediment TransportDocument10 pagesAbramian Et Al. 2020 - Laboratory Rivers Adjust Their Shape To Sediment TransportClemente GotelliNo ratings yet

- Abul Azm 1993 Wave Diffraction Through Submerged BreakwatersDocument19 pagesAbul Azm 1993 Wave Diffraction Through Submerged Breakwaterswangzerun1997No ratings yet

- BathurstDocument19 pagesBathurstJairo MejíaNo ratings yet

- (Asce) Hy 1943-7900 0000153Document15 pages(Asce) Hy 1943-7900 0000153ANUBHAB PANIGRAHINo ratings yet

- Mass Transfer IN Laminar Region Between Liquid AND Packing Material Surface in The Packed Bed'Document5 pagesMass Transfer IN Laminar Region Between Liquid AND Packing Material Surface in The Packed Bed'Juan A. AglrNo ratings yet

- Chemical Engineering Science Volume 19 Issue 3 1964. N.K. Roy D.K. Guha M.N. Rao. Suspension of Solids in A Bubbling LiquidDocument11 pagesChemical Engineering Science Volume 19 Issue 3 1964. N.K. Roy D.K. Guha M.N. Rao. Suspension of Solids in A Bubbling LiquidMaria Luisa Sandoval OchoaNo ratings yet

- Analytical Solution For Two-Dimensional Displacement Flow in A Curved Down-Sloping DuctDocument14 pagesAnalytical Solution For Two-Dimensional Displacement Flow in A Curved Down-Sloping DuctNasim KazemiNo ratings yet

- Chapter 8 18 PDFDocument1 pageChapter 8 18 PDFAlwin WanNo ratings yet

- Hydraulic ConductivityDocument20 pagesHydraulic Conductivitybenjielust22No ratings yet

- CHAMANI e RAJARATNAM 1994Document6 pagesCHAMANI e RAJARATNAM 1994Valter AlbinoNo ratings yet

- International Journal of Heat and Mass TransferDocument12 pagesInternational Journal of Heat and Mass Transferjean miguel oscorima celisNo ratings yet

- Scaling and Intermittency in Turbulent Flows of Elastoviscoplastic FluidsDocument12 pagesScaling and Intermittency in Turbulent Flows of Elastoviscoplastic FluidsiantocNo ratings yet

- FBR DesignDocument12 pagesFBR Designabdul qaharNo ratings yet

- Viscoelastic Fluid Effect On The Surface Wave PropagationDocument8 pagesViscoelastic Fluid Effect On The Surface Wave PropagationDante Ali Vilchez SanchezNo ratings yet

- Analysis of Swirling Flow in Hydrocyclones Operating Under Dense RegimeDocument11 pagesAnalysis of Swirling Flow in Hydrocyclones Operating Under Dense RegimeZhao YuqiaoNo ratings yet

- Formula For Sediment Transport in Rivers, Estuaries and Coast PDFDocument12 pagesFormula For Sediment Transport in Rivers, Estuaries and Coast PDFDaniel Bucheli PérezNo ratings yet

- MacVicar and Obach 2015Document13 pagesMacVicar and Obach 2015Satya PrakashNo ratings yet

- Paleev 1966Document5 pagesPaleev 1966tritium.1984No ratings yet

- Effects of Sediment Grain Size and Channel Slope On The Stability of River BifurcationsDocument15 pagesEffects of Sediment Grain Size and Channel Slope On The Stability of River BifurcationsHưng Huỳnh TấnNo ratings yet

- Gravitational Fall Velocity of in Viscous Fluid by Tsang-Jung Chang and Ben Chie Yen,:Z Fellow, ASCEDocument7 pagesGravitational Fall Velocity of in Viscous Fluid by Tsang-Jung Chang and Ben Chie Yen,:Z Fellow, ASCEyasamanNo ratings yet

- An Evaluation of Suspended Sediment Concentration On Von Karman's ConstantDocument10 pagesAn Evaluation of Suspended Sediment Concentration On Von Karman's ConstantInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Suppression of Von Karman Vortex Streets Past PoDocument31 pagesSuppression of Von Karman Vortex Streets Past PoLuis PressoNo ratings yet

- F M D C: Luid Echanics in The Riven AvityDocument45 pagesF M D C: Luid Echanics in The Riven AvitydindarkarNo ratings yet

- Ellison, Turner - 1959 - Turbulent Entrainment in Stratified FlowsDocument26 pagesEllison, Turner - 1959 - Turbulent Entrainment in Stratified FlowsmatishNo ratings yet

- Ce376 Pipe Flow-2Document47 pagesCe376 Pipe Flow-2enes arikanNo ratings yet

- Sediment Gravity FlowDocument38 pagesSediment Gravity FlowkorewaNo ratings yet

- Lab 12Document4 pagesLab 12Samuel RodgersNo ratings yet

- Atomic Structure For Grade 10Document4 pagesAtomic Structure For Grade 10Aja AndersonNo ratings yet

- PHA6113 LAB ViscosityDocument4 pagesPHA6113 LAB ViscosityPeter Jon SantiagoNo ratings yet

- Microstrip AntennaDocument56 pagesMicrostrip AntennaPrajakta MoreNo ratings yet

- Physics 2nd Shifting Concepts-2Document2 pagesPhysics 2nd Shifting Concepts-2BRIDGETTE KAYCEE CRUZNo ratings yet

- Chemistry Form 5 (Soaps)Document7 pagesChemistry Form 5 (Soaps)emir906No ratings yet

- Fundamentals of Beam BracingDocument16 pagesFundamentals of Beam Bracingofingjbrm100% (1)

- l5 Spring BalanceDocument11 pagesl5 Spring BalanceNur Syamiza ZamriNo ratings yet

- Relation To Other Fields: Difference Between Classical and Modern PhysicsDocument1 pageRelation To Other Fields: Difference Between Classical and Modern Physicspiping stressNo ratings yet

- Details of Fluid MechanicsDocument25 pagesDetails of Fluid MechanicsJeevan RoyNo ratings yet

- Study of Zero Chromatic Dispersion in PCF Using Different MaterialDocument3 pagesStudy of Zero Chromatic Dispersion in PCF Using Different MaterialerpublicationNo ratings yet

- Aiman Hakimi Assignment ChemistryDocument6 pagesAiman Hakimi Assignment ChemistryKaremNo ratings yet

- 2 Physics of WeldingDocument28 pages2 Physics of WeldingSUMEETNo ratings yet

- 8 X Y 16 X 8 Y: 3. Compounds Are Composed of Atoms of More Than OneDocument10 pages8 X Y 16 X 8 Y: 3. Compounds Are Composed of Atoms of More Than OneSamantha DumagpiNo ratings yet

- D4923-Standars Specification For Reinforced Thermosetting Plastic PolesDocument11 pagesD4923-Standars Specification For Reinforced Thermosetting Plastic PoleshedpalNo ratings yet

- Practical 22.1 Iron Wool Redox TitrationDocument6 pagesPractical 22.1 Iron Wool Redox TitrationDanielle CarterNo ratings yet

- Seminar Presentation PPT On Reactive Powder Concrete (Civil Engineering)Document39 pagesSeminar Presentation PPT On Reactive Powder Concrete (Civil Engineering)Siddhartha Siddhu100% (19)

- ADMIX - RotosolverDocument2 pagesADMIX - RotosolverRaul DiazNo ratings yet

- Chapter 12. Heat Transfer To Fluids Without Phase ChangeDocument10 pagesChapter 12. Heat Transfer To Fluids Without Phase ChangeSwapna VadlamaniNo ratings yet

- Powder Technology Lecture SlidesDocument12 pagesPowder Technology Lecture Slidesruano25No ratings yet

- Datasheet DXDocument2 pagesDatasheet DXAsnawirarrr100% (2)

- Effects of Moisture Content On The Foundry Properties of Yola Natural SandDocument12 pagesEffects of Moisture Content On The Foundry Properties of Yola Natural SandatikNo ratings yet

- Chapter 1Document13 pagesChapter 1Daniel ParkerNo ratings yet

- Chapter 1 Introduction To Engineering EconomyDocument8 pagesChapter 1 Introduction To Engineering EconomyJason AdiaNo ratings yet

- Solubility of Oxalic, Malonic, Succinic, Adipic, Maleic, Malic, Citric, and Tartaric Acids in Water - Alexander Apelblat & Emanuel ManzurolaDocument4 pagesSolubility of Oxalic, Malonic, Succinic, Adipic, Maleic, Malic, Citric, and Tartaric Acids in Water - Alexander Apelblat & Emanuel ManzurolaGerardoEstebanRodríguezNo ratings yet

- ME6601 QbsdfwsdfsDocument8 pagesME6601 QbsdfwsdfsvivekzzNo ratings yet