Professional Documents

Culture Documents

MTU Gendrive Spec 4000G 03 3D3E W2A

Uploaded by

Petrus GunturOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

MTU Gendrive Spec 4000G 03 3D3E W2A

Uploaded by

Petrus GunturCopyright:

Available Formats

Gendrive

Series 4000 Gx3

for Power Generation Standard Backup Applications

with water-to-air charge air cooling

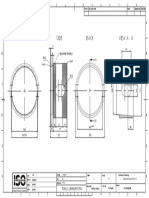

Dimensions and Masses

Engine Dimensions (LxWxH) mm (in) Mass, dry kg (lbs)

12V 2490 x 1610 x 1870 (98 x 63 x 74) 6200 (13670)

16V 2865 x 1660 x 1810 (113 x 65 x 71) 7700 (16975)

20V 3410 x 1615 x 2050 (134 x 64 x 81) 9640 (21255)

All dimensions are approximate, for complete information refer to the installation drawing.

Engine Model

Bore/stroke mm (in) 170/210 (6.7/8.3)

Cylinder configuration 90°V

Displacement/cylinder l (cu in) 4.77 (291)

Displacement, total l (cu in) 12V: 57.2 (3491), 16V: 76.3 (4655), 20V: 95.4 (5822)

Fuel specification EN 590, Grade No.1-D/2-D (ASTM D975-00)

Application group Power definition

Standby Power (3D) Emergency service, fuel stop power, Load factor: ≤ 85%, Operating hours: max. 500 h/year,

IFN Overload: Fuel stop power (IFN)

Standby Power with Overload (3E) Emergency service, ICXN Load factor: ≤ 85%, Operating hours: max. 500 h/year,

Overload: 10% capability (ICXN)

Power definition according to ISO 3046 (ratings also correspond to SAE J 1995 and SAE J 1349 standard conditions).

Consult your MTU distributor/dealer for the rating that will apply to your specific application.

Rated power is without fan drive. The power consumption of any fan drive has to be deducted during designing of a generator set.

Power. Passion. Partnership.

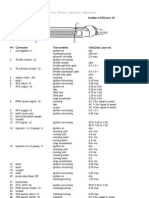

Standby Power (3D)

Engine Type Rated power kW (bhp) at 1500 rpm (50Hz) Optimization

24 31

NEA Singapore for ORDE

China NRMM Stage III

Fuel consumption

(GB20981-2014)

optimized

12V 4000 G23 1575 (2112) x x x

12V 4000 G63 1750 (2347) x x

16V 4000 G23 1965 (2635) x x x

16V 4000 G63 2185 (2930) x x x

20V 4000 G23 2420 (3245) x x x

20V 4000 G63 2670 (3580) x x x

20V 4000 G63L 2850 (3822) x x x

Fan power requirement not considered

Engine Type Rated power kW (bhp) at 1800 rpm (60Hz) Optimization

3 19

EMERG Tier 2 (40 CFR 60)

US EPA Nonroad Tier 2

compliant (40 CFR 89)

US EPA Stationary

Fuel consumption

optimized

12V 4000 G43 1736 (2328) x x x

12V 4000 G83 1910 (2561) x x x

16V 4000 G43 2280 (3058) x x x

16V 4000 G83 2500 (3352) x x x

16V 4000 G83L 2740 (3674) x x x

20V 4000 G43 2740 (3674) x x x

20V 4000 G83 3010 (4036) x x x

20V 4000 G83L 3490 (4680) x x x

Fan power requirement not considered

3 19 24 31 reference to emission level in price list

2 I Standard Backup Applications

Standby Power with Overload (3E)

Engine Type Rated power kW (bhp) at 1500 rpm (50Hz) Optimization

1 24 31

NEA Singapore for ORDE

China NRMM Stage III

(NOx < 1700 mg/m3N)

Fuel consumption

TA-Luft optimized

(GB20981-2014)

optimized

12V 4000 G23 1420 (1904) x x x x

12V 4000 G63 1575 (2112) x x x

16V 4000 G23 1798 (2411) x x x x

16V 4000 G63 1965 (2635) x x x x

20V 4000 G23 2200 (2950) x x x x

20V 4000 G63 2420 (3245) x x x x

20V 4000 G63L 2590 (3473) x x x x

Fan power requirement not considered

1 24 31 reference to emission level in price list

3 I Standard Backup Applications

Subject to change. | 32310321 | Edition 01/16 | ENC 2016-03.

Standard Equipment

Starting System 2 electric starters (24 VDC/2-pole)

Fuel System “Common-Rail“ fuel injection system, with low and high pressure fuel pumps, fuel pressure accumulator, high pressure

fuel lines and electronically controlled injection

Lube Oil System Forced feed lubrication system with piston cooling, lube oil circulation pump with safety valve, lube oil multi-stage

filter, lube oil heat exchanger, oil centrifugal filter (only for 3G, 3F and 3H)

Combustion Air System Exhaust turbochargers, intercooler

Cooling System Coolant circulation pump and coolant thermostat for jacket water cooling circuit, coolant circulation pump and

coolant thermostat for charge air cooling circuit

Engine Mounting Set of engine mounting brackets at engine free and driving end

Engine Management Integrated electronic engine control and monitoring system ADEC

Optional Equipment

Starting System Compressed air starter, redundant starting system

Fuel System Fuel pre-filter, special fuel pre-filter with water separator

Lube Oil System Centrifugal lube oil filter, oil replenishment system

Combustion Air System Heavy duty air filters

Cooling System Electric coolant pre-heating unit with circulating pump, thermoastat and non-return flap

Engine Mounting Resilient engine mounts (rubber elements), rigid engine mounts

Reference conditions:

– Intake-air temperature: 25°C (77°F)

– Ambient air pressure: 1 bar (14.5 psi)

– Altitude above sea level: 100 m (328 ft)

Subject to change without notice. Customization possible. Engines illustrated in this document may feature options not fitted as standard.

MTU Friedrichshafen GmbH I MTU Asia Pte Ltd I MTU America Inc.

Rolls-Royce Power Systems Companies

www.mtu-online.com

You might also like

- MTU Gendrive Spec 4000Gx03 3F3H W2A 1 16Document4 pagesMTU Gendrive Spec 4000Gx03 3F3H W2A 1 16TapasNo ratings yet

- MTU Gendrive Spec 2000G 05 3D W2ADocument4 pagesMTU Gendrive Spec 2000G 05 3D W2AcafubodoNo ratings yet

- Gaki-Papanastassiou Et Al 1997-Coastal Vulnerability Assessment to Sea-level Rise BαsedDocument4 pagesGaki-Papanastassiou Et Al 1997-Coastal Vulnerability Assessment to Sea-level Rise BαsedJoharsyahNo ratings yet

- Series 2000 Gx5: For Power Generation Continuous/Prime/Peak Applications With Air-To-Air Charge Air CoolingDocument4 pagesSeries 2000 Gx5: For Power Generation Continuous/Prime/Peak Applications With Air-To-Air Charge Air CoolingPrince ChaudharyNo ratings yet

- DETROIT 4000 03 DieselGeneratorDocument2 pagesDETROIT 4000 03 DieselGeneratorMarvin Garcia50% (2)

- Series 12V 1600 G - 0: For Gendrive Application With Air Charge-Air CoolingDocument2 pagesSeries 12V 1600 G - 0: For Gendrive Application With Air Charge-Air CoolingJim LiebNo ratings yet

- MTU Gendrive Spec 12V16V18V2000Gx5 3D 3E W2ADocument3 pagesMTU Gendrive Spec 12V16V18V2000Gx5 3D 3E W2Atinhotrading .jinchaoNo ratings yet

- Series 4000: Generator/Pump Power Packages For The Oil & Gas Industry - Constant SpeedDocument2 pagesSeries 4000: Generator/Pump Power Packages For The Oil & Gas Industry - Constant Speedavinash_1229No ratings yet

- Series 1600 Gx0: For Power Generation Continuous/Peak Applications With Air-To-Air Charge Air CoolingDocument5 pagesSeries 1600 Gx0: For Power Generation Continuous/Peak Applications With Air-To-Air Charge Air CoolingAlberto F. Apablaza MezaNo ratings yet

- MtuDocument2 pagesMtuGerman O.No ratings yet

- MTU Datasheet s4000px3 Constant SpeedDocument2 pagesMTU Datasheet s4000px3 Constant SpeedKrish100% (1)

- Mtu 300-1000kvaDocument3 pagesMtu 300-1000kvaivanNo ratings yet

- MTU 400 KW 8V1600G80S EPA Tier 3 Emissions Engine Spec SheetDocument2 pagesMTU 400 KW 8V1600G80S EPA Tier 3 Emissions Engine Spec SheetJoanne CordesNo ratings yet

- Mtu Series 4000Document2 pagesMtu Series 4000Mohammad Hazbehzad100% (1)

- SERIES 4000: Oil & GasDocument3 pagesSERIES 4000: Oil & GasSarita IndustriesNo ratings yet

- MTU4000 Industrial Spec S4000Cx1Document2 pagesMTU4000 Industrial Spec S4000Cx1amir sadighiNo ratings yet

- Series 4000: Engines For Industrial and Mining ApplicationsDocument2 pagesSeries 4000: Engines For Industrial and Mining Applicationswaleed yehia100% (1)

- Series 2000 Gx6: For Power Generation Continuous/Prime/Peak Applications With Water-To-Air Charge Air CoolingDocument4 pagesSeries 2000 Gx6: For Power Generation Continuous/Prime/Peak Applications With Water-To-Air Charge Air Cooling林哲弘No ratings yet

- Series 2000: Stationary Industrial Engines For The Oil & Gas IndustryDocument2 pagesSeries 2000: Stationary Industrial Engines For The Oil & Gas IndustryLeonardo ViilalobosNo ratings yet

- MTU Rail Spec 4000 03Document2 pagesMTU Rail Spec 4000 03emmsh71No ratings yet

- MTU Series 2000 Mining Engines 12V2000Cx6 3235061 1505796670Document2 pagesMTU Series 2000 Mining Engines 12V2000Cx6 3235061 1505796670jamal molana100% (1)

- Carrefour Ramadan PromotionDocument3 pagesCarrefour Ramadan PromotionHdjdhdbrb3odfbNo ratings yet

- Avds-1790 Series Engine.: For Combat Vehicles 895 KW (1200HP), 783 KW (1050HP), 700 KW (940HP)Document2 pagesAvds-1790 Series Engine.: For Combat Vehicles 895 KW (1200HP), 783 KW (1050HP), 700 KW (940HP)Omar ZinelabidineNo ratings yet

- Diesel Engines Series 4000 R04: For Push-Pull Trains and Locomotives Eu Stage IiibDocument2 pagesDiesel Engines Series 4000 R04: For Push-Pull Trains and Locomotives Eu Stage IiibJavier Quintero100% (1)

- Marine Spec 10V12V16V2000M86 1DDocument2 pagesMarine Spec 10V12V16V2000M86 1DnaufragatoNo ratings yet

- DIESEL ENGINES 10V/12V/16V 2000 M96: MarineDocument2 pagesDIESEL ENGINES 10V/12V/16V 2000 M96: MarineFelice CimminoNo ratings yet

- Diesel Engines 16V 4000 M53M63 1ADocument2 pagesDiesel Engines 16V 4000 M53M63 1AMario100% (1)

- Mtu 12V 16V4000M90 1DSDocument2 pagesMtu 12V 16V4000M90 1DSzaki100% (1)

- Servicios Jac MotoresDocument250 pagesServicios Jac MotoresArbey Gonzalez67% (3)

- Diesel Engines 10V/12V/16V 2000 M86: For Fast Vessels With Intermittent Load Factors (1D)Document2 pagesDiesel Engines 10V/12V/16V 2000 M86: For Fast Vessels With Intermittent Load Factors (1D)Micael FigueiraNo ratings yet

- OG Spec 6R1000Document2 pagesOG Spec 6R1000adlonusNo ratings yet

- DIESEL ENGINES 12V/16V 2000 M92: MarineDocument2 pagesDIESEL ENGINES 12V/16V 2000 M92: MarineAlexlo LopezNo ratings yet

- Diesel Engines 16V 4000 M63R/M63/M63L: For Vessels With Unrestricted Continuous Operation (1A)Document2 pagesDiesel Engines 16V 4000 M63R/M63/M63L: For Vessels With Unrestricted Continuous Operation (1A)bbssNo ratings yet

- MTU Marine Spec 10V12V16V2000M96LX 1DSDocument2 pagesMTU Marine Spec 10V12V16V2000M96LX 1DSfernando machadoNo ratings yet

- Competitive Analysis: Electric Power C175 Package Generator SetDocument13 pagesCompetitive Analysis: Electric Power C175 Package Generator SetJose FavaNo ratings yet

- Mtu Series 2000 IndustrialDocument2 pagesMtu Series 2000 Industrialhelen TasiopoulouNo ratings yet

- Mtu Series 2000 IndDocument2 pagesMtu Series 2000 Indhelen TasiopoulouNo ratings yet

- PG Spec 4000GS 60HzDocument2 pagesPG Spec 4000GS 60HzrehanNo ratings yet

- Volvo B12BDocument6 pagesVolvo B12Btomas.paslaugosNo ratings yet

- Diesel Engines 8V/12V/16V 4000 M60R: For Vessels With Unrestricted Continuous Operation (1A)Document2 pagesDiesel Engines 8V/12V/16V 4000 M60R: For Vessels With Unrestricted Continuous Operation (1A)Jorge Bellido100% (1)

- CAT 3208 Mrine Engine SpecificationDocument4 pagesCAT 3208 Mrine Engine SpecificationCher Wee67% (3)

- Mini Excavators - 8040, 8045 Zts and 8050 RTS/ZTS: Static DimensionsDocument6 pagesMini Excavators - 8040, 8045 Zts and 8050 RTS/ZTS: Static DimensionsMagyar Plazma és Lézervágó CNC MűvekNo ratings yet

- 2ar FeDocument69 pages2ar Feroberto cruz100% (5)

- As Catalog - enDocument1 pageAs Catalog - enRanndolf JavierNo ratings yet

- Mtu MT 881Document2 pagesMtu MT 881AndrewScotson100% (1)

- Diesel Engine 12V 2000 M61: For Vessels With Unrestricted Continuous Operation (1A)Document2 pagesDiesel Engine 12V 2000 M61: For Vessels With Unrestricted Continuous Operation (1A)wellington freitasNo ratings yet

- Forward Moving Vibratory Plate APFDocument6 pagesForward Moving Vibratory Plate APFMuhaiminNo ratings yet

- Diesel Engine 6R 460 C: IndustrialDocument2 pagesDiesel Engine 6R 460 C: Industrialguichen wangNo ratings yet

- 01 d155 IntroductionDocument22 pages01 d155 IntroductionDeyvi Cconocuyca HuallparimachiNo ratings yet

- Imv3 Rev4 Master Book 29dec08Document95 pagesImv3 Rev4 Master Book 29dec08rvozgovNo ratings yet

- Mitsubishi Diesel Engine - S16R-Y2PTAW2Document2 pagesMitsubishi Diesel Engine - S16R-Y2PTAW2Christian Rivera FloverNo ratings yet

- Diesel Engine S60: MarineDocument2 pagesDiesel Engine S60: MarinenaufragatoNo ratings yet

- Gensets GEC300ED 300 kVA (240 Kwe) at 1500 RPMDocument2 pagesGensets GEC300ED 300 kVA (240 Kwe) at 1500 RPMAung MhNo ratings yet

- OG Spec 4R1000Document2 pagesOG Spec 4R1000Esma KarabulutNo ratings yet

- 6599014-Download 2004 2005 Yamaha Outboard 9 9c 15c Service Manual 2 StrokeDocument135 pages6599014-Download 2004 2005 Yamaha Outboard 9 9c 15c Service Manual 2 StrokeEmmanuele Ellul100% (4)

- Aexj0118 01Document2 pagesAexj0118 01fatos_sejdajNo ratings yet

- DIESEL ENGINES 12V/16V 2000 M93: MarineDocument2 pagesDIESEL ENGINES 12V/16V 2000 M93: MarinenaufragatoNo ratings yet

- Engine, Turbine & Power Transmission Equipment World Summary: Market Values & Financials by CountryFrom EverandEngine, Turbine & Power Transmission Equipment World Summary: Market Values & Financials by CountryNo ratings yet

- PG Spec 12V4000DS2000 2080kVA 3D FC 50HzDocument5 pagesPG Spec 12V4000DS2000 2080kVA 3D FC 50HzPetrus GunturNo ratings yet

- Iphone 11 Pro Max 03404876 InfoDocument2 pagesIphone 11 Pro Max 03404876 InfoPetrus GunturNo ratings yet

- Surface Finishing: - Diamond Knurls Pitch 14Document1 pageSurface Finishing: - Diamond Knurls Pitch 14Petrus GunturNo ratings yet

- Kombinasi @380 KWDocument4 pagesKombinasi @380 KWPetrus GunturNo ratings yet

- Surface Finishing: - Diamond Knurls Pitch 14Document1 pageSurface Finishing: - Diamond Knurls Pitch 14Petrus GunturNo ratings yet

- Kombinasi @1600 KWDocument4 pagesKombinasi @1600 KWPetrus GunturNo ratings yet

- MTU Gendrive S4000 NOMENCLATURE PDFDocument9 pagesMTU Gendrive S4000 NOMENCLATURE PDFmohsen_cumminsNo ratings yet

- A A A A A A A A A: Voltmeter VoltmeterDocument1 pageA A A A A A A A A: Voltmeter VoltmeterPetrus GunturNo ratings yet

- Solution Guide: Power GenerationDocument45 pagesSolution Guide: Power GenerationPetrus GunturNo ratings yet

- Operating Instructions: Diesel Engine 12V2000G65, G65-TB 16V2000G65, G65-TB 18V2000G65, G65-TB Application Group 3ADocument155 pagesOperating Instructions: Diesel Engine 12V2000G65, G65-TB 16V2000G65, G65-TB 18V2000G65, G65-TB Application Group 3APetrus GunturNo ratings yet

- Functional Description Manual MTU 6R Series 1600 MS13023Document94 pagesFunctional Description Manual MTU 6R Series 1600 MS13023Alberto F. Apablaza Meza100% (1)

- Operating InstructionsDocument155 pagesOperating InstructionsPetrus Guntur0% (1)

- Operating Instructions: Gas Engine 12 V 4000 L62 16 V 4000 L62Document187 pagesOperating Instructions: Gas Engine 12 V 4000 L62 16 V 4000 L62Petrus GunturNo ratings yet

- Operating Instructions: Gas Engine 12 V 4000 L62 16 V 4000 L62Document187 pagesOperating Instructions: Gas Engine 12 V 4000 L62 16 V 4000 L62Petrus GunturNo ratings yet

- Operating Instructions: Diesel Engine 12V2000G65, G65-TB 16V2000G65, G65-TB 18V2000G65, G65-TB Application Group 3ADocument155 pagesOperating Instructions: Diesel Engine 12V2000G65, G65-TB 16V2000G65, G65-TB 18V2000G65, G65-TB Application Group 3APetrus GunturNo ratings yet

- Solution Guide: Power GenerationDocument45 pagesSolution Guide: Power GenerationPetrus GunturNo ratings yet

- Tutorial 4: Complex Numbers II and Inverse Functions and LogarithmsDocument14 pagesTutorial 4: Complex Numbers II and Inverse Functions and LogarithmsPetrus GunturNo ratings yet

- Regular VerbDocument2 pagesRegular VerbPetrus GunturNo ratings yet

- Regular Verb 3Document2 pagesRegular Verb 3Petrus GunturNo ratings yet

- 2543 33130 T5 SolutionDocument6 pages2543 33130 T5 SolutionPetrus GunturNo ratings yet

- 2D CADD InterbatDocument15 pages2D CADD InterbatPetrus GunturNo ratings yet

- Exercises English For PAT Petra Grade 3Document4 pagesExercises English For PAT Petra Grade 3Petrus GunturNo ratings yet

- Regular Verb2Document2 pagesRegular Verb2Petrus GunturNo ratings yet

- Complete The SentencesDocument1 pageComplete The SentencesPetrus GunturNo ratings yet

- PC2182 6076 PDFDocument474 pagesPC2182 6076 PDFwal_mza100% (2)

- tp6258 MITSUBISHI GENERADORDocument72 pagestp6258 MITSUBISHI GENERADORMarcos Vinicio Stizzioli100% (1)

- SM - 51 Cruze Specification DiagnosticDocument17 pagesSM - 51 Cruze Specification DiagnosticRafael Luque0% (1)

- Catalogue Hartech GensetDocument4 pagesCatalogue Hartech Gensetdwiendroprastya0% (1)

- Chapter A - Basic 5Document3 pagesChapter A - Basic 5João AnsorgeNo ratings yet

- Parts Catalogue: Model Model ModelDocument134 pagesParts Catalogue: Model Model ModelEsteban Elias Marquez EscalanteNo ratings yet

- I C Engine Lab ManualDocument46 pagesI C Engine Lab Manualمحمد رأفتNo ratings yet

- Kenr5396 04 01 AllDocument76 pagesKenr5396 04 01 AlllunikmirNo ratings yet

- Formula Pro GuideDocument62 pagesFormula Pro GuideRustyNo ratings yet

- RTA-59 Procedures and Relevant Information For RTA Engines To Comply With The Annex VI NOx LimitDocument7 pagesRTA-59 Procedures and Relevant Information For RTA Engines To Comply With The Annex VI NOx LimitCatalin CataNo ratings yet

- Turbocharger: and How It WorksDocument17 pagesTurbocharger: and How It Workskeithdcosta81No ratings yet

- John Deere 6100DDocument4 pagesJohn Deere 6100DEmanuel MtzNo ratings yet

- Description and Construction of Cylinder HeadDocument7 pagesDescription and Construction of Cylinder HeadSujithNo ratings yet

- MDKBJ BW Parts ManualDocument62 pagesMDKBJ BW Parts ManualLycurgueNo ratings yet

- Field Service Tips: Low Oil Pressure Warnings D13C Euro 5Document5 pagesField Service Tips: Low Oil Pressure Warnings D13C Euro 5yazeed naibanNo ratings yet

- Crane Solid Flat Tappet CamsDocument6 pagesCrane Solid Flat Tappet CamspepobossNo ratings yet

- Acert Technology For Off-Highway C15 Engines: Caterpillar ConfidentialDocument62 pagesAcert Technology For Off-Highway C15 Engines: Caterpillar ConfidentialMilorad ZelenovicNo ratings yet

- GN65770NDocument134 pagesGN65770NCoordinador - MantenimientosNo ratings yet

- A MagnetoDocument2 pagesA MagnetoCyrus Mutua MbwikaNo ratings yet

- INNOVA Bensin Engine Wiring DiagramDocument1 pageINNOVA Bensin Engine Wiring DiagramMuhammad Januar Susanto100% (8)

- Chapter 23 - Engine Control System WECS 3000Document59 pagesChapter 23 - Engine Control System WECS 3000sezar100% (1)

- CNG Kit ComponentsDocument5 pagesCNG Kit ComponentsAnisha VyasNo ratings yet

- Codigos HondaDocument25 pagesCodigos Hondamarquin84No ratings yet

- Zenoah G230PU Petrol EngineDocument4 pagesZenoah G230PU Petrol EngineJarkko PuustinenNo ratings yet

- Chery Manual de MotorDocument49 pagesChery Manual de Motorcarlitox1192100% (1)

- Localizacion Valvulas CatDocument2 pagesLocalizacion Valvulas CatEdin Raul Yalle RafaelNo ratings yet

- Ci Fuel System Notes PDFDocument19 pagesCi Fuel System Notes PDFNduati JohnNo ratings yet

- Module 5 (Me 213)Document22 pagesModule 5 (Me 213)Joshua S. LanzaderasNo ratings yet

- FD FXD (84-109 HP) 7-4-205Document2 pagesFD FXD (84-109 HP) 7-4-205markNo ratings yet

- Bosch 35 Pin Early Motronic Pinout (BMW 5,6,7)Document2 pagesBosch 35 Pin Early Motronic Pinout (BMW 5,6,7)Posada Burgueño Carlos67% (3)