Professional Documents

Culture Documents

NSC 1020 TR 0102 8.8 WPS 08

NSC 1020 TR 0102 8.8 WPS 08

Uploaded by

BIIS QAQC Babu Siva0 ratings0% found this document useful (0 votes)

7 views3 pagesOriginal Title

NSC-1020-TR-0102-8.8-WPS-08

Copyright

© © All Rights Reserved

Available Formats

XLSX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as XLSX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

7 views3 pagesNSC 1020 TR 0102 8.8 WPS 08

NSC 1020 TR 0102 8.8 WPS 08

Uploaded by

BIIS QAQC Babu SivaCopyright:

© All Rights Reserved

Available Formats

Download as XLSX, PDF, TXT or read online from Scribd

You are on page 1of 3

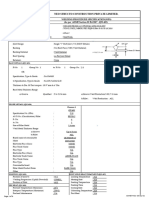

NEO STRUCTO CONSTRUCTION PRIVATE LIMITED.

WELDING PROCEDURE SPECIFICATION(WPS)

(As per ASME Section IX Ed.2017 , QW-482)

WPS No : NSC-1020-TR-0102-8.8-WPS-08 Rev:0 Dtd: 09.02.2019

Procedure Qualification Record No : NSC/TR/1020/347/PQR - 01 , Dtd: 09.02.2019

Welding Process(es) : GTAW

Types (Manual, Automatic, Semi-Auto,Machine) : MANUAL

JOINTS (QW-402)

Joint Design : Single "V" Butt Joint (W1 Joint details)

Backing : No (Root Pass) / YES (Weld Material)

Backing Material : Weld Material

Root Spacing : As Per Joint Detail

Retainers : None

BASE METALS (QW-403)

P-No 8 Group No 1 to P-No 8 Group No : 1

OR

Specification, Type & Grade : A376TP347H/A182GR.WP347H

to Specification, Type & Grade : A376TP347H/A182GR.WP347H

Thickness & Dia. Of Test coupon : 8.18 & 8" Dia

Base Metal Thickness Range

a) Groove Qulified : 1.5 mm to 16.36 mm a) Groove : Weld Production - 5.08,8.18 mm

b) Fillet : NA b) Fillet : Weld Production - NA

FILLER METALS (QW-404)

Process-1

GTAW

Specification No. (SFA) : 5.9

AWS No. (Classification)/Filler : ER 347

F- No. : 6

A- No. : 8

Size of Filler Metal : 1.6,2.4 mm

Weld Metal Thickness Range

a) Groove : Up to 16.36 mm

b) Fillet : NA

Electrode-Flux (Class) : NA

Electrode Trade Name ADOR / D&H

Flux Trade Name : NA

Flux Type : NA

Consumable Insert NO

Filler Metal Product Form : BARE (Solid)

Filler addition /deletion : GTAW with filler

Other : NA

POSITION (QW-405) POST WELD HEAT TREATMENT(QW-407)

Position of Groove : ALL Loading Temperature : 350 ˚C

Welding Progression (Uphill/Downhill) : UPHILL Heating Rate : 250-300˚C /Hrs.

Position of Fillet : ALL Soaking Temperature : 900±4˚C

PRE HEAT (QW-406) Soaking Time : 4 HRS.

Pre heat Temperature (Minimum) : 10°C Cooling Rate : AIR COOLED ( Note-3 )

Interpass Temperature (Maximum) : 175°C- Unloading Temperature : NA

Pre heat Maintenance : NONE Post Heat : NA

Note: Thermal cryons may be used for temp. measurement.

Page 1 of 3 EXHIBIT NO: WE-01 R2

NEO STRUCTO CONSTRUCTION PRIVATE LIMITED.

WELDING PROCEDURE SPECIFICATION(WPS)

(As per ASME Section IX Ed.2017 , QW-482)

WPS No : NSC-1020-TR-0102-8.8-WPS-08 Rev:0 Dtd: 09.02.2019

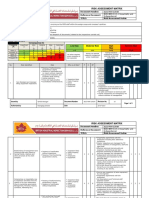

GAS (QW-408)

Gas % Composition (Mixture) Flow Rate

Shielding Gas ARGON 99.995% Pure 14-18 LPM

Trailing Gas NONE NONE NONE

Backing Gas ARGON 99.995% Pure 10-14 LPM

ELECTRICAL CHARACTERISTICS (QW-409)

Pulsing current or Power source : DC

Current or Polarity : EN(GTAW)

Amps Range : Amps - 78-150

Volts Range : Volts - 15-26

Tungsten Electrode Size and Type : 2.5 mm dia & 2% Thoriated (EWTh-2)

Mode of Metal Transfer (for GMAW) : NA

Electrode Wire Feed Speed Range : NA

TECHNIQUE (QW-410)

String or Weave : 1st Stringer Bead/Rest pass Weave Bead

Orifice or Gas Cup Size : 6 mm , 8 mm & 10mm

Initial and Inter pass Cleaning : Grinding/ Brushing

Method of Back gouging : NO

Oscillation : <=3 times electrode diameter

Closed to out Chamber : NA

Electrode Spacing : NA

Contact Tube to Work Distance : NA

Multiple or Single Pass (per side) : Multiple

Multiple or Single Electrode : Single

Travel Speed (Range) : 43-46 mm/min

Peening : NO

Thermal Processes : NONE

Manual Or Automatic : Manual * NA=Not Applicable

Filler Metal Current

Sl. Volts Tr.Speed

Pass Process AWS Amps Remark

No. Dia (mm) Polarity Range mm/Min

Class. Range

1 Root GTAW ER347 1.6 DCEN 78-85 15-17 43

2 Hot GTAW ER347 2.4 DCEN 139-143 15-18 46

3 Fill up GTAW ER347 2.4 DCEN 140-148 19-23 45

4 Final GTAW ER347 2.4 DCEN 145-150 24-26 45

Note (s): 1. Weaving not exceeding 3 times electrode dia.

2. Use only austenitic SS wire brush for cleaning purpose & SS clit use for fitt up

3. Insulation to be open immediately after soaking time.

Signature

Name

Date

Welding Engineer Quality Manager Client/Inspection/TPI

Page 2 of 3 EXHIBIT NO: WE-01 R2

Annexure 1

WPS NO : NSC-1020-TR-0102-WPS-03 Rev:0 Dtd: 09.08.2018

Dia Pipe :6" Dia & 10.97mm

Position : 6G

Root Gap (G) Root Face ®

Joint Detail Thickness (t) Included Angle

Min. Max. Min. Max.

Single V Groove

10.97 mm 1.60 mm 3.20 mm 1.20 mm 1.60 mm 75 ± 5 °

Butt Joint

You might also like

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Hazards Identification and Risk Assessment - New FormatDocument2 pagesHazards Identification and Risk Assessment - New FormatBIIS QAQC Babu Siva100% (1)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5810)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (844)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- WPS 01Document11 pagesWPS 01BIIS QAQC Babu SivaNo ratings yet

- WPS 002Document19 pagesWPS 002BIIS QAQC Babu SivaNo ratings yet

- PQR 347H TRDocument20 pagesPQR 347H TRBIIS QAQC Babu SivaNo ratings yet

- PWPS CS To SS446-3Document5 pagesPWPS CS To SS446-3BIIS QAQC Babu SivaNo ratings yet

- (P22) Nsc-1020-Tr-0102-5a.5a-Wps-04-NewDocument4 pages(P22) Nsc-1020-Tr-0102-5a.5a-Wps-04-NewBIIS QAQC Babu SivaNo ratings yet

- Tecnicas Reunidas S.A: Welding Procedure Specification (WPS)Document2 pagesTecnicas Reunidas S.A: Welding Procedure Specification (WPS)BIIS QAQC Babu SivaNo ratings yet

- (P1) NSC-1020-TR-0102-1.1-WPS-06Document6 pages(P1) NSC-1020-TR-0102-1.1-WPS-06BIIS QAQC Babu SivaNo ratings yet

- (P22) Nsc-1020-Tr-0102-5a.5a-Wps-04Document9 pages(P22) Nsc-1020-Tr-0102-5a.5a-Wps-04BIIS QAQC Babu SivaNo ratings yet

- Biis-Sf-01 Accident RecordDocument1 pageBiis-Sf-01 Accident RecordBIIS QAQC Babu SivaNo ratings yet

- Biis-Sf-02 Personal Protective EquipmentDocument2 pagesBiis-Sf-02 Personal Protective EquipmentBIIS QAQC Babu SivaNo ratings yet

- Biis-Sf-03-Risk Assessment Form-GeneratorDocument3 pagesBiis-Sf-03-Risk Assessment Form-GeneratorBIIS QAQC Babu SivaNo ratings yet

- Details Required For The Vendor RegistrationDocument1 pageDetails Required For The Vendor RegistrationBIIS QAQC Babu SivaNo ratings yet

- Vechicles ListDocument2 pagesVechicles ListBIIS QAQC Babu SivaNo ratings yet

- Biis-Sc-02 Subcontractor Evaluation & Re Evaluation FormDocument2 pagesBiis-Sc-02 Subcontractor Evaluation & Re Evaluation FormBIIS QAQC Babu SivaNo ratings yet

- Biis-Kpi-01-Key Performance Indicator-Rev-01-17-07-2019Document1 pageBiis-Kpi-01-Key Performance Indicator-Rev-01-17-07-2019BIIS QAQC Babu SivaNo ratings yet

- OT Request FormDocument1 pageOT Request FormBIIS QAQC Babu SivaNo ratings yet

- Biis CL 46 Storage Rack InspectionDocument2 pagesBiis CL 46 Storage Rack InspectionBIIS QAQC Babu SivaNo ratings yet

- Biis-Sc-01 Approved Subcontractor ListDocument2 pagesBiis-Sc-01 Approved Subcontractor ListBIIS QAQC Babu SivaNo ratings yet

- Risk Assessment Matrix: Consequence (C) Low Risk Moderate Risk High Risk Extreme RiskDocument3 pagesRisk Assessment Matrix: Consequence (C) Low Risk Moderate Risk High Risk Extreme RiskBIIS QAQC Babu SivaNo ratings yet

- WPS 012Document11 pagesWPS 012BIIS QAQC Babu SivaNo ratings yet

- Mobile Crane AssessmentDocument4 pagesMobile Crane AssessmentBIIS QAQC Babu SivaNo ratings yet