Professional Documents

Culture Documents

HS Weld Spotter - UNI-4550 - Manual

Uploaded by

dmh.agent.00770 ratings0% found this document useful (0 votes)

4 views1 pageThe document provides instructions for using a shrink gun to repair automotive body panels. It describes how to use the shrink gun to relieve oil canning and shrink high spots by placing the shrink tip on the problem area and squeezing the trigger for under a second. It also instructs users to work in a spiral motion and quench with a damp cloth. For high spots, it recommends tapping with a body hammer while the metal is still warm. The document contains additional instructions for stud welding, using a slide hammer to remove dents, and installing molding rivets. Safety glasses should be worn when operating the equipment.

Original Description:

Manual de uso para soldador de puntos HS

Original Title

HS weld spotter - UNI-4550_manual

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThe document provides instructions for using a shrink gun to repair automotive body panels. It describes how to use the shrink gun to relieve oil canning and shrink high spots by placing the shrink tip on the problem area and squeezing the trigger for under a second. It also instructs users to work in a spiral motion and quench with a damp cloth. For high spots, it recommends tapping with a body hammer while the metal is still warm. The document contains additional instructions for stud welding, using a slide hammer to remove dents, and installing molding rivets. Safety glasses should be worn when operating the equipment.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

4 views1 pageHS Weld Spotter - UNI-4550 - Manual

Uploaded by

dmh.agent.0077The document provides instructions for using a shrink gun to repair automotive body panels. It describes how to use the shrink gun to relieve oil canning and shrink high spots by placing the shrink tip on the problem area and squeezing the trigger for under a second. It also instructs users to work in a spiral motion and quench with a damp cloth. For high spots, it recommends tapping with a body hammer while the metal is still warm. The document contains additional instructions for stud welding, using a slide hammer to remove dents, and installing molding rivets. Safety glasses should be worn when operating the equipment.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 1

M7735:Layout 1 5/2/08 2:42 PM Page 1

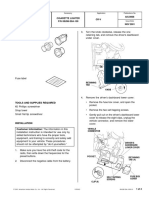

OPERATING INSTRUCTIONS SHRINKING

Insert shrink tip. Press gun against ground panel

until outer ring touches, keeping contact between

SAFETY GLASSES/GOGGLES SHOULD BE WORN AT ALL TIMES

4500

4500 outer ring and bare metal. Press trigger for one

half to one second, do not remove gun until

trigger has been released. IMPORTANT: Never

…just like a UNI-SPOTTER STUD EASE TECHNOLOGY, Stud Ease Technology holds the stud in welder for

easy out of position welding. Increase accuracy depress trigger for longer than one second.

REDUCE THE PITA (PAIN IN THE ...!) when pulling small dents or placing molding rivets. TO RELIEVE OIL CANNING:

NEVER DROP A STUD AGAIN! Working around and then into the stretched area,

make several small shrink spots until oil can is

relieved. A spiral action is recommended.

Quenching with a damp cloth to avoid chasing the

oil can may be necessary on light gauge panels.

TO SHRINK HIGH SPOTS:

Follow shrinking procedures, placing shrink tip

directly on high spot. If high spot has not been

completely reduced, tap with body hammer while

metal is still warm. IMPORTANT: Never depress

trigger for longer than one second.

PARTS & ACCESSORIES

▲ NEVER OPERATE ▲ STUD WELDING ▲ USE OF SLIDE HAMMER ▲ REMOVING STUDS ▲ MOLDING RIVETS

WITHOUT A TIP Grind damaged area to bare metal. Insert stud Push roller cam away from you to open. Insert To remove studs, grip under head with sidecutters Remove Stud Welding tip from welder. Insert

To insert tip: Place tip in electrode – tapered end welding tip. Insert stud, press gun against stud into tool. Turn roller cam towards you to grip and rotate to break/cut studs from surface. 1005 Molding Rivet Welding Tip. Tap into place

in. Tap firmly with the palm of your hand to seat damaged panel until outer ring touches. Keep a stud. Pull damage as required. To release, push with palm of hand. Insert 1003 Uni-Spotter

firm contact between outer (ground) ring and bare tool toward panel or turn roller away from you. Molding Rivets – flat end first – into welding tip. 1003 1001 1002

the taper. FOR OPTIMUM PERFORMANCE USE ONLY GENUINE

Molding Rivets Flexpert Heavyweight

metal. Press trigger for one half to one second. Do UNI-SPOTTER WELDING STUDS Rivet will be held in place by magnet in tip. 2.2 mm Studs 2.6 mm Studs

To remove tip: Tips may be hot after use – do not A steady pull on handle and tapping damaged area

not remove gun until trigger has been released. Press gun against ground panel until ground ring

touch with bare hands. with body hammer will remove most dents. For

Weld studs as required. IMPORTANT: NEVER touches. Keeping contact between ground ring

extra pull force slide action may be required. As

• Using sidecutters/dykes: lightly grasp tip in space DEPRESS TRIGGER FOR LONGER THAN ONE and bare metal, press trigger for one half to one

process is repeated on welded studs, damage will

between head and electrode, and pry gently. SECOND. There should not be more than 1⁄8” second. Do not remove gun until trigger has been

be gently removed.

• Using screwdriver: insert blade in space between discoloration around weld for maximum strength. released. 1004 1005 1007

Stud Welding Tip Molding Rivet Tip Shrink Tip

head and electrode and pry gently.

KIT CONTENTS HOW TO USE THE OPTIONAL DK1000 DENT KILLER

1028 Uni-Puller 1016 “T” Handle Slide Hammer

• 4590 Stud gun – the most powerful lightweight 1045 ELIMINATOR Studless, lever action dent pulling attachment

for all Uni-Spotter Stud Welders (optional)

Deluxe “T” Handle

stud gun available Slide Hammer

Side-by-Side Adapter with Service Kit

• 4516 Slide hammer Stud Ease (not included in this kit) • Works great to restore body lines

• 1004 Stud welding tip • Quick and easy to use

• 1001 Flexpert welding studs • Weld studs close together to build • Lightweight and portable for out-of-position

pulling block of studs to be used with the pulls

Visit www.hsautoshot.com for the full line of 1080 Uni-Clamp.

Uni-Spotter tools and accessories. • Can be used for stud welding, shrinking and

1045 Eliminator 1041 Eliminator 1044 Eliminator

Side-by-Side Side-by-Side Extend-A-Tip with

molding rivet welding. Adapter with Adapter – Collar Stud Ease

Stud Ease Only

• Can rotate 360°.

MAINTENANCE TIPS • Lets you pinpoint exact stud or molding rivet HOW TO USE THE OPTIONAL

NOTE: Disconnect from power supply before

attempting to clean your 4590.

location. 1080 UNI-CLAMP

Installation Instructions (not included in this kit)

1080 Uni-Clamp 1082 Uni-Clamp 1083 Uni-Clamp

• To insure good contact, keep the ground ring • Be sure ground ring and center taper on spring- This method can be used with body frame Multiple Stud Screw Wrench Shackle Only

and welding tips clean. loaded electrode are clean (see maintenance equipment or even a come-along. We recommend Puller Only

• To clean metal deposits on ground ring, use a tips). part no. 1002 – heavy pull studs, for use on

fine, flat file. After filing, blow with air. • Insert tapered end of Extend-a-Tip into center rockers, rails and other heavy pulls.

• Never file electrode (centre piece that holds spring loaded electrode. Tap into place with palm

welding tips). of hand. • Weld 2 to 11 studs where required.

• To clean tips, use medium-fine steel wool. • Push Side-by-Side Adapter Collar over ground • Spacing is not important as studs are flexible

• Molding rivet tip is magnetized and can pick up ring until it is firmly seated. It must be a and easily bent to fit close hole pattern

metal filings. Occasionally blow with air. relatively easy push fit and should turn by hand. 1045 Eliminator • Use screw wrench included to tighten each stud

• If the overload relay trips, let welder cool for 10 • Insert the appropriate tip and follow instructions Side-by-Side • Use narrow 5-hole side for tighter areas, wide

minutes before resetting, and observe duty cycle above. Adapter with 11-hole side for larger pulls

of 1 second on MAXIMUM. Stud Ease • Place shackle in appropriate hole, and pull.

HOW TO USE THE OPTIONAL Manufactures of World Class

1095 MINI-PULL’R Tools and Equipment for the

(not included in this kit) Automotive Industry

1. Insert stud into tool Georgetown, ON • Niagara Falls, NY

2. Turn roller towards you to grip stud. Pull as

required.

1-888-677-3798

Toll free:

3. Push in on tool, Mini-Pull’r will release from

Posi-cam locked www.hsautoshot.com

stud. DK8004 – Replacement welding tips for DK1000 Email: info@hsautoshot.com

You might also like

- Practice Sheet Tammy TaylorDocument1 pagePractice Sheet Tammy TaylorStefanie Provoost75% (12)

- New Holland LB75.B Loader Backhoe Parts Manual PDFDocument1,098 pagesNew Holland LB75.B Loader Backhoe Parts Manual PDFOFAM80% (5)

- Physics 73 3rd LE SamplexDocument16 pagesPhysics 73 3rd LE SamplexMiguel Panagsagan100% (1)

- Cat c15 Cylinder Head InstallationDocument7 pagesCat c15 Cylinder Head InstallationMUHSIN MTNo ratings yet

- Secunorm Smartcut: Safety Poster Instructions For The Safe Handling of Your Cutting ToolDocument1 pageSecunorm Smartcut: Safety Poster Instructions For The Safe Handling of Your Cutting ToolKrooqidNo ratings yet

- MARTOR SECUNORM SMARTCUT MDP Poster GBDocument1 pageMARTOR SECUNORM SMARTCUT MDP Poster GBKrooqidNo ratings yet

- Dimarucut Activity$Document2 pagesDimarucut Activity$Anthony BoydNo ratings yet

- DEH 3100SD Installation Manual PDFDocument7 pagesDEH 3100SD Installation Manual PDFAdriaono Gonzaga RibeiroNo ratings yet

- Secunorm Handy MDP: Safety Poster Instructions For The Safe Handling of Your Cutting ToolDocument1 pageSecunorm Handy MDP: Safety Poster Instructions For The Safe Handling of Your Cutting ToolKrooqidNo ratings yet

- Power Team Cribbing Blocks - CatalogDocument1 pagePower Team Cribbing Blocks - CatalogTitanplyNo ratings yet

- Si 7C26C 000 EngDocument1 pageSi 7C26C 000 EngsolerviNo ratings yet

- Nexus 7 Installation Service ManualDocument2 pagesNexus 7 Installation Service ManualsolerviNo ratings yet

- Dti Installation: Applied BoltingDocument2 pagesDti Installation: Applied BoltingAli KhalafNo ratings yet

- Yakima HighLite InstructionsDocument15 pagesYakima HighLite InstructionsrackwarehouseNo ratings yet

- Vacumm PadDocument8 pagesVacumm PadRafael Mena FredesNo ratings yet

- M16A1 ComicBook Maintenance ManualDocument16 pagesM16A1 ComicBook Maintenance Manualmai100100% (1)

- Quick Guide: Puncture Depth Setting Lancet Holder Trigger ButtonDocument1 pageQuick Guide: Puncture Depth Setting Lancet Holder Trigger Buttonhusain1983No ratings yet

- Laminated Paper Plane Saber InnstructionsDocument1 pageLaminated Paper Plane Saber InnstructionsMugenNo ratings yet

- JSA Circular Saw OperationDocument1 pageJSA Circular Saw OperationNira100% (1)

- Nerf Retaliator Instruction ManualDocument4 pagesNerf Retaliator Instruction ManualarphaxadronNo ratings yet

- Front Door Outer Panel (Assy) : Body Panel Replacement BP-19Document2 pagesFront Door Outer Panel (Assy) : Body Panel Replacement BP-19pomacabasNo ratings yet

- Snap Ups (Tiger) : Assembly InstructionsDocument2 pagesSnap Ups (Tiger) : Assembly InstructionsElia CFNo ratings yet

- GX270T2/UT2 GX390T2/UT2/RT2 Engine Assembly Information: Piston/Crankshaft/BalancerDocument2 pagesGX270T2/UT2 GX390T2/UT2/RT2 Engine Assembly Information: Piston/Crankshaft/BalancerAugusto BellezaNo ratings yet

- Toyoya Land Crusier Prado 2010 M - BP - 0034Document2 pagesToyoya Land Crusier Prado 2010 M - BP - 0034Angy SalasNo ratings yet

- RGA22G Scale Guide: A B C DHDocument2 pagesRGA22G Scale Guide: A B C DHKaya Eralp AsanNo ratings yet

- Manuel SISL2Document2 pagesManuel SISL2stewenNo ratings yet

- The Highest Level of Reloading PrecisionDocument3 pagesThe Highest Level of Reloading PrecisionToxophilus TheLuckyNo ratings yet

- Double Road Engine Shed v2Document13 pagesDouble Road Engine Shed v2ruedanton131100% (1)

- CNT 0011886 01 PDFDocument3 pagesCNT 0011886 01 PDFElia CFNo ratings yet

- Bender MB 105Document14 pagesBender MB 105EdSoloNo ratings yet

- Rear Door Outer Panel (Assy) : Body Panel Replacement BP-21Document2 pagesRear Door Outer Panel (Assy) : Body Panel Replacement BP-21pomacabasNo ratings yet

- Instruction Manual: Solderpro™Document1 pageInstruction Manual: Solderpro™余日中No ratings yet

- Tinshed Flow SheetDocument1 pageTinshed Flow SheetEzra BellaNo ratings yet

- Illustrated Tool DictionaryDocument32 pagesIllustrated Tool Dictionaryapi-524390398No ratings yet

- Split SRB ManualDocument2 pagesSplit SRB ManualJose RoseNo ratings yet

- QT3989Document2 pagesQT3989Alexander PohlNo ratings yet

- Ramset DynasetDocument8 pagesRamset Dynasetchong pak limNo ratings yet

- Traffic Signal - Operating-InstructionsDocument4 pagesTraffic Signal - Operating-Instructionsarainzada807No ratings yet

- Kevlar Skid Plate Installation InstructionsDocument6 pagesKevlar Skid Plate Installation Instructionschase simpsonNo ratings yet

- Detail A A: 0 M M SS SE LF - TA PP ING)Document12 pagesDetail A A: 0 M M SS SE LF - TA PP ING)Raaj ChandranNo ratings yet

- 2023 English Catalog Full CompleteDocument91 pages2023 English Catalog Full Completeghost2humanNo ratings yet

- Sten Field StrippingDocument2 pagesSten Field Strippingaquisty29No ratings yet

- Speed Post: InstallationDocument2 pagesSpeed Post: InstallationFrancisco GonzalezNo ratings yet

- Shinobi Squad Advanced: Draft 2.2Document50 pagesShinobi Squad Advanced: Draft 2.2tokunetsNo ratings yet

- Start Here: Unpacking 1Document2 pagesStart Here: Unpacking 1btrsasNo ratings yet

- Installation Instructions: Parts ListDocument4 pagesInstallation Instructions: Parts ListPeggyNo ratings yet

- Plywood EdgeDocument2 pagesPlywood EdgeE100% (1)

- CNT 0011397 02 PDFDocument2 pagesCNT 0011397 02 PDFTácilla MaiaraNo ratings yet

- CNT 0011397 02 PDFDocument2 pagesCNT 0011397 02 PDFMaiara TNo ratings yet

- Ip SK Valving STDDocument15 pagesIp SK Valving STDinteraxNo ratings yet

- Budischowsky Tp-70Document5 pagesBudischowsky Tp-70JustinNo ratings yet

- Enduro Fork Seals: 36 Talas Rc2Document23 pagesEnduro Fork Seals: 36 Talas Rc2Juan Manuel AcebedoNo ratings yet

- Routing: Hinge MortisesDocument1 pageRouting: Hinge MortisesNormann StoehrNo ratings yet

- NT Handrail Handling Installation Guide English Rev1.00Document2 pagesNT Handrail Handling Installation Guide English Rev1.00Ton marquesNo ratings yet

- Koyo Bearing Datasheet PDFDocument2 pagesKoyo Bearing Datasheet PDFDee JavuNo ratings yet

- Tension Watch Tw200 Instruction Manual: Position Gauge RingDocument1 pageTension Watch Tw200 Instruction Manual: Position Gauge RingCARLOS JAVIER PANTOJA MEDINANo ratings yet

- Grundfosliterature 5153654 PDFDocument16 pagesGrundfosliterature 5153654 PDFRazziel Ignacio Robledo CardenasNo ratings yet

- Trapezoid eDocument1 pageTrapezoid ePhisit PanasophonkulNo ratings yet

- 2016 Dewalt - SalesDocument65 pages2016 Dewalt - SalesRiverland Welding and Tool SuppliesNo ratings yet

- Dinemics MCQ - 2Document13 pagesDinemics MCQ - 2MUHAMMAD BILLAL HOSSAINNo ratings yet

- Diagrama Eléctrico de Tablero Tornatech GPDDocument8 pagesDiagrama Eléctrico de Tablero Tornatech GPDJorge Calcaneo Martinez100% (1)

- ITP Instrument-Cover EXAMPLEDocument6 pagesITP Instrument-Cover EXAMPLECharles RobiansyahNo ratings yet

- Humidification Strategies For Data Centers and Network RoomsDocument13 pagesHumidification Strategies For Data Centers and Network Rooms(unknown)No ratings yet

- Procedures For Hvac System Design and InstallationDocument5 pagesProcedures For Hvac System Design and Installationrawadsultan100% (1)

- DBA12630 Interlock MonitorDocument2 pagesDBA12630 Interlock MonitorkkaranagNo ratings yet

- Honda Serie B Table de TorquesDocument4 pagesHonda Serie B Table de TorquesDoom Bringer65No ratings yet

- Impetus Metalmaster LatheDocument19 pagesImpetus Metalmaster LatheIan Foreman100% (1)

- Nagano Keiki GV Catalog PDFDocument4 pagesNagano Keiki GV Catalog PDFaryopn0% (1)

- Welding InspectionDocument139 pagesWelding Inspectionvanchai sapaNo ratings yet

- Despiese Tennant t20 PDFDocument314 pagesDespiese Tennant t20 PDFDaniel Mondragon100% (1)

- Steam Blowing Procedure Unit-1 ParadeepDocument9 pagesSteam Blowing Procedure Unit-1 ParadeepMahadev KovalliNo ratings yet

- Design of Planted Shear Walls of Tall BuldingDocument5 pagesDesign of Planted Shear Walls of Tall BuldingLuisito Sta. InesNo ratings yet

- Seismic RetrofittingDocument22 pagesSeismic RetrofittingJeevan ReddyNo ratings yet

- TroubleshootingDocument12 pagesTroubleshootingpavel35No ratings yet

- KGC250Document2 pagesKGC250Ahmed NabilNo ratings yet

- NB-27 - 2012 A Guide For Blowoff VesselsDocument1 pageNB-27 - 2012 A Guide For Blowoff VesselsOleg ShkolnikNo ratings yet

- Mt01'06 (5yu3) Brazil (Cor Vdvm1)Document91 pagesMt01'06 (5yu3) Brazil (Cor Vdvm1)Pablo HenriqueNo ratings yet

- Catalogo Fisica Cienytec SF 2017Document51 pagesCatalogo Fisica Cienytec SF 2017sapietiatuaNo ratings yet

- RAISEPlus GRADE 9 Impulse and MomentumDocument2 pagesRAISEPlus GRADE 9 Impulse and Momentumpj oroscoNo ratings yet

- Projet RockyDocument19 pagesProjet RockyCassella AdrianoNo ratings yet

- Track Type Tractor SEM822DDocument2 pagesTrack Type Tractor SEM822DPample Houette100% (1)

- Catalogue-Of-Valves MSADocument52 pagesCatalogue-Of-Valves MSAJenn LozNo ratings yet

- What We Know About Fluid Mechanics: Lecture 3 Morrison Transport I CM3110 9/8/2014Document23 pagesWhat We Know About Fluid Mechanics: Lecture 3 Morrison Transport I CM3110 9/8/2014Bhavya PatelNo ratings yet

- Aluminium Extrusion SpecificationDocument1 pageAluminium Extrusion Specificationmnair123No ratings yet

- Department of Education: Care of Sewing MachineDocument6 pagesDepartment of Education: Care of Sewing MachineLorily B. AbadNo ratings yet

- New StandardsWELDING STANDARDS - VOLVODocument22 pagesNew StandardsWELDING STANDARDS - VOLVORadivojJovanovNo ratings yet