Professional Documents

Culture Documents

010 RT-flex Design Rev-5.0

Uploaded by

Piotr StankiewiczOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

010 RT-flex Design Rev-5.0

Uploaded by

Piotr StankiewiczCopyright:

Available Formats

RT-FLEX TRAINING

Philosophy and Design Aspects of RT-flex Technology

and Differences to Conventional RTA Engines

1 © Wärtsilä PUBLIC 11-Jan-19 RT-Flex Training / Busan Training Centre

RT-FLEX DESIGN ASPECTS

History

• RTA

• RTA introduced in 1982

• Over 2’800 RTA engines sold with 69’401’216 BHP / 51’030’306 kW

• RT-flex

• First RT-flex workshop in 1996

• Start of first RT-flex engine in 2001 (6RT-flex58T-B / GYPSUM CENTENNIAL)

• Over 1’550 RT-flex engines sold with total more than 33’700’000 kW (Feb. 2018)

• W-X

• Start of first W-6X35 engine in 2012

• Start of first W-6X72 engine in 2013

• Over 350 W-X engines sold with total more than 7’450’000 kW (Feb. 2018)

• 2S DF

• Start of first RT-flex50DF engine in 2013

• Already 100 2S DF engines sold with total more than 2’000’000 kW (June 2018)

2 © Wärtsilä PUBLIC 11-Jan-19 RT-Flex Training / Busan Training Centre

RT-FLEX DESIGN ASPECTS

RTX Generations

1st generation 2nd generation 3rd generation

RTX-1 RTX-2 (62) RTX-3 (58)

3 © Wärtsilä PUBLIC 11-Jan-19 RT-Flex Training / Busan Training Centre

RT-FLEX DESIGN ASPECTS

RTX Generations

4th generation 5th generation 6th generation

RTX-4 (60) RTX-5 (50DF) RTX-6 (50)

2008 2013 2014

4 © Wärtsilä PUBLIC 11-Jan-19 RT-Flex Training / Busan Training Centre

RT-FLEX DESIGN ASPECTS

Characteristic Data

5 © Wärtsilä PUBLIC 11-Jan-19 RT-Flex Training / Busan Training Centre

RT-FLEX DESIGN ASPECTS

Cylinder Pressures

6 © Wärtsilä PUBLIC 11-Jan-19 RT-Flex Training / Busan Training Centre

RT-FLEX DESIGN ASPECTS

Engine Rating Fields

7 © Wärtsilä PUBLIC 11-Jan-19 RT-Flex Training / Busan Training Centre

RT-FLEX DESIGN ASPECTS

Engine Portfolio

8 © Wärtsilä PUBLIC 11-Jan-19 RT-Flex Training / Busan Training Centre

RT-FLEX DESIGN ASPECTS

Differences RTA to RT-flex Engines

9 © Wärtsilä PUBLIC 11-Jan-19 RT-Flex Training / Busan Training Centre

RT-FLEX DESIGN ASPECTS

Differences to RTA engines

10 © Wärtsilä PUBLIC 11-Jan-19 RT-Flex Training / Busan Training Centre

RT-FLEX DESIGN ASPECTS

Comparison Table

Conventional Engine RT-flex

Developing fuel oil pressure One fuel pump per cylinder Fuel pumps on supply unit

„Storing“ of fuel oil pressure - Fuel rail

Timing of injection Fuel cam on camshaft WECS-9520 / ICU

Developing pressure for One activating pump per

Servo pumps on supply unit

exhaust valve activation cylinder

„Storing“ of servo oil pressure - Servo rail

Timing of exhaust valve

Valve cam on camshaft WECS-9520 / VCU

activation

Fuel pump actuator Regulating power/speed Keeping fuel rail pressure

Releasing fuel pump position Releasing fuel command to

Electronic governor

to the actuator WECS

Power/speed control by Fuel pump Fuel quantity piston

11 © Wärtsilä PUBLIC 11-Jan-19 RT-Flex Training / Busan Training Centre

RT-FLEX DESIGN ASPECTS

Comparison Table

Conventional Engine RT-flex

Timing of starting air Starting air distributor WECS-9520

Reversing Reversing of cam WECS-9520

Alarm and monitoring system External (internal: OSC-3) External

Backup panels deliver

By mechanic shaft and cams manoeuvring signals and fuel

Emergency control acting on pneumatic valves of commands to WECS inputs,

the engine control independent from the RC

inputs channels

RC receives load signal from WECS supplies a fuel

Load signal angle transmitter on command feedback as load

intermediate shaft signal to the RC system

Functions provided in RC Functions (plus VEO) included

VIT, VEC, FQS

system in WECS

Wiring from engine to external Individual cables Bus-system

12 © Wärtsilä PUBLIC 11-Jan-19 RT-Flex Training / Busan Training Centre

RT-FLEX DESIGN ASPECTS

Why Common-Rail

• Drastic smoke reduction at part load

• Possibilities to reduce torsional vibration

• Reduced fuel consumption at part load

• Possibilities to reduce emissions

• Lower minimum engine speed

• Better maneuverability

• Easy engine de-rating

• Individual tunings

• High precision on related systems (Cyl. Lub)

13 © Wärtsilä PUBLIC 11-Jan-19 RT-Flex Training / Busan Training Centre

RT-FLEX DESIGN ASPECTS

Advantages of RT-flex

Wärtsilä 6 RT-flex58T-B MV Gypsum Centennial Smoke measurement on combinator curve

during sea trials

0.50

0.45

0.40

Filter Smoke Number [ FSN ]

HFO

380 cSt

0.35 3% sulphur

0.1% ash

0.30

ON OFF Aux. Blower

0.25

0.20

Smoke visibility limit

0.15

Conventional low speed engine

0.10

0.05

6RT-flex 58T-B with common rail

0.00

0 10 20 30 40 50 60 70 80 90 100

Engine Load [% ]

14 © Wärtsilä PUBLIC 11-Jan-19 RT-Flex Training / Busan Training Centre

RT-FLEX DESIGN ASPECTS

Advantages of RT-flex

15 © Wärtsilä PUBLIC 11-Jan-19 RT-Flex Training / Busan Training Centre

RT-FLEX DESIGN ASPECTS

MARPOL 73/78 Annex VI

• REGULATIONS FOR THE PREVENTION OF AIR POLLUTION FROM SHIPS

• Regulation 12 – Ozone depleting substances

• Regulation 13 – Nitrogen oxides

• Regulation 14 – Sulphur oxides

• Regulation 15 – Volatile organic compounds

• Regulation 16 – Shipboard incineration

• Regulation 17 – Reception facilities

• Regulation 18 – Fuel oil quality

16 © Wärtsilä PUBLIC 11-Jan-19 RT-Flex Training / Busan Training Centre

RT-FLEX DESIGN ASPECTS

IMO NOx Limits

Tier I

Ships built 2000 onwards

Engines > 130 kW

Retrofit: Ships built

1990 - 2000

Engines > 90 litres/cylinder

and > 5000 kW

Tier II (global 2011)

Ships built 2011 onwards

Engines > 130 kW

Tier III (ECAs 2016)

Ships in designated

areas, 2016 onwards

Engines > 130 kW

17 © Wärtsilä PUBLIC 11-Jan-19 RT-Flex Training / Busan Training Centre

RT-FLEX DESIGN ASPECTS

IMO NOx Limits

• The Tier III controls apply only to the specified ships while operating in Emission Control Areas (ECA)

established to limit NOx emissions.

Total weighted cycle emission limit (g/kWh)

Ship construction date on or after

n = engine’s rated speed (rpm)

n < 130 n = 130 – 1999 n ≥ 2000

45·n-0,2

Tier I 1 January 2000 17,0 9,8

e.g. 720 rpm – 12,1

44·n-0,23

Tier II 1 January 2011 14,4 7,7

e.g. 720 rpm – 9,7

9·n-0,2

Tier III 1 January 2016 3,4 2,0

e.g. 720 rpm – 2,4

“Ship constructed” = Date of Keel-Laying

18 © Wärtsilä PUBLIC 11-Jan-19 RT-Flex Training / Busan Training Centre

RT-FLEX DESIGN ASPECTS

NOR (NOx Reducer)

Catalyst – replace according to condition.

Typical interval:

• Diesel applications: 3-5 years

• Gas applications: ~10 years

19 © Wärtsilä PUBLIC 11-Jan-19 RT-Flex Training / Busan Training Centre

RT-FLEX DESIGN ASPECTS

IMO SOx Limit

• Global limit

• 3,50 % from Jan.1, 2012

• 0,50 % from Jan.1, 2020

• Emission Control Areas

• 1,00 % from July 1, 2010

• 0,10 % from Jan.1, 2015

• Fuel type

• Not regulated. Both HFO and distillate are permitted.

• Exhaust gas cleaning(Wartsila Scrubber)

• Permitted alternative to achieve any regulated limit.

• Particulate Matter (PM)

• Not regulated. Both HFO and distillate are permitted.

20 © Wärtsilä PUBLIC 11-Jan-19 RT-Flex Training / Busan Training Centre

RT-FLEX DESIGN ASPECTS

Wärtsilä Scrubbers

V-SOX – Venturi Scrubber I-SOX - Inline Scrubber Q-SOx – Quench Scrubber

Scrubber systems

• Open loop systems

• Closed loop systems

• Hybrid systems

• Dual water systems

Scrubber types

• V-SOx – Venturi Scrubber

• I-SOx – Inline Scrubber

• Q-SOx – Quench Scrubber

All these types can work as open

or closed loop systems, and can • Possible to operate in open loop • Possible to operate in open • Possible to operate in open loop

with 3,5% sulfur fuel and still loop with 2,5% sulfur fuel and with 3,5% sulfur fuel and still

be fitted to both new buildings comply with 0,1% sulfur fuel limit still comply with 0,1% sulfur fuel comply with 0,1% sulfur fuel limit

and retrofit installations. limit

21 © Wärtsilä PUBLIC 11-Jan-19 RT-Flex Training / Busan Training Centre

RT-FLEX DESIGN ASPECTS

Engine Numbering and Designations

Numbering starts at the flywheel

Components

01

01 Turbocharger

02 Auxiliary Blower 1

02 04

03 Thrust Bearing Pads

04 Auxiliary Blower 2

05 Cylinder Number

06 Main Bearing Number 05

DRIVING END FREE END

06

03

22 © Wärtsilä PUBLIC 11-Jan-19 RT-Flex Training / Busan Training Centre

RT-FLEX DESIGN ASPECTS

Engine Numbering and Designations

Numbering starts from the centre of flywheel

Components

01

01 Rail Unit

02 Supply Unit

02

23 © Wärtsilä PUBLIC 11-Jan-19 RT-Flex Training / Busan Training Centre

You might also like

- 737 Performance Reference Handbook - EASA EditionFrom Everand737 Performance Reference Handbook - EASA EditionRating: 4.5 out of 5 stars4.5/5 (3)

- Introduction to Fly-By-Wire Flight Control SystemsFrom EverandIntroduction to Fly-By-Wire Flight Control SystemsRating: 5 out of 5 stars5/5 (1)

- 1 RT-flex DesignDocument14 pages1 RT-flex DesignarunNo ratings yet

- 10 RT-flex Design Rev-03Document11 pages10 RT-flex Design Rev-03Arun ChandranNo ratings yet

- 010 RT-flex W-X DesignDocument14 pages010 RT-flex W-X DesignАнтон СорокаNo ratings yet

- 20 RT-flex MechanicalDocument60 pages20 RT-flex MechanicalKesavan Vimal KumarNo ratings yet

- 20 - RT-flex - Mechanical Features PDFDocument75 pages20 - RT-flex - Mechanical Features PDFИгорь БакановNo ratings yet

- 020 RT-flex Comp-Syst Rev-5.0Document186 pages020 RT-flex Comp-Syst Rev-5.0Piotr StankiewiczNo ratings yet

- RT-flex 1Document48 pagesRT-flex 1rafaelNo ratings yet

- 45 RT-flex WECS-9500 ShortDocument16 pages45 RT-flex WECS-9500 ShortАндрей СиманенковNo ratings yet

- Rtflex System PDFDocument67 pagesRtflex System PDFPintu KumarNo ratings yet

- 010 - RT-flex - W-X Design Aspect - Rev - 002Document13 pages010 - RT-flex - W-X Design Aspect - Rev - 002Alok KumarNo ratings yet

- Du Sulzer RT Flex EnglishDocument41 pagesDu Sulzer RT Flex Englishgiuliocool100% (1)

- 04 RT Flex Comp SystDocument64 pages04 RT Flex Comp SystA MovahediNo ratings yet

- 20 RT Flex Comp SystDocument124 pages20 RT Flex Comp SystАндрей СиманенковNo ratings yet

- 20 RT-flex MechanicalDocument43 pages20 RT-flex MechanicalGannavarapu KrishnaNo ratings yet

- 40 RT-flex Control-SystemDocument67 pages40 RT-flex Control-SystemАндрей СиманенковNo ratings yet

- 40 RT-flex Control-System Rev01Document68 pages40 RT-flex Control-System Rev01Mayvon Botelho100% (2)

- 40 RT-flex Control SystemDocument66 pages40 RT-flex Control SystemKesavan Vimal KumarNo ratings yet

- Edition: October 2003: RT-flex October 03 / 1 / RBDocument46 pagesEdition: October 2003: RT-flex October 03 / 1 / RBАндрей АндреевичNo ratings yet

- RT Flex Presentation Eng PDFDocument11 pagesRT Flex Presentation Eng PDFHanish SainiNo ratings yet

- 04 RT - Flex4 Course D Control Systems 9500Document56 pages04 RT - Flex4 Course D Control Systems 9500Franky D'costa100% (1)

- RT-flex-Introduction May13 Rev1Document96 pagesRT-flex-Introduction May13 Rev1NAGENDRA KUMAR D100% (1)

- RT-flex Course D1. ControlSystemsDocument32 pagesRT-flex Course D1. ControlSystemsAnonymous LM9RaUA4yNo ratings yet

- 10 RT-Flex DesignDocument16 pages10 RT-Flex DesignTudor-Mădălin Andrei100% (2)

- 003 5-Day RT-flex O-P General Information Rev-5.0Document15 pages003 5-Day RT-flex O-P General Information Rev-5.0Piotr StankiewiczNo ratings yet

- RT-flex82 WECS-9520 Control Rev.00Document60 pagesRT-flex82 WECS-9520 Control Rev.00Gaby CrisNo ratings yet

- Engine RT-flex Operation Practical AdvancedDocument3 pagesEngine RT-flex Operation Practical AdvancedPiotr StankiewiczNo ratings yet

- Vocabulario KomatsuDocument9 pagesVocabulario KomatsuFeri100% (1)

- Mohammed Hafez Soliman (2) 2Document14 pagesMohammed Hafez Soliman (2) 2كورا تيوبNo ratings yet

- 070.410-SPC1 RXF 12-50Document2 pages070.410-SPC1 RXF 12-50Mahmoud MohamedNo ratings yet

- Design of Mechanical Variable Valve ActuatorDocument10 pagesDesign of Mechanical Variable Valve ActuatoriocsachinNo ratings yet

- Electronically Controlled WinGD RT-FLEX - X EnginesDocument32 pagesElectronically Controlled WinGD RT-FLEX - X EnginesAlok KumarNo ratings yet

- 2004 Wartsila RT Flex DescDocument15 pages2004 Wartsila RT Flex Desckarloneilz100% (1)

- Aircraft - SpecSheetDetails - AT72-1025 - 27jun2021 r1Document11 pagesAircraft - SpecSheetDetails - AT72-1025 - 27jun2021 r1Heder NietoNo ratings yet

- 力士乐电液作动器样本Servo-Hydraulic Actuator SHA - 2018Document12 pages力士乐电液作动器样本Servo-Hydraulic Actuator SHA - 2018peterNo ratings yet

- RT-flex Course, 5-Days: For Service Engineers Ship's Machinery Crew Ship's Electrical Engineer Engine Builder PersonnelDocument10 pagesRT-flex Course, 5-Days: For Service Engineers Ship's Machinery Crew Ship's Electrical Engineer Engine Builder PersonnelGauravNo ratings yet

- RT-flex Course, 5-Days: For Service Engineers Ship's Machinery Crew Ship's Electrical Engineer Engine Builder PersonnelDocument10 pagesRT-flex Course, 5-Days: For Service Engineers Ship's Machinery Crew Ship's Electrical Engineer Engine Builder Personnelaz marine servicesNo ratings yet

- Sulzer Rta SeriesDocument24 pagesSulzer Rta SeriesIgorNo ratings yet

- AC TDS 9 36 DriveDocument375 pagesAC TDS 9 36 Drivenobodymagdesign100% (1)

- MTU 12V1600 DS650: Diesel Generator SetDocument4 pagesMTU 12V1600 DS650: Diesel Generator SetBao Le VietNo ratings yet

- Wise Masts ADocument120 pagesWise Masts ArkchdryNo ratings yet

- 04-07 Delta TuningDocument3 pages04-07 Delta Tuningr100% (1)

- Amm Ata 70 PDFDocument259 pagesAmm Ata 70 PDFcristianocfs100% (4)

- Fatigue Analysis Electric ActuatorDocument36 pagesFatigue Analysis Electric ActuatorAjimKe'en100% (1)

- RT Flex SulzerDocument59 pagesRT Flex SulzerEmurhohwo Jeremiah75% (4)

- RT-flex MechanicalDocument60 pagesRT-flex MechanicalAlok KumarNo ratings yet

- Steering SystemDocument79 pagesSteering SystemHassan ZAFFA CISNEROSNo ratings yet

- Enviando - 1866228934 PDFDocument451 pagesEnviando - 1866228934 PDFcarlosorizabaNo ratings yet

- A330 RR Trent 700 T7lm05r80-Ata-73 & 76Document36 pagesA330 RR Trent 700 T7lm05r80-Ata-73 & 76Shusant SahaNo ratings yet

- EASA Mod 15 BK 8 Jet Eng InstalDocument73 pagesEASA Mod 15 BK 8 Jet Eng InstalaviNo ratings yet

- SI-912-032 - SI-914-033 - SI-2ST-011 - Running Modifications of The Bing Constant Depression Carburetor For ROTAX Engine Type 912 and 914 Series and 582 UL Mod. 99-Mod. 17 SeriesDocument11 pagesSI-912-032 - SI-914-033 - SI-2ST-011 - Running Modifications of The Bing Constant Depression Carburetor For ROTAX Engine Type 912 and 914 Series and 582 UL Mod. 99-Mod. 17 SeriesAO BeltranNo ratings yet

- RT FlexDocument15 pagesRT FlexprasadcshettyNo ratings yet

- Service Training PDFDocument270 pagesService Training PDFLenin Valderrama Segura100% (2)

- Introduction to Fly-by-Wire Flight Control Systems: The professional pilot’s guide to understanding modern aircraft controlsFrom EverandIntroduction to Fly-by-Wire Flight Control Systems: The professional pilot’s guide to understanding modern aircraft controlsNo ratings yet

- Thomson Electrac HD Linear Actuator Motion Control per CAN BusFrom EverandThomson Electrac HD Linear Actuator Motion Control per CAN BusNo ratings yet

- Aviation Maintenance Technician Handbook—Powerplant (2024): FAA-H-8083-32BFrom EverandAviation Maintenance Technician Handbook—Powerplant (2024): FAA-H-8083-32BNo ratings yet

- Engine RT-flex Operation Practical AdvancedDocument3 pagesEngine RT-flex Operation Practical AdvancedPiotr StankiewiczNo ratings yet

- Linki YT ADocument1 pageLinki YT APiotr StankiewiczNo ratings yet

- Linki YTDocument1 pageLinki YTPiotr StankiewiczNo ratings yet

- Technicalupdate-HotWorkPermitandSafety Precautions in Connection With Welding and Cutting Work OnboardDocument39 pagesTechnicalupdate-HotWorkPermitandSafety Precautions in Connection With Welding and Cutting Work OnboardPiotr StankiewiczNo ratings yet

- 2.03 Moduł PDFDocument25 pages2.03 Moduł PDFPiotr StankiewiczNo ratings yet

- 2.03 Moduł PDFDocument25 pages2.03 Moduł PDFPiotr StankiewiczNo ratings yet

- RECYFIX STANDARD 100 Tipe 010 MW - C250Document2 pagesRECYFIX STANDARD 100 Tipe 010 MW - C250Dadang KurniaNo ratings yet

- Brahms Symphony No 4Document2 pagesBrahms Symphony No 4KlausNo ratings yet

- Lect2 - 1151 - Grillage AnalysisDocument31 pagesLect2 - 1151 - Grillage AnalysisCheong100% (1)

- I Pmtea 2020 HandoutDocument94 pagesI Pmtea 2020 HandoutAbhijeet Dutta100% (1)

- Enrico Fermi Pioneer of The at Ted GottfriedDocument156 pagesEnrico Fermi Pioneer of The at Ted GottfriedRobert Pérez MartinezNo ratings yet

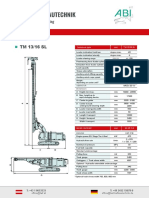

- ABI TM 13 16 SL - EngDocument1 pageABI TM 13 16 SL - EngJuan Carlos Benitez MartinezNo ratings yet

- Marion Nicoll: Life & Work by Catharine MastinDocument147 pagesMarion Nicoll: Life & Work by Catharine MastinArt Canada InstituteNo ratings yet

- Maha Vedha DikshaDocument1 pageMaha Vedha DikshaBallakrishnen SubramaniamNo ratings yet

- Final MS Access Project Class-10Document17 pagesFinal MS Access Project Class-10aaas44% (9)

- S Setting Value, C Check Value) OT Outside Tolerance (X Is Set)Document1 pageS Setting Value, C Check Value) OT Outside Tolerance (X Is Set)BaytolgaNo ratings yet

- Clint Freeman ResumeDocument2 pagesClint Freeman ResumeClint Tiberius FreemanNo ratings yet

- De Thi Chon Hoc Sinh Gioi Cap Tinh Mon Tieng Anh Lop 12 So GD DT Thanh Hoa Nam Hoc 2015 2016Document11 pagesDe Thi Chon Hoc Sinh Gioi Cap Tinh Mon Tieng Anh Lop 12 So GD DT Thanh Hoa Nam Hoc 2015 2016Thuy LinggNo ratings yet

- Classification of Books Using Python and FlaskDocument5 pagesClassification of Books Using Python and FlaskIJRASETPublicationsNo ratings yet

- Paper 1 AnalysisDocument2 pagesPaper 1 AnalysisNamanNo ratings yet

- LEMBAR JAWABAN CH.10 (Capital Budgeting Techniques)Document4 pagesLEMBAR JAWABAN CH.10 (Capital Budgeting Techniques)Cindy PNo ratings yet

- The Great Muslim Scientist - Imam Jaffer Sadiq (ADocument78 pagesThe Great Muslim Scientist - Imam Jaffer Sadiq (ASalman Book Centre100% (2)

- Crisis of The World Split Apart: Solzhenitsyn On The WestDocument52 pagesCrisis of The World Split Apart: Solzhenitsyn On The WestdodnkaNo ratings yet

- Spring 2010 - CS604 - 1 - SolutionDocument2 pagesSpring 2010 - CS604 - 1 - SolutionPower GirlsNo ratings yet

- Bgrim 1q2022Document56 pagesBgrim 1q2022Dianne SabadoNo ratings yet

- Hannah Mancoll - Research Paper Template - 3071692Document14 pagesHannah Mancoll - Research Paper Template - 3071692api-538205445No ratings yet

- Transparency and Digitalization in The Public Administration of RomaniaDocument8 pagesTransparency and Digitalization in The Public Administration of RomaniaMădălina MarincaşNo ratings yet

- Newsletter 1-2021 Nordic-Baltic RegionDocument30 pagesNewsletter 1-2021 Nordic-Baltic Regionapi-206643591100% (1)

- Cool Fire Manual 45M620N2UK 01 PDFDocument198 pagesCool Fire Manual 45M620N2UK 01 PDFPaun MihaiNo ratings yet

- Computer System Servicing 1 NC-II MODULE 8A (Second Semester: Week 6 - 7)Document19 pagesComputer System Servicing 1 NC-II MODULE 8A (Second Semester: Week 6 - 7)Carl John GomezNo ratings yet

- Enzymes IntroDocument33 pagesEnzymes IntropragyasimsNo ratings yet

- Reflection in Sexually Transmitted DiseaseDocument1 pageReflection in Sexually Transmitted Diseasewenna janeNo ratings yet

- Women Are Better Managers Than MenDocument5 pagesWomen Are Better Managers Than MenCorazon ValdezNo ratings yet

- Zimbabwe - Medical - CPIN - v2.0 - GOV - UKDocument39 pagesZimbabwe - Medical - CPIN - v2.0 - GOV - UKsammy redganjiNo ratings yet

- Matrix PBX Product CatalogueDocument12 pagesMatrix PBX Product CatalogueharshruthiaNo ratings yet

- Engineering DrawingDocument1 pageEngineering DrawingDreamtech PressNo ratings yet