Professional Documents

Culture Documents

Syllabus - Facilities Planning and Material Handling - Spring 2024

Uploaded by

christinahaddadin020 ratings0% found this document useful (0 votes)

1 views3 pagesThis document outlines the details of an undergraduate course on Facilities Planning and Material Handling offered during the spring semester of 2024 at the University of Jordan. The 3-credit course is taught by Dr. Nibal Albashabsheh and covers topics such as strategic facilities planning, product and process design, layout planning, and warehouse operations. Assessment includes a midterm, quizzes, projects, and a final exam. Upon completing the course, students will be able to understand facilities planning processes, analyze relationships between facility components, and consider necessary space and flow requirements.

Original Description:

Original Title

Syllabus_Facilities Planning and Material Handling_ Spring 2024

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis document outlines the details of an undergraduate course on Facilities Planning and Material Handling offered during the spring semester of 2024 at the University of Jordan. The 3-credit course is taught by Dr. Nibal Albashabsheh and covers topics such as strategic facilities planning, product and process design, layout planning, and warehouse operations. Assessment includes a midterm, quizzes, projects, and a final exam. Upon completing the course, students will be able to understand facilities planning processes, analyze relationships between facility components, and consider necessary space and flow requirements.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

1 views3 pagesSyllabus - Facilities Planning and Material Handling - Spring 2024

Uploaded by

christinahaddadin02This document outlines the details of an undergraduate course on Facilities Planning and Material Handling offered during the spring semester of 2024 at the University of Jordan. The 3-credit course is taught by Dr. Nibal Albashabsheh and covers topics such as strategic facilities planning, product and process design, layout planning, and warehouse operations. Assessment includes a midterm, quizzes, projects, and a final exam. Upon completing the course, students will be able to understand facilities planning processes, analyze relationships between facility components, and consider necessary space and flow requirements.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 3

The University of Jordan

School of Engineering

Industrial Engineering Department

Spring semester 2024

Course name: Facilities Planning and Material Handling

Course code: 0906425

Credits hours 3

Contact hours& room\office Monday, Wednesday 10:00-11:30 am

hours:

Nibal Albashabsheh, Ph.D.

Course instructor’s name, E-

mail, and phone:

n.albashabsheh@ju.edu.jo

22938

Course Coordinator: Nibal Albashabsheh, Ph.D.

Text book: Facilities Planning, Tompkins and others, 4th Ed., Wiley and Sons, 2010.

“Operations Management: Process and Supply Chains”, By: Lee L.

Other reference(s): Krajweski and Others, Pearson, Eleventh Edition, 2015.

This course is designed to introduce Strategic Facilities Planning, Location

Selection. Product, Process and Schedule Design. Flow, Space and Activity

Course Description:

Relationships, Personnel Requirements. Material Handling. Layout,

Computer-Aided Layout. Warehouses.

Providing Department: Industrial Engineering

Prerequisite Course: 0906421

Course type Mandatory

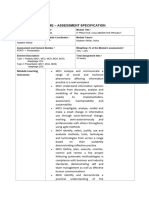

Method Weight % Date

Midterm 30 TBDL

Assessment Methods: Quizzes 20 TBDL

Projects/HomeWorks 10 TBDL

Final Exam 40 TBDL

After successful completion of this

# SO

course, the student will be able to

To understand significance of strategic 1

facilities planning process and developing

CLO1

strategies for various types of facilities.

Course Learning Outcomes: To determine the interrelationship 2

CLO2 between product, process and scheduling

design.

To provide the necessary considerations, 2

flow system, activity relationship and

CLO3

space requirements in determining the

necessities in a facility.

Page 1 of 3 Revised on:

Week # Topic

1 Introduction: Facilities Planning Defined, Significance of Facilities

Planning, Objectives of Facilities Planning, Facilities Planning Process,

Strategic Facilities Planning, Developing Facilities Planning Strategies.

2-3 Product, Process, and Schedule Design: Introduction, Product Design,

Process Design, Schedule Design, Facilities Design.

4-5 Flow Systems, Activity Relationships, and Space

Requirements: Introduction, Flow Systems, Material Flow System,

Departmental Planning, Activity Relationships, Space Requirements.

6-9 Personnel Requirements: Introduction, The Employee– Facility

Interface, Restrooms, Food Services, Health Services, Office Facility

Planning.

Brief list of topics 10-12 Material Handling: Introduction, Scope and Definitions of Material

Handling, Material Handling

Principles, Designing Material Handling Systems, Unit Load Design,

Material Handling Equipment, Estimating Material Handling Costs, Safety

Considerations.

13-15 Layout Planning models and Design Algorithms:

Introduction, Basic Layout Types, Layout Procedures,

Algorithmic Approaches, Department Shapes and Mail

Aisles, Multi-Floor Facility Layout, Commercial Facility Layout Packages,

the impact of Change, Developing Layout Alternatives.

16 Warehouse Operations: Introduction, Missions of a

Warehouse, Functions in the Warehouse, Receiving and Shipping

Operations, Dock Locations, Storage Operations.

• Do not hesitate to ask questions.

• You are required to bring a notebook and take notes in classes.

• Students are expected to attend every class session and they are responsible for all

material, announcements, schedule changes, etc., discussed in class.

• Discuss the assignments among yourselves.

• Don’t Cheat; direct copying of others work will NOT be allowed or tolerated and will

Important Notes: result in a reduction of grade. If you are found to be cheating in any way, on an exam

or assignment, even signing the roll sheet for another student, you will be given an

“F” for the course. There will be no exceptions.

• All cases of academic dishonesty will be handled in accordance with university

policies and regulations. JU policy requires the faculty member to assign ZERO grade

(F) if a student misses 15% of the classes that are not excused, and 20% of the classes

that are excused.

• Students are expected to be ready to take a quiz any time they have a class. There will

be no make-up quizzes or homework.

Page 2 of 3 Revised on:

Any students with disabilities who need accommodations in this course are encouraged to

speak with the instructor as soon as possible to make appropriate arrangements for these

accommodations.

The B.Sc. in industrial Engineering program enables students to achieve, by the time of graduation the

following program learning outcome (SOs)

an ability to identify, formulate, and solve complex engineering problems by applying principles of

1 engineering, science, and mathematics

an ability to apply engineering design to produce solutions that meet specified needs with consideration of

2 public health, safety, and welfare, as well as global, cultural, social, environmental, and economic factors

3 an ability to communicate effectively with a range of audiences

an ability to recognize ethical and professional responsibilities in engineering situations and make

4 informed judgments, which must consider the impact of engineering solutions in global, economic,

environmental, and societal contexts

an ability to function effectively on a team whose members together provide leadership, create a

5 collaborative and inclusive environment, establish goals, plan tasks, and meet objectives

an ability to develop and conduct appropriate experimentation, analyze and interpret data, and use

6 engineering judgment to draw conclusions

7 an ability to acquire and apply new knowledge as needed, using appropriate learning strategies

Page 3 of 3 Revised on:

You might also like

- CalibrationDocument155 pagesCalibrationBhegz Escalona100% (3)

- 3512B B 1014bkW 1360bhp 1600rpmDocument6 pages3512B B 1014bkW 1360bhp 1600rpmMILADNo ratings yet

- FATE - Atomic Robo - Majestic 12Document82 pagesFATE - Atomic Robo - Majestic 12jonjay100% (1)

- Engineering Education: Curriculum, Pedagogy and Didactic AspectsFrom EverandEngineering Education: Curriculum, Pedagogy and Didactic AspectsNo ratings yet

- Statement of Work (Sow) Examples Pernyataan Kerja (Sow) ContohDocument5 pagesStatement of Work (Sow) Examples Pernyataan Kerja (Sow) ContohAndi Didik Wira PutraNo ratings yet

- Yanbu Industrial College: High Voltage Cables (Day1)Document23 pagesYanbu Industrial College: High Voltage Cables (Day1)Latif Ismail Shaikh100% (1)

- 5539 Project ManagementDocument6 pages5539 Project Managementmeelas123No ratings yet

- Management Science NotesDocument20 pagesManagement Science NotesKaruNo ratings yet

- Cse205Document25 pagesCse205Aman SinghNo ratings yet

- Course Outline - Managing Complex Projects in Technical ConcernsDocument6 pagesCourse Outline - Managing Complex Projects in Technical Concernsrimsha suman036No ratings yet

- Çankaya University: IE 302 Facilities Design and Location Spring 2017Document2 pagesÇankaya University: IE 302 Facilities Design and Location Spring 2017santhosh kumar t mNo ratings yet

- UT Dallas Syllabus For cs6359.002.09s Taught by (rxb080100)Document6 pagesUT Dallas Syllabus For cs6359.002.09s Taught by (rxb080100)UT Dallas Provost's Technology GroupNo ratings yet

- MBCQ 722 Operations & Materials Management L T P C 2 1 0 3 Pre-requisites/Exposure Graduate in Engineering/Science Discipline Co-RequisitesDocument8 pagesMBCQ 722 Operations & Materials Management L T P C 2 1 0 3 Pre-requisites/Exposure Graduate in Engineering/Science Discipline Co-RequisitesSenthil Kumar GanesanNo ratings yet

- NAAC NBA WS 1 Dixit PDFDocument29 pagesNAAC NBA WS 1 Dixit PDFMadhusudhan D100% (1)

- Cs2201 Operating Systems Mahesh Jangid CoursehandoutDocument5 pagesCs2201 Operating Systems Mahesh Jangid CoursehandoutTactician VXPNo ratings yet

- Cse317 Spring2023 DaaDocument8 pagesCse317 Spring2023 DaaZainab KhanNo ratings yet

- Semester 2 - 2020 Abpl90293: Commercial Construction: Introduction and Course InformationDocument22 pagesSemester 2 - 2020 Abpl90293: Commercial Construction: Introduction and Course InformationBhargav PrakashNo ratings yet

- CDB3044 Process Plant Design Semester Jan 2020: Course Syllabus Learning OutcomesDocument13 pagesCDB3044 Process Plant Design Semester Jan 2020: Course Syllabus Learning OutcomesAqilah HanimNo ratings yet

- April 2022 Syllabus Production Managememt - AsiinDocument8 pagesApril 2022 Syllabus Production Managememt - AsiinQuỳnh DungNo ratings yet

- Course File: B.L.D.E.A's Vachana Pitamaha Dr. P.G. Halakatti College of Engineering & Technology, Vijayapur - 586 103Document60 pagesCourse File: B.L.D.E.A's Vachana Pitamaha Dr. P.G. Halakatti College of Engineering & Technology, Vijayapur - 586 103jagaenatorNo ratings yet

- Course Handout-Computer Networks - CS1602Document9 pagesCourse Handout-Computer Networks - CS1602none nadaNo ratings yet

- Attachment 1614632736Document5 pagesAttachment 1614632736Usama AliNo ratings yet

- CEB814 Project Management - CDDocument3 pagesCEB814 Project Management - CDalexNo ratings yet

- Manipal University JaipurDocument8 pagesManipal University JaipurAatmaj SalunkeNo ratings yet

- DAA-2020-21 Final Updated Course FileDocument49 pagesDAA-2020-21 Final Updated Course FileTejasvi QueenyNo ratings yet

- UT Dallas Syllabus For cs6359.501.08f Taught by (rxb080100)Document6 pagesUT Dallas Syllabus For cs6359.501.08f Taught by (rxb080100)UT Dallas Provost's Technology GroupNo ratings yet

- Course Outline - OPN501Document4 pagesCourse Outline - OPN501Raisul45No ratings yet

- Course Handout (Student & Faculty) : Course Plan Project Management (ME 743)Document5 pagesCourse Handout (Student & Faculty) : Course Plan Project Management (ME 743)Nikhil ChechiNo ratings yet

- Core OM - Term 1 - 2019Document5 pagesCore OM - Term 1 - 2019chandel08No ratings yet

- For Bachelor of Science in Information Technology (2022 Course) (With Effect From 2022-23)Document6 pagesFor Bachelor of Science in Information Technology (2022 Course) (With Effect From 2022-23)Mit MakwanaNo ratings yet

- IT PRACTICE PORT1 Specs 23 - 24Document8 pagesIT PRACTICE PORT1 Specs 23 - 24alaamriotaxiNo ratings yet

- MCA-4sem Microprocessor and Systems SoftwareDocument34 pagesMCA-4sem Microprocessor and Systems Softwareatul211988No ratings yet

- MCA-4sem Computer Graphics and AnimationDocument34 pagesMCA-4sem Computer Graphics and Animationatul211988No ratings yet

- MBA CBCS Syllabus BookletDocument262 pagesMBA CBCS Syllabus BookletV A R UNNo ratings yet

- 1 Daycourse NotesDocument67 pages1 Daycourse NotesHtet lin AgNo ratings yet

- IT3102 - SE - Course Handout - Aug - Nov 2022Document8 pagesIT3102 - SE - Course Handout - Aug - Nov 2022mayankNo ratings yet

- Alliance College of Engineering and Design: Data Base Management SystemsDocument7 pagesAlliance College of Engineering and Design: Data Base Management SystemsAishwarya RajeshNo ratings yet

- CSE320 Lecture0Document34 pagesCSE320 Lecture0naman vermaNo ratings yet

- Course Outline - OMSDocument5 pagesCourse Outline - OMSKaranNo ratings yet

- Department of Computer Science & EngineeringDocument27 pagesDepartment of Computer Science & EngineeringImranNo ratings yet

- B Cee 451 Course OutlineDocument4 pagesB Cee 451 Course OutlineBrunoNo ratings yet

- Operations Research IDocument3 pagesOperations Research IKhaled TitiNo ratings yet

- Week 2 - A Sample of A Short Research ProposalDocument4 pagesWeek 2 - A Sample of A Short Research ProposalIsrael PopeNo ratings yet

- Course Information SBEC 4763 - Construction Site Management - 2020.2021.2Document6 pagesCourse Information SBEC 4763 - Construction Site Management - 2020.2021.2NUR AZLIN IDAYUNo ratings yet

- Engg Project Management Lec1-2 (CASE Islamabad)Document108 pagesEngg Project Management Lec1-2 (CASE Islamabad)Rameez AnwarNo ratings yet

- Civ420 Syllabus 2014Document4 pagesCiv420 Syllabus 2014hib_aliNo ratings yet

- Outcome Based Education: Vinaychandna@Yahoo - Co.InDocument17 pagesOutcome Based Education: Vinaychandna@Yahoo - Co.InTovindra Kumar SahuNo ratings yet

- Ceng 423: Methods and Equipment For Construction I: Knassar@aucegypt - EduDocument5 pagesCeng 423: Methods and Equipment For Construction I: Knassar@aucegypt - Edudina wagdyNo ratings yet

- B. ARCH - Syllabus - Subject Wise 9 & 10 Semester PDFDocument17 pagesB. ARCH - Syllabus - Subject Wise 9 & 10 Semester PDFSHUBHAM ARORANo ratings yet

- Module Outline: Building Services (BLD 61904)Document10 pagesModule Outline: Building Services (BLD 61904)jarren foongNo ratings yet

- Module OutlineDocument4 pagesModule OutlineNajmah RaheemNo ratings yet

- CSE 357 Zero LectureDocument16 pagesCSE 357 Zero Lectureashokgehlot2100No ratings yet

- CMPS 307 Fall 2022Document5 pagesCMPS 307 Fall 2022lejogo2027No ratings yet

- CSE320 Lecture0Document34 pagesCSE320 Lecture0prashantpanwar003003No ratings yet

- UntitledDocument90 pagesUntitledSujal SahuNo ratings yet

- Module Title Project Management Type/ Status Prerequisites N/A Module Code Credits: 3 (Lectures 45 Hours) Learning OutcomesDocument4 pagesModule Title Project Management Type/ Status Prerequisites N/A Module Code Credits: 3 (Lectures 45 Hours) Learning Outcomesasela deshapriyaNo ratings yet

- ECVL420 F22 SyllabusDocument4 pagesECVL420 F22 SyllabusEng. Chris Kioko NdandiNo ratings yet

- BDA Lab ManualDocument62 pagesBDA Lab ManualReyansh PerkinNo ratings yet

- Construction Site ManagementDocument6 pagesConstruction Site ManagementThe BRT ConsultNo ratings yet

- Lab Manual Dsa Fymca MgmuDocument24 pagesLab Manual Dsa Fymca MgmuBeta12 SinghNo ratings yet

- 32 CivsyllDocument63 pages32 CivsyllTamil Selvi CIVILNo ratings yet

- Sample Proposal With CommentDocument3 pagesSample Proposal With CommentarulgasparNo ratings yet

- MPMC Theory Handout CS1403Document7 pagesMPMC Theory Handout CS1403John CameronNo ratings yet

- Course Outline Project MGT BBA7th Fall 2023Document5 pagesCourse Outline Project MGT BBA7th Fall 2023Liam NoahNo ratings yet

- STUDENT 01slide Week 1Document67 pagesSTUDENT 01slide Week 1TENZINNo ratings yet

- Using Slide Master in Powerpoint 2010Document5 pagesUsing Slide Master in Powerpoint 2010AHMAD AZHARNo ratings yet

- Comments On Candidate Performance: ReadingDocument13 pagesComments On Candidate Performance: ReadingBarun BeheraNo ratings yet

- HSC 2008 Mathematics Extension 2 Solutions - Jan HansenDocument14 pagesHSC 2008 Mathematics Extension 2 Solutions - Jan HansenGao WeiquanNo ratings yet

- JBL Professional Enclosure Guide: Box Dimensions Are in InchesDocument5 pagesJBL Professional Enclosure Guide: Box Dimensions Are in InchesArmando BNo ratings yet

- Kinetics Body Work&Energy Impulse&MomentumDocument26 pagesKinetics Body Work&Energy Impulse&MomentumKano MolapisiNo ratings yet

- (ECM) X1 (Diesel)Document5 pages(ECM) X1 (Diesel)Jairo CoxNo ratings yet

- Space Robotics: PreviewDocument21 pagesSpace Robotics: PreviewAnvit TiwariNo ratings yet

- Tesis Damian TDocument359 pagesTesis Damian TpalfrancaNo ratings yet

- The Influence of The Integrated Marketing Communication On The Consumer Buying Behaviour PDFDocument5 pagesThe Influence of The Integrated Marketing Communication On The Consumer Buying Behaviour PDFPrimaGriseldaNo ratings yet

- Test Bank For Campbell Biology, 10th Edition, Jane B. Reece, Lisa A. Urry, Michael L. Cain, Steven A. Wasserman, Peter V. Minorsky Robert B. JacksonDocument35 pagesTest Bank For Campbell Biology, 10th Edition, Jane B. Reece, Lisa A. Urry, Michael L. Cain, Steven A. Wasserman, Peter V. Minorsky Robert B. Jacksonhermeticfairhoodr2ygm100% (10)

- Brain Controlled Car For Disabled Using AiDocument21 pagesBrain Controlled Car For Disabled Using AiS.T KAUSALYAA100% (1)

- Space TelescopesDocument141 pagesSpace TelescopesPat StakemNo ratings yet

- Catalog Telecommunication Cable PDFDocument29 pagesCatalog Telecommunication Cable PDFVictor AxelsonNo ratings yet

- All Thread ChartsDocument6 pagesAll Thread ChartsSHANENo ratings yet

- Fc406 q1 Tabilin, GizelleDocument3 pagesFc406 q1 Tabilin, GizelleGizelle Alcantara-TabilinNo ratings yet

- Bridge Design Manual - M23-50.03CompleteDocument1,302 pagesBridge Design Manual - M23-50.03CompleteJavier TalledoNo ratings yet

- Matthew Weise, "Understanding Meaningfulness in Video Games"Document80 pagesMatthew Weise, "Understanding Meaningfulness in Video Games"MIT Comparative Media Studies/WritingNo ratings yet

- Mercury Mariner CDI Electronics DVA ChartsDocument16 pagesMercury Mariner CDI Electronics DVA ChartsFstaRockr Burns100% (1)

- Joshua Anzalones ResumeDocument1 pageJoshua Anzalones Resumeapi-404755828No ratings yet

- Lesson Planning Quadratic & LinearDocument1 pageLesson Planning Quadratic & LinearJonathan RobinsonNo ratings yet

- JES-Equipment Maintenance LOG SheetDocument1 pageJES-Equipment Maintenance LOG Sheetlike saddamNo ratings yet

- 1902 - Rayleigh - On The Distillation of Binary MixturesDocument17 pages1902 - Rayleigh - On The Distillation of Binary MixturesmontoyazumaetaNo ratings yet

- Samina Shahid: Personal DataDocument3 pagesSamina Shahid: Personal DataHansNo ratings yet

- Chapter 1 5 Group 4Document31 pagesChapter 1 5 Group 4John Patrick TurgoNo ratings yet