Professional Documents

Culture Documents

RP 546

Uploaded by

Victor TobosqueOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

RP 546

Uploaded by

Victor TobosqueCopyright:

Available Formats

AAR Manual of Standards and Recommended Practices

04/2008

Locomotives and Locomotive Interchange Equipment

RP-546 PART 3

Part 3

MINIMUM REQUIREMENTS FOR MAIN RESERVOIR SYSTEM ON NEW AND

REBUILT DIESEL-ELECTRIC, ELECTRIC, AND GAS TURBINE

LOCOMOTIVES OF 800-HP CAPACITY AND GREATER

Recommended Practice

RP-546

Adopted: 1957; Revised: 1994, 2001

1.0 SCOPE

This recommended practice describes the minimum requirements for main reservoir air systems

on diesel-electric, electric, and gas turbine locomotives of 800-hp capacity and greater.

2.0 Air compressors shall be located in the coolest possible surroundings and shall be provided

with intercoolers of ample cooling capacity and minimum internal resistance to air flow. Adequate

louvres with filters shall be provided near the compressor unrestricted for air flow to compressor

intake filters.

3.0 Air compressor crankcase oil level indicators shall be so arranged that accurate readings can

be obtained with the compressor running.

4.0 Air compressor crankcase filling arrangement shall be such that it will be impossible to

overfill the crankcase.

5.0 Air compressor discharge connection shall be a four-bolt flanged type suitable for a minimum

of 2-in. IPS pipe.

6.0 Air compressor discharge safety valve, where used, shall be located so that a pipe tee to it is

4 ft to 6 ft from compressor discharge. The branch pipe from a tee to a safety valve is to be in a

vertical position, 12 in. to 18 in. long and not less than 1 1/4 in. IPS.

7.0 Compressors on locomotives arranged for multiple compressor operation shall be

synchronized.

8.0 Each air compressor shall be provided with not less than 60 ft of 2-in. IPS pipe or equivalent

between the compressor discharge and No. 1 main reservoir. Pipe shall be arranged to drain into

the No. 1 main reservoir or sump and shall be located on the roof or a place where it can readily

dissipate heat without accumulating a coating of dirt and grease. Where the return of the

radiating pipe passes through the engine room, it shall be well insulated.

9.0 The sump or No. 1 main reservoir receiving discharge from cooling coils shall be located

where it will not absorb engine room heat.

10.0 The No. 1 and No. 2 main reservoirs shall be connected with a minimum length of pipe of not

less than 1 1/2-in. IPS.

11.0 The main reservoir safety valve is to be located adjacent to the discharge end of the No. 1

main reservoir. When the safety valve is mounted on a branch pipe, the pipe is to be not less than

1 1/4-in. IPS, and the length is to not exceed 6 ft.

12.0 Each main reservoir, sump, air filter, intercooler, and dirt collector used in the main

reservoir radiation and air brake systems is to include manual drain cocks protected against

damage. No syphon drain arrangements are to be used.

13.0 The No. 1 main reservoirs (or main discharge sump) are to be provided with automatic drain

valves so located to maintain elimination of condensate and oil at all times.

14.0 No less than 6 in. of outlet pipe shall extend inside the No. 1 main reservoir.

04/2008 M [RP-546] 275

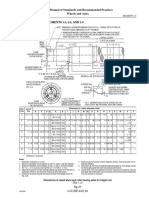

AAR Manual of Standards and Recommended Practices

04/2008

Locomotives and Locomotive Interchange Equipment

PART 3 RP-546

1 ½" PIPE B

2" DISCHARGE PIPE

COMPRESSOR MANUAL OVERRIDE

SOLENOID VALVE

OPTIONAL AUXILIARY AIR FILTER

FLANGE COUPLINGS TO PERMIT EASY

REMOVAL OF RADIATION PIPING FOR CLEANING 1 ¼" PIPE

150 LB. SAFETY VALVE

NO. 1 RESERVOIR 2" PIPE 824 FILTER OR EQUIV.

2" PIPE

C D 1" PIPE 1" PIPE

VENTED TO AUXILIARY DEVICES,

1" MAIN RESERVOIR C.O.C. END HORN, SANDING, WINDOW

VENTED END CHECK VALVE WIPERS, TOILET,

WATER COOLER, ETC.

NO. 2

TO BELL SHUTTER SOLENOID MAIN RESERVOIR E

TO AIR BRAKE

EQUIPMENT 1" PIPE 1" PIPE

1 ¼" PIPE

CHECK VALVE

F 1 ¼" MAIN RESERVOIR EQUALIZING PIPE WITH 1" SIDE

CONTROL AIR RESERVOIR G H

VENT CUT OUT COCKS AND 1" HOSE HAVING "L" TYPE

IF REQUIRED PER RULE 205(a) 1" COUPLINGS. (TWO OUTLETS ON END OF LOCOMOTIVE)

SIDE VENT IN 1" M.R. C.O.C. IN EQUALIZING PIPE (OPTIONAL).

Fig. 14.1 Main reservoir and radiation system for locomotives

A Optional safety valve located in vertical 1 1/2-in. pipe, 12 in. to 18 in. long with pipe tee located 4 ft to 6 ft from compressor.

B Unit equipped with dual-control, compressor governor control switch with solenoid. Switch to be panel-mounted and to

include quick disconnect piping and wiring, gauge, and test connection.

C Not less than 60 ft of 2-in. radiation piping to be sloped to drain into No. 1 main reservoir. Piping should be under running

board and must have a free sweep of cooling air. Provide sufficient openings in running board to ensure adequate air

circulation. Open-type grating is suitable for this.

D Automatic drain valve combined with manual drain valve to be readily accessible for convenient draining.

E Check valve optional, as specified by purchaser. To be provided with 5/16-in. orifice.

Alternate: C-1 main reservoir cut-off valve set at 75 psi to 85 psi.

F Manual drain valve reservoir to be readily accessible for convenient draining.

G Brake equipment filter should be moisture-collecting type. To be approved by the AAR Brake Committee. To be equipped

with automatic and manual drain valves. Capacity to equal or exceed New York Air Brake (NYAB) or WABCO Type Hor

Salem 824 filters.

H Automatic drain valve combined with manual drain valve to be readily accessible for convenient draining.

General Notes

1. All main reservoirs are to be sloped towards drain valve end, not less than 1/4 in./ft, to ensure drainage. Main reservoirs to

be free of any interior obstruction that can act as dams and prevent complete drainage. Air reservoirs with tell-tale drilling may

be located inside or outside. Location on roof should be avoided because of solar radiation. Reservoirs, whether inside or

outside, should have free sweep of outside ambient air.

2. Pipe system to have minimum number of bends and fittings. All pipes to be bent after fittings are applied by welding.

3. Threaded fittings are to be avoided if possible. Use bends, welded fittings, and/or flange fittings. Welded fittings are to be

butt-welded process, with argon/CO2 75/25 shielding gas, wire 0.030 in., Linde '65 or equivalent.

4. Exhaust from main reservoir drain valves to be deflected and directed toward center of track so as to not create a safety haz-

ard or raise dust that might interfere with train viewing en route.

5. Tell-tale holes to be drilled in main reservoir per Rules for Inspecting and Testing Locomotives Other Than Steam, Rule 206

(c), Department of Transportation, Federal Railroad Administration, Ex Parte 243.

M [RP-546] 276 04/2008

You might also like

- Example of Annual Audit Planning Work ProgramDocument2 pagesExample of Annual Audit Planning Work Programrindwa100% (1)

- Character QuestionsDocument3 pagesCharacter QuestionsAaron FarmerNo ratings yet

- Dokumen - Tips Equipment Iwcf CourseDocument42 pagesDokumen - Tips Equipment Iwcf CourseFranklinNo ratings yet

- Fuel Metering Valve: Operation and Maintenance InstructionsDocument33 pagesFuel Metering Valve: Operation and Maintenance Instructionsalaa fadhelNo ratings yet

- Condenser ManualDocument48 pagesCondenser ManualVishal Kumar Laddha100% (1)

- AWS Lecture NotesDocument4 pagesAWS Lecture NotesAsad Bin Ala Qatari0% (1)

- Purgador Aire HansenDocument12 pagesPurgador Aire Hansenyoye1968No ratings yet

- ValvesDocument82 pagesValvespuru55980No ratings yet

- 10 ValvesDocument23 pages10 ValvesPower PlantNo ratings yet

- BHEL Valves PDFDocument135 pagesBHEL Valves PDFNitin Aggarwal100% (1)

- Manual Llenado e Inspeccion Bladder TankDocument83 pagesManual Llenado e Inspeccion Bladder TankPaulina Andrea Jiménez VarasNo ratings yet

- RH Series Coiled Tubing Hangers - Wellhead Control ProductsDocument29 pagesRH Series Coiled Tubing Hangers - Wellhead Control Productsclaudio godinezNo ratings yet

- Contemporary Anaesthetic Equipments.: An Aid for Healthcare ProfessionalsFrom EverandContemporary Anaesthetic Equipments.: An Aid for Healthcare ProfessionalsNo ratings yet

- Recommendations For Stilling Wells For Tank Gauging - Honeywell EnrafDocument12 pagesRecommendations For Stilling Wells For Tank Gauging - Honeywell Enraffragercito100% (3)

- Prevention of Actuator Emissions in the Oil and Gas IndustryFrom EverandPrevention of Actuator Emissions in the Oil and Gas IndustryNo ratings yet

- Instruction Manual - EJ17 Ejector Chlorine, Sulfur Dioxide and AmmoniaDocument14 pagesInstruction Manual - EJ17 Ejector Chlorine, Sulfur Dioxide and AmmoniaAlexandre EmmerickNo ratings yet

- Electrical Service Minimum RequirmentDocument97 pagesElectrical Service Minimum RequirmentachniajosiNo ratings yet

- Close Up b1 AnswersDocument6 pagesClose Up b1 Answersmega dragos100% (1)

- TAMU - Pemex Offshore Drilling: Lesson 4 Blowout Preventers and Their ControlDocument59 pagesTAMU - Pemex Offshore Drilling: Lesson 4 Blowout Preventers and Their Controldriller220% (1)

- ZXDC48 FB101 Lithium-Ion Battery User Manual V1.0Document43 pagesZXDC48 FB101 Lithium-Ion Battery User Manual V1.0Luis Cruz96% (24)

- Toro 006Document2 pagesToro 006Eric CNo ratings yet

- System - Rated - Plus - W - Sub - 150 Water Hammer PPPDocument2 pagesSystem - Rated - Plus - W - Sub - 150 Water Hammer PPPJeffry GabilanNo ratings yet

- Manual - Vacuum Pump WRP25Document20 pagesManual - Vacuum Pump WRP25juaanxpoonceNo ratings yet

- Capital Controls® Series Nxt3000: Modular Design Gas Feed System With Self Contained Automatic Switchover CapabilityDocument8 pagesCapital Controls® Series Nxt3000: Modular Design Gas Feed System With Self Contained Automatic Switchover CapabilityLoan NguyênNo ratings yet

- BOPs and Their ControlDocument59 pagesBOPs and Their ControlMahmoud NassarNo ratings yet

- BS 31122 D (OilServ)Document14 pagesBS 31122 D (OilServ)Abou Mariya MoadNo ratings yet

- Twintower, Heatless, Regenerative Compressed Air Dryers - 8-75 CFM Models (PDF, 913KB)Document4 pagesTwintower, Heatless, Regenerative Compressed Air Dryers - 8-75 CFM Models (PDF, 913KB)Sudar MyshaNo ratings yet

- AP003j Auto PurgerDocument20 pagesAP003j Auto Purgerchris jonesNo ratings yet

- SH1 RFP - P4 OTR - Ch8 Balance of Plant - p21-24Document4 pagesSH1 RFP - P4 OTR - Ch8 Balance of Plant - p21-24SonNguyenNo ratings yet

- Deluge Valve Modelh5Document16 pagesDeluge Valve Modelh5Mariana HusainNo ratings yet

- High Capacity Gas Chlorinator: MODEL 2101Document4 pagesHigh Capacity Gas Chlorinator: MODEL 2101Al Patrick Dela CalzadaNo ratings yet

- Informacion TecnicaDocument20 pagesInformacion Tecnicasandra fiorelaNo ratings yet

- Fan Coil Unit - Small Profile - Unilux-2PipeDocument4 pagesFan Coil Unit - Small Profile - Unilux-2PipePamela De MeloNo ratings yet

- Manual de Válvula de Prevención de SobrellenadoDocument14 pagesManual de Válvula de Prevención de SobrellenadoEmiliano CamarenaNo ratings yet

- Banlaw TankVentsDocument6 pagesBanlaw TankVentsPriyogo SutantiyoNo ratings yet

- Deluge Valve Model-H2: HD Fire Protect Pvt. Ltd. (Cast Steel) Technical DataDocument16 pagesDeluge Valve Model-H2: HD Fire Protect Pvt. Ltd. (Cast Steel) Technical DataNethajiNo ratings yet

- 08-Conv Valves Product InfoDocument18 pages08-Conv Valves Product Infoakrk777No ratings yet

- Model D ManualDocument38 pagesModel D ManualVahidNo ratings yet

- SEC 226200 Laboratory Vacuum SystemDocument8 pagesSEC 226200 Laboratory Vacuum SystemAkilaJosephNo ratings yet

- API-Mechanical Seal-Piping Plan Booklet-LORES-4C-MAR2016 PDFDocument90 pagesAPI-Mechanical Seal-Piping Plan Booklet-LORES-4C-MAR2016 PDFrvkumar61No ratings yet

- Valvula Piloto 1.5 inDocument10 pagesValvula Piloto 1.5 inDurvis Joel Romero LopezNo ratings yet

- RegO 2014 Product GuideDocument8 pagesRegO 2014 Product GuideJason D ClarkNo ratings yet

- TARGET-Mechanical BOQDocument37 pagesTARGET-Mechanical BOQDILSHAD AHEMADNo ratings yet

- BJ INDONESIA CT and NITROGEN UNITDocument11 pagesBJ INDONESIA CT and NITROGEN UNITizzyguyNo ratings yet

- F51 450 FP AccessoriesDocument4 pagesF51 450 FP AccessoriesFayez Al-ahmadiNo ratings yet

- ACV 113-6RFP Specification SheetDocument4 pagesACV 113-6RFP Specification SheetWattsNo ratings yet

- Is 14845-2000 (Air Relief Valves) PDFDocument18 pagesIs 14845-2000 (Air Relief Valves) PDFSarbendu PaulNo ratings yet

- General Ducty Valves SpecDocument12 pagesGeneral Ducty Valves SpecpursuitofhappynessinNo ratings yet

- 2 Continental Hydraulics Directional Control Valves PDFDocument11 pages2 Continental Hydraulics Directional Control Valves PDFDaniel VillarroelNo ratings yet

- Subsea Engineering Training ReportDocument4 pagesSubsea Engineering Training ReportAbdulgar AbuduNo ratings yet

- Tyco Water Motor Alarm PDFDocument4 pagesTyco Water Motor Alarm PDFAlvin Minero100% (1)

- Cavitation and Water Hammer PDFDocument22 pagesCavitation and Water Hammer PDFsumeghNo ratings yet

- Valves Deluge Valve Model h3Document16 pagesValves Deluge Valve Model h3RaviNo ratings yet

- Lessons Learned-FINAL-NEW PDFDocument8 pagesLessons Learned-FINAL-NEW PDFImtinan MohsinNo ratings yet

- 1-XI - GB Steam Conditioning ManualDocument20 pages1-XI - GB Steam Conditioning ManualtxagusNo ratings yet

- Ciat LCH 1600ZDocument14 pagesCiat LCH 1600ZYoughourthen HendelNo ratings yet

- Valves Deluge Valve Model h3-bkp-03-04-2018Document16 pagesValves Deluge Valve Model h3-bkp-03-04-2018Benny Kurniawan LimNo ratings yet

- HP/LP Bypass System: House Load OperationDocument23 pagesHP/LP Bypass System: House Load Operationravi roshanNo ratings yet

- ML023300641 PDFDocument1 pageML023300641 PDFharryNo ratings yet

- Auto-Purger M "Energy Saver" Compact, Non-Condensible Gas (Air) PurgerDocument16 pagesAuto-Purger M "Energy Saver" Compact, Non-Condensible Gas (Air) PurgerJulian ArizaNo ratings yet

- Deluge Valve C1Document16 pagesDeluge Valve C1Rajadurai SinghNo ratings yet

- Duplex "Space Saver" Lubricated Rotary Vane Medical Vacuum Systems 1 Through 5 HPDocument2 pagesDuplex "Space Saver" Lubricated Rotary Vane Medical Vacuum Systems 1 Through 5 HPEng.Gihad EladlNo ratings yet

- 4 Water FloodDocument6 pages4 Water FloodEduardoWire100% (1)

- Is.14845.2000 0Document21 pagesIs.14845.2000 0Er Vikram BistaNo ratings yet

- Bop Control Unit SpecificationsDocument5 pagesBop Control Unit SpecificationsHKC EQUIPEMENTSNo ratings yet

- Msrp-G-Ii RP-633Document72 pagesMsrp-G-Ii RP-633Victor TobosqueNo ratings yet

- MSRP-G M-107 - 208Document36 pagesMSRP-G M-107 - 208Victor TobosqueNo ratings yet

- AAR Manual of Standards and Recommended Practices Coupler and Yoke DetailsDocument2 pagesAAR Manual of Standards and Recommended Practices Coupler and Yoke DetailsVictor TobosqueNo ratings yet

- Capitulo 11 Seccion CiiDocument18 pagesCapitulo 11 Seccion CiiVictor TobosqueNo ratings yet

- MSRP-G M-101Document20 pagesMSRP-G M-101Victor TobosqueNo ratings yet

- 2020-21 Series Test 1 QPDocument1 page2020-21 Series Test 1 QPred18ggmuNo ratings yet

- Features and ApplicationsDocument36 pagesFeatures and ApplicationsFWEFWEFWNo ratings yet

- Final Model Paper Computer Science HSSC-IIDocument9 pagesFinal Model Paper Computer Science HSSC-IIMUhammad Milad AwanNo ratings yet

- Form-1: Application Form For Gate Registration Fee Refund Under Teqip-IiiDocument1 pageForm-1: Application Form For Gate Registration Fee Refund Under Teqip-IiiWasim LaskarNo ratings yet

- TOC - Question AnswerDocument41 pagesTOC - Question AnsweretgegrgrgesNo ratings yet

- NCLFNP - Mr. Robert McClelland CaseDocument4 pagesNCLFNP - Mr. Robert McClelland CaseAiresh Lamao50% (2)

- Best IIT JEE NEET and ICSE, CBSE, SSC Classes in Hadapsar PuneDocument18 pagesBest IIT JEE NEET and ICSE, CBSE, SSC Classes in Hadapsar PuneTrinity AcademyNo ratings yet

- Learning Activity Sheet in Science-9: Week 7-Quarter 3Document5 pagesLearning Activity Sheet in Science-9: Week 7-Quarter 3theinvaderNo ratings yet

- PDF EnglishDocument36 pagesPDF EnglishSanti CheewabantherngNo ratings yet

- APP PinAAcle 900 Elemental Analysis of Beer by FAAS 012049 01Document3 pagesAPP PinAAcle 900 Elemental Analysis of Beer by FAAS 012049 01strubingeraNo ratings yet

- TUYA ManualDocument2 pagesTUYA ManualMagandang MallNo ratings yet

- Instructional Module: IM No.: IM-NSTP 1-1STSEM-2021-2022Document6 pagesInstructional Module: IM No.: IM-NSTP 1-1STSEM-2021-2022Princess DumlaoNo ratings yet

- Materi 2 - Obligation, Prohibition, and Suggestion - AdviceDocument12 pagesMateri 2 - Obligation, Prohibition, and Suggestion - AdviceShadrina ChaerunissaNo ratings yet

- LED Lighting Applications Design GuideDocument20 pagesLED Lighting Applications Design GuideBank100% (3)

- S&S PDFDocument224 pagesS&S PDFMohammed MateenNo ratings yet

- Service Manual: DDX24BT, DDX340BTDocument94 pagesService Manual: DDX24BT, DDX340BTDumur SaileshNo ratings yet

- B737 SRM 51 - 40 - 08 Rep - Fiberglass OverlaysDocument6 pagesB737 SRM 51 - 40 - 08 Rep - Fiberglass OverlaysAlex CanizalezNo ratings yet

- Pure Theory of Law Hans Kelson-Ltp..Document45 pagesPure Theory of Law Hans Kelson-Ltp..ShabnamNo ratings yet

- Getting You To Test Day: An 8-Week Prep Plan For The TOEFL TestDocument2 pagesGetting You To Test Day: An 8-Week Prep Plan For The TOEFL Testsmith90No ratings yet

- VRV Heat Recovery REYQ-XDocument20 pagesVRV Heat Recovery REYQ-XFrancisco LinaresNo ratings yet

- Principal's Corner: School ProfileDocument7 pagesPrincipal's Corner: School ProfileAngel Mae LabadorNo ratings yet

- Ineo+ 200 Parts Guide ManualDocument90 pagesIneo+ 200 Parts Guide ManualOláh GyörgyNo ratings yet