Professional Documents

Culture Documents

ML023300641 PDF

Uploaded by

harryOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

ML023300641 PDF

Uploaded by

harryCopyright:

Available Formats

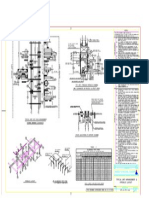

LlNE C O D I N G

VALVE ACCESSORIES, DEFINITIONS A N D ABBREVIATIONS

&

OIAPHRAGM VALVE

GATE VALVE

-D.<t

GLOBE VALVE

BUTTERFLY

VALVE IOPEN)

--I Ef b-

BUTTERFLY

VALVE ICLOSED)

--I b-

-*

BALL VALVE

h

'P

VACUUM

BREAKER

A1

ANGLE VALVE

3-WAY VALVE

4-WAY VALVE

ANGLE R E L I E F OR

SAFETY VALVE

CONTROL

NEEOLE V K V E

+

+

,

CHECK VALVE

1 SWING1

ORIFICED VALVE

_(>t-

CHECK VALVE

(LIFT)

STOP CHECK VALVE

STOP CHECK VALVE

HANO OPERATEO

--

*

A

%

-4%

OUT OF SYSTEM

DASHED

VALVES ARE

SELF REGULATING

VALVE

-&

THROTTLE VALVE.

HANUAL. GATE.

GLOBE. ETC.

STOP VALVE

INSTRUMENT

ACTUATEO

PREFILTER I A I R OR GAS1

REOUCTION

STRAINER

TRAP

4EF

FILTER

I m E R S I O N HEATER

1 STEAM OR ELECTRICAL1

BAG F I L T E R

FLEXIBLE CONNECTION

ROUGHING F I L T E R

u

u

FLOW METER

ORIFICE

El-

MULTI-PRESSURE

REOUCING ORIFICE

W I C K COUPLING

BREAKDOWN

ORIFICE

RUPTURE DISC

START UP F I L T E R

ROOF EXHAUST FAN

--II:

HOSE ADAPTOR FLANGE

--3

CAWED L I N E

TEST CONNECTION

GRAVITY VENT

LOUVER

MOISTURE SEPERATOR AN0

MEDIR TYPE M I S T

ELIMINGTOR

IF

v

STRAINER

IY-TYPE1

-0-

SIGHT FLOW

INOICATOR

STRRIGHTENING

VANES

4

E

FAN AXIAL BLOWER

TEMPORARY

STRAINER

STRAINER

(FLUSH TYPE1

HEATING OR COOLING C O I L

POSITIVE

OISPLACEMENT

PUMP

SAFETY CLASS

SAFETY CLASS 1 ISC-11

SAFETY CLASS 2 1 s t - 2 1

SAFETY CLASS 3 (SC-31

NON-NUCLEAR SAFETY CLASS 1

INNS-CL11

NON-NUCLEAR SAFETY CLASS 2

INNS-CL21

P

F

L

T

C

A

0

R

S

W

- PRESSURE

- FLOW

- LEVEL

- TEMPERATURE

OR TRANSMITTER OR TEST

- CONOUCTIVITY OR CONTROL

- ANALYZER OR ALARM

- POWER

- RADIATION OR RECOROING

- SPEEO OR SWITCH

- WEIGHT

I- I M I C A T O R

G - GAUGE OR GLASS

V - VALVE

A0 - A I R TO OPEN

AC - A I R TO CLOSE

HI

LO

Y

E

H

M

RW - RAW WATER

SO - SANITARY DRAIN 8. STORM DRAINS

TW

OWC -DOMESTIC WATER - COLD

FA1

FC

OWH -DOMESTIC WATER - HOT

FO

DWHR - DOMESTIC WATER HOT RECIRCULATING

TO

CR - CONDENSATE RETURN ITRAPS)

PO

GA - GAS ANALYZER

PH

OH - ORAIN HEADER

L.C.

CG - CARBON OIOXIOE GAS

L.O.

PW - POTABLE WATER

- HIGH

-

LOW

MISCELLANEOUS

ELEMENT

HAND

MODIFIER

- TESTWELL

- F A I L AS I S

- F A I L CLOSED

- F A I L OPEN

- TEMPERATURE OIFFERANCE

- PRESSURE OIFFERANCE

- PH

- LOCKED CLOSE0

- LOCKED OPEN

1

1

2

3

4

USAS

USAS

USAS

USAS

0 3 1 . 7 CLASS I

031.7 CLASS I1

031.7 CLASS 111

831.1

USAS 031.1

VOLUME DAMPER (MANUAL)

ASME

ASME

ASME

ANSI

111 CLASS 1

111 CLASS 2

111 CLASS 3

831.1

OAMPER WITH FUSE L I N K

AND SPRING OPENER.

HEAT EXCHANGER

(ANY TYPE)

OIAPHRAGM GLOBE

WlPffiT

OIAPHRAGM

OPERATOR

AIR OR

WATER COOLED C O I L

FACE AN0 BYPASS

OAMPER

11. EN0 PREPARATION FOR STAINLESS STEEL P I P I N G SHALL BE I N

ACCOROANCE WITH ORAWING XB-545-M-158 UNLESS OTHERWISE NOTEO.

12. EN0 PREPARATION FOR CARBON STEEL P I P I N G SHALL BE I N

ACCORDANCE WITH ASA 0 1 6 . 2 5 FIGURES A1B OR S.AS APPl ITABLE.

1 3 . P I P I N G AN0 EOUIPMENT I N T H I S SYSTEM SHALL BE INSULATE0 I N

ACCORDANCE WITH G R H SPECIFICATION H - 3

ANSI 831.1

111 H V d 1 L I M I T E D COEI F I R E

PROlECTION OR RAOIOACTIVE

WASTE D I S P O S d

CONTINUATION FLAG

MATCH L E T I E R ( S I

E-23866-210-12O.SH.2B

\

'-DRAWING

T O REFER TO

FOR CONTINUATION

SMALL CANNED

MOTOR PUMP

1. P I P I N G 2" AN0 SMALLER SHALL BE RUN I N F I E L O TO S U I T LOCAL

CONOITIONS SUBJECT TO APPROVAL OF THE ENGINEERS.

2. A L L LOCATIONS SHDWN ON OESIGN ORAWINGS ARE FOR P I P E I N

THE COLD ERECTED POSITION.

3. NO ALLOWANCE HAS BEEN MADE FOR WELD GAPS OR GASKET

THICKNESS.

4. A L L OPEN ORAINS AN0 FREEBLOWS MUST BE V I S I B L E AT P O I N I

OF DISCHARGE.

5. ANY EXCEPTIONS TO THE GENERAL NOTES ARE SHOWN ON THE

OESIGN ORAWINGS.

6. ALL TE. T I AND TW INSTRUMENT CONNECTIONS ON P I P I N G SHALL

BE 1' SCREWED UNLESS OTHERWISE NOTEO.

7. ALL F T , PA, PC. P I AND PT INSTRUMENT CONNECTIONS ON P I P I N G

SHALL BE I'S.W.UNLESS

OTHERWISE NOTEO.

NON-COE

P I P I N G CODE OF

CONSTRUCTION

0AMPER.OPPOSED BLADES

GEAR PUMP

GENERAL NOTES:

OUALITY ASSURANCE

CLASS

COE

COE

CUE

111

CENTRIFUGAL

PUMP

4%

CONTINUATION FLAG

17. EN0 TO END DIMENSIONS OF VALVES. WHERE SHOWN, ARE TO BE MAINTAINEO.

18. P I P I N G SHALL BE SUPPORTED I N A MANNER THAT PREVENTS UNDUE

STRESSES ON EOUIPMENT.

14. F I E L D RUN P I P I N G SHALL NOT INTERFERE WITH PLATFORMS AND

ACCESS TO VALVES AN0 OTHER EOUIPMENT.

20. FOR ROOT VALVE NUMBER ON A L L INSTRUMENT CONNECTIONS.

SEE APPROPRIATE FLOW OIAGRRM.

21. ALL INSTRUMENT CONNECTIONS ON P I P I N G HEAOERS SHALL BE SOCKET

WELO TYPE EXCEPT AS INOICATEO I N NOTE 'q AND ON OESIGN ORAWINGS.

22. P I P I N G FABRICATOR TO PROVIDE COMPANION FLANGES TO AGREE WITH

CERTIFIED MANUFACTURES EOUIPMENT ORAWINGS.

23. FOR VENTILATION NOTES SEE G & H DRAWING 11485-M-76.

24. A L L GLOBE VALVES SHALL BE NORMALLY INSTALLED WITH FLOW

UNDER SEAT. FOR EXCEPTIONS.REFER TO NOTES ON P I P I N G ORAWINGS

AN0 G 6. H FLOW DIAGRAMS.

25. WHERE PURCHASE0 EQUIPMENT DIFFERS FROM THAT SHOWN ON ORAWINGS.

VENTILATION CONTRACTOR TO MODIFY OUCTWORK TO S U I T

F I E L D CONOITIONS.

26. WHERE PURCHASED VALVES AM0 MECHANICAL EOUIPMENT DIFFER FROM THAT

SHOWN ON P I P I N G 0RAWINGS.PIPING CONTRACTOR TO MOOIFY P I P I N G

TO S U I T F I E L D CONOITIONS.

MOTOR

WERATOR

TANK ACCESS OPENING

PISTON

OPERATOR

+L

SOLENOID

OPERATED VALVE

REMOTE

MECHANICALLY

OPERATEO VALVE

-!r

-&-

SYMBOL

1

2

3

4

0RMPER.PRRALLEL BLADES

THROTTLE VALVE

REMOTE MANUAL

TRIP VALVE

SAFETY CLASS BOUNOARY

BETWEEN SC-1 AND SC-2

OAMPER.

COUNTER WEIGHT OPERATEO

4-

ELECTRICAL CONTROi L I N E S

SYMBOL INDICATES SAFETY CLASS 1 THRU

NON-NUCLEAR SAFETY CLASS 1.

SOLID INDICATES NUN-NUCLEAR SAFETY CLASS 2

INNS-CLZI

EXAMPLE:

IN-DUCT HEATER

I

I

T R I P VALVE

INTERNAL

CHECK VALVE

1

I CONTROL

OF ACCUMULATMI

I

I- - - OPERATOR

----

ANNUNCIATE0 ALARM

SYMBOL

ICONT'D.1

FAN. BLOWER.

OR COMPRESSOR

HOSE COUPLING

UNION

CONTAINMENT PURGE

A I R OUCTWORK

TRIP AND CONTROL ROOM

DEMINISTER

THERMAL SLEEVE

--II

CONTROL ROOM ANNUNCIATED A L M M

RC - REACTOR COOLANT SYSTEM

S I - SAFETY INJECTION SYSTEM

AC - AUXILIARY COOLANT SYSTEM

CH - CHEMICAL R VOLUME CONTROL SYSTEM

SL - SAMPLING SYSTEM

WD -WASTE OISPOSAL SYSTEM

MS - M A I N STEAM

AS - W X I L I A R Y STEAM

BD - BLOWDOWN

FW - FEEOWATER

CA - PLANT A I R

I A - INSTRUMENT A I R

HG - HYDROGEN

NG - NITROGEN

OW - OEMINERALIZEO WATER

CF - CHEMICAL FEE0

V - VENT

0 - DRAIN

CSR - CONTAINMENT SPRAY 8 REFUELING WATER SYSTEM

ROLL F I L T E R

-1)-

BLIND FLANGE

0----Q

0.

= HIGH ALARM. HH = VERY HIGH ALARM

* * L = LOW ALARN. L L = VERY LOW ALARM

tH = HIGH REACTOR TRIP

ttl = LOW REACTOR TRIP

ACCUMMULATOR

EXPANSION JOINT

A I R FLOW FROM OR TO OPEN

AREAS WITHOUT OUCTWORK

SH

VALVE W/POSITION

INDICATOR R

L I M I T SWITCHES

1--n/s-----

TRANSITION PIECE

1E.G.SlAINLESS TO CARBON1

F I R E OAMPER

-.--@REACTOR

4%

THROTTLE VALVE

SELF K T U A T E D

HIGH

CONTROL ROOM ANNUNCIATOR

Low

VENT

-El-43-

2

3F

F I X E D BULB TEMPERATURE

DETECTOR

HIGH EFFICIENCY F I L T E R

( A I R OR GAS1

STOP VALVE

REMOTE MANURL

THROTTLE VALVE

INSTRUMENT

ACTUATEO

ELECTRICAL CONTROLS LEADS

PANEL MOUNTEO TRANSMITTER

CAPPED STEM

-El

2,;~"-8

LOCALLY MOUNTEO TRANSMITTER

ELECTRICAL HEAT TRACING

BELLOWS SEAL

LOCKED

CLOSEO VALVE

SEAL w m o

OPEN VALVE

INSTRUMENT A I R SUPPLY

FIXEO PRESSURE

AREA BOUNOARIES

LOOP SEAL ITRAP)

+IF

SEAL WIRE0

CLOSEO VALVE

PANEL MOUNTEO INSTRUMENT

QUICK OPENING

NORMALLY

CLOSED VALVE

LOCKEO

OPEN VALVE

SECONOARY PROCESS FLOW L I N E S

[OUT OF SYSTEM DASHED1

PNEUMATIC CONTROL L I N E S

@3

MIXER

d b -

LOCALLY MOUNTEO INSTRUMENI

FLOAT CHECK

VALVE

7-

SPARGER

M A I N PROCESS L I N E S

I O U 1 OF SYSTEM DASHED1

OIAPHRAGM SEAL

PLUG VALVE

& k;y;E

ABSOLUTE F I L T E R

EOUCTOR OR EJECTOR

+Rb-

5+

SPRAY NOZZLES

FOOT VALVE

LlNE SYMBOLS

HEATER (ANY TYPE1

REMOTE SAMPLE

REMOTE

OPERATEO VALVE

LOCAL SAMPLE

HANO WHEEL

OPERATED VALVE

F I R E OETECTOR

FORT CALHOUN STATION

SYMBOL LIST

P & ID

You might also like

- Quick Guide On RSP and Kiln Gas Analyzer TroubleshootingDocument5 pagesQuick Guide On RSP and Kiln Gas Analyzer Troubleshootingjun101phNo ratings yet

- Cocktails For A CrowdDocument117 pagesCocktails For A CrowdΓιώργης Δημητρίου100% (2)

- Ab 036180 001Document1 pageAb 036180 001narutothunderjet216No ratings yet

- Types of ProcurementDocument7 pagesTypes of ProcurementrahulNo ratings yet

- Steam Trap - DrawingDocument17 pagesSteam Trap - DrawingSeindahNya100% (1)

- PNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGFrom EverandPNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGNo ratings yet

- Choke Maintnance PDFDocument42 pagesChoke Maintnance PDFbtrasla9023No ratings yet

- Blasting and Painting Procedure PDFDocument9 pagesBlasting and Painting Procedure PDFharry50% (2)

- 1st Floor DrawingsDocument1 page1st Floor DrawingsBedan KivuvaNo ratings yet

- GAD OrientationDocument58 pagesGAD OrientationKevin Dalangin100% (2)

- E.R Diagram BW UTIKDocument48 pagesE.R Diagram BW UTIKJoseph SchneiderNo ratings yet

- D - 1 Auliary Boiler DrawingsDocument76 pagesD - 1 Auliary Boiler DrawingsEnrique MonteroNo ratings yet

- NORSOK Z-CR-007 Mechanical Completion and CommissioningDocument27 pagesNORSOK Z-CR-007 Mechanical Completion and CommissioningWilkin Llanca Blas100% (1)

- Contemporary Anaesthetic Equipments.: An Aid for Healthcare ProfessionalsFrom EverandContemporary Anaesthetic Equipments.: An Aid for Healthcare ProfessionalsNo ratings yet

- Project List 2000 CurrentDocument15 pagesProject List 2000 CurrentharryNo ratings yet

- PID NotesDocument40 pagesPID Notesmegha ingulkarNo ratings yet

- Control Valves in Process PlantDocument8 pagesControl Valves in Process Plantmukramah.yusufNo ratings yet

- The Room - SartreDocument14 pagesThe Room - SartreYue Biohazard100% (1)

- Air Consumption Calculations For Pneumatic Valves: LegendsDocument1 pageAir Consumption Calculations For Pneumatic Valves: Legendsshibu1487No ratings yet

- Fig-40 - Simbología Central NuclearDocument2 pagesFig-40 - Simbología Central NuclearAlfonso José García LagunaNo ratings yet

- RTAC Customer PackageDocument15 pagesRTAC Customer PackageAldo MartinezNo ratings yet

- RP 546Document2 pagesRP 546Victor TobosqueNo ratings yet

- B. Prestart Checks of Boiler LightupDocument14 pagesB. Prestart Checks of Boiler LightupPrudhvi RajNo ratings yet

- Mechanical Equipment Typical Connection DetailsDocument73 pagesMechanical Equipment Typical Connection DetailsDhirendra Singh RathoreNo ratings yet

- Ip060-45!62!01 Control Valve (Glove) (Buyer's Scope)Document5 pagesIp060-45!62!01 Control Valve (Glove) (Buyer's Scope)Rahul DevaNo ratings yet

- HalonDocument60 pagesHalontahir428No ratings yet

- Standard Operating Procedure: Operation and Preventive Maintenance of Air Handling Unit. 1.0 PURPOSE: 2.0 SAFETYDocument8 pagesStandard Operating Procedure: Operation and Preventive Maintenance of Air Handling Unit. 1.0 PURPOSE: 2.0 SAFETYMaryanthony NamyaloNo ratings yet

- Gas ValveDocument9 pagesGas ValveJJNo ratings yet

- H Series Valves-EnDocument12 pagesH Series Valves-EnWalther Ernesto Molina DominguezNo ratings yet

- HP/LP Bypass System: House Load OperationDocument23 pagesHP/LP Bypass System: House Load Operationravi roshanNo ratings yet

- Valves: An Introduction To GC ValvesDocument27 pagesValves: An Introduction To GC Valvesharsh421100% (1)

- A 310-600 743 Qustion - 240110 - 150240Document78 pagesA 310-600 743 Qustion - 240110 - 150240fmyrahmdy8No ratings yet

- Interlock List (r0)Document5 pagesInterlock List (r0)AnujGargNo ratings yet

- Bleed Air Troubleshooting Guide: For Reference Only, Please Check Maintenance Manual and MPD 25Document6 pagesBleed Air Troubleshooting Guide: For Reference Only, Please Check Maintenance Manual and MPD 25Edwar ZulmiNo ratings yet

- Iranian Petroleum Standards: Typical Unit Arrangement & Piperack Layout IPS-D-PI-102Document1 pageIranian Petroleum Standards: Typical Unit Arrangement & Piperack Layout IPS-D-PI-102reza329329No ratings yet

- BFL Chanju - 13846 SPV o & M Manual PDFDocument64 pagesBFL Chanju - 13846 SPV o & M Manual PDFजितेन्द्र कुमार शर्माNo ratings yet

- Oxygen Plant Manual SupplementDocument8 pagesOxygen Plant Manual SupplementInge NecoNo ratings yet

- Pumps, Compressor, Heat Exchanger, Valves Quick ReviewDocument10 pagesPumps, Compressor, Heat Exchanger, Valves Quick ReviewSamman NaazNo ratings yet

- Peco Filter CaseDocument11 pagesPeco Filter CaseLuis MaureraNo ratings yet

- Utomation Omponents NC.: Product OverviewDocument6 pagesUtomation Omponents NC.: Product OverviewAshraf Adel Nashed ZakiNo ratings yet

- Phthalic AnhydrideDocument24 pagesPhthalic AnhydridehugomauleNo ratings yet

- Quick Closing ValvesDocument18 pagesQuick Closing ValvescaptsavioNo ratings yet

- Gilian Operating ManualDocument37 pagesGilian Operating ManualMatthew KingNo ratings yet

- SR-1 Spring Brake Valve (SD-03-4508)Document8 pagesSR-1 Spring Brake Valve (SD-03-4508)EdvinCastleNo ratings yet

- Pneumatic FloatDocument4 pagesPneumatic Floatalamsyah_syamNo ratings yet

- Instrument Interview Question For Petro Chemical IndustriesDocument4 pagesInstrument Interview Question For Petro Chemical IndustriespraveenteckieNo ratings yet

- Intake AndDocument16 pagesIntake AndGonzalez RubenNo ratings yet

- Alkon Valves CatalogDocument88 pagesAlkon Valves CatalogZoran JankovNo ratings yet

- Lessons Learned-FINAL-NEW PDFDocument8 pagesLessons Learned-FINAL-NEW PDFImtinan MohsinNo ratings yet

- Maintenance and Operation Manual Hydraulic Choke and Control ConsoleDocument42 pagesMaintenance and Operation Manual Hydraulic Choke and Control ConsoleMehdi Hajd KacemNo ratings yet

- P2 Series InstallationlManualDocument6 pagesP2 Series InstallationlManualGianna FrolaNo ratings yet

- Potter - Purgador de Aire PAARDocument3 pagesPotter - Purgador de Aire PAARJames HansonNo ratings yet

- 7-EN 520-D - D5S 2-PortDocument16 pages7-EN 520-D - D5S 2-Portabuzer1981No ratings yet

- Scanned From A Xerox Multifunction DeviceDocument49 pagesScanned From A Xerox Multifunction DeviceAnand NarayananNo ratings yet

- Do Not Discard Instructions. This Manual Must Remain With The Unit For Future Reference. This Emergency Information Must Be Prominently DisplayedDocument24 pagesDo Not Discard Instructions. This Manual Must Remain With The Unit For Future Reference. This Emergency Information Must Be Prominently DisplayedIcemaster RefrigeraciónNo ratings yet

- Williams V Series Pump IomDocument32 pagesWilliams V Series Pump IomHectorMaldonado100% (1)

- 189 010 - en 15.710057 V3.0Document12 pages189 010 - en 15.710057 V3.0balzac191No ratings yet

- Hydraulic Simulation Using EASY5 SoftwareDocument13 pagesHydraulic Simulation Using EASY5 Softwarechuckhsu1248No ratings yet

- Types of Safety Relief ValvesDocument30 pagesTypes of Safety Relief ValvesJasbir ChaudharyNo ratings yet

- Emglo TroubleshootingDocument1 pageEmglo TroubleshootingramseyNo ratings yet

- Bhel - Trichy: Training Programme FOR Power Sector Executives ON CFBC BoilersDocument41 pagesBhel - Trichy: Training Programme FOR Power Sector Executives ON CFBC Boilersrashm006ranjanNo ratings yet

- Job OrderDocument2 pagesJob OrderGenceNo ratings yet

- AFA Alco Series ValveDocument3 pagesAFA Alco Series ValveRay RavelNo ratings yet

- Dodge Trouble Codes PDFDocument12 pagesDodge Trouble Codes PDFbelchiorNo ratings yet

- Electronic Amplifiers for Automatic Compensators: International Series of Monographs on Automation and Automatic ControlFrom EverandElectronic Amplifiers for Automatic Compensators: International Series of Monographs on Automation and Automatic ControlNo ratings yet

- WemcoDocument2 pagesWemcoharryNo ratings yet

- WemcoDocument2 pagesWemcoharryNo ratings yet

- An Experimental Study of Flame Lengths & Emission of Fully-Modulate Diffusion FLames PDFDocument124 pagesAn Experimental Study of Flame Lengths & Emission of Fully-Modulate Diffusion FLames PDFratninp9368No ratings yet

- WemcoDocument2 pagesWemcoharryNo ratings yet

- WemcoDocument2 pagesWemcoharryNo ratings yet

- WemcoDocument2 pagesWemcoharryNo ratings yet

- WemcoDocument2 pagesWemcoharryNo ratings yet

- 8 Design Philosophy and Criteria: White Rose DA Volume 2 (Development Plan) - January 2001Document17 pages8 Design Philosophy and Criteria: White Rose DA Volume 2 (Development Plan) - January 2001Ruly IrawanNo ratings yet

- 1FSC E1 PADocument2 pages1FSC E1 PAharryNo ratings yet

- 048Document6 pages048kokykarkarNo ratings yet

- D01 Deoiler Cyclones Rev 11-12Document2 pagesD01 Deoiler Cyclones Rev 11-12harryNo ratings yet

- Safety in Design PDFDocument11 pagesSafety in Design PDFharryNo ratings yet

- 5f55a 0Document4 pages5f55a 0RandiRahmansyahNo ratings yet

- D01 Deoiler Cyclones Rev 11-12Document2 pagesD01 Deoiler Cyclones Rev 11-12harryNo ratings yet

- D01 Deoiler Cyclones Rev 11-12Document2 pagesD01 Deoiler Cyclones Rev 11-12harryNo ratings yet

- Nice and TightDocument2 pagesNice and TightharryNo ratings yet

- Catb3 001 - 9 10Document2 pagesCatb3 001 - 9 10harry0% (1)

- 5f55a 0Document4 pages5f55a 0RandiRahmansyahNo ratings yet

- Jendela 10 e PDFDocument8 pagesJendela 10 e PDFharryNo ratings yet

- Appendix A1 Mobile Cranes Lift Plans Addendum Standard Lift Plan FormDocument1 pageAppendix A1 Mobile Cranes Lift Plans Addendum Standard Lift Plan FormharryNo ratings yet

- SSD 2017-Feedback CardDocument1 pageSSD 2017-Feedback CardharryNo ratings yet

- Industrial SafetyDocument7 pagesIndustrial SafetymuneebNo ratings yet

- Safety in Design PDFDocument11 pagesSafety in Design PDFharryNo ratings yet

- Wireless Adaptor Setup Guide (Windows) - TL-WR702N - V1.1 PDFDocument4 pagesWireless Adaptor Setup Guide (Windows) - TL-WR702N - V1.1 PDFharryNo ratings yet

- Unhcr Medevac ProceduresDocument32 pagesUnhcr Medevac ProceduresharryNo ratings yet

- 048Document6 pages048kokykarkarNo ratings yet

- Conference Proceedings: Inhaled Nitric Oxide: Delivery Systems and MonitoringDocument27 pagesConference Proceedings: Inhaled Nitric Oxide: Delivery Systems and MonitoringPhanNo ratings yet

- Quorum Sensing PDFDocument9 pagesQuorum Sensing PDFShareenMuneebNo ratings yet

- DBM MonetizationDocument2 pagesDBM MonetizationrsdiamzNo ratings yet

- Put The Verbs in Brackets Into The - Ing Form or The InfinitiveDocument10 pagesPut The Verbs in Brackets Into The - Ing Form or The InfinitiveThao DaoNo ratings yet

- EN Ultra V Mini STP410S C54 UmhDocument2 pagesEN Ultra V Mini STP410S C54 Umhjabt4568No ratings yet

- Fosroc Conplast SP335: Multi-Range Water Reducing AdmixtureDocument2 pagesFosroc Conplast SP335: Multi-Range Water Reducing AdmixtureVincent JavateNo ratings yet

- Weigh Bridge Miscellaneous Items DetailsDocument1 pageWeigh Bridge Miscellaneous Items DetailsChandan RayNo ratings yet

- Formula Sheet Pre-MidDocument4 pagesFormula Sheet Pre-MidUzair KhanNo ratings yet

- Final Workshop Report On Value Addition and AgroprocessingDocument31 pagesFinal Workshop Report On Value Addition and AgroprocessingBett K. BernardNo ratings yet

- GR 15 Juan Esteban Berrio Cordoba Guia 4 ENVIRONMENTAL PROBLEMSDocument7 pagesGR 15 Juan Esteban Berrio Cordoba Guia 4 ENVIRONMENTAL PROBLEMSJuan Esteban Berrio CordobaNo ratings yet

- Nutrition Label ResponseDocument1 pageNutrition Label ResponseZoe JonesNo ratings yet

- Dental Caries PrevelenceDocument11 pagesDental Caries PrevelenceSonal KaleNo ratings yet

- Targets: Chris Paul P. Pagaoa, LPT, Msc. Biology - InstructorDocument4 pagesTargets: Chris Paul P. Pagaoa, LPT, Msc. Biology - InstructorVince RetutaNo ratings yet

- Plant Based Plan White PaperDocument24 pagesPlant Based Plan White PaperSara AdemovicNo ratings yet

- Magicad Heating&Piping and Ventilation Version 2011.11: User'S GuideDocument285 pagesMagicad Heating&Piping and Ventilation Version 2011.11: User'S GuideCalin CalinNo ratings yet

- Cell Division-Mitosis Notes: 2 New CellsDocument21 pagesCell Division-Mitosis Notes: 2 New CellsCristina MariaNo ratings yet

- Full Download Book Microbiome Immunity Digestive Health and Nutrition Epidemiology Pathophysiology Prevention and Treatment PDFDocument41 pagesFull Download Book Microbiome Immunity Digestive Health and Nutrition Epidemiology Pathophysiology Prevention and Treatment PDFmildred.walker324100% (15)

- Financial Problems Are Commonly Faced by EveryoneDocument2 pagesFinancial Problems Are Commonly Faced by EveryoneGrace Ann Mancao PototNo ratings yet

- Budget Reform ProgramDocument31 pagesBudget Reform ProgramSannyboy DatumanongNo ratings yet

- 493M GHC MG Mep WS L3 205 1B 00Document1 page493M GHC MG Mep WS L3 205 1B 00shehanNo ratings yet

- Savage Inequalities Reading ReflectionDocument2 pagesSavage Inequalities Reading Reflectionapi-367127133No ratings yet

- L-2 Single and Composite Heat TransferDocument44 pagesL-2 Single and Composite Heat Transfer271758 ktr.chem.18No ratings yet

- Alix Pelletier Luginbühl - Works / PRINT VERSIONDocument44 pagesAlix Pelletier Luginbühl - Works / PRINT VERSIONJonathan Philippe LEVYNo ratings yet

- Ableism - What It Is and Why It Matters To EveryoneDocument28 pagesAbleism - What It Is and Why It Matters To Everyonellemma admasNo ratings yet

- LabStan - July 16-17, 23-24, 30-31, Aug 6-7Document25 pagesLabStan - July 16-17, 23-24, 30-31, Aug 6-7CandypopNo ratings yet

- Material SelfDocument9 pagesMaterial Selfic perlasNo ratings yet