Professional Documents

Culture Documents

Chemical Seal

Chemical Seal

Uploaded by

muralikrishnan.govindarajOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Chemical Seal

Chemical Seal

Uploaded by

muralikrishnan.govindarajCopyright:

Available Formats

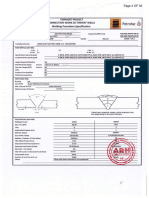

Flush Diaphragm Seal

MODEL : CSU-FDF

Features

Process fluids which are highly viscous or containing solid particles could plug or clog the Diaphragm Seal cavity on the process side of the

diaphragm. In order to overcome this difficulty, Flush Diaphragm Seal are used. In this design, since the Diaphragm is directly welded on the

Flange Face, there are no cavities or hidden ports where the process fluid can enter and clog the system.

Optionally, Flushing Ring (Spacer Ring) with 1/4” NPT(F) or 1/2” NPT(F) connection can be provided as per the requirement. Flushing

Connection enables the user to purge / flush out / clean the area below the diaphragm without removing the Seal from the process line.

Optional Feature

n Cooling Tower

n Capillary for Remote mounting of the Pressure Instrument

n Flushing Ring (Spacer Ring) for purging / cleaning the area below the diaphragm without removing the Seal from the process line.

n Stud / Nut & Gasket, for assembling the Diaphragm Seal with Process Flange.

Note: This catalogue indicates the general specifications used for most of the process applications.

Any other specification not appearing here also can be provided as per customer requirement.

10/17 REV.: 00

Under Technical Collaboration with M/s. Gauges Bourdon, France

www.generalinstruments.co.in 78 www.general-gauges.com

Ordering Information

FLUSH DIAPHRAGM SEAL (Flange)

MODEL: CSU-

CONNECTION TYPE OPTION

FDF Flush Diaphragm, Flanged Conn. 4AR(*) SS 316 Capillary, SS 304 Armoured

4PV(*) SS 316 Capillary, SS 304 Armoured+PVC Covered

FLANGE (Non-wetted part) 6AR(*) SS 316 Capillary, SS 316 Armoured

CST CS 6PV(*) SS 316 Capillary, SS 316 Armoured+PVC Covered

S4S SS 304 CLT Cooling Tower

S4L SS 304L FR4(**) Flushing Ring, 1/4" NPT(F)

S6S SS 316 FR2(**) Flushing Ring, 1/2" NPT(F)

S6L SS 316L GSK Gasket

321 SS 321 STN Stud & Nuts

TTM Titanium L Nil

XXX Other (Please Specify) XXX Other (Please specify)

* Specify the length of Capillary in Meters.

DIAPHRAGM (wetted part) ** Specify Ring material (Refer Diaphragm table)

S4S SS 304 HCB Hastelloy B

S4L SS 304L HCC Hastelloy C

FILLING FLUID

S6S SS 316 TAN Tantalum

DC1 DC-710

S6L SS 316L N20 Nickel 200

DC2 Silicone Oil (DC-200)

S6T SS 316Ti MN4 Monel 400

DC4 DC-704

321 SS 321 XXX Other (Please Specify)

DC5 DC-705

TTM Titanium#

FLU Fluorolube

PROCESS CONNECTION GLY Glycerine

HLC Halocarbon

FLANGED

VGO Food grade oil

CONN CODE SIZE CODE RATING CODE FACING CODE XXX Other (Please specify)

Flange F 1" 25 150 A RF RF

1-1/2" 40 300 B RTJ RJ

2" 50 600 C

3" 80 900 D

4" 10 1500 E

2500 F

e.g. For 100 NB 150# RF flange, Model Code: F10ARF

# For Titanium Diaphragm, Flange also shall be Titanium only

Minimum Span of Range

Flange Size Min Span of Range Min Span of Range

(RF flange) (RTJ flange)

1" NB 6 kg/cm2.g N.A.

1-1/2" NB 2.5 kg/cm2.g 60 kg/cm2.g

2" NB 1 kg/cm2.g 2.5 kg/cm2.g

3" NB 1 kg/cm2.g 2.5 kg/cm2.g

10/17 REV.: 00

Sample model Code: CSU-FDF-CST-S6L-F40BRF-DC4-FR2(S6L)

www.generalinstruments.co.in 79 www.general-gauges.com

You might also like

- Materials Data for Cyclic Loading: Low-Alloy SteelsFrom EverandMaterials Data for Cyclic Loading: Low-Alloy SteelsRating: 5 out of 5 stars5/5 (2)

- FM IS Standard 3615Document33 pagesFM IS Standard 3615SureshNo ratings yet

- Orientation Part 1Document121 pagesOrientation Part 1jojoNo ratings yet

- Analysis and Design of Clarifier in Staad-ProDocument26 pagesAnalysis and Design of Clarifier in Staad-Proshrikantharle100% (1)

- Thermo ProblemsDocument12 pagesThermo ProblemsElaineNo ratings yet

- Pan Cake Diaphragm Seal 1Document2 pagesPan Cake Diaphragm Seal 1Shankar PediredlaNo ratings yet

- Pressure Gauge Diaphragm Seal Sandwich TypeDocument2 pagesPressure Gauge Diaphragm Seal Sandwich TypeSUSOVAN BISWAS100% (1)

- Sandwich Type Diaphragm SealDocument2 pagesSandwich Type Diaphragm SealManoj NirgudeNo ratings yet

- Extended Diaphragm SealDocument2 pagesExtended Diaphragm SealShankar PediredlaNo ratings yet

- In Line Flow Through Type Diaph. Seal 1Document6 pagesIn Line Flow Through Type Diaph. Seal 1Shankar PediredlaNo ratings yet

- Model: A100: Flushing RingDocument2 pagesModel: A100: Flushing RingTÀi VÕNo ratings yet

- Manifold As TavaDocument2 pagesManifold As Tavamike.stavrianakos2717No ratings yet

- Brochure FSA, 50 Hz1-Dikonversi - Pdf. TerbaruDocument6 pagesBrochure FSA, 50 Hz1-Dikonversi - Pdf. TerbaruDt BarusNo ratings yet

- Brochure FSA, 60 HZDocument6 pagesBrochure FSA, 60 HZIbrahim SanusiNo ratings yet

- Hitungan Volume Pompa EbaraDocument6 pagesHitungan Volume Pompa EbaraApriliyanto Rahadi PradanaNo ratings yet

- Brosur EBARA - FSADocument6 pagesBrosur EBARA - FSAdirumah AjaNo ratings yet

- DFS (GS 06p01y01-E-E - 008)Document30 pagesDFS (GS 06p01y01-E-E - 008)tetioNo ratings yet

- NeedleValve LT0389Document8 pagesNeedleValve LT0389zkmostafaNo ratings yet

- Selection Chart CreatorDocument201 pagesSelection Chart CreatorrenepunterNo ratings yet

- Air Trap JA3Document2 pagesAir Trap JA3M Numan FarooqiNo ratings yet

- Diaphragm - Type Diaphragm SealType L990.10Document4 pagesDiaphragm - Type Diaphragm SealType L990.10harglugurNo ratings yet

- Catalogue CNA 50Hz Rev.1 Update 6-1Document6 pagesCatalogue CNA 50Hz Rev.1 Update 6-1Rido MardanNo ratings yet

- SSTC10 075Document2 pagesSSTC10 075suphanat joomjanNo ratings yet

- Tablamateriales enDocument1 pageTablamateriales enLeandro Ribeiro Do PradoNo ratings yet

- Assembly Part Number Example: 2 in (50 MM), Group 1Document2 pagesAssembly Part Number Example: 2 in (50 MM), Group 1RICHARDNo ratings yet

- Fire Fighting Pump Model FSPA and CNPA: Compliance To NFPA 20Document14 pagesFire Fighting Pump Model FSPA and CNPA: Compliance To NFPA 20Gage Cendk HNo ratings yet

- Rosemount Seal m1199rtwDocument3 pagesRosemount Seal m1199rtwMiguel Jiménez FloresNo ratings yet

- P PT Industrial Stainless Steel Filter HousingsDocument4 pagesP PT Industrial Stainless Steel Filter Housingsliceth.emilio30mpNo ratings yet

- Butterfly Valve Wafer TypeDocument2 pagesButterfly Valve Wafer TypeHardik ShahNo ratings yet

- Plummech Check ValvesDocument1 pagePlummech Check ValvesNguyễn Đăng PhúcNo ratings yet

- TLV SJ3FXDocument2 pagesTLV SJ3FXÁlvaro Martínez FernándezNo ratings yet

- Free Float Steam Trap: Model Ductile Cast Iron Cast IronDocument2 pagesFree Float Steam Trap: Model Ductile Cast Iron Cast IronSamerNo ratings yet

- StrainerDocument2 pagesStrainermayNo ratings yet

- G-Line Series: STX MTX XLTDocument4 pagesG-Line Series: STX MTX XLTErickzelaya2014No ratings yet

- Series 2700 Maintenance ManualDocument12 pagesSeries 2700 Maintenance ManualLuciusNo ratings yet

- I.Manual For FSADocument11 pagesI.Manual For FSAVu DangNo ratings yet

- Tabel Material RBDocument268 pagesTabel Material RBRanda SadorNo ratings yet

- Safety Relief Valve VSEODocument4 pagesSafety Relief Valve VSEOShashank HNo ratings yet

- Flow Indicator 1Document2 pagesFlow Indicator 1Vara PrasadNo ratings yet

- Class 125 Bronze: Butterfly Valves - 200 PsiDocument1 pageClass 125 Bronze: Butterfly Valves - 200 Psithilina lakhithaNo ratings yet

- HF Series: Cartridge Filter HousingsDocument2 pagesHF Series: Cartridge Filter HousingsAnwar SadatNo ratings yet

- Technical Proposal: Inquiry No.: Proposal No.: 9089873-TECH Revision: 0Document13 pagesTechnical Proposal: Inquiry No.: Proposal No.: 9089873-TECH Revision: 0Martin DanzeNo ratings yet

- Molde Soldadura SSDocument1 pageMolde Soldadura SSMarcos Ivan Ramirez AvenaNo ratings yet

- Diaphragm ValveDocument2 pagesDiaphragm ValveHardik ShahNo ratings yet

- Astm A334 PDFDocument2 pagesAstm A334 PDFgaminNo ratings yet

- ScrewDownNonreturnValve PDFDocument2 pagesScrewDownNonreturnValve PDFokaNo ratings yet

- Temp. Control ValveDocument7 pagesTemp. Control Valvesaurabh kumarNo ratings yet

- Summary Welding Procedure QualificationsDocument1 pageSummary Welding Procedure QualificationsBoran YelkenciogluNo ratings yet

- Consumables For SSDocument14 pagesConsumables For SSELongLeeNo ratings yet

- 35 Frame 3545-3541D-3541C-3547-3547C-en 2018-08Document4 pages35 Frame 3545-3541D-3541C-3547-3547C-en 2018-08Daniel SaucedaNo ratings yet

- Technical DrawingDocument6 pagesTechnical DrawingRosyad AminNo ratings yet

- Swing Check Valve Rubber DiscDocument2 pagesSwing Check Valve Rubber DiscsathishNo ratings yet

- NKM-G NKP-G: Standardised Enbloc Centrifugal PumpsDocument36 pagesNKM-G NKP-G: Standardised Enbloc Centrifugal PumpsRoberthNo ratings yet

- FK76M E LoresDocument18 pagesFK76M E LoresFRANCONo ratings yet

- WPS Tsila 012Document2 pagesWPS Tsila 012AslaouiNo ratings yet

- SR Series: J Flow ControlsDocument5 pagesSR Series: J Flow ControlsJimmy RojasNo ratings yet

- Hydraulic - Flanges HEAD PLUG CODE 62Document1 pageHydraulic - Flanges HEAD PLUG CODE 62VIVEK UPADHYAYNo ratings yet

- Swing Check Valve - Flanged: Technical FeaturesDocument1 pageSwing Check Valve - Flanged: Technical FeaturesAhmed El MorsyNo ratings yet

- Tsa 2Document6 pagesTsa 2Amit SurtiNo ratings yet

- High Precision Ball Bearings: Sapporo Precisiq/J IncDocument20 pagesHigh Precision Ball Bearings: Sapporo Precisiq/J IncAnonymous m6A7tNaMgfNo ratings yet

- Beric Forged Steel ValvesDocument32 pagesBeric Forged Steel ValvesKit AnnoncerNo ratings yet

- SC Serie SC 4160Document8 pagesSC Serie SC 4160Anderson QuintãoNo ratings yet

- Uploads - Valvulas - Valvulas de Bola - Bola Flotante Aop - Aop CT 3000 Especificacion PDFDocument8 pagesUploads - Valvulas - Valvulas de Bola - Bola Flotante Aop - Aop CT 3000 Especificacion PDFMonica CarrenoNo ratings yet

- IEC 60228 Conductors of Insluated Cables PDFDocument52 pagesIEC 60228 Conductors of Insluated Cables PDFSureshNo ratings yet

- 02500003e 0 enDocument33 pages02500003e 0 enSureshNo ratings yet

- FM IS Standard 3600Document14 pagesFM IS Standard 3600SureshNo ratings yet

- Floating Ball ValveDocument36 pagesFloating Ball ValveSureshNo ratings yet

- FM IS Standard 3611Document42 pagesFM IS Standard 3611SureshNo ratings yet

- FM IS Standard 3610 PDFDocument16 pagesFM IS Standard 3610 PDFSureshNo ratings yet

- Steel StandardsDocument53 pagesSteel StandardsSureshNo ratings yet

- SR - No 1 Thermowell Installations in Piping: InstrumentDocument4 pagesSR - No 1 Thermowell Installations in Piping: InstrumentSureshNo ratings yet

- ATEX and IEC ExDocument1 pageATEX and IEC ExSureshNo ratings yet

- Data Sheet Ionotrode: Application FieldsDocument1 pageData Sheet Ionotrode: Application FieldsSureshNo ratings yet

- SR - No 1 Thermowell Installations in Piping: InstrumentDocument4 pagesSR - No 1 Thermowell Installations in Piping: InstrumentSureshNo ratings yet

- Iec 60584Document2 pagesIec 60584SureshNo ratings yet

- fLOW 3265 PDFDocument1 pagefLOW 3265 PDFSureshNo ratings yet

- fLOW PDFDocument1 pagefLOW PDFSureshNo ratings yet

- Fe-7151 Case 3 PDFDocument1 pageFe-7151 Case 3 PDFSureshNo ratings yet

- Flow Element: Base Maximum Flow Normal Flow Property MethodDocument1 pageFlow Element: Base Maximum Flow Normal Flow Property MethodSureshNo ratings yet

- Fe-7151 Case 1 PDFDocument1 pageFe-7151 Case 1 PDFSureshNo ratings yet

- 2-Wire 4/20ma 5 Digit Indicator: Intrinsically Safe For Use in All Gas & Dust Hazardous AreasDocument2 pages2-Wire 4/20ma 5 Digit Indicator: Intrinsically Safe For Use in All Gas & Dust Hazardous AreasSureshNo ratings yet

- Product Information Plump Oleoactive Mar2020 (Asof23042020)Document4 pagesProduct Information Plump Oleoactive Mar2020 (Asof23042020)Saowalak PhonseeNo ratings yet

- Iron Deficiency AnemiaDocument45 pagesIron Deficiency AnemiaGiane PaulaNo ratings yet

- Functionalities of NalcoDocument26 pagesFunctionalities of NalcoSmrutiranjan ParidaNo ratings yet

- IMD Series Info 0417Document2 pagesIMD Series Info 0417MoriyasuNguyenNo ratings yet

- Caltherm Heat Transfer Fluids General SheetDocument3 pagesCaltherm Heat Transfer Fluids General SheetMohamed IbrahimNo ratings yet

- 1st Quiz PharDocument4 pages1st Quiz PharnikhilNo ratings yet

- Inhalation Solutions - Which One Are Allowed To Be MixedDocument9 pagesInhalation Solutions - Which One Are Allowed To Be MixedYolanda PerezNo ratings yet

- Penetration Test ProceduresDocument1 pagePenetration Test ProceduresMirabella Di BastidaNo ratings yet

- Certificado de Calidad TerminalesDocument4 pagesCertificado de Calidad TerminalesJerson CarbajalNo ratings yet

- KME CatalogueDocument19 pagesKME CatalogueArmağan DemirelNo ratings yet

- Rasa Preparation: - Amit Naphade Kupipakva-RasayanaDocument62 pagesRasa Preparation: - Amit Naphade Kupipakva-RasayanaSundara Veer Raju MED100% (1)

- Revised MS For WaterproofingDocument9 pagesRevised MS For WaterproofingChamux skalNo ratings yet

- Epicor Customization Inspection Plans Define UD TablesDocument1 pageEpicor Customization Inspection Plans Define UD TablesTrevor LynnNo ratings yet

- Appendix 1 Design Rules PDFDocument18 pagesAppendix 1 Design Rules PDFDavid QuinteroNo ratings yet

- Use of Nanomaterials in Coatings 0 PDFDocument18 pagesUse of Nanomaterials in Coatings 0 PDFCong ChinhNo ratings yet

- Complex Acid-Base Systems PDFDocument35 pagesComplex Acid-Base Systems PDFHannah CenaNo ratings yet

- Solar TowerDocument26 pagesSolar TowerEthan Hurley85% (13)

- Dumitru 2nd EdDocument1,536 pagesDumitru 2nd Ed정광익No ratings yet

- Pressure Biotic MaterialDocument2 pagesPressure Biotic Materialsarath.kumarnmk930No ratings yet

- Sustainablet Extiles From LotusDocument9 pagesSustainablet Extiles From LotusJacquelaine WongNo ratings yet

- People. Passion. Performance. CPE/CPF SeriesDocument4 pagesPeople. Passion. Performance. CPE/CPF SeriesNicky BradNo ratings yet

- 39 Space Air DistributionDocument25 pages39 Space Air DistributionPRASAD326100% (3)

- Well Test Standards WTS 3.8 Coflexip Hoses: Global ManualDocument9 pagesWell Test Standards WTS 3.8 Coflexip Hoses: Global ManualEmmanuel100% (1)

- Nanoencapsulation of Food Ingredients PDFDocument24 pagesNanoencapsulation of Food Ingredients PDFHuỳnh NhungNo ratings yet

- Solutions To 7.012 Problem Set 1Document4 pagesSolutions To 7.012 Problem Set 1attiqueNo ratings yet

- C67SDocument1 pageC67SHans GoetheNo ratings yet

- Determination of ArsenicDocument2 pagesDetermination of ArsenicAnonymous n4bJbeLAqNo ratings yet