Professional Documents

Culture Documents

Cargo Ballast Mooring and Engine Room

Uploaded by

Marian SerbanOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Cargo Ballast Mooring and Engine Room

Uploaded by

Marian SerbanCopyright:

Available Formats

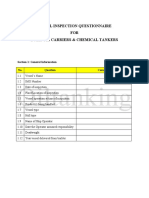

CARGO, BALLAST AND ENGINE ROOM

CHAPTER VIQ QUESTION INSPECTOR REMARK

8 Was the inert gas system in use at the time of the Vessel was inspected at shipyard before

inspection? delivery. IGS was not used.

8 Are the following, where fitted, in good order and is Cargo tank level monitoring system in the

there recorded evidence of regular testing? cargo control room was not in working

condition.

8 Is the stress and stability information included with The stress and stability information for the

the cargo plan and are any limitations discharge was not included in the cargo plan.

understood by the cargo watch officers?

8 Is the level of lighting in the pump room adequate? Cargo pump room entrance light had been put

out the light condition.

8 Have senior deck officers had open-water ship to Master and C /O had not STS transfer

ship transfer experience within the last 12 months? experience at open water within 12 months.

8 If the vapour return manifolds are designed for use No cruciform bollards, only lashing eyes were

at single buoy moorings, do they comply with fitted in line with vapour manifolds. Mooring

requirements? bits were arranged with an offset of approx 3m

sideways.

8 Are the P/V valves in good order, inspected and During the inspection of the ship’s Cargo

cleaned as part of a regular maintenance routine and Containment Area and confirmed by records

are there records to support this? held on board in the Ship’s Certificates files, it

was found that the vessel was fitted with

Tanktec Pressure/Vacuum valves, New ISO H

125/V 80, which are reported to be

unacceptable in certain countries.

8 Are pressure gauges also fitted to the offshore The pressure gauges on the inactive manifolds

manifolds and regularly checked during on both the onshore and offshore sides were

the discharge for manifold valve leakage? found to be closed during discharge operations

8 Is crude oil washing being carried out on this Vessel was inspected at shipyard before

occasion? delivery. C OW was not carried out at this

port.

8 Where filter-type respirators have been provided, is The vessel had filter type respirators on board.

there an adequate system of control in They did not have a system for controlling the

place? use of these respirators

8 Are the following, where fitted, in good order and is E4.14 - Deck valves hydraulic power pack,

there recorded evidence of regular testing? hydraulic valves cabinet - oil leakages

8 If the vapour return manifolds are designed for use Vapour return manifolds not designed for

at single buoy moorings, do they comply with operations at SBM, VRM was not painted red/

requirements? yellow/red, no ‘closed chock’ fitted at ship’s

side in line with the VR manifold pipelines, no

‘cruciform bollard’ fitted on deck in way of

the VR manifolds and no ‘deck eyes’ in

vicinity on deck.

8 If the vapour return manifolds are designed for use No closed chock in line with the VRS manifold

at single buoy moorings, do they comply with No cruciform bollard had been in line with the

requirements? VRS manifold.

8 Are cargo and/or ballast tanks free of sloshing or Please see 8.9. Guidelines were provided for

other restrictions? reducing or minimising free surface effect,

sloshing and stability restrictions.

07 February 2007 Page 1 of 18

CHAPTER VIQ QUESTION INSPECTOR REMARK

8 If a loading computer or programme is in use, is it Loading computer programme not class

class approved? approved, same as 2.15

If a class approved loading computer is not

available, record how stress and stability

calculations are performed.

8 Are manifold pressure gauges fitted with valves or Manifold back pressure gauges where fitted

cocks? without valves or cocks.

8 Are vapour locks fitted with full depth sounding Vapour lock were not fitted with full depth

pipes? sounding pipes.

8 Are sufficient closed fairleads and mooring bitts There were open mooring fairleads fitted

provided? which were not suitable for STS operations

8 Is a log kept of inert gas operations? The log of inert gas operations had incomplete

entries of the last inerting operation.

8 Are personnel aware of the hazards associated with The Chief Mate reported that cargo tanks were

tank cleaning after the carriage of volatile products? purged before washing. There was no record

of this in either the tank cleaning log or the IG

operation log.

The tank cleaning records indicated that

during the last tank cleaning and gas freeing

operation the inert gas was not in operation

during washing, neither were the cargo tanks

purged before gas freeing.

8 The secondary venting system was pressure

monitoring system. It was noted that the tanks

indicated different pressures. Tank 6 stbd

sensor was not working and indicated zero.

8 Is the cargo pump room gas monitoring system in PUMP ROOM FLAMMABLE

good order and regularly checked? ATMOSPHERE MONITORING WAS NOT

AS REC OMMENDED BY INDUSTRY

GUIDELINES. THE GAS SENSORS WERE

LOC ATED AT BOTTOM LEVEL OF THE

ROOM ONLY.( OC IMF-AN

INFORMATION PAPER ON PUMP ROOM

SAFETY 1995.)

8 Are all officers familiar with the carriage THE OXYGEN RESUSC ITATOR WAS

requirements for the cargoes on board? NOT READILY AVAILABLE. THE

EQUIPMENT WAS

KEPT LOC KED UP IN THE HOSPITAL

WITH ONLY A FEW PERSONS HOLDING

A KEY.

THE RESUSCITATOR WAS PLACED IN

THE C CR DURING THE INSPEC TION.

8 Is a written procedure provided for the safe handling No procedures in place for the safe handling

of heavy weather ballast in cargo tanks on of heavy weather ballast in cargo tanks of

segregated ballast tankers? segregated ballast tanks.

8 Is the inert gas system and/or storage and associated The vessel was fitted with positive locking

pipework, where fitted, in good devices on the IG tank isolation valves. The

order? key was in the control of the pump man not a

responsible officer.

8 Are the following, where fitted, in good order and is

there recorded evidence of regular testing?

07 February 2007 Page 2 of 18

CHAPTER VIQ QUESTION INSPECTOR REMARK

8 Are pressure gauges also fitted to the offshore Pressure gauges were not fitted at the off-

manifolds and regularly checked during cargo shore manifold during the discharge operation.

transfer for manifold valve leakage?

8 Are metal tapes and other gauging or sampling The earthing (grounding) straps were noted as

devices effectively bonded before being introduced being missing from the vessel's three

into tanks? UTIullaging tapes.

8 Are vapour locks fitted with full depth sounding It was reported that the vessel's ullage pipes

pipes? were not fitted to the full depth of the cargo

tanks

8 Is the inert gas system including instrumentation, The inlet mesh on the Inert Gas Plant had been

alarms, trips and pressure and oxygen recorders, in removed exposing the rotating interal

good order? fanimpeller

It was noted that there was a slight weep of

water from a pipe flange weld after the Deck

Seal unit indicating that the line was corroding

internally.

8 Are records maintained of equipment maintenance, There was no maintenance routine for the

including the overhaul of the non-return valve? overhaul of the Inert Gas Non-Return valve

but there was a stenciled notation on the inert

gas pipe that stated that the valve had been

overhauled on 26.October.2006

8 Are flame screens easily accessible and removable, The vacuum valve flame screens were

in good order and inspected and cleaned as part of a accessible but it was noted that on some

regular maintenance routine and are there records valves they had been partially painted over.

available? There were records of the valves being

'operated and greased' but there were no

records of them having been opened-up,

cleaned and overhauled.

8 If stop valves are fitted which permit isolation of The vessel is fitted with isolating valves in the

individual tanks from the common venting system, Inert Gas supply lines to each cargo tank.

are they provided with positive locking These valves are hydraulically operated and

arrangements and are the keys under the control of a cannot be locked. The operational status of

responsible officer? these valves is clearly marked in the cargo

control room and the C hief Officer has

positioned a clear notice giving instructions

that these valves are not to be operated

without permission.

8 Are pressure gauges also fitted to the offshore

manifolds and regularly checked during cargo

transfer for manifold valve leakage?

8 Have senior deck officers had open-water ship to Senior officers do not have experience in open-

ship transfer experience within the last 12 months? water ship to ship transfer operation.

8 Are the following, where fitted, in good order and is No independent cargo tanks overfill Audible

there recorded evidence of regular testing? and visual alarm fitted for the cargo tanks.

8 If the vapour return manifolds are designed for use The VRSM’s were not fitted with cruciform

at single buoy moorings, do they comply with bollards or enclosed chocks and were not

requirements? suitable at SPM’s.

8 Are manifold blank flanges of an equivalent rating to The vapour manifold blanks were of a smaller

that of the manifold pipelines? plate thickness then the pipelines.

8 Are the following, where fitted, in good order and is There were no records of checking and

there recorded evidence of regular testing? documenting the accuracy of the cargo tank

radar gauging system.

07 February 2007 Page 3 of 18

CHAPTER VIQ QUESTION INSPECTOR REMARK

8 If a loading computer or programme is in use, is it The loading computer on line function was no

class approved? longer operational.

If a class approved loading computer is not

available, record how stress and stability

calculations are performed.

8 Are cargo pipelines tested annually? Cargo pumps, There was no record that the cargo lines were

pipes, highe level alarms etc. pressure tested annually or during drydock.

8 Is crude oil washing being carried out on this Part discharge only.

occasion?

8 Are manifold pressure gauges fitted with valves or Manifold pressure gauge was not fitted with

cocks? valve or cock.

8 Are sufficient closed fairleads and mooring bitts The vessel is fitted with open type roller

provided? fairleads forward and aft. Though stell pipes

are fitted on aft rollers these would not

prevent ropes from jumping off the rollers.

8 On vessels with pump rooms, are they free of Moderate leak was evident at the flange of No.

evidence of significant leaks from machinery, 2 cargo pump discharge line in the pump

pipework, valve glands and instrumentation? room. (SHOULD READ AS BALLAST

PUMP)

8 Does the P/V breaker appear to be in good order? The P/V breaker was filled with water only

and not added with an anti-freeze.

8 Are SOLAS secondary venting requirements being The audio alarm of the cargo tank pressure

complied with? monitoring system was not working at the time

of inspection.

8 Is information readily available on maximum No information on the venting capacity of the

loading rates and venting capacities? cargo tank individual high velocity P/V valves

(vent pipe diameter was only 80 mm)

8 Is the stress and stability information included with For information not provided with damaged

the cargo plan; have stability and where applicable, stability manual.

stress calculations been performed for the current

cargo operation and do the cargo watch officers

understand any limitations?

8 Are sufficient closed fairleads and mooring bitts Vessel was not fitted with sufficient close

provided? fairleads forward for ship to ship transfer

operation.

8 Where fitted and in use, is the condition of the cargo There was no record that the cargo tanks

tank heating system satisfactory, is it regularly tested thermal heating system was regularly pressure

and is any observation tank free of oil? tested. Vessel was classed as a Asphalt tanker.

8 Is the cargo pump room gas monitoring system in Ballast pumproom not fitted with gas

good order and regularly checked? monitoring system

8 If the vapour return manifolds are designed for use Vapour Return Manifolds not designed for

at single buoy moorings, do they comply with operations at SBM;

requirements?

8 Do records indicate that the loading computer is Accuracy check with test conditions in the

tested regularly for operational accuracy? stability information booklet of the Excel

programme for draft, trim and stability

calculation has not been carried out.

8 are there records indicating that the operational Accuracy test of loading computer no record

accuracy of the load computer is tested regularly? available

07 February 2007 Page 4 of 18

CHAPTER VIQ QUESTION INSPECTOR REMARK

8 Is the vessel fitted with a crude oil washing system? Crude oil washing system / manual was not

approved by Class but tank cleaning system

was fitted.

As clean product handled only, C OW was not

carried out.

8 Was the fixed oxygen analyser calibrated There was no record of testing the O2 analyser

immediately prior to use of the inert gas system? prior to IGS use at the port call. The last record

related to the previous port, 5 days earlier. The

electrician stated that he had omitted filling in

the

record sheet after performing the test.

8 If the vapour return manifolds are designed for use No cruciform bollards were fitted for vapour

at single buoy moorings, do they comply with line connections. An eyelet with 12 t SWL was

requirements? fitted in the vicinity that was used for bunker

hose handling.

8 Is the vessel free of inherent intact stability The vessel is double hull tanker with wide

problems? centre cargo tanks and no longitudinal

bulkhead on centerline. The vessel has

restrictions on combination of cargo and

ballast tanks that can be slack at any given

time during operations or sailing. These

restrictions were posted in Ship's Office but

Chief Officer did not seem very conversant

with them and maintained that on current

trading pattern with multiple grades and draft

restrictions it was almost impossible to follow

these instructions.

8 If fixed tank gauges are not fitted, are sufficient Fixed gauging system float type pulled – no.4

portable tapes provided to simultaneously gauge center tank found gauge not working

each tank being worked?

8 Can double hull spaces be inerted? Double hull spaces are not provided with

inerting facility.

8 On vessels with pump rooms, are they free of Tank cleaning pump outlet line and tank

evidence of significant leaks from machinery, cleaning heater outlet line had been repaired

pipework, valve glands and instrumentation? with jubilee clamps

8 Is the cargo venting system in a satisfactory Operating lever of high velocity vent of cargo

condition? tank no. 1 port and 3 port groove had

considerable play and had dropped down to

almost open position

8 Are flame screens easily accessible and removable, Vacuum relief valve were moderately rusted

in good order and inspected and cleaned as part of a and did not show any sign of maintanance

regular maintenance routine and are there records

available?

8 Do records indicate that the loading computer is No records of testing loading computer for

tested regularly for operational accuracy? accuracy.

8 If the vapour return manifolds are designed for use Vapour Return Manifolds not designed for

at single buoy moorings, do they comply with operations at SBM; no closed chocks fitted at

requirements? ship’s side in line with the (port & starboard)

VR manifold pipelines and also no cruciform

bollard fitted on deck in way of the VR

manifolds.

Drain on starboard VR manifold consisted of

very small bore pipeline & also noted

pipeline opening (at over the spill tray) was

flattened & near closed as result.

[For information, there were deck eyes & one ‘

2-bitts’ deck bollard fitted in line between

ship’s side & VR manifold].

07 February 2007 Page 5 of 18

CHAPTER VIQ QUESTION INSPECTOR REMARK

8 Are SOLAS secondary venting requirements being No secondary ‘full flow’ venting arrangement

complied with? fitted to cargo tanks.

[Tanks fitted with individual IG ‘branch line’

& vent stack with ‘breather’ type P/V valves].

8 Have senior deck officers had open-water ship to Chief Mate had only participated in STS off

ship transfer experience within the last 12 months? Singapore at anchorage in the recent year.

8 If the vapour return manifolds are designed for use No closed chock and cruciform bitt fitted in

at single buoy moorings, do they comply with line with vapour return manifolds.

requirements?

8 If the vapour return manifolds are designed for use The vapour return manifolds at the port and

at single buoy moorings, do they comply with starboard side were fitted with drain cockbut

requirements? without line connection to the spill tray. There

was no closed chock and cruciform bittsited in

line (2 padeyes fitted were nearly in line with

the manifold).

8 Is the inert gas system including instrumentation, The fresh air intake for the I.G. system had

alarms, trips and pressure and oxygen recorders, in been fitted inside the Engine room, just above

good order? the scupper. Suction was being drawn from

within the Engine room spaces only.

8 Is crude oil washing being carried out on this Vessel was inspected at shipyard before

occasion? delivery. C OW was not carried out at this

port.

8 If the vapour return manifolds are designed for use Vapour return manifolds not designed for

at single buoy moorings, do they comply with operations at SBM, no `closed chock' fitted at

requirements? ship's side in line with the (port and starboard)

VR manifold pipelines, no `cruciform bollard'

fitted on deck in way of the VR manifolds and

means to drain the VRSM.

8 If fixed tank gauges are not fitted, are sufficient Vessel has only 3 UTI tapes and no spare

portable tapes provided to simultaneously gauge tapes as the vessel load a maximum of three

each tank being worked? tanks simultaneously and the fixed level

gauging system is not in use condition.

8 Was the fixed oxygen analyser calibrated Oxygen analyser was last calibrated at the

immediately prior to use of the inert gas system? previous discharge port on 26 Dec. 2006.

8 Are vapour locks fitted with full depth sounding The vapour locks were not fitted with full

pipes? depth sounding pipes. As per records vessel

had operated with tanks in inert condition

when carrying volatile and static accumulator

cargoes.

8 Where fitted and in use, is the condition of the cargo The deck steam heating manifold for slop

tank heating system satisfactory, is it regularly tested starboard and 6C were with minor leakage.

and is any observation tank free of oil? The

individual heating coil flange connections for

COT 6C were with heavily wasted securing

bolts.

8 On vessels with pump rooms, are they free of Four leaks were observed from not fully

evidence of significant leaks from machinery, tightened flanges / connections in the

pipework, valve glands and instrumentation? Pumproom. Three of these were from the

stripping lines (minor leaks) and the last from

the Pump casing of #3 COP (moderate leak).

Leaks had been stopped prior completion of

the Inspection.

07 February 2007 Page 6 of 18

CHAPTER VIQ QUESTION INSPECTOR REMARK

8 If the vapour return manifolds are designed for use Vapour return manifolds not designed for

at single buoy moorings, do they comply with operations at SBM, no‘closed chock’ fitted at

requirements? ship’s side in line with the VR manifold

pipelines, no ‘cruciform bollard’ fitted on

deck in

way of the VR manifolds and the ‘deck eyes’

in vicinity on deck were not positioned one

to either side of the line from the closed chock

to the VRSM.

8 On vessels with pump rooms, are they free of The No. 3 COP was leaking steam condensate

evidence of significant leaks from machinery, from the deckhead areas in way of driveshaft

pipework, valve glands and instrumentation? penetration. No. 3 cargo pump turbine was

leaking live steam in way of its steamtrunking.

8 Is the oxygen content of the inert gas delivery at or The cargo tank remote temperature gauges for

below the permitted maximum? two tanks wre not showing correct readings.

The remote level gauges for the water ballast

Record if the oxygen delivery is more than 5% or if tanks were not operational. Tanks were being

a high oxygen level alarm is not fitted, regardless of monitored by manual soundings.

the date of delivery.

8 Are all cargo derricks, cranes and other lifting The lifting gear annual inspection was

equipment properly marked and has periodical overdue. Last annual inspection was done on

testing and inspection been carried out? 14.12.05

8 Are SOLAS secondary venting requirements being Secondary venting system consisted of Hi jet

complied with? PV valves fitted to each tank on the IG branch

line. However the PV valves were not for full

flow venting but only to allow for thermal

variation.

8 Have senior deck officers had open-water ship to The ship and staff had not been engaged in

ship transfer experience within the last 12 months? STS in recent years.

8 Are the following, where fitted, in good order and is The SAAB SUM 21 fixed level gauge for

there recorded evidence of regular testing? COT No.1, 2, 3 and 5 were faulty and

unreliable.

The No. 3 COP was leaking steam condensate

from the deckhead areas in way of drive

shaft penetration. No. 3 cargo pump turbine

was leaking live steam in way of its steam

trunking.

8 Does the P/V breaker appear to be in good order? No maintenance record maintained for the

flame screen as fitted at the top opening to the

P/V breaker.

8 Are the following, where fitted, in good order and is The no. 2 S WBT Level gauge was out of order

there recorded evidence of regular testing?

8 Do records indicate that the loading computer is The testing for operational accuracy of the

tested regularly for operational accuracy? Loading computer was last carried out ten

months ago.

8 Do records indicate that the loading computer is Loading computer test data approved by Class

tested regularly for operational accuracy? not on board.

8 Are all cargo derricks, cranes and other lifting The safety latch on the lifting hook for the

equipment properly marked and has periodical provisions crane was broken.

testing and inspection been carried out?

8 Are all cargo derricks, cranes and other lifting There were no certificates attesting to load

equipment properly marked and has tests for any of the vessel's lifting equipment.

periodical testing and inspection been carried out? The port Provisions crane was not marked

with a SWL.

07 February 2007 Page 7 of 18

CHAPTER VIQ QUESTION INSPECTOR REMARK

8 Is the inert gas system and/or storage and associated Inert Gas Deck Seal had numerous doublers

pipework, where fitted, in good welded to it.

order?

8 Is the oxygen content of the inert gas delivery at or Noted that the Oxygen content within the

below the permitted maximum? Deck line as measured with portable meters

was 7 %. The fixed detector displayed 3.0% at

Record if the oxygen delivery is more than 5% or if this time.

a high oxygen level alarm is not fitted, regardless of

the date of delivery.

8 Are Material Safety Data Sheets (MSDS) on board No MSDS(material safety data sheet) for last

for all the products being handled and are all officers bunker operation was retained on board.

familiar with their use?

8 Do the readings on the local, bridge and cargo Noted that the Oxygen content within the

control room oxygen and pressure recorders, where Deck line as measured with portable meters

fitted, agree? was 7%. The fixed detector displayed 3.0% at

this time.

8 Are all cargo derricks, cranes and other lifting SWL was marked only starboard side of Hose

equipment properly marked and has periodical handling C rane and Provision C rane.

testing and inspection been carried out?

8 Are manifold pressure gauges fitted with valves or All pressuer gauges as fitted outboard or cargo

cocks? (port/starboard) manifolds valves, were

without `stop cock' (block valves) arrangement.

8 Are the following, where fitted, in good order and is There was no formal record of cargo tank high

there recorded evidence of regular testing? level alarm tests at regular intervals

being maintained.

8 Have senior deck officers had open-water ship to Master and Chief Officer have had no 'Open

ship transfer experience within the last 12 months? water' STS experience in the past 12 months.

8 Is the cargo pump room gas monitoring system in The audible / visual alarms for the fixed Gas

good order and regularly checked? detection system inside the Pumproom was in-

operational.

8 If the vapour return manifolds are designed for use The ships VRM did not comply with OCIMF

at single buoy moorings, do they comply with recommendations in respect to SBM

requirements? operations as the vapour manifoild was not

equipped with a closed chock at the ships side

and a cruciform bollard in line with the

manifold

8 Are the following, where fitted, in good order and is Cargo tank's high(95%) and overfill(98%)

there recorded evidence of regular testing? alarm system was integrated with fixed tank

level gauge system,not of independent system.

As well as neither outer visual/audible alalrm

nor local test proof are available on deck.

8 If the vapour return manifolds are designed for use Vapour return manifolds were fitted but there

at single buoy moorings, do they comply with was no closed chock in line with the manifold

requirements? fitted at the vessel side, nor cnrxifix fittings.

The Master advised that this was the original

design of the vessel.

8 Are SOLAS secondary venting requirements being The fix tank gauging system included a cargo

complied with? tank pressure sensor and alarm system. The

settings for the alrarms were +2,277 mmwg

and -1,000 mmwg, well in excess of the relief

pressure of the p/v ,valves at +1,400 mmwq

and -350 mmwq.

8 Do tank hatches, tank cleaning apertures and There was cargo weepage from No. 1 Port and

sighting ports appear to be liquid and gas tight? No. 5 Stbd cargo tank hatch lid packing.

07 February 2007 Page 8 of 18

CHAPTER VIQ QUESTION INSPECTOR REMARK

8 Are all cargo derricks, cranes and other lifting Engine room crane (S.W.L. 6.75 tonnes) was

equipment properly marked and has periodical last load tested on 2nd December 2005 and

testing and inspection been carried out? due for annual inspection by class surveyor.

8 If stop valves are fitted which permit isolation of IG inlet/vent lines were fitted with isolating

individual tanks from the common venting system, valves which were chained and padlocked.

are they provided with positive locking Master keys for the padlocks were kept by the

arrangements and are the keys under the control of a Chief Mate, the Pumpman and the duty AB.

responsible officer? This did not constitute a system with the keys

under the control of a responsible officer. A

key board was provided in the cargo control

room, with individual keys for each padlock,

but the system was not used.

9 Is mooring equipment marked with its SWL? SWL markings on deck bitts, fairleads,

universal fairleads & bow chain stoppers were

painted marks & not ‘beat weld’ type marks.

9 Are pedestal fairleads, roller fairleads and other CLOSED C HOC KS FORWARD AND AFT

rollers well greased and free to turn and are bitts and WERE WITH MODERATE/ DEEP

chocks free of grooving? GROOVING

9 If the vessel is equipped for mooring at single point The pick-up line could only be led to the

moorings, can the pick-up hawser be led to a winch winch drum via 2 pedestal fairleads with

storage drum rather than the warping drum end and change of angles of approximately 165

without the use of one or more pedestal fairleads degrees at each.

involving an acute angle of lead?

9 If the vessel is equipped for mooring at single point The pick up rope had to be led from the bow

moorings, can the pick-up hawser be led to a winch stopper via a pedestal and fairlead roller to a

storage drum rather than the warping drum end and winch drum at acute angles.

without the use of one or more pedestal fairleads

involving an acute angle of lead?

9 If the vessel is equipped for mooring at single point The vessel was fitted with a single SBM

moorings, can the pick-up hawser be led to a winch stopper, rated at 200 tonnes swl but the was

storage drum rather than the warping drum end and no direct lead to the windlass drums

without the use of one or more pedestal fairleads

involving an acute angle of lead?

9 Are mooring winches in good order? There bow stopper did not meet OCIMF

recommendations for SBM operations the

distance from the stopper to the roller fairlead

was about 1.5 meters.

9 If the vessel is equipped for mooring at single point There was no direct lead from the bow stopper

moorings, can the pick-up hawser be led to a winch to a winch storage drum for an SBM pick-up

storage drum rather than the warping drum end and hawser. There was a lead via a pedestral roller

without the use of one or more pedestal fairleads with an acute angle to the warping drum only

involving an acute angle of lead? of a winch.

9 Do all mooring ropes and where fitted, mooring wire Most of in use mooring wires were

tails, meet OCIMF guidelines? constructed of 6 x 36(WS) + Fibre C ore

rather than

IWRC material as recommended by ISGOTT

mooring guideline.

9 Do brake linings, drums and pins appear to be in Port mooring winch aft warping drum cheeks

good order? have trimmed down considerably

9 Are emergency towing arrangements readily The forward emergency towing chain was

available for deployment forward and aft? heavily corroded with thick rust scale.

9 Are mooring winches in good order? Winch controls were not marked with heave

and slack directions.

07 February 2007 Page 9 of 18

CHAPTER VIQ QUESTION INSPECTOR REMARK

9 If the vessel is equipped for mooring at single point The vessel was equipped with 1 bow stopper

moorings, can the pick-up hawser be led to a winch for SBM's. The pick up line involving an

storage drum rather than the warping drum end and acute angle led to the winch drum via 2

without the use of one or more pedestal fairleads pedestal rollers..

involving an acute angle of lead?

9 Is mooring equipment marked with its SWL? Part of the mooring gear SWL was not weld

bead outlined.

9 Do all mooring ropes and where fitted, mooring wire The MBL of the tails (784 KN) exceeded the

tails, meet OCIMF guidelines? recommended value of 25%compared to the

MBL of the wires (MBL wires 421 KN).

9 If the vessel is equipped for mooring at single point The SBM chain pick up rope has to be turned

moorings, can the pick-up hawser be led to a winch around two rollers (1 x pedestal + 1 x bow

storage drum rather than the warping drum end and fairlead) before reaching the fixed drum of

without the use of one or more pedestal fairleads mooring winch on port side. The rope would

involving an acute angle of lead? make almost reciprocal angle on the fairlead

roller.

9 Is mooring equipment marked with its SWL? SWL was stenciled on mooring fittings but

was not bead welded.

9 Are certificates available for all mooring ropes and Certificates for the mooring ropes and wires

wires? were not available on board.

9 If the vessel is equipped for mooring at single point The pick up rope from the bow chain stopper

moorings, can the pick-up hawser be led to a winch did not lead direct to the winch drum but via

storage drum rather than the warping drum end and two

without the use of one or more pedestal fairleads pedestal rollers.

involving an acute angle of lead?

9 Are mooring winches in good order? Observed steam leaking moderately from the

steam chest of all forward mooring winches

and spring winches. The underside of the

steam chest for the spring winches was heavily

corroded and steam leaking from the gasket

connection.

9 Are mooring winches in good order? The mooring winches brake drums outer edge

raised section was wasted.

9 If the vessel is equipped for mooring at single point The vessel had two SPM’s each requiring two

moorings, can the pick-up hawser be led to a winch roller leads to the storage drum. The inner

storage drum rather than the warping drum end and roller lead of each SPM to the storage drum

without the use of one or more pedestal fairleads was an acute angle not in compliance with

involving an acute angle of lead? industry recommendations.

9 Are pedestal fairleads, roller fairleads and other Two roller leads for the mooring winches

rollers well greased and free to turn and are bitts and located on the tank deck were frozen.

chocks free of grooving?

9 Are mooring wires, ropes and synthetic tails in good One nylon tail located on the starboard side

order? forward was excessively ragged.

9 Are certificates available for all mooring ropes and Survey certificates for all mooring wires

wires? showed a higher MBL than the MBL used in

the winch brake testing calculations. On

reviewing the mooring wire and mooring tails

certification, it was not clear which wires and

tails were fitted to which winch.

9 If the vessel is equipped for mooring at single point The SPM mooring arrangement required the

moorings, can the pick-up hawser be led to a winch lead through the bow stopper to pass round 3

storage drum rather than the warping drum end and pedestal leads at an acute angle before leading

without the use of one or more pedestal fairleads to the storage drum.

involving an acute angle of lead?

07 February 2007 Page 10 of 18

CHAPTER VIQ QUESTION INSPECTOR REMARK

9 Is mooring equipment marked with its SWL? The SWL of the mooring chocks and fairleads

is not clearly marked with the weld bead

outline. It was stencilled with paint.

9 Are the fire wires of appropriate size and do they The fire wires on board were of fibre core

conform to OCIMF recommendations? construction.

9 Is there a policy in place for the testing of winch The vessel has been testing and measuring the

brakes and are the results recorded? rendering point of the winch brakes annually

as per the OCIMF Guidelines and the

operating company's procedures.

However, the indicators fitted by the vessel to

try and facilitate the application of the correct

torque to attain the correct rendering point had

been mounted in such a manner that they

would stop the application of the correct

torque once the brake bands had begun to

wear.

9 Is there a policy in place for the testing of winch The vessel was conducting winch brakes tests

brakes and are the results recorded? as required with a hydraulic jack. However,

the winches were single drum and the test

calculations were based upon a single layer on

the drum.

9 On split drum winches are all the lines made fast Mooring winches did not have split drums.

with no more than one layer on each tension side of

the drum?

9 Are mooring wires, ropes and synthetic tails in good The vessel was fitted with both wires and soft

order? ropes on fixed winches. However, the

breaking strength of the lines varied by 30

tons: Wires BS 50 tons and Rope 82 tons.

9 Do brake linings, drums and pins appear to be in Winch brake drums had corrosion and surface

good order? breakdown reducing the contact area with the

brake lining

9 Is mooring equipment marked with its SWL? Mooring equipment was not permanently

marked by bead welded figures, but painted on

only.

9 Are emergency towing arrangements readily The emergency towing arrangement operating

available for deployment forward and aft? instructions were not posted on the bridge.

9 Do brake linings, drums and pins appear to be in The brake band of the centre winch on the

good order? poop deck is badly corroded and its

crosssectional

area greatly reduced.

9 If the vessel is equipped for mooring at single point The lead to each of the winch storage drums

moorings, can the pick-up hawser be led to a winch require the use of one pedestal roller. The

storage drum rather than the warping drum end and angle of lead at each of the pedestal rollers

without the use of one or more pedestal fairleads was acute

involving an acute angle of lead?

9 Are mooring winches in good order? Two of the mooring winches were found to be

in gear

9 Is mooring equipment marked with its SWL? SWL of mooring winches were painted. They

were not permanently marked by weldings

9 Do all mooring ropes and where fitted, mooring wire One nylon tail located on the starboard side

tails, meet OCIMF guidelines? forward was excessively ragged.

07 February 2007 Page 11 of 18

CHAPTER VIQ QUESTION INSPECTOR REMARK

9 Are mooring wires, ropes and synthetic tails in good Tipto multiplat mooring rope on forward

order? winch found with localized damage to outer

covering and deep into its inner strands. Rope

in this respect should be repaired or replaced.

9 Are all powered mooring lines secured on brakes Observed the engaging and disengaging gear

and are the winches out of gear? for the forward spring mooring winch was in

engage position and unable to disengage the

gear as the gear was seized in engage position.

9 Is mooring equipment marked with its SWL? Mooring equipment was not marked with its

SWL by weld bead outline.

9 Is single point mooring (SPM) and associated SPM and associated fitted not according to

equipment fitted to OCIMF recommendations? OCIMF recommedations

9 Is mooring equipment marked with its SWL? The SWL was marked, (stencilled) on the

mooring bitts, chain stoppers and mooring

winches only, but not by welded bead outline.

9 If the vessel is equipped for mooring at single point The pick-up rope from the bow chock through

moorings, can the pick-up hawser be led to a winch the chain stopper went straight to the

storage drum rather than the warping drum end and pedestal fairlead located at aft of the winches

without the use of one or more pedestal fairleads (as seen from forward) and turned back at

involving an acute angle of lead? acute angle to the inner winch drum of the

opposite side.

9 Are bitter end securing arrangements unobstructed No bitter end securing arrangements outside

and outside the chain locker? the chain lockers.

9 Are the emergency towing-off wires properly rigged C1.13 - Aft emergency towing off wire (fire

to meet terminal requirements? wire) is not properly rigged - slack on deck

9 If the vessel is equipped for mooring at single point The pick up line for SBM operations could

moorings, can the pick-up hawser be led to a winch not be lead to the storage drum without using

storage drum rather than the warping drum end and multiple fairleads at acute angles of lead

without the use of one or more pedestal fairleads

involving an acute angle of lead?

11 Are oil mist detectors fitted in hydraulic aggregate

pump compartments?

11 Are concise starting instructions for the emergency The emergency diesel generator was fitted

generator clearly displayed? with 2 battery sets, but no spare starter motor

was

available onboard.

11 Are detailed bunker transfer instructions available? No. Bunker transfer checklists had been used

to cover sludge / bulk lub oil transfers this

port.

11 Are diesel engine high and low pressure fuel FO Purifier pump was diserved not free from

delivery pipes adequately jacketed or screened? obvious shaft gland leaking.

11 Are the arrangements for the provision of heading The gyro repeater compass at the emergency

information adequate? steering position was without light. It waslater

rectified.

11 If the machinery space is certified for unmanned Vessel was classed for UMS operations, but

operation is it being operated in that mode? was being operated manned.

11 Are emergency steering gear changeover procedures Steering control block diagramme with

clearly displayed in the steering compartment and in drawing in wheelhouse was not readily

the wheelhouse? displayed.

07 February 2007 Page 12 of 18

CHAPTER VIQ QUESTION INSPECTOR REMARK

11 Are concise starting instructions for the emergency No spare `starter motor' available for the

generator clearly displayed? emergency generator. (for information,

starting of emergency generator was by means

of single `starter motor' which was powered by

1 or 2 banks of batteries.

11 Are records maintained for the regular inspection Annual inspection of engine room overhead

and testing of lifting devices? crane had been overdue and not carried out yet.

11 Is all moving machinery provided with effective The guard for the 2 Stbd. Cargo pump shaft on

guards where this presents a hazard? main deck was observed missing. As per

Master it was lost during heavy weather in last

voyage.

11 Are purifier rooms and fuel and lubricating oil Fuel handling area was locally oily in the save

handling areas ventilated and clean? alls and one pump was slightlyleaking.

11 Are concise starting instructions for the emergency No spare ‘starter motor’ available for the

generator clearly displayed? emergency generator. (for information,

starting of

emergency generator was by means of single ‘

starter motor’ which was powered by 1 or

2 banks of batteries).

11 Are the following, where applicable, all in good The major refurbishing of the exhaust gas

order and do they appear to be well maintained? economiser was in progress for the last 20days

by shore technicians and significant amount of

work remains outstanding.

The alarm printer in the engine control room

was with garbled printouts. The data

loggerprinter was reported not in used for a

long time.

The scrubber tower flue gas inlet trunk casing

was holed at two locations due to corrosion.

11 Are the following, where applicable, all in good One of the Aux engine (generator) was not in

order and do they appear to be well maintained? operations. The Bow thruster though fitted

could not be used

11 Are the following, where applicable, all in good Main engine response was incorrect. The

order and do they appear to be well maintained? ahead order resulted in astern movement.

11 Are the following, where applicable, all in good One working air compressor was under

order and do they appear to be well maintained? repair.Two generators showed slight oil

leakages.Fresh water heater for

accommodation was leaking seriously.Steering

gear was locally oily.

11 Are records maintained for the regular inspection No procedure had been place for the

and testing of lifting devices? inspection of the portable lifting equipment

such as

chain blocks.

11 If the machinery space is certified for unmanned The engine room was certified for UMS, but

operation is it being operated in that mode? was presently manned, due to vessel's age.

11 Are the duties of the watch-standing officers and The engine room was certified for UMS, but

ratings clearly defined? was presently manned, due to vessel's age.

11 Are switchboards free of significant earth faults? Noted 220 V main switchboard earth fault of

0.2 Mohm.

11 Are the following, where applicable, all in good Observed heavy oil floating in main engine

order and do they appear to be well maintained? piston cooling water tank.

07 February 2007 Page 13 of 18

CHAPTER VIQ QUESTION INSPECTOR REMARK

11 Is the bilge high level alarm system regularly tested No record of test for the bilge alarm.

and are records maintained?

11 Is a planned maintenance system being followed and Computerised ‘planned maintenance system’

is it up to date? (PMS) onboard had been developed by

Company but was not formally endorsed by C

lass.

11 Are machinery spaces and steering compartments There was a small clamp patch on the heat

clean and free from obvious leaks and is the overall exchanger for the jacket cooling water system.

standard of housekeeping and fabric maintenance The patch was on the inlet side at the flange. It

satisfactory? had been noted by the C E and was to be

repaired at the first opportunity.

11 Are there adequate procedures to prevent The vessel operated in the UMS mode at sea

uncontrolled entry into the engine room? and was manned by an engineer and oiler in

port. However, the engine room entrances did

not have any post warnings about UMS period

of operations and the UMS procedures posted.

11 Are seawater pumps, sea chests and associated a)Sea water outlet line to the jacket cooling

pipework in a satisfactory condition and free of hard system was soft patched.

rust and temporary repairs, particularly outboard of b) L.O. cam shaft cooler end cover was soft

the ship-side valves? patched.

11 Are concise starting instructions for the emergency The emergency generator was fitted with 2

generator clearly displayed? banks of batteries but there was no spare

starter motor. The Chief Engineer advised that

a request for a spare motor would be

submitted to the company.

11 Is an inspection and maintenance programme in Found three wire slings that were damaged

place for other lifting equipment such as wire slings? with broken wires and flattened areas and one

with a kink in the wire. The slings were

removed from service.

11 Are concise starting instructions for the emergency Emergency generator started by two banks of

generator clearly displayed? battery and not provided with spare starter

motors.

11 Is all loose gear in the machinery spaces, stores and In inert gas flat there were two spare

steering compartment properly secured? calibration gas cylinders that were lashed with

small fibre line that could chaff through.

11 Is an inspection and maintenance programme in No detail inspection record of all engine room

place for other lifting equipment such as wire slings? wire slings only had recorded inspection of

wire sling for the engine room overhead crane

in the engine log book.

11 Are records maintained for the regular inspection No detail inspection record of all engine room

and testing of lifting devices? chain blocks, only had recorded inspection of

chain block for the engine room overhead

crane in the engine log book.

11 Do records indicate the regular testing of emergency a) No records of testing the main engine fuel

equipment? leak detection alarm.

b) No records of testing the steering gear

reservoir tank’s low level alarm.

11 Does the operator subscribe to a fuel, lubricating and L.O. analysis report dated 6th December 2006

hydraulic oil testing programme? for Auxiliary Engine no.1 & 2 reported

contamination is higher than normal and is

recommended that the whole oil charge to be

renewed. C hief Engineer reported that the oil

charge for number 1 Auxiliary Engine had

been changed on 9th December 2006 and had

planned to change no.2 Auxiliary Engine oil

charge on departure this port.

07 February 2007 Page 14 of 18

CHAPTER VIQ QUESTION INSPECTOR REMARK

11 Is the level of lighting in all areas of the engine room There were 3 light fixtures in the lower engine

satisfactory? room with the plastic covers broken or held in

place with tie wraps or baling wire.

11 Are machinery spaces and steering compartments There were a number of small leaks about the

clean and free from obvious leaks and is the overall engine spaces including steam leaks at valve

standard of housekeeping and fabric maintenance stems and fuel leaks on the main engine

satisfactory?

11 Are machinery spaces and steering compartments There were areas of oil soaked lagging in the

clean and free from obvious leaks and is the overall engine room at the main and auxiliary engines.

standard of housekeeping and fabric maintenance

satisfactory?

11 Is all electrical equipment including junction boxes Observed two explosion proof lights inside the

and cable runs in good order? forward bosun store with missing securing

bolts.

11 Is a planned maintenance system being followed and Planned maintenance system not available

is it up to date?

11 Is all loose gear in the machinery spaces, stores and Majority of the Floor Plates in the Engine

steering compartment properly secured? room were not nut screwed down

11 Are main engine bearing temperature monitors, or The main engine oil mist detector had been

the crankcase oil mist detector, in good order? dismantled nad reportedly sent ashore for

servicing. It has not yet been returned to the

vessel.

11 Are concise starting instructions for the emergency 10.The emergency generator was fitted with

generator clearly displayed? two banks of batteries and an electric starter.

The vessel did not have a spare starter motor

on board.

11 If the machinery space is certified for unmanned Engine Room was operating in the manned

operation is it being operated in that mode? condition due to problem with boiler water

level

and must be regulated manually.

11 Are concise starting instructions for the emergency Emergency generator operating instruction

generator clearly displayed? were not displayed.

11 Are emergency escape routes clearly marked, Emergency Escape Route in Engine Room

unobstructed and adequately lit? were not clearly marked.

11 Is a planned maintenance system being followed and The vessel was delivered on 14.11.2006. The

is it up to date? Planned maintenance was yet to be placed

and implemented on board.

11 Is deck insulation provided to the front and rear of Insulation rubber mat was not placed in front

medium power (i.e. 220V and above) electrical of following starter(440V).

switchboards and is it in a satisfactory condition? 1)Bosun store Group starter.

2)Fire station Group starter.

3)Steering room starter.

11 Are chemicals properly stowed and are Material THE ENGINE ROOM CHEMIC ALS WERE

Safety Data Sheets available? STOWED IN AN OPEN, UN PROTEC TED

LOC ATION

IN THE STEERING GEAR ROOM.

11 Are switchboards free of significant earth faults? Very low insulation (0.2 Mega ohms) noted

on the 100 V panel in the Engine room.

11 Are concise starting instructions for the emergency No spare starting motor provided for the

generator clearly displayed? Emergency Generator. Generator relied on

only 2 battery packs for starting.

07 February 2007 Page 15 of 18

CHAPTER VIQ QUESTION INSPECTOR REMARK

11 Is an engineer’s call alarm fitted and is it in good Engineer's call alarm failed to activate even

order and tested regularly and the results recorded? after 10 minutes of non-acknowledgement of

an UMS alarm.

11 Is a planned maintenance system being followed and PMS had not been installed on board as yet.

is it up to date?

11 Is the steering compartment fitted with suitable The ships steering flat had a painted steel deck

handrails, gratings or other nonslip surfaces? and no there were no raised gratings present.

Although Non slip painted walkways were

observed access to the emergency sterering

position would prove difficult in the event of a

significant hydraulic oil leakage.

11 Is a planned maintenance system being followed and While the ship has established a number of

is it up to date? ongoing maintenance routines a

comprehensive structured or class approved

PMS was not in place.

11 Are machinery spaces and steering compartments Steam boiler has a leaking steam gland on the

clean and free from obvious leaks and is the overall boiler surculating pump valve.

standard of housekeeping and fabric maintenance

satisfactory?

11 Is the vessel provided with adequate operator’s Procedure for rescue of person suffered with

instructions and procedures? electric shock were not posted the main

switchboard in engine room compartment.

11 Are the following, where applicable, all in good Economiser was not in operational condition.

order and do they appear to be well maintained? [Reported repairs had been carried out during

recent docking & minor works still in hand &

economiser expected to be operational

sometime in December 2006].

11 Are machinery spaces and steering compartments Domestic hot water system return line repaired

clean and free from obvious leaks and is the overall with jubilee clamp

standard of housekeeping and fabric maintenance

satisfactory?

11 Are machinery spaces and steering compartments Water leaking from main seawater cooling

clean and free from obvious leaks and is the overall pump seal.

standard of housekeeping and fabric maintenance

satisfactory?

11 Are machinery spaces and steering compartments Water leaking from boiler feed pump no. 1 seal

clean and free from obvious leaks and is the overall

standard of housekeeping and fabric maintenance

satisfactory?

11 Is a planned maintenance system being followed and Planned Maintenance system was not class

is it up to date? approved

11 Are concise starting instructions for the emergency Spare starter of emergency generator not on

generator clearly displayed? board.

11 Are seawater pumps, sea chests and associated Pipe at bilge level in engine room noted with

pipework in a satisfactory condition and free of hard moderate rust

rust and temporary repairs, particularly outboard of

the ship-side valves?

11 Are the following, where applicable, all in good Moderate oil leakages were noted from all

order and do they appear to be well maintained? three Aux engines.

11 Are detailed bunker transfer instructions available? Last bunkering plan was not prepared – no

record available

07 February 2007 Page 16 of 18

CHAPTER VIQ QUESTION INSPECTOR REMARK

11 Are the following, where applicable, all in good E2.23 - Steering gear - Oil leakage

order and do they appear to be well maintained?

11 Are hot surfaces, particularly diesel engines, free of There was patches of oil soaked lagging to be

any evidence of fuel, diesel and lubricating oil? found at various locations in the engine room

especially in the vicinity of the main engine

and the sludge pump.

11 Are seawater pumps, sea chests and associated Moderate leak was evident on the gland

pipework in a satisfactory condition and free of hard packing of the GS / Fire pump and also of the

rust and temporary repairs, particularly outboard of aircon

the ship-side valves? cooling water pump.

11 Are machinery spaces and steering compartments Inspector Observations

clean and free from obvious leaks and is the overall Reference above 11.22 - Oil stains were

standard of housekeeping and fabric maintenance evident on the after part of the casing of the

satisfactory? diesel generators owing to slight leak of the

lubricating oil system.

Reference above 11.23 - The main engine fuel

oil supply pumps (two) in the purifier

room were leaking at the gland packing.

11 Are purifier rooms and fuel and lubricating oil The main engine fuel oil supply pumps (two)

handling areas ventilated and clean? in the purifier room were leaking at the

gland packing.

11 Are hot surfaces, particularly diesel engines, free of Oil stains were evident on the after part of the

any evidence of fuel, diesel and lubricating oil? casing of the diesel generators owing to

slight leak of the lubricating oil system.

11 Are the following, where applicable, all in good Cascade tank slight glass was opaque/ without

order and do they appear to be well maintained? lighting

11 Are seawater pumps, sea chests and associated Several sea water pipes observed with leakage

pipework in a satisfactory condition and free of hard

rust and temporary repairs, particularly outboard of

the ship-side valves?

11 Is an inspection and maintenance programme in Inspection record for chain block and wire

place for other lifting equipment such as wire slings? sling not maintained

11 Are concise starting instructions for the emergency The emergency diesel generator was fitted

generator clearly displayed? with 2 sets of starter batteries, but no spare

starter motor was onboard. A spare starter

motor was on order.

11 If the machinery space is certified for unmanned The Engine room watches were unmanned,

operation is it being operated in that mode? (Comment should be manned)

11 Are there adequate procedures to prevent The vessel certified as UMS but operator

uncontrolled entry into the engine room? insisted to operate manned for cree to familiar

with equipment

11 Is the steering compartment fitted with suitable The immediate area around thesteering gear

handrails, gratings or other nonslip surfaces? has been fitted with floor gratings and

handrails. However, the general access to this

protected area has not been fitted with gratings

or handrails.

11 Are bilges free of oil, rubbish and sediment? Some areas of the bilges were noted as being

dirty.

Note: The design of these areas of the bilges is

such that they are very difficult to access.

07 February 2007 Page 17 of 18

CHAPTER VIQ QUESTION INSPECTOR REMARK

11 Are machinery spaces and steering compartments The upper areas of the engine room were

clean and free from obvious leaks and is the overall noted as being very dirty and coated in soot.

standard of housekeeping and fabric maintenance The general standard of housekeeping in the

satisfactory? engine room was poor with old equipment

andempty containers being stored at various

locations around the engine room.

11 Do engine room machine tools have adequate eye 1. The engine room lathe has been fitted with

protection available? a fluorescent light which is not suitable for use

with rotating machinery.

2. The gap between the tool rests and the

grinding wheels on several of the vessel's

grinding wheels was excessive and needed

adjusting.

11 Are the main switchboard, alternators and other The sea water cooling pipes for the engine

electrical equipment satisfactorily protected from control room air conditioning unit are located

water spray? behind the main switchboard without any

protection being provided in the event of these

pipes failing.

11 Are engine room emergency stops and shut offs No record of test for the emergency stops for

clearly marked and do records indicate that they ventilation fans and fuel pumps.

have been regularly tested?

11 Are the following, where applicable, all in good Minor exhaust gas leakage from No. 2 Aux

order and do they appear to be well maintained? Engine exhaust cracked bellows.

11 Are diesel engine high and low pressure fuel M/E fuel Injector of unit No. 4 was observed

delivery pipes adequately jacketed or screened? leaking. The used proximity area next to the

unit was observed oily and stained.

11 Are detailed bunker transfer instructions available? No MSDS had been delivered during recent

bunker supplies at the builders’ yard in Japan.

11 Is the dead man alarm system, where fitted, in good There was no dead man alarm fitted.

order and used as required?

11 Are the following, where applicable, all in good E4.4 - Purifiers bilge - leakages

order and do they appear to be well maintained?

11 Are the following, where applicable, all in good E3.40 - Auxiliary Boiler fuel pumps - fuel oil

order and do they appear to be well maintained? leakages (corrected before the operation

permit was issued)

11 Are the following, where applicable, all in good E3.16 - Fresh water boiler is leaking and the

order and do they appear to be well maintained? insulation is heavily damaged

11 Are switchboards free of significant earth faults? E3.12 - Main Switchboard - 220V insulation

monitor (megohmmeter) is not working

11 Is a planned maintenance system being followed and The planned maintenance system was not fully

is it up to date? implemented

11 Are the following, where applicable, all in good No.3 cylinder temperature gauge of No.2

order and do they appear to be well maintained? D/generator was broken down condition.

07 February 2007 Page 18 of 18

You might also like

- Naval Mechanical Engineering: Gas Turbine Propulsion, Auxiliary, and Engineering Support SystemsFrom EverandNaval Mechanical Engineering: Gas Turbine Propulsion, Auxiliary, and Engineering Support SystemsNo ratings yet

- Excellent PSC ChecklistDocument100 pagesExcellent PSC Checklistshishir4870100% (1)

- Laurin Maritime M/T Bolero: Ship / Shore Safety Check ListDocument4 pagesLaurin Maritime M/T Bolero: Ship / Shore Safety Check ListPavel ViktorNo ratings yet

- Section 10 Cow ChecklistDocument2 pagesSection 10 Cow ChecklistTIPU SAHNo ratings yet

- Load Port Checklist: Vessel Name: Port: Date: S.No. Activity Yes No N/A Remarks Cargo GearDocument3 pagesLoad Port Checklist: Vessel Name: Port: Date: S.No. Activity Yes No N/A Remarks Cargo GearErnest DineshNo ratings yet

- Vetting CDI ObservationsDocument42 pagesVetting CDI Observationsstopless_dalian685100% (5)

- VIQ Bulletin From 1 To 17Document39 pagesVIQ Bulletin From 1 To 17Cristel_DCNo ratings yet

- Issue 1 Inspectors Newsletter 4Document4 pagesIssue 1 Inspectors Newsletter 4DeepakNo ratings yet

- 1.2 Manage Fuel, Lubrication and Ballast 2-1Document10 pages1.2 Manage Fuel, Lubrication and Ballast 2-1Yudo LaksonoNo ratings yet

- The Ultimate Guide To Cargo Operations For TankersDocument87 pagesThe Ultimate Guide To Cargo Operations For TankersAndis OrravsNo ratings yet

- B118-14 - Trans Mountain Response To City Burnaby IR No.1.22.03e-Attachment1 - A3Y2F9Document6 pagesB118-14 - Trans Mountain Response To City Burnaby IR No.1.22.03e-Attachment1 - A3Y2F9ye100% (1)

- Ship/Shore Safety Check ListDocument3 pagesShip/Shore Safety Check ListAshutosh SinghNo ratings yet

- Ship/Shore Safety Check List: N. B.-Spanish Law in Force From May 13, 1989. Spanish Law of Ports, in Force 01.01.1993Document5 pagesShip/Shore Safety Check List: N. B.-Spanish Law in Force From May 13, 1989. Spanish Law of Ports, in Force 01.01.1993Вълко ВълковNo ratings yet

- PressureVacuum PV Valves For Chemical TankersDocument3 pagesPressureVacuum PV Valves For Chemical TankersSahil Biswas100% (1)

- Spillages Through Pumproom Sea ValvesDocument12 pagesSpillages Through Pumproom Sea ValvesGamalMahran50% (2)

- Indian Maritime University: T2203 Cargo Handling & StowageDocument22 pagesIndian Maritime University: T2203 Cargo Handling & StowageMohd AkifNo ratings yet

- VOM - Tankers (Em) - Issue 1 - Rev 15 01 22 718Document2 pagesVOM - Tankers (Em) - Issue 1 - Rev 15 01 22 718veruthepNo ratings yet

- Oil Delivery ChecklistDocument6 pagesOil Delivery Checklistshakti123456789No ratings yet

- 07 Liquid Level GaugingDocument6 pages07 Liquid Level GaugingKamal MuktarNo ratings yet

- Inspector Bulletin: Issue 4Document2 pagesInspector Bulletin: Issue 4Deepak100% (1)

- Chemical Section 8 - Preparation For Discharge and Discharge Operations1Document10 pagesChemical Section 8 - Preparation For Discharge and Discharge Operations1ZIAUL KARIMNo ratings yet

- Sop-Gtd 260613 R1Document68 pagesSop-Gtd 260613 R1antopaul2No ratings yet

- Barge-Inspection FormDocument2 pagesBarge-Inspection FormyasirNo ratings yet

- Pc23 06 MPA Singapore Bunkering Checklist 2023-03-22Document7 pagesPc23 06 MPA Singapore Bunkering Checklist 2023-03-22kyaw zin tun TunNo ratings yet

- Top Detentions Item On Gas TankerDocument3 pagesTop Detentions Item On Gas TankerNord SeaNo ratings yet

- Tro 16B - On Board Training Project For Engine CadetsDocument5 pagesTro 16B - On Board Training Project For Engine CadetsDuhanNo ratings yet

- (Company Name) VGP Annual Barge Inspection Report Form: Vessel General Permit ComplianceDocument2 pages(Company Name) VGP Annual Barge Inspection Report Form: Vessel General Permit ComplianceManuel AguilarNo ratings yet

- Cow ChecklistDocument4 pagesCow ChecklistGarvit MalhotraNo ratings yet

- Codeline User Guide 80UDocument41 pagesCodeline User Guide 80Udwi yuliantoNo ratings yet

- Ship Shore Safety Checklist Part ADocument5 pagesShip Shore Safety Checklist Part AAZWAR SIDINo ratings yet

- COO 07 Loading ProcedureDocument14 pagesCOO 07 Loading Procedureimgesu tahtaNo ratings yet

- VIQ 7 - Knowlwdge Based Questions For Officers - Oil Tankers PDFDocument4 pagesVIQ 7 - Knowlwdge Based Questions For Officers - Oil Tankers PDFFaisal Karim Shazib100% (2)

- Ship Shore Safety Check ListDocument6 pagesShip Shore Safety Check ListMaktrukNo ratings yet

- Oil Tanking Insp QuestrDocument10 pagesOil Tanking Insp QuestrpradeepNo ratings yet

- 17 Maintenance Check ListDocument18 pages17 Maintenance Check ListJoweeGesilvaNo ratings yet

- Inspector Bulletin: Issue 14Document3 pagesInspector Bulletin: Issue 14DeepakNo ratings yet

- Engine Cadet Monthly Task Book #6 Kakha NagervadzeDocument3 pagesEngine Cadet Monthly Task Book #6 Kakha NagervadzeGoraychuk SemenNo ratings yet

- OIS-E&HS - OCTG Inspected Tubular Loading Process Flow DRAFTDocument4 pagesOIS-E&HS - OCTG Inspected Tubular Loading Process Flow DRAFTDheeraj MenonNo ratings yet

- 05cDocument7 pages05cFabio Miguel100% (1)

- Maintaining Valves The Right Way: by Nwaoha Chikezie of CASEIDocument2 pagesMaintaining Valves The Right Way: by Nwaoha Chikezie of CASEIRajibNo ratings yet

- PT Gemilang Bina Lintas Tirta Ship Management: Ship / Shore Safety Checklist / Recurring Item ChecklistDocument7 pagesPT Gemilang Bina Lintas Tirta Ship Management: Ship / Shore Safety Checklist / Recurring Item ChecklistSantoso WahyudiNo ratings yet

- Load Line Survey On ShipsDocument4 pagesLoad Line Survey On ShipsmanNo ratings yet

- Chief Officer Handing Over Note 14-May-2022Document5 pagesChief Officer Handing Over Note 14-May-2022Sriram SridharNo ratings yet

- Pre Arrival at Load-Disport Checklist (Tanker)Document2 pagesPre Arrival at Load-Disport Checklist (Tanker)Anonymous fpLGbRDl100% (1)

- Clarkson-Wafer Slurry Valve KnifeDocument16 pagesClarkson-Wafer Slurry Valve KnifeTramet - ProducciónNo ratings yet

- IB (03-21) - Safety Notices at Western AustraliaDocument28 pagesIB (03-21) - Safety Notices at Western AustraliaishaqNo ratings yet

- PV Valves Operation and Maintenance ProcedureDocument6 pagesPV Valves Operation and Maintenance ProcedureJeet SinghNo ratings yet

- Ship Shore Safety Checklist-TankersDocument6 pagesShip Shore Safety Checklist-TankersJoe Smith100% (1)

- Mooring Risk Focus and Risk AssessmentDocument8 pagesMooring Risk Focus and Risk AssessmentKartik BalaNo ratings yet

- Parr Instrument 4592 20151029154753Document30 pagesParr Instrument 4592 20151029154753dharmendraNo ratings yet

- XIII Special ProceduresDocument126 pagesXIII Special ProceduresMaoui RoumaissaNo ratings yet

- Safe Bunkering PracticesDocument2 pagesSafe Bunkering Practiceskabirsharma76No ratings yet

- GL CL For Onboard MaintenanceDocument18 pagesGL CL For Onboard Maintenanceacere18100% (1)

- A. Checklist Cargo Ops OKDocument44 pagesA. Checklist Cargo Ops OKIhwan Asrul100% (1)

- Cargo Crew - 6Document32 pagesCargo Crew - 6Osman Mert Atabay100% (1)

- Ships Bunkering Operation - Planning, Preparation, Safety Checks & ConfirmationDocument15 pagesShips Bunkering Operation - Planning, Preparation, Safety Checks & ConfirmationTammam HassanNo ratings yet

- User Guide Ecoline 8 InchDocument36 pagesUser Guide Ecoline 8 Inchalexmuchmure2158No ratings yet

- Venting System For TankerDocument4 pagesVenting System For TankeribnuharyNo ratings yet

- Watertight Integrity Check List: VESSEL: - DATEDocument1 pageWatertight Integrity Check List: VESSEL: - DATEРудик НикитаNo ratings yet

- OUTDATED-AQUARIUS EC Case Study 082012 Hi ResDocument2 pagesOUTDATED-AQUARIUS EC Case Study 082012 Hi ResÇağlayan TopNo ratings yet

- Amirikiann A.analysis and Design .1957.TRANSDocument55 pagesAmirikiann A.analysis and Design .1957.TRANSMohamed FouadNo ratings yet

- Sound SignalsDocument2 pagesSound SignalsHaitham Alcheikh DibNo ratings yet

- DA 17 MOSH TrainingDocument8 pagesDA 17 MOSH Trainingmarlon armamentoNo ratings yet

- Government RegulationsDocument7 pagesGovernment RegulationsALEX-UKRNo ratings yet

- Navy Ship Movements 2-11-43Document11 pagesNavy Ship Movements 2-11-43rjwgdi8406No ratings yet

- Weber, David - Honor Harrington Antologies 02, Shadow of SaganamiDocument528 pagesWeber, David - Honor Harrington Antologies 02, Shadow of Saganamibluesoln100% (5)

- Maritime Industry AuthorityDocument8 pagesMaritime Industry Authorityaolaya14No ratings yet

- References: Marine Propulsion SystemsDocument2 pagesReferences: Marine Propulsion SystemsAlbertoNo ratings yet

- Ballast Water Record BookDocument6 pagesBallast Water Record BookMayank HandaNo ratings yet

- Bdoc NotesDocument60 pagesBdoc Notesjoe_a_salvatoreNo ratings yet

- Seagull TestDocument22 pagesSeagull TestTuyen Nguyen67% (3)

- A Book of Discovery: by M. B. SYNGE, F.R.Hist.SDocument370 pagesA Book of Discovery: by M. B. SYNGE, F.R.Hist.SGutenberg.org100% (1)

- TID 164 A Steam Tug EbookDocument73 pagesTID 164 A Steam Tug Ebookmhammer_18100% (1)

- Savage Worlds - Fantasy GearDocument80 pagesSavage Worlds - Fantasy GearMauricio Hurel100% (2)

- IMO HistoryDocument7 pagesIMO HistoryBurduja IonNo ratings yet

- JB Francis - Lowell NotesDocument2 pagesJB Francis - Lowell NotesedpsousaNo ratings yet

- Hydrographic Surveys: Lesson 36-37Document22 pagesHydrographic Surveys: Lesson 36-37matthew cometaNo ratings yet

- BMA MSIR Seabourn Encore Collision (2017) Published April 2019Document59 pagesBMA MSIR Seabourn Encore Collision (2017) Published April 2019Marcin ToporekNo ratings yet

- V6 - LIGHT LIST Volume VI PACIFIC COAST AND PACIFIC ISLANDSDocument301 pagesV6 - LIGHT LIST Volume VI PACIFIC COAST AND PACIFIC ISLANDSDaniel Brumbaugh Sr.No ratings yet

- Oil - BasicsDocument68 pagesOil - BasicsSubi KumarNo ratings yet

- Billy RuffianDocument6 pagesBilly RuffianL.E. LeylandNo ratings yet

- Final Year Project 1Document28 pagesFinal Year Project 1iqbal_syawal100% (1)

- Lecture Seven - Ship Registration and ClassificationDocument14 pagesLecture Seven - Ship Registration and ClassificationRealtime Travel SquadNo ratings yet

- Master Standing OrderDocument1 pageMaster Standing OrderDavid Durham100% (2)

- HunterDocument5 pagesHunterDenison Yacht SalesNo ratings yet

- We Are Not Afraid To DieDocument7 pagesWe Are Not Afraid To DieRamya C.MNo ratings yet

- Bulk Carrier Practice - Inspections During VoyageDocument3 pagesBulk Carrier Practice - Inspections During VoyagesbdmanNo ratings yet

- MV "RS Mistral": 712 TEU Geared Cellular Container VesselDocument1 pageMV "RS Mistral": 712 TEU Geared Cellular Container VesselMeryNo ratings yet

- L1 - FPSO IntroductionDocument32 pagesL1 - FPSO IntroductionZulkamal RoseleyNo ratings yet