Professional Documents

Culture Documents

Jurnal 1 Geotek

Uploaded by

putrielsari26Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Jurnal 1 Geotek

Uploaded by

putrielsari26Copyright:

Available Formats

EXPERIMENTAL INVESTIGATION OF FUNCTIONS OF

GEOTEXTILES IN ROAD CONSTRUCTION

Dheemu Lavanya Kumari1, Ummenthala Veda Vyas2, Veerabathini Srujith Kumar3

1, 2, 3

Assistant Professor, TKR Engineering College (R9), Hyderabad, Telangana State.

ABSTRACT is generally regarded to encompass eight main

The economical development of a country is products categories. They include geotextiles,

closely related to its road transport geogrids, geonets, geomembrane, geosynthetic

infrastructure facilities available. The clay liners, geofoam, geocells and geocomposite.

periodic maintenance of the road is limited The most popular geosynthetics used are the

due to cost consideration which will disrupt geotextiles and geomembrane. The ASTM

the service and affect the function of the road. (1994) defines geotextiles as permeable textile

To overcome these constraints, Geotextiles materials used in contact with soil, rock, earth or

shall be used in pavements to extend the any other geotechnical related material as an

service life of the pavement which requires integral part of civil engineering project,

less repair and maintenance and also reduces structure, or system. Geomembrane is an

the total thickness of the pavement system. In essentially impermeable membrane in the form

this paper, an attempt is made to enhance the of manufactured sheet used widely as cut-offs

performance of the flexible pavement using and liners. A geocomposite is an assembled

woven geotextiles and non-woven geotextiles polymeric material in the form of manufactured

between the layers of soft subgrade and base sheet or strips, consisting of at least, one

course and also effective utilization of fly ash geosynthetic among the components, used in

in subgrade for stabilization. Fly ash geotechnical environmental and transportational

stabilization along with inclusion of engineering applications.

geotextiles increases the California Bearing

Ratio (CBR) value in unsoaked and soaked 1.1 AIM AND OBJECTIVES

condition. The performance of geotextiles is The aim of this research work is to assess the

better when compared to woven geotextiles different types of geosynthetics available and to

because of its better puncture resistance when evaluate the effectiveness of the geotextile in

subjected to impact loading and also good road construction and maintenance. To achieve

drainage properties than woven geotextiles. this aim, the following objectives have been

Key words: Geotextile, Geosynthetics, identified:

Geomembranes, Fly ash and California (1) To classify the available geosynthetics

Bearing Ratio. in the country.

(2) To determine the constituent material

1. INTRODUCTION used in producing the geotextile, one of

Geosynthetics have been defined by the the geosynthetic materials.

American Society for Testing and Materials (3) To incorporate the geotextile in some

(ASTM) Committee D35 on geosynthetics as collected soil materials and assess

planar products manufactured from polymeric performance.

materials used with soil, rock, earth, or other (4) To analyse the results and make

geotechnical engineering related material as an appropriate recommendations for

integral part of a man-made project, structure or optimal use.

system. Geosynthetics is the term used to

describe a range of polymeric products used for

Civil Engineering construction works. The term

ISSN (PRINT): 2393-8374, (ONLINE): 2394-0697, VOLUME-5, ISSUE-5, 2018

51

INTERNATIONAL JOURNAL OF CURRENT ENGINEERING AND SCIENTIFIC RESEARCH (IJCESR)

1.2 NEED OF THE STUDY sunlight and certain highly corrosive

The high rate of erosion and poor drainage chemicals) (Okunade, 2010)

system in different parts of the country has led to

speedy road degradation and extra costs incurred 2. TYPES OF GEOSYNTHETICS

on road rehabilitation; hence the use of Geosynthetics are usually produced either in

geosynthetics is aimed at controlling this sheets or in fabric filaments (fibres) with the

phenomenon. The benefits of a geosynthetic major variations in their composition, thickness

material in any application are defined by six and strength. These are then further worked upon

discrete functions: separation, filtration, in the production process to produce the

drainage, reinforcement, sealing and protection. construction geosynthetics group. The different

The geotextile acts as a filter through which types of this geosynthetics group products are

water passes while it restricts fine-grained soil geotextiles (geofabrics), geogrids, geonets,

from entering into coarse-grained soil (sand or geomembranes, geosynthetic clay liners (GCL),

gravel) and thus prevent their being washed geopipes or geotubes, geocells, geofoams,

away and forestall failure of the road. drainage/infiltration cells and geocomposites.

1.3 SCOPE OF THE STUDY 3. METHODOLOGY

This work shall be limited to the use of The designed methodology is based on previous

geosynthetics as a soil stabilizer in road years of research and experiencein geotextile

construction. It would involve the collection of filtration design. The approach presents a logical

soil materials and determination of their progressionthrough four steps.

geotechnical properties both soaked and Step 1: Defining the Application Filter

unsoaked after which the geotextile would be Requirements

incorporated into the soil sample and their Step 2: Defining Boundary Conditions

geotechnical properties also determined in both Step 3: Determiningthe Soil Retention

the soaked and unsoaked conditions. The result Requirements

would be analysed and the effect of the geotextile 3.1 SAMPLE COLLECTION

on the tested soil sample would be evaluated and The materials that were used for this

the appropriate recommendations would be investigation are clayey, organic and lateritic

made for their best use. soils. For the laboratory tests, three soil samples

In developing countries, the use of geosynthetics were collected. Organic soil and clayey soil were

is relatively new but gaining widespread gotten from Apatapiti layout, Akure and Laterite

popularity in construction. Geosynthetics are gotten from Akure-Lagos Expressway opposite

becoming rapidly popular in construction FUTA North Gate. The materials were gotten in

because of their ability to perform certain polythene to prevent loss of moisture to the

necessary functions while offering practical atmosphere. Analysis was carried out in order to

advantages such as: ascertain the physical and engineering properties

i. A wide availability of products from of the samples

the market place 3.2 LABORATORY TEST

ii. The relative ease of shipping and field Tests implemented or performed on natural

handling (flexibility) clayey, organic and lateritic soils collected for

iii. Rapid installation techniques, i.e fast this project include particle size distribution,

speed of construction, without the need grain size analysis, moisture content, Atterberg

for heavy equipment such as earth- limits and California Bearing ratio tests (CBR) in

moving machines. order to assess their geotechnical properties

iv. Lightweight in comparison with other 3.2.1 Soil Atterberg Limits

construction materials, therefore The test was carried out on natural soil samples

imposing less stress upon the in order to classify into standard groups and these

foundation limits include: liquid, plastic and shrinkage

v. Durability and long life when properly limits. Some useful information obtained from

selected knowledge of these limits are:

vi. General environment safety, since they 1. It enables to identify and classify the soil.

will not degrade. (However, there is 2. Shear strength of soil can be inferred from

possibility of degradation if exposed to these properties.

ISSN (PRINT): 2393-8374, (ONLINE): 2394-0697, VOLUME-5, ISSUE-5, 2018

52

INTERNATIONAL JOURNAL OF CURRENT ENGINEERING AND SCIENTIFIC RESEARCH (IJCESR)

3. Results of the liquid limit can be useful in 4. PAVEMENT MODELING

assessment of the settlement of soil. In modeling forth pavement, four (4) wooden

For fine-grained soils, the plasticity index moulds were constructed, three to contain the

(PI) should be determined usingthe Atterberg different soil layers and the geosynthetic material

Limits test procedureBS 1377-2. and the last one without geotextile. The mould

3.2.2 California Bearing Ratio (CBR) had dimensions length = 40cm, breadth = 20cm

Test procedure was according to BS 1377-4: and height = 50cm to accommodate for the

Soils for civil engineering purposes: Part height of the three sections of the pavement

4:Compaction related tests. Includes:- the which are the base-course, sub-base and sub-

California bearing ratio, and the various methods grade all 150mm in height with a camber of 4

of determining the dry density, moisture content percent for drainage.

relationship of soil. 3kg of oven-dried sample In compaction of the sub-grades, the moulds

was thoroughly mixed with an appropriate were marked with the respective dimensions and

amount of water and placed in a mould. The consideration was given to the camber and with

extension collar and base plate was fixed. The the aid of a rammer, it was compacted with

soil in the mould was compacted in 3 equal several blows. The compacted soils were left to

layers; each layer compacted with 25blows of the consolidate for a week and then the geotextile

2.5kg rammer. The collar was removed and the was laid on the surface on the sub-grade.

soil was trimmed off. The base plate and The sandcrete which is the sub-base had a mix

displacer disc was removed and the mould was ratio of 3:1. 3 head-pans of stone dust to 1 head-

weighed with the compacted soil. pan of cement was thoroughly mixed without the

The penetration piston was placed at the centre presence of water and placed in the mould and

of the specimen with the smallest possible load compacted then sprinkled with water for 7 days

so that full contact between the piston and the to cure and to attain maximum strength. Finally,

sample was established. The strain and stress dial the granite chippings used for the base course

gauge was set to zero and load was applied on was placed and compacted also with the

the piston and records were taken after every ramming rod with the camber still maintained.

30secs. The maximum load corresponding to the The side of the mould with the lower slope was

penetration was determined when there was no removed. The moisture content of the sub-grade

increase in the value of the dial reading. The was determined to check the effectiveness of the

mould was detached and about 15g was taken geotextile placed between the soil layers

from the top to determine the moisture content.

.

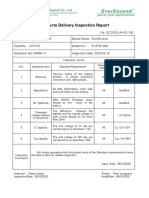

Fig 1: Mould showing dimensions of the various cross sections

5. RESULTS AND DISCUSSION

5.1 PARTICLE-SIZE DISTRIBUTION

This test was performed on the natural soils and the results are shown in the appendix. They were

used for the classification of the samples.

ISSN (PRINT): 2393-8374, (ONLINE): 2394-0697, VOLUME-5, ISSUE-5, 2018

53

INTERNATIONAL JOURNAL OF CURRENT ENGINEERING AND SCIENTIFIC RESEARCH (IJCESR)

Graph 1: Particle size distribution graph for Sample A

Graph 2&3: Particle Size distribution graph for Sample B&C

5.2 CALIFORNIA BEARING RATIO

This test was performed on the samples to readily know the true behavior of the soil and the soil

resistance to shear. The results are shown in appendix III with graphs showing the relationship

between the dry densities and moisture content

ISSN (PRINT): 2393-8374, (ONLINE): 2394-0697, VOLUME-5, ISSUE-5, 2018

54

INTERNATIONAL JOURNAL OF CURRENT ENGINEERING AND SCIENTIFIC RESEARCH (IJCESR)

Table 1: CBR result

2.5 mm CBR Penetration Values 5.0 mm CBR Penetration Values

SAMPLES TOP BOTTOM TOP BOTTOM

SAMPLE A 7.6% 4.2% 8.5% 4.6%

SAMPLE B 6.04% 4.5% 6% 5.26%

SAMPLE C 13.62% 15.095% 15.12% 16.29%

The low CBR values exhibited by the samples A After allowing the model to properly compact,

& B indicates that the sub-grade had a weak each model was tested by leaving them in the

bearing strength and is susceptible to erosion on open and letting normal weather conditions such

exposure to precipitation or surface runoff, as sunshine and rainfall act on them and then the

thereby encouraging and exacerbating rutting moisture content of the sub-grade were taken.

and deformation of pavement. Below are the average moisture content for

5.3 PAVEMENT MODEL TEST samples.

5.4 DRAINAGE TEST:

Fig 2: Side view of the pavement models, the 1st on the left without geotextile and the rest with geotextile

incorporated

This test was performed by taking the moisture the higher moisture content after exposure to

content of the varying sample sub-grades. It was natural weather conditions

observed that the soil without the geotextile had

Table 2: Showing the moisture content of the soil sample used as sub-grades with and without

geotextile.

Weight of can Weight of Weight of Moisture

Weight Weight of Wt of

Samples + wet can + dry wet content

of can dry soil(g) moisture(g)

sample(g) sample(g) sample(g) %

Sample A +

Geotextile 29.3 56.2 50.7 24.9 21.4 3.5 25.7

layer

Sample B +

29.7 68.7 62.1 39 32.4 6.6 20.4

Geotextile

Sample C +

29.4 46.7 44 17.3 14.6 2.7 18.5

Geotextile

Sample A

without 30 47.5 43.4 17.5 13.4 4.1 30.6

Geotextile

ISSN (PRINT): 2393-8374, (ONLINE): 2394-0697, VOLUME-5, ISSUE-5, 2018

55

INTERNATIONAL JOURNAL OF CURRENT ENGINEERING AND SCIENTIFIC RESEARCH (IJCESR)

5.5 SEPARATION TEST:

This test to shows that the geotextile material ensures proper separation of layers in the road section

as shown in the plates below

Fig 3: Proper Separation of sub-grade from the sub-base

This helps to prevent the poor subgrade from material. Plate 8 on the other hand shows an

pumping up into the aggregate base course and it improper separation between the subgrade and

also prevents the aggregate base course from the sub-base. From the plate, it is evident that the

sinking into or mixing with the weaker subgrade sub-base has sunk into the subgrade

Fig 4: Merging - Improper Separation of sub-grade from the sub-base

CONCLUSION This project has been able to show the beneficial

From the above analysis taken on both soil functions of geotextiles in road construction as

sample and material it is of economic benefit to sampled on the various soil types. From results

introduce the use of geotextiles in road gotten it is quite economical to introduce the use

construction as it reduces the act of “borrowing of geosynthetics as a whole into the Engineering

to fill” when the in-situ soil can easily be industry. The material should be used also in

enhanced by use of geosynthetics. effective separation of subgrade and sub-base

Geotextiles are effective tools in the hands of the courses in road construction and other

civil engineer that have proved to solve amyriad engineering constructions.

of geotechnical problems. With the availability REFERENCES

of variety of products with 1. Kundan Meshram., Mittal, S. K.,. Jain, P. K.,

differingcharacteristics, the design engineer Agarwal, P. K. Application of Coir Geotextile in

needs to be aware of not only the application Rural Roads Construction on BC Soil Subgrade.

possibilitiesbutalso more specifically the reason International Journal of Engineering and

why he is using the geotextile and the governing Innovative Technology (IJEIT) Volume 3, Issue

geotextilefunctional properties to satisfy these 4, 2013,pp. 264-268.

functions. Design and selection of geotextiles 2. Senthil Kumar, P., and Rajkumar, R Effect of

based onsound engineering principles will serve Geotextile on CBR Strength of Unpaved Road

the long-term interest of both the user and the with Soft Sub grade, Electronic Journal of

industry.

ISSN (PRINT): 2393-8374, (ONLINE): 2394-0697, VOLUME-5, ISSUE-5, 2018

56

INTERNATIONAL JOURNAL OF CURRENT ENGINEERING AND SCIENTIFIC RESEARCH (IJCESR)

Geotechnical Engg., Vol. 17, 2012, pp.1355-

1363.

3. Singh, H.P. Improvement in CBR value of soil

reinforced with jute geotextile layers,

International Journal of Environmental Science

and Engineering, Vol. (05), 2012, pp. 1438-

1442.

4. Chandra, S., Viladkar, M.N and Nagrale.

Mechanistic approach for fiber-reinforced

flexible pavements, Journal of Transportation

Engineering, Vol.134 (1), 2008, pp. 15-23.

5. Ashish Mehta., Kanak Parate and Ruprai, B.S.

Stabilization of black cotton soil by Fly Ash,

International Journal of Application or

Innovation in Engineering & Management

(IJAIEM), 2013, ISSN 2319 – 4847

6. Gyanen. Takhelmayum, Savitha.A.L and

Krishna Gudi. Laboratory Study on Soil

Stabilization Using Fly ash Mixtures,

International Journal of Engineering Science and

Innovative Technology (IJESIT), Volume 2,

Issue 1, 2013, pp 477-482.

7. Rama Krishna, M and Naga Malleswara Rao,

B. Evaluation of CBR using Geosynthetics in

soil layers, International Journal of Research in

Engineering and Technology, Volume 4, Issue 5,

2015, pp 423-427.

8. Barnali Ghosh.., Dr V Ramesh and

Rajarajeswari B Vibhuti. Improvement of Soil

Characteristics Using Jute Geo-Textile,

International Journal of Science, Engineering

and Technology Research (IJSETR), Volume 3,

Issue 7, 2014, pp 1983-1986.

9. Behaviour of Stone Column in Layered Soils

Using Geotextile Reinforcement, S. Siva Gowri

Prasad, Ch. Vasavi and K. Praveen Sai, Volume

8, Issue 8, August 2017, pp. 453-462.

International Journal of Civil Engineering and

Technology (IJCIET).

ISSN (PRINT): 2393-8374, (ONLINE): 2394-0697, VOLUME-5, ISSUE-5, 2018

57

You might also like

- Eco-efficient Rendering Mortars: Use of Recycled MaterialsFrom EverandEco-efficient Rendering Mortars: Use of Recycled MaterialsNo ratings yet

- The Useof Geosyntheticsin RoadconstructionDocument47 pagesThe Useof Geosyntheticsin RoadconstructionJohn Francis PedrosoNo ratings yet

- The Use of Geosynthetics in Road ConstructionDocument47 pagesThe Use of Geosynthetics in Road ConstructionPaulo Nascimento100% (2)

- Experimental and Numerical Studies On Geotextile Reinforced Subgrade SoilDocument14 pagesExperimental and Numerical Studies On Geotextile Reinforced Subgrade SoilweeerieNo ratings yet

- Draft IRC SP 59 Draft-20!07!2018Document99 pagesDraft IRC SP 59 Draft-20!07!2018Harsh JoshiNo ratings yet

- The Use of Geosynthetics in Road Construction (Case Study - Geotextile)Document48 pagesThe Use of Geosynthetics in Road Construction (Case Study - Geotextile)Suresh DevarajanNo ratings yet

- Nanasaheb Mahadik College of Engineering 2Document8 pagesNanasaheb Mahadik College of Engineering 2Shramik ManeNo ratings yet

- Review of Geosynthetics As A Barrier For Water Table: Proceedings CIGMAT-2019 Conference & ExhibitionDocument3 pagesReview of Geosynthetics As A Barrier For Water Table: Proceedings CIGMAT-2019 Conference & Exhibitionمريم محمدNo ratings yet

- Abdirahman Part 3Document27 pagesAbdirahman Part 3ABDIRAHMANNo ratings yet

- Performance Evaluation of Soil Erosion Control Geotextile Materials On Road Cut SlopeDocument13 pagesPerformance Evaluation of Soil Erosion Control Geotextile Materials On Road Cut SlopeCecille MarcosNo ratings yet

- Experimental Study of Geotextile Effect On Improving Soil Bearing Capacity in Aggregate Surfaced Roads PDFDocument7 pagesExperimental Study of Geotextile Effect On Improving Soil Bearing Capacity in Aggregate Surfaced Roads PDFmojeebmashalNo ratings yet

- Soil Stabilization Using Plain and Treated Coir FibresDocument3 pagesSoil Stabilization Using Plain and Treated Coir FibresAnonymous kw8Yrp0R5rNo ratings yet

- Unit 1BDocument107 pagesUnit 1BNaveen KumarNo ratings yet

- GEOTEXTILES AND GEOMEMBRANESDocument16 pagesGEOTEXTILES AND GEOMEMBRANESsai srinivasNo ratings yet

- Abdi & Zandieh (2014)Document11 pagesAbdi & Zandieh (2014)Jéssica OliveiraNo ratings yet

- Effect of Fly Ash Stabilization On Geotechnical Properties of Chittagong Coastal SoilDocument5 pagesEffect of Fly Ash Stabilization On Geotechnical Properties of Chittagong Coastal Soilmohd razidi azizNo ratings yet

- Usage of Woven Geo-Textiles in The Construction of Subgrade in Flexible PavementsDocument3 pagesUsage of Woven Geo-Textiles in The Construction of Subgrade in Flexible PavementsLuis Alberto VelasquezNo ratings yet

- Recent Innovations in Geosynthetics ProjectsDocument14 pagesRecent Innovations in Geosynthetics ProjectsShashi RajwadeNo ratings yet

- Stabilization of Soft Soil by A Sustainable Binder Comprises Ground Granulated Blast Slag (GGBS) and Cement Kiln Dust (CKD)Document18 pagesStabilization of Soft Soil by A Sustainable Binder Comprises Ground Granulated Blast Slag (GGBS) and Cement Kiln Dust (CKD)Shaker QaidiNo ratings yet

- IRC SP 59-2019 DraftDocument102 pagesIRC SP 59-2019 DraftSatyam LakheraNo ratings yet

- Final CIV REPORTDocument14 pagesFinal CIV REPORTpiggyNo ratings yet

- Reivew PaperDocument4 pagesReivew PaperVgkBharadwajNo ratings yet

- The Study of Geotextile Material: Presented By: Roll No: Division: Guided byDocument17 pagesThe Study of Geotextile Material: Presented By: Roll No: Division: Guided byPOOJA VNo ratings yet

- IJEAS0303031Document6 pagesIJEAS0303031erpublicationNo ratings yet

- Compressibility Behaviour of Preloaded Highly Plastic ClaysDocument9 pagesCompressibility Behaviour of Preloaded Highly Plastic ClaysabinNo ratings yet

- Silo - Tips Case Studies On The Usage of Geosynthetics in Earthen Dams and EmbankmentsDocument6 pagesSilo - Tips Case Studies On The Usage of Geosynthetics in Earthen Dams and Embankmentsrf123_456No ratings yet

- Properties of geosynthetics exhumed from a landfillDocument11 pagesProperties of geosynthetics exhumed from a landfillShahnawaz MullaNo ratings yet

- An Evaluation of The Tropical Soils Subjected Physicochemical Stabilization For Remote Rural RoadsDocument10 pagesAn Evaluation of The Tropical Soils Subjected Physicochemical Stabilization For Remote Rural RoadsYidenek MekonnenNo ratings yet

- Koerner 2010Document11 pagesKoerner 2010javiera chavezNo ratings yet

- The Effect of Aggressive Environments on Stabilized Expansive Soils Using Construction and Demolition WasteDocument6 pagesThe Effect of Aggressive Environments on Stabilized Expansive Soils Using Construction and Demolition WasteMohammed ElaidyNo ratings yet

- Stabilization of Soils Using Geosynthetics Ijariie7098Document14 pagesStabilization of Soils Using Geosynthetics Ijariie7098Rachitha PrachithaNo ratings yet

- Soil Stabilization Using Natural Fiber Coir: International Research Journal of Engineering and Technology (IRJET)Document5 pagesSoil Stabilization Using Natural Fiber Coir: International Research Journal of Engineering and Technology (IRJET)Ali Saleh Saad ALiSAWiNo ratings yet

- Soil Stabilization Using Geotextile MaterialDocument10 pagesSoil Stabilization Using Geotextile Materialmazin jaderNo ratings yet

- Cement effects on physical properties of expansive clay soil and compressive strength of blocksDocument9 pagesCement effects on physical properties of expansive clay soil and compressive strength of blocksSam ChongNo ratings yet

- Utilization of Geotextile for Soil StabilizationDocument8 pagesUtilization of Geotextile for Soil StabilizationmandeeeeeNo ratings yet

- 1.1 Back GroundDocument2 pages1.1 Back GroundShamim RajaNo ratings yet

- Effects of Scrap Tyre Rubber Fibre On Swelling Behaviour of Two Clayey Soils in AlgeriaDocument10 pagesEffects of Scrap Tyre Rubber Fibre On Swelling Behaviour of Two Clayey Soils in AlgeriaKarely González GálvezNo ratings yet

- Effect of Geotexile and Coir Geocell On CBR Strength of Subgrade SoilDocument5 pagesEffect of Geotexile and Coir Geocell On CBR Strength of Subgrade SoilInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- A Study On The Coefficient of Friction of Soil/geotextile InterfacesDocument12 pagesA Study On The Coefficient of Friction of Soil/geotextile InterfacesMalik RizwanNo ratings yet

- Geosynthetic Effects On Seismic Stability of A DamDocument9 pagesGeosynthetic Effects On Seismic Stability of A DamSumanth BhatNo ratings yet

- Application of Coir Geotextile For Road Construction Some IssuesDocument5 pagesApplication of Coir Geotextile For Road Construction Some IssuesChampakali DasNo ratings yet

- Physical properties and mineralogy of termite mound materialDocument21 pagesPhysical properties and mineralogy of termite mound materialDany Josua KmNo ratings yet

- Transportation Geotechnics: Nitin Tiwari, Neelima Satyam, Anand J. PuppalaDocument9 pagesTransportation Geotechnics: Nitin Tiwari, Neelima Satyam, Anand J. PuppalaMeghna SharmaNo ratings yet

- Geomembrane Protection Using Cushioning Geotextiles: November 2014Document9 pagesGeomembrane Protection Using Cushioning Geotextiles: November 2014Maruda8382No ratings yet

- Application of Recron 3S Fibre in Improving Silty Subgrade BehaviourDocument5 pagesApplication of Recron 3S Fibre in Improving Silty Subgrade BehaviourIOSRjournalNo ratings yet

- Utilization of Geotextile For Soil Stabilization: August 2018Document9 pagesUtilization of Geotextile For Soil Stabilization: August 2018Arham SheikhNo ratings yet

- Analysis of Chemical Stabilizer On The Behavior of Expansive SoilDocument10 pagesAnalysis of Chemical Stabilizer On The Behavior of Expansive SoilIJRASETPublicationsNo ratings yet

- HASSAN - Strength Improvement of Clayey Soil With Waste Plastic Strips and Cement Kiln DustDocument5 pagesHASSAN - Strength Improvement of Clayey Soil With Waste Plastic Strips and Cement Kiln DustVitória MoraisNo ratings yet

- Soil StabilizationDocument4 pagesSoil StabilizationEngr Fahad AbroNo ratings yet

- Soil Stabilization Methods and MaterialsDocument38 pagesSoil Stabilization Methods and Materialstyas_pramesthi100% (5)

- Prediction of Compaction Parameters A ReviewDocument1 pagePrediction of Compaction Parameters A ReviewGaurav VermaNo ratings yet

- Daño Inducido Por Áridos Reciclados en El Comportamiento A La Tracción A Corto Plazo de Un Geotextil de Alta ResistenciaDocument8 pagesDaño Inducido Por Áridos Reciclados en El Comportamiento A La Tracción A Corto Plazo de Un Geotextil de Alta Resistenciamanuel velasquez camposNo ratings yet

- Design Procedures For Soil-Lime Stabilization For Road and Railway Embankments - 1 - Review of Design MethodsDocument10 pagesDesign Procedures For Soil-Lime Stabilization For Road and Railway Embankments - 1 - Review of Design MethodsPawelNo ratings yet

- Bio-Enzymatic Stabilization of A Soil Having Poor EngineeringDocument9 pagesBio-Enzymatic Stabilization of A Soil Having Poor EngineeringROHIT KUMARNo ratings yet

- GeoTextiles PDFDocument6 pagesGeoTextiles PDFAsım DavulcuNo ratings yet

- Stabilization of Sub-Grade Using Fly Ash and Geosynthetic MaterialDocument12 pagesStabilization of Sub-Grade Using Fly Ash and Geosynthetic MaterialSarabpreet SobtiNo ratings yet

- International Society For Soil Mechanics and Geotechnical EngineeringDocument9 pagesInternational Society For Soil Mechanics and Geotechnical EngineeringRENZO CASTAÑEDA CERNADESNo ratings yet

- History of GeotextilesDocument6 pagesHistory of Geotextilesachmad sidiq100% (1)

- Full-Scale Investigations Into Installation Damage of Nonwoven GeotextilesDocument15 pagesFull-Scale Investigations Into Installation Damage of Nonwoven GeotextilesGholamhossein Tavakoli MehrjardiNo ratings yet

- Geo SyntheticsDocument20 pagesGeo SyntheticsPradeepBansalNo ratings yet

- Internship Report Zannatul Ferdousi Alam YameemDocument51 pagesInternship Report Zannatul Ferdousi Alam YameemZannatul Ferdousi Alam YameemNo ratings yet

- Mercury Poisoning Symptoms and TreatmentsDocument1 pageMercury Poisoning Symptoms and TreatmentsRakheeb BashaNo ratings yet

- 1.1 Enterprise AssessmentDocument1 page1.1 Enterprise AssessmentGermanRobertoFongNo ratings yet

- Cebuano LanguageDocument15 pagesCebuano LanguageIsla PageNo ratings yet

- Health Fitness Guide UK 2018 MayDocument100 pagesHealth Fitness Guide UK 2018 MayMitch Yeoh100% (2)

- Bahasa Inggris Kelas XIIDocument2 pagesBahasa Inggris Kelas XIIMuhammad ImadudinNo ratings yet

- 2008-14-03Document6 pages2008-14-03RAMON CALDERONNo ratings yet

- Chemical ReactionDocument13 pagesChemical ReactionSujit LawareNo ratings yet

- 6 An Indian American Woman in Space 2Document11 pages6 An Indian American Woman in Space 2Manju YadavNo ratings yet

- Finding The Answers To The Research Questions (Qualitative) : Quarter 4 - Module 5Document39 pagesFinding The Answers To The Research Questions (Qualitative) : Quarter 4 - Module 5Jernel Raymundo80% (5)

- F FS1 Activity 3 EditedDocument15 pagesF FS1 Activity 3 EditedRayshane Estrada100% (1)

- Engr2227 Apr03Document10 pagesEngr2227 Apr03Mohamed AlqaisiNo ratings yet

- Factory Test Report For OPzS 800 EED-20041724 2VDocument3 pagesFactory Test Report For OPzS 800 EED-20041724 2VmaherNo ratings yet

- Gfk-1383a 05012Document108 pagesGfk-1383a 05012occhityaNo ratings yet

- V14 EngDocument8 pagesV14 EngJamil PavonNo ratings yet

- Lesson 2Document10 pagesLesson 2angeliquefaithemnaceNo ratings yet

- A Review of The Management of Cerebral Vasospasm After Aneurysmal Subarachnoid HemorrhageDocument15 pagesA Review of The Management of Cerebral Vasospasm After Aneurysmal Subarachnoid HemorrhageAlanNo ratings yet

- JKSTREGIESDocument59 pagesJKSTREGIESmss_singh_sikarwarNo ratings yet

- The Accidental AddictsDocument6 pagesThe Accidental AddictsnorthandsouthnzNo ratings yet

- Nelson Climate Change Plan UpdateDocument37 pagesNelson Climate Change Plan UpdateBillMetcalfeNo ratings yet

- Annual Report 18Document363 pagesAnnual Report 18Safeer UllahNo ratings yet

- RTR Piping Inspection GuideDocument17 pagesRTR Piping Inspection GuideFlorante NoblezaNo ratings yet

- CS6711 Security Lab ManualDocument84 pagesCS6711 Security Lab ManualGanesh KumarNo ratings yet

- Cheat Codes SkyrimDocument13 pagesCheat Codes SkyrimDerry RahmaNo ratings yet

- LETTER OF AUTHORIZATION CREDO INVEST DownloadDocument1 pageLETTER OF AUTHORIZATION CREDO INVEST DownloadEsteban Enrique Posan BalcazarNo ratings yet

- Audio Narration SINGLE Slide: Google Form in The Discussion ForumDocument2 pagesAudio Narration SINGLE Slide: Google Form in The Discussion Forumfast sayanNo ratings yet

- Radio Drama (Rubric)Document1 pageRadio Drama (Rubric)Queenie BalitaanNo ratings yet

- FacebookH Cking 1 3 (SFILEDocument10 pagesFacebookH Cking 1 3 (SFILEFitra AkbarNo ratings yet

- ZiffyHealth Pitch DeckDocument32 pagesZiffyHealth Pitch DeckSanjay Kumar100% (1)

- Sem Iii Sybcom Finacc Mang AccDocument6 pagesSem Iii Sybcom Finacc Mang AccKishori KumariNo ratings yet

- Dark Matter and the Dinosaurs: The Astounding Interconnectedness of the UniverseFrom EverandDark Matter and the Dinosaurs: The Astounding Interconnectedness of the UniverseRating: 3.5 out of 5 stars3.5/5 (69)

- The Other End of the Leash: Why We Do What We Do Around DogsFrom EverandThe Other End of the Leash: Why We Do What We Do Around DogsRating: 5 out of 5 stars5/5 (64)

- The Ancestor's Tale: A Pilgrimage to the Dawn of EvolutionFrom EverandThe Ancestor's Tale: A Pilgrimage to the Dawn of EvolutionRating: 4 out of 5 stars4/5 (811)

- Alex & Me: How a Scientist and a Parrot Discovered a Hidden World of Animal Intelligence—and Formed a Deep Bond in the ProcessFrom EverandAlex & Me: How a Scientist and a Parrot Discovered a Hidden World of Animal Intelligence—and Formed a Deep Bond in the ProcessNo ratings yet

- Roxane Gay & Everand Originals: My Year of Psychedelics: Lessons on Better LivingFrom EverandRoxane Gay & Everand Originals: My Year of Psychedelics: Lessons on Better LivingRating: 3.5 out of 5 stars3.5/5 (33)

- Roxane Gay & Everand Originals: My Year of Psychedelics: Lessons on Better LivingFrom EverandRoxane Gay & Everand Originals: My Year of Psychedelics: Lessons on Better LivingRating: 5 out of 5 stars5/5 (5)

- Fire Season: Field Notes from a Wilderness LookoutFrom EverandFire Season: Field Notes from a Wilderness LookoutRating: 4 out of 5 stars4/5 (142)

- World of Wonders: In Praise of Fireflies, Whale Sharks, and Other AstonishmentsFrom EverandWorld of Wonders: In Praise of Fireflies, Whale Sharks, and Other AstonishmentsRating: 4 out of 5 stars4/5 (223)

- Wayfinding: The Science and Mystery of How Humans Navigate the WorldFrom EverandWayfinding: The Science and Mystery of How Humans Navigate the WorldRating: 4.5 out of 5 stars4.5/5 (18)

- The Revolutionary Genius of Plants: A New Understanding of Plant Intelligence and BehaviorFrom EverandThe Revolutionary Genius of Plants: A New Understanding of Plant Intelligence and BehaviorRating: 4.5 out of 5 stars4.5/5 (137)

- Spoiled Rotten America: Outrages of Everyday LifeFrom EverandSpoiled Rotten America: Outrages of Everyday LifeRating: 3 out of 5 stars3/5 (19)

- The Mind of Plants: Narratives of Vegetal IntelligenceFrom EverandThe Mind of Plants: Narratives of Vegetal IntelligenceRating: 4.5 out of 5 stars4.5/5 (11)

- The Lives of Bees: The Untold Story of the Honey Bee in the WildFrom EverandThe Lives of Bees: The Untold Story of the Honey Bee in the WildRating: 4.5 out of 5 stars4.5/5 (44)

- When You Find Out the World Is Against You: And Other Funny Memories About Awful MomentsFrom EverandWhen You Find Out the World Is Against You: And Other Funny Memories About Awful MomentsRating: 3.5 out of 5 stars3.5/5 (13)

- Why Fish Don't Exist: A Story of Loss, Love, and the Hidden Order of LifeFrom EverandWhy Fish Don't Exist: A Story of Loss, Love, and the Hidden Order of LifeRating: 4.5 out of 5 stars4.5/5 (699)

- The Hidden Life of Trees: What They Feel, How They CommunicateFrom EverandThe Hidden Life of Trees: What They Feel, How They CommunicateRating: 4 out of 5 stars4/5 (1002)

- The Secret Life of Lobsters: How Fishermen and Scientists Are Unraveling the Mysteries of Our Favorite CrustaceanFrom EverandThe Secret Life of Lobsters: How Fishermen and Scientists Are Unraveling the Mysteries of Our Favorite CrustaceanNo ratings yet

- Last Child in the Woods: Saving Our Children From Nature-Deficit DisorderFrom EverandLast Child in the Woods: Saving Our Children From Nature-Deficit DisorderRating: 4 out of 5 stars4/5 (283)