Professional Documents

Culture Documents

Sampling Plan

Uploaded by

Hasnaoui AsmaaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Sampling Plan

Uploaded by

Hasnaoui AsmaaCopyright:

Available Formats

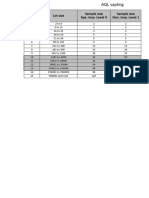

The table below identifies the size of sample to be taken for inspection

based on the total quantity of items received or processed. To the right of

the sample size are the number of nonconformances permissible within the

sampling to accept or reject the entire lot depending on the Acceptable

Quality Level or AQL. The AQL is established based on the criticality of

the item, the lower the AQL, the more critical the item. With the exception

of an AQL that has been defined by the customer, AQL = 1.0 is to be used

during Receiving Inspection. This table is based on ANSI/ASQC Z1.4

(formally MIL-STD-105E) and reflects those requirements for Single

sampling plans for Normal inspection.

SAMPLE AQL = 1.0 AQL = 1.5 AQL = 2.5 AQL = 4.0 AQL = 6.5

LOT SIZE

SIZE

ACC REJ ACC REJ ACC REJ ACC REJ ACC REJ

2 to 8 2 0 1 0 1 0 1 0 1 0 1

9 to 15 3 0 1 0 1 0 1 0 1 0 1

16 to 25 5 0 1 0 1 0 1 0 1 0 1

26 to 50 8 0 1 0 1 0 1 0 1 1 2

51 to 90 13 0 1 0 1 0 1 1 2 2 3

91 to 150 20 0 1 0 1 1 2 2 3 3 4

151 to 280 32 0 1 1 2 2 3 3 4 5 6

281 to 500 50 1 2 2 3 3 4 5 6 7 8

501 to 1200 80 2 3 3 4 5 6 7 8 10 11

1201 to 3200 125 3 4 5 6 7 8 10 11 14 15

3201 to 10000 200 5 6 7 8 10 11 14 15 21 22

10001 to 35000 315 7 8 10 11 14 15 21 22 21 22

35001 to 150000 500 10 11 14 15 21 22 21 22 21 22

150001 to 500000 800 14 15 21 22 21 22 21 22 21 22

500001 and over 1250 21 22 21 22 21 22 21 22 21 22

You might also like

- Jung - A Complete Introduction - Teach Yourself PDFDocument539 pagesJung - A Complete Introduction - Teach Yourself PDFIuliana Ignat100% (6)

- AQL For SafemateDocument1 pageAQL For SafemateEkklesia Bema PrasyantiNo ratings yet

- Hypothesis Testing Sept 2016Document54 pagesHypothesis Testing Sept 2016Somil GuptaNo ratings yet

- Aql Calculator: Inspection Type: General InspectionDocument1 pageAql Calculator: Inspection Type: General InspectionArchana MukundhaNo ratings yet

- AQL Sampling TableDocument66 pagesAQL Sampling Tablesherviny100% (1)

- Question Formulation TechniqueDocument12 pagesQuestion Formulation TechniqueAnouMalie100% (1)

- Single Sampling Plan Lot Size Code Letter Sample Size 1 1.5 Ac Re Ac ReDocument2 pagesSingle Sampling Plan Lot Size Code Letter Sample Size 1 1.5 Ac Re Ac ReAri RosyadiNo ratings yet

- Zero-Based Acceptance Sampling PlanDocument1 pageZero-Based Acceptance Sampling PlanIvan ValenciaNo ratings yet

- Sampling PlanDocument6 pagesSampling PlanGaurang DaveNo ratings yet

- Context & Strategy Analysis: ISO 9001:2015 QMSDocument3 pagesContext & Strategy Analysis: ISO 9001:2015 QMSshailendra singhNo ratings yet

- Professional Development Activities For TeachersDocument9 pagesProfessional Development Activities For TeachersJulius Yap UyNo ratings yet

- Actual Sampling PlanDocument2 pagesActual Sampling PlanAtlasLiu100% (1)

- Perception of Grade 11 Students Towards The Need To Implement Comprehensive Sex Education in Leyte National High SchoolDocument65 pagesPerception of Grade 11 Students Towards The Need To Implement Comprehensive Sex Education in Leyte National High SchoolJhon AmorNo ratings yet

- How To Write A Research ProposalDocument4 pagesHow To Write A Research ProposalAbdulla HussainNo ratings yet

- Issues and Challenges Experienced by Solo Parent1Document43 pagesIssues and Challenges Experienced by Solo Parent1April Joy Andres MadriagaNo ratings yet

- Aql StandardDocument13 pagesAql StandardVaradhan Stylewiz-incNo ratings yet

- Kpi MeiDocument7 pagesKpi MeianggaNo ratings yet

- Sampling PlanDocument2 pagesSampling PlanAtlasLiuNo ratings yet

- Acceptable Quality Label (AQL) Acceptable Quality Label (AQL)Document1 pageAcceptable Quality Label (AQL) Acceptable Quality Label (AQL)faysal2523535No ratings yet

- Lot Size: Zero Defect SamplingDocument2 pagesLot Size: Zero Defect SamplingSudhagarNo ratings yet

- Tabla Dodge Roming 2 HojasDocument2 pagesTabla Dodge Roming 2 HojasVicente VazquezNo ratings yet

- Aql1 5Document2 pagesAql1 5duttbishwajeetNo ratings yet

- WI 03 Control of Sampling PlansDocument4 pagesWI 03 Control of Sampling PlansvinNo ratings yet

- Aql Numune Alma Yeni̇ Elsmar Mil STD 105dDocument2 pagesAql Numune Alma Yeni̇ Elsmar Mil STD 105dSÜMME AÇIKGÖZNo ratings yet

- AIG-ST-004 AQL StandardDocument1 pageAIG-ST-004 AQL StandardTariq Mahmood100% (1)

- SKV FM QA 07 Sampling PlanDocument1 pageSKV FM QA 07 Sampling PlanSaurabh BhadouriyaNo ratings yet

- 65 DoublenormalDocument1 page65 DoublenormalchamindawNo ratings yet

- ANSI Z1.4 - 1993: Professional Inspection and Audit ServicesDocument2 pagesANSI Z1.4 - 1993: Professional Inspection and Audit ServicesMarina KhalafNo ratings yet

- Acceptabl Equal I Tyl I Mi Tchart:: Aa Pentagonkni Tcom. LTD&GL ObalapparelparkltdDocument1 pageAcceptabl Equal I Tyl I Mi Tchart:: Aa Pentagonkni Tcom. LTD&GL ObalapparelparkltdMd MasumNo ratings yet

- Sr. No. Lot Size Sample Size Spe. Insp. Level 4 Sample Size Gen. Insp. Level 1Document6 pagesSr. No. Lot Size Sample Size Spe. Insp. Level 4 Sample Size Gen. Insp. Level 1Shahbaz KhanNo ratings yet

- 6 OutputDocument5 pages6 OutputmawNo ratings yet

- 1° Identificamos Los GDL, Las Direcciones, Las Juntas y Los ElementosDocument3 pages1° Identificamos Los GDL, Las Direcciones, Las Juntas y Los ElementosCarlos BrayanNo ratings yet

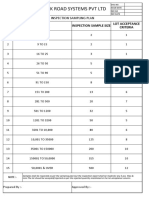

- Abhishek K Road Systems PVT LTD: Inspection Sampling PlanDocument1 pageAbhishek K Road Systems PVT LTD: Inspection Sampling Planpardeep kumarNo ratings yet

- FRM-QC-32 Rev 0 Sample PlanDocument3 pagesFRM-QC-32 Rev 0 Sample PlanAhmad KhalifaNo ratings yet

- SP (Sampling Plan)Document1 pageSP (Sampling Plan)sanjaysharmajiNo ratings yet

- Libro 1Document2 pagesLibro 1dulcedelarosa1803No ratings yet

- AQL Charger Project - GB2828-2012 Sampling PlanDocument1 pageAQL Charger Project - GB2828-2012 Sampling PlanMohammad KamruzzamanNo ratings yet

- Garments AQLsDocument1 pageGarments AQLsRejaalNo ratings yet

- Table Mil STD 105eDocument16 pagesTable Mil STD 105eAgus BaruNo ratings yet

- Atividade BalançaDocument2 pagesAtividade BalançadouglasgobitschNo ratings yet

- INTERNAL TEST-1 Mark Details ACADEMIC YEAR:2018-19 Sub. Name: Ee8251 Circuit TheoryDocument24 pagesINTERNAL TEST-1 Mark Details ACADEMIC YEAR:2018-19 Sub. Name: Ee8251 Circuit TheoryRaja pandiyanNo ratings yet

- Diseño Del Trabajo - Tabla TimestudDocument10 pagesDiseño Del Trabajo - Tabla Timestudcarlos robayoNo ratings yet

- eSRC HANDS ON ACTIVITYDocument66 pageseSRC HANDS ON ACTIVITYRaulJunioRamos100% (2)

- Short UEQ Data Analysis ToolDocument106 pagesShort UEQ Data Analysis ToolMUHAMMAD DANY RAHMANNo ratings yet

- Short UEQ Data Analysis ToolDocument106 pagesShort UEQ Data Analysis ToolIT SamuelNo ratings yet

- BD20022 OprDocument12 pagesBD20022 OprDeepNo ratings yet

- Short UEQ Data Analysis Tool V12Document124 pagesShort UEQ Data Analysis Tool V12Riyan MardiyantaNo ratings yet

- Bela JarDocument7 pagesBela JarKezia IreneNo ratings yet

- Plano de Amostragem: Processo: Engenharia N°.: Pág.: 1/1Document6 pagesPlano de Amostragem: Processo: Engenharia N°.: Pág.: 1/1cleozinhaNo ratings yet

- Monev Kelengkapan Rekam MedisDocument144 pagesMonev Kelengkapan Rekam MedisPUSKESMAS GONDANGLEGINo ratings yet

- Plano de Amostragem: Processo: Engenharia N°.: Pág.: 1/1Document6 pagesPlano de Amostragem: Processo: Engenharia N°.: Pág.: 1/1cleozinhaNo ratings yet

- Neonatos - Obitos 2011Document3 pagesNeonatos - Obitos 2011Yhoel Lino Uñapilco VillafuerteNo ratings yet

- BodegaDocument36 pagesBodegaSweet SimyunnNo ratings yet

- Kuder and Richardson Formula 20Document4 pagesKuder and Richardson Formula 20JM LomoljoNo ratings yet

- Table I-Sample Size Code LettersDocument13 pagesTable I-Sample Size Code LettersAhmed AymanNo ratings yet

- Bài5 Mgo t83Document10 pagesBài5 Mgo t83thanhthao9104No ratings yet

- FormulaDocument3 pagesFormulaMiguel0173No ratings yet

- Derg Zamovlennya 2022Document5 pagesDerg Zamovlennya 2022Itachi UchihaNo ratings yet

- SP3 LB1 PUSKESMAS TEJO AGUNG Febuari 2018Document16 pagesSP3 LB1 PUSKESMAS TEJO AGUNG Febuari 2018SISKANo ratings yet

- Table II-ADocument1 pageTable II-AIrfan KhanNo ratings yet

- Dasar 01Document2 pagesDasar 01imaharNo ratings yet

- Pengaturan BebanDocument2 pagesPengaturan BebanFrido Jimmy TariganNo ratings yet

- Stochastic Processes PracticalsDocument36 pagesStochastic Processes PracticalsVicky GuptaNo ratings yet

- STATISTICSDocument12 pagesSTATISTICSAryan DuttaNo ratings yet

- 2) 16-Pf-Prueba (1) (3) - 1Document42 pages2) 16-Pf-Prueba (1) (3) - 1Navarro Viera Shary JazmínNo ratings yet

- Restaurant: Roun D Num Ber Order Recd Mater Ial Sent Order Place D Mater Ial Recd Inven Tory / Backo RderDocument3 pagesRestaurant: Roun D Num Ber Order Recd Mater Ial Sent Order Place D Mater Ial Recd Inven Tory / Backo RderAbhinavSagarNo ratings yet

- App C - Motor TestDocument2 pagesApp C - Motor TestDeepak AnejaNo ratings yet

- Become Competent in 15 Minutes - The Suitability of Micro LearnDocument18 pagesBecome Competent in 15 Minutes - The Suitability of Micro LearnHasnaoui AsmaaNo ratings yet

- S3 Minutes 02Document4 pagesS3 Minutes 02Hasnaoui AsmaaNo ratings yet

- Wijaya 2020 IOP Conf. Ser. Mater. Sci. Eng. 835 012053Document13 pagesWijaya 2020 IOP Conf. Ser. Mater. Sci. Eng. 835 012053Hasnaoui AsmaaNo ratings yet

- 6 1-Etc2014Document7 pages6 1-Etc2014Hasnaoui AsmaaNo ratings yet

- Very Detailed Document For TGF - USE IT AS REFERENCEDocument41 pagesVery Detailed Document For TGF - USE IT AS REFERENCEHasnaoui AsmaaNo ratings yet

- 1.2 Product Reliability Targets Study PlanDocument1 page1.2 Product Reliability Targets Study PlanHasnaoui AsmaaNo ratings yet

- Semester Cohort: SMK Kai Chung (Yfb 6301) Peti Surat 100, 96507 Bintangor, SarawakDocument6 pagesSemester Cohort: SMK Kai Chung (Yfb 6301) Peti Surat 100, 96507 Bintangor, SarawakUng Hie HuongNo ratings yet

- South African Universities in World RankingsDocument21 pagesSouth African Universities in World RankingsmarietheronNo ratings yet

- PP Lesson 1Document5 pagesPP Lesson 1Raguwaran SamayyahNo ratings yet

- Diss 11-Lesson 6Document26 pagesDiss 11-Lesson 6Stephen Gagarin SidayonNo ratings yet

- Getachew Lemma PDFDocument172 pagesGetachew Lemma PDFaregawi weleabezgiNo ratings yet

- Lecture1 2 3Document86 pagesLecture1 2 3Jee HiNo ratings yet

- Multiple Choice Questions 1. Why Do You Need To Review The Existing Literature?Document2 pagesMultiple Choice Questions 1. Why Do You Need To Review The Existing Literature?angelaNo ratings yet

- Customer Satisfaction - A Case Study of ICICI BANK Conducted in The Area of Kharar (Punjab)Document3 pagesCustomer Satisfaction - A Case Study of ICICI BANK Conducted in The Area of Kharar (Punjab)Dipak MandavkarNo ratings yet

- The Psychological and Performance Demands of Association Football RefereeingDocument23 pagesThe Psychological and Performance Demands of Association Football RefereeingAnonymous A1DOvPjNo ratings yet

- "Business Statistics For Managers" Unit 5Document34 pages"Business Statistics For Managers" Unit 5Suragiri VarshiniNo ratings yet

- 12696 ตัวเล่ม PDFDocument414 pages12696 ตัวเล่ม PDFduy tuanNo ratings yet

- 3.2.4 Performance Models: Chapter ThreeDocument1 page3.2.4 Performance Models: Chapter ThreeanothersomeguyNo ratings yet

- Dis4 Lab 2.1.3.2 StudentDocument3 pagesDis4 Lab 2.1.3.2 StudentAulia0% (1)

- Peran Penyuluh Pertanian Sebagai Komunikator Dalam Penerapan Usaha Pertanian Lahan Sempit Di Desa Hukurila Kotamadya AmbonDocument7 pagesPeran Penyuluh Pertanian Sebagai Komunikator Dalam Penerapan Usaha Pertanian Lahan Sempit Di Desa Hukurila Kotamadya AmbonKrisman SaragihNo ratings yet

- Role Model ThesisDocument7 pagesRole Model Thesisdwm7sa8p100% (1)

- The Macro ProcessDocument14 pagesThe Macro ProcessSahil ShitoleNo ratings yet

- MGMT 306 SyllabusDocument4 pagesMGMT 306 SyllabusLucChuNo ratings yet

- Sample Board Performance Evaluation FormDocument8 pagesSample Board Performance Evaluation Formpalama1No ratings yet

- Fenomena Politik Uang (Money Politic) Pada Pemilihan Calon Anggota Legislatif Di Desa Sandik Kecamatan Batu Layar Kabupaten Lombok BaratDocument9 pagesFenomena Politik Uang (Money Politic) Pada Pemilihan Calon Anggota Legislatif Di Desa Sandik Kecamatan Batu Layar Kabupaten Lombok BaratOld ManNo ratings yet

- Lecture 8 - Goms IIDocument21 pagesLecture 8 - Goms IIkipkoecharonz korirNo ratings yet

- Johari WindowDocument5 pagesJohari WindowManoj Bal100% (1)

- Chapter 3Document3 pagesChapter 3Ariel DicoreñaNo ratings yet