Professional Documents

Culture Documents

KAR1904 PRO CA 0000 GEN 0001 - Rev 01 - Pipeline SS and TR Analysis

Uploaded by

Mojtaba YousefiOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

KAR1904 PRO CA 0000 GEN 0001 - Rev 01 - Pipeline SS and TR Analysis

Uploaded by

Mojtaba YousefiCopyright:

Available Formats

Pipeline Steady State and

Transient Analysis

FEED Services For Water Injection Project,

Khurmala Dome

KAR1904-PRO-CA-0000-GEN-0001_Rev 1

31 March 2021

KAR Engineering and Construction Co.

Mott MacDonald

Festival Tower

Dubai Festival City

PO Box 11302, Dubai

United Arab Emirates

T +971 (0)4 206 9111

F +971 (0)4 232 8050

mottmac.com

KAR Engineering and

Construction Co. Pipeline Steady State and

Transient Analysis KAR1904-PRO-CA-0000-GEN-

0001_Rev 0

C:\Users\mun85066\Desktop\KAR Group\408505-KAR-MML-T-0226\KAR1904-DES-DQ-

0000-GEN-0001_RevA_Surge Analysis.docx

Mott MacDonald

FEED Services For Water Injection Project,

Khurmala Dome

KAR1904-PRO-CA-0000-GEN-0001_Rev 1

31 March 2021

Mott MacDonald Limited. Registered in

England and Wales no. 1243967.

Registered office: Mott MacDonald House,

8-10 Sydenham Road, Croydon CR0 2EE,

KAR Engineering and Construction Co.

United Kingdom

Mott MacDonald | Pipeline Steady State and Transient Analysis

FEED Services For Water Injection Project, Khurmala Dome

KAR1904-PRO-CA-0000-GEN-0001_Rev 1

Issue and Revision Record

Revision Date Originator Checker Approver Description

0 18/11/19 SKG VM VRP Issued for Design

0A 15/02/21 SKG SK SK Re-Issued for Review (For Re-

FEED scope)

1 31/03/21 SKG SK SK Re-Issued for Design (For Re-

FEED scope)

Document reference: KAR1904-PRO-CA-0000-GEN-0001_Rev 01

Information class: Standard

This document is issued for the party which commissioned it and for specific purposes connected with the above-

captioned project only. It should not be relied upon by any other party or used for any other purpose.

We accept no responsibility for the consequences of this document being relied upon by any other party, or being

used for any other purpose, or containing any error or omission which is due to an error or omission in data supplied

to us by other parties.

This document contains confidential information and proprietary intellectual property. It should not be shown to other

parties without consent from us and from the party which commissioned it.

This R eport has been prepar ed sol ely for us e by the party w hich commissi oned it (the 'Client') in connection wi th the capti on ed pr oject. It shoul d not be used for any other purpose. N o pers on other than the Client or any party w ho has expr essly agreed terms of reli ance with us (the 'Recipi ent(s)') may r ely on the content, information or any views expr ess ed in the R eport. T his R eport is confi denti al and c ontains pr opri etary intell ectual pr operty and we ac cept no duty of car e, r esponsibility or li ability to any other recipi ent of this R eport. N o repr esentati on, w arranty or undertaki ng, ex press or im plied, is made and no res ponsi bility or liability is ac cepted by us to any party other than the Client or any Reci pient(s), as to the acc uracy or com pleteness of the i nformati on c ontai ned i n this R eport. F or the avoi danc e of doubt thi s Report does not i n any w ay pur port to i nclude any leg al, ins uranc e or fi nanci al advic e or opi nion.

We dis claim all and any liability w hether arising i n tort, contr act or otherwis e w hich we might otherwise have to any party other than the Cli ent or the Reci pient(s), in res pect of this Report, or any inform ation contained in it. W e acc ept no res ponsi bility for any error or omissi on in the Report w hich is due to an error or omissi on in data, i nformation or statements s upplied to us by other parti es i ncludi ng the Cli ent (the 'Data'). We hav e not independently v erified the D ata or otherwis e exami ned i t to determi ne the acc uracy, com pleteness, sufficiency for any purpose or feasi bility for any partic ular outc ome incl uding fi nanci al.

Forec asts pres ented i n this docum ent w ere pr epared usi ng the Data and the Repor t is dependent or bas ed on the D ata. Inevitabl y, s om e of the ass umptions us ed to dev elop the for ecasts will not be realised and unantici pated ev ents and circumstanc es m ay occ ur. C onsequently, we do not guarantee or w arrant the conclusions c ontained in the R eport as ther e are lik ely to be differenc es betw een the forecas ts and the actual res ults and those differ ences may be m aterial. While we c onsi der that the information and opini ons given in this R eport are s ound all parti es m ust rely on their ow n s kill and judgem ent when m aking us e of it.

Information and opi nions ar e c urrent only as of the date of the Report and w e acc ept no res ponsi bility for updati ng such information or opi nion. It s houl d, therefor e, not be assum ed that any s uc h inform ati on or opi nion conti nues to be acc urate subs equent to the date of the Report. U nder no circum stanc es m ay this Report or any ex trac t or summ ary thereof be us ed i n c onnecti on with any public or priv ate s ec urities offeri ng incl udi ng any related m emor andum or pr os pec tus for any securiti es offering or stock exchange listi ng or announcem ent.

By acc eptanc e of this Repor t y ou agree to be bound by this disclaim er. T his disclaim er and any iss ues, dis putes or cl aims ari sing out of or in c onnection wi th it (whether c ontractual or non-contractual i n natur e s uc h as cl aims i n tort, from br eac h of statute or regul ati on or otherwise) s hall be gov erned by, and constr ued i n acc ordance with, the law s of Engl and and W ales to the exclusion of all c onflict of l aws principles and r ules . All dis putes or claims arising out of or r elati ng to this discl aimer s hall be s ubjec t to the excl usive juris dicti on of the English and Welsh courts to w hich the parties irrev ocably submit.

KAR1904-PRO-CA-0000-GEN-0001_Rev 0 | 31 March 2021

Mott MacDonald | Pipeline Steady State and Transient Analysis

FEED Services For Water Injection Project, Khurmala Dome

KAR1904-PRO-CA-0000-GEN-0001_Rev 1

Contents

1 Introduction 1

1.1 General Information 1

1.2 Project Background 1

1.3 Scope of Work 1

1.3.1 FEED design of water intake and treatment facilities at Zab River 1

1.3.2 FEED design of Water Transfer Pipeline 2

1.3.3 Tie-in at Khurmala Oil Field for Treated Produced Water Lines from

CPS-1 and CPS-2 2

1.3.4 FEED design for Receiving Facilities and Water Injection Pump

Station 2

1.3.5 FEED design for water injection distribution network along Khurmala

Oil Field 2

1.4 Scope of Document 3

1.5 Abbreviation 3

2 Input for Transient Analysis 5

2.1 Fluid Properties 5

2.2 Basis & Assumption 5

2.3 Meteorological Data 5

2.4 Pipeline Data 5

3 Software for Transient Analysis 7

3.1 Transient Scenarios 7

4 Steady State Analysis 8

5 Transient Analysis Cases 9

5.1 Transient Scenarios 9

5.2 Transient State Back Pressure 9

5.3 Transient State-Flow Profile 10

5.4 Transient State-Upstream Pressure Profile 10

5.5 Transient State-Downstream Pressure Profile 11

6 Conclusion 12

A

KAR1904-PRO-CA-0000-GEN-0001_Rev 0 | 31 March 2021

Mott MacDonald | Pipeline Steady State and Transient Analysis 1

FEED Services For Water Injection Project, Khurmala Dome

KAR1904-PRO-CA-0000-GEN-0001_Rev 1

1 Introduction

1.1 General Information

Project Name : KAR- Water Injection FEED Project

Project Location : Khurmala, Kurdistan, Iraq

1.2 Project Background

Khurmala dome is spread from 30 km south west of Erbil city, 22 km long and 3 km wide. Due to increase of

maximum recovery of crude oil production, reservoir fields are depleted, so that water injection project is required

to sustain crude oil production and maintain reservoir pressure based on the field development plan. Source of

water is available from the upper Zab river as well as treated produced water from the crude oil separation

facilities at CPS-1 and CPS-2.

The objective of this project is FEED design of River Water Intake Facilities, River Water Treatment, River Water

Transfer Pipeline, River Water Storage, Tie-ins for treated produced water from CPS-1 and CPS-2, Water

Booster Pumps for CPS-1, Water Injection Pumps, injection Manifold and associated utilities.

Zab river water is taken in River Water Intake Sump by gravity through concrete pipe with attached screen at

river bed. Water is filtered through coarse and fine screens in River Water Intake sump and pumped for further

treatment. The subsequent treatment includes sedimentation, flocculation, coagulation and filtration through

sand filters, carbon filters and cartridge filters to achieve injection water qualities. Treated water is stored in

Treated River Water Tank and is transferred using River Water Transfer Pumps via River Water Transfer

Pipeline from River location to Khurmala Oil Field. In order to facilitate pigging operation permanent Pig

Launcher and Pig Receiver will be located at river intake station and Khurmala Oil Field respectively.

Treated River Water is stored in River Water Storage Tank. Water Injection Pumps are provided for injecting

treated river water to water injection wells. The Water injection wells are spread across North to South Stations

along the Khurmala Oil Field. Water injection distribution network will be designed with 24 number of 6” off takes

connection for individual water injection well heads.

Treated water from CPS-1 has currently less pressure than required water injection pressure, hence water

Booster Pumps are provided to meet the required water injection pressure. Booster pumps discharge is

connected to injection manifold.

Treated water from CPS-2 is at required water injection pressure and will be directly connected to the water

injection manifold.

At river location, Diesel Generators will be used for power generation. Potable water system is provided for

operations personnel. Instrument Air System is provided to cater process and instrument requirement.

At Khurmala Oil Field location, Instrument Air System is provided to cater process and instrument requirement.

Potable water system is provided for operations personnel.

1.3 Scope of Work

The scope of work covers the FEED for the entire water treatment and injection project from the river intake

facilities to the water injection well heads (location and flow rate/pressure) of the Water Injection wells.

Scope of work includes:

1.3.1 FEED design of water intake and treatment facilities at Zab River

The scope of work includes:

A. Study of the Zab river area and choose the best area to locate the water intake facilities and

evaluation of the various options for the intake facilities

B. FEED design of the raw water treatment facilities

KAR1904-PRO-CA-0000-GEN-0001_Rev 0 | 31 March 2021

Mott MacDonald | Pipeline Steady State and Transient Analysis 2

FEED Services For Water Injection Project, Khurmala Dome

KAR1904-PRO-CA-0000-GEN-0001_Rev 1

C. Electrical FEED design for the intake facilities

D. Instrument & Control FEED design

E. Mechanical FEED design

1.3.2 FEED design of Water Transfer Pipeline

Water Transfer Pipeline from Zab river intake facilities to Khurmala Oil Field is approximately 44 km long.

The scope of work includes:

A. Pipeline routing survey/study

B. Sizing of pipeline

C. Pipeline material selection for underground pipeline for 25 years of life.

1.3.3 Tie-in at Khurmala Oil Field for Treated Produced Water Lines from CPS-1 and CPS-2

Treated Produced Water from CPS-1 and CPS-2 is received at Khurmala Oil Field for injection to Well Heads

along with treated river water.

The scope of work includes:

A. Sizing of Treated Water lines from CPS-1 and CPS-2.

B. FEED design of Tie-in connections

1.3.4 FEED design for Receiving Facilities and Water Injection Pump Station

The scope of work includes:

A. Optimization of the location and configuration of the water injection pump stations.

B. Pump Station to be designed to receive the treated river water from Zab river and treated produced

water from CPS-1 and CPS-2

1.3.5 FEED design for water injection distribution network along Khurmala Oil Field

The Water Injection wells are spread across North to South Stations along the Khurmala Oil Field. Water

injection distribution network will be designed with 24 number of 6” off takes connection for individual Water

Injection well heads.

The Scope of work includes:

A. Distribution scheme optimization

B. Sizing Calculations

C. Material selection for the underground pipelines taking in consecration of the life time of the project

(25 years)

KAR1904-PRO-CA-0000-GEN-0001_Rev 0 | 31 March 2021

Mott MacDonald | Pipeline Steady State and Transient Analysis 3

FEED Services For Water Injection Project, Khurmala Dome

KAR1904-PRO-CA-0000-GEN-0001_Rev 1

1.4 Scope of Document

The scope of work of this document to complete the steady state and transient analysis of water transfer pipeline

and water injection lines.

1.5 Abbreviation

Abbreviation Description

API American Petroleum Institute

ASME American Society of Mechanical Engineers

BFD Block Flow Diagram

BGL Below Ground Level

BoD Basis of Design

BPD Barrels Per Day

BWPD Barrels of Water Per Day

BS British Standard

CS Carbon Steel

DCS Distributed Control System

DOR Division of Responsibility

EDG Emergency Diesel Generator

ESD Emergency Shutdown

FEED Front End Engineering Design

FGS Fire and Gas System

H2S Hydrogen Sulphide

HP High Pressure

HSE Health, Safety and Environment

ICCP Impressed Current Cathodic Protection

ICSS Integrated Control and Safety System

ID Inner Diameter

ISO International Standardisation Organisation

LP Low Pressure

KAR1904-PRO-CA-0000-GEN-0001_Rev 0 | 31 March 2021

Mott MacDonald | Pipeline Steady State and Transient Analysis 4

FEED Services For Water Injection Project, Khurmala Dome

KAR1904-PRO-CA-0000-GEN-0001_Rev 1

NACE National Association of Corrosion Engineers

NFPA National Fire Protection Association

NW-SE North West South East

OIW Oil in Water

P&ID Piping & Instrumentation Diagram

PFD Process Flow Diagram

ppm Part Per Million

RCC Reinforced Cement Concrete

SAW Sub-Merged Arc Welded Line Pipe

SG Specific Gravity

SIS Safety Instrumented System

TDS Total Dissolved Solids

TSS Total Suspended Solids

UCP Unit Control Panel

UPS Uninterruptable Power Supply

VTA Vendor to Advise

KAR1904-PRO-CA-0000-GEN-0001_Rev 0 | 31 March 2021

Mott MacDonald | Pipeline Steady State and Transient Analysis 5

FEED Services For Water Injection Project, Khurmala Dome

KAR1904-PRO-CA-0000-GEN-0001_Rev 1

2 Input for Transient Analysis

2.1 Fluid Properties

Compositional fluid as WATER is selected as Software Input. The water properties at operating pressure and

temperature are generated by Software

2.2 Basis & Assumption

1) Water flow rate through pipeline for earlier study was 2100 m3/hr. As per new scope, revised water flow

rate through pipeline: 2,00,000 BPD (1400 m3/hr)

2) Landing pressure at Tank B/L: 2 barg

2.3 Meteorological Data

Black bulb temperature : 82C

Solar radiation : 120 mW/cm2

Soil thermal resistivity : 240 cm.C/W

2.4 Pipeline Data

The following pipeline data has been considered for transient calculations:

Nominal Pipeline Size, inch 30”

Pipeline OD (mm) 760

Wall Thickness, mm 8.74

Pipe wall roughness (PE), mm 0.015

Operating Temperature, oC 4 – 55

Design Pressure, barg 30

Minimum Design Temperature, °C -10

Maximum Design Temperature, °C 85

Approximate Length, km 44

Pipeline profile Refer Note-1,2 below

Design Life, years 25

Notes

1. Geotechnical survey for pipeline has not been carried out during the FEED stage. Hence exact

pipeline profile is not available. For carrying out hydraulics of pipeline, the profile of pipeline running

parallel to the upcoming water transfer pipeline is used for reference. The final pipeline hydraulics

shall be carried out based on actual pipeline profile during detailed engineering.

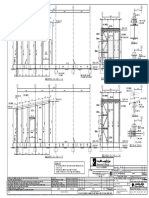

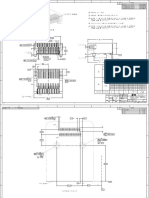

2. The reference pipeline profile used for hydraulics is as per figure below.

KAR1904-PRO-CA-0000-GEN-0001_Rev 0 | 31 March 2021

Mott MacDonald | Pipeline Steady State and Transient Analysis 6

FEED Services For Water Injection Project, Khurmala Dome

KAR1904-PRO-CA-0000-GEN-0001_Rev 1

Elevation from FGL Meter 0 195 8 60

Distance from source Km 0 11 26.8 44

KAR1904-PRO-CA-0000-GEN-0001_Rev 0 | 31 March 2021

Mott MacDonald | Pipeline Steady State and Transient Analysis 7

FEED Services For Water Injection Project, Khurmala Dome

KAR1904-PRO-CA-0000-GEN-0001_Rev 1

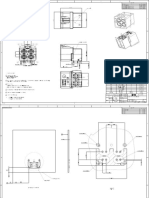

3 Software for Transient Analysis

Pipeline Studio Software Version 4.1.1.0 is used for carrying out transient calculations.

Model selection

Model Type TLNET

Fluid Type Compositional Fluid

Type – Auto-generated

Fluid – Water (100% H2O)

Equation of State Default

Temperature Tracking Yes

Number of Iterations (max) 200

Time Step, sec 0.01

Convergence tolerance Min - 0.001 and Max – 0.01

3.1 Transient Scenarios

Size

Scenario Time Step

(inch)

Starting/Closing time for manual valve 30 30 seconds interval which corresponds to 33% closing

Pump Trips @ Closure of manual valve At 0% Manual valve opening; Flow is 0.0 m3/hr

KAR1904-PRO-CA-0000-GEN-0001_Rev 0 | 31 March 2021

Mott MacDonald | Pipeline Steady State and Transient Analysis 8

FEED Services For Water Injection Project, Khurmala Dome

KAR1904-PRO-CA-0000-GEN-0001_Rev 1

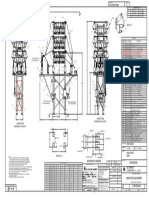

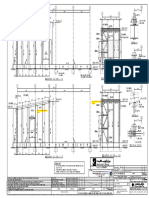

4 Steady State Analysis

For the revised water flow rate of 1400 m3/hr and given pipeline details the steady sate source pressure

calculated by TL Net is 11.49 barg for fixed downstream pressure (at Tank B/L) of 2 barg.

Results of Steady State Analysis

Pressure Unit Remark

Source pressure 11.49 barg Calculated

Destination Pressure 2.0 barg Fixed

Steady State Pressure Drop 9.49 bar

As the pipeline profile is not

Margin on Pressure Drop 25 % available, 25% design margin is

considered for conservative design

Pressure drop with margin 11.86 bar

Supply pressure required at

13.86 barg

source

Supply pressure used for water

14.0 Barg

transfer pumps

Steady State Pressure Profile

KAR1904-PRO-CA-0000-GEN-0001_Rev 0 | 31 March 2021

Mott MacDonald | Pipeline Steady State and Transient Analysis 9

FEED Services For Water Injection Project, Khurmala Dome

KAR1904-PRO-CA-0000-GEN-0001_Rev 1

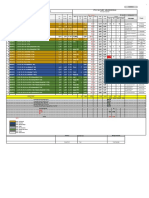

5 Transient Analysis Cases

For the revised water flow rate of 1400 m3/hr and given pipeline details, transient state hydraulics is run for the

two scenarios mentioned in above section 3.1

From the results (refer section 5.2 to 5.5) is evident that,

• Transient state back pressure reached at settled conditions in pipeline is 15.06 barg

• The maximum upstream pressure reaching in the pipeline is 21 barg.

• The maximum downstream pressure reaching in the pipeline is 16 barg.

Hence, water transfer pipeline is suitable and safe w.r.t. the surge pressures in the network due to various

operating/start-up/shutdown scenarios as maximum pressure reached in the pipeline is less than design

pressure (30 barg)

5.1 Transient Scenarios

Transient hydraulic analysis is carried out for the following two scenarios. The results are pressented from

section 5.2 onnways

Size

Scenario Time Step

(inch)

Starting/Closing time for manual valve 30 30 seconds interval which corresponds to 33% closing

Pump Trips @ Closure of manual valve

At 0% Manual valve opening, flow is 0.0 m3/hr

(due to high discharge pressure)

Results of Transient Analysis

5.2 Transient State Back Pressure

KAR1904-PRO-CA-0000-GEN-0001_Rev 0 | 31 March 2021

Mott MacDonald | Pipeline Steady State and Transient Analysis 10

FEED Services For Water Injection Project, Khurmala Dome

KAR1904-PRO-CA-0000-GEN-0001_Rev 1

5.3 Transient State-Flow Profile

5.4 Transient State-Upstream Pressure Profile

KAR1904-PRO-CA-0000-GEN-0001_Rev 0 | 31 March 2021

Mott MacDonald | Pipeline Steady State and Transient Analysis 11

FEED Services For Water Injection Project, Khurmala Dome

KAR1904-PRO-CA-0000-GEN-0001_Rev 1

5.5 Transient State-Downstream Pressure Profile

KAR1904-PRO-CA-0000-GEN-0001_Rev 0 | 31 March 2021

Mott MacDonald | Pipeline Steady State and Transient Analysis 12

FEED Services For Water Injection Project, Khurmala Dome

KAR1904-PRO-CA-0000-GEN-0001_Rev 1

6 Conclusion

1. The steady state pipeline operating pressure is 14.00 barg.

2. River Water Transfer Pumps needs to be designed for required discharge pressure of 14.0 barg

3. The water transfer pipeline is suitable and safe w.r.t. the surge pressures in the network due to various

operating/start-up/shutdown scenarios.

Disclaimer

Geotechnical survey for pipeline has not been carried out during the FEED stage and hence exact pipeline

profile is not available. The pipeline steady state and transient analysis is carried out based on reference profile

of pipeline running parallel to the upcoming water transfer. Pipeline steady state pressure and transient pressure

(Design Pressure) shall be confirmed during Detailed Engineering, based on actual pipeline profile.

KAR1904-PRO-CA-0000-GEN-0001_Rev 0 | 31 March 2021

Mott MacDonald | Pipeline Steady State and Transient Analysis 13

FEED Services For Water Injection Project, Khurmala Dome

KAR1904-PRO-CA-0000-GEN-0001_Rev 1

mottmac.com

KAR1904-PRO-CA-0000-GEN-0001_Rev 0 | 31 March 2021

You might also like

- (Encloser 2) KAR1904-PPL-DS-0000-GEN-0004 - Rev 0 - Data Sheet For Pig Launcher Receiver 1Document10 pages(Encloser 2) KAR1904-PPL-DS-0000-GEN-0004 - Rev 0 - Data Sheet For Pig Launcher Receiver 1DarshAwadNo ratings yet

- 2-18-2020 - GAC MSC - Acworth - Add2 Full SetDocument21 pages2-18-2020 - GAC MSC - Acworth - Add2 Full SetRicardo Mayorga ParedesNo ratings yet

- HUG-99-104071-CS-7880-00001-0002-01Document1 pageHUG-99-104071-CS-7880-00001-0002-01anandNo ratings yet

- Werkstatt 01 SchematicsDocument9 pagesWerkstatt 01 Schematicsfelas37616No ratings yet

- SPI Connections Revision HistoryDocument19 pagesSPI Connections Revision Historytolak anginNo ratings yet

- DWG ISSUED FOR TENDER AND APPROVALDocument5 pagesDWG ISSUED FOR TENDER AND APPROVALDilshad TabasumNo ratings yet

- Early Tie-In Foundation PlanDocument1 pageEarly Tie-In Foundation PlanKAVINNo ratings yet

- RAS Markaz Crude Oil Park Project Phase 1 GA Drawings Rest ShelterDocument5 pagesRAS Markaz Crude Oil Park Project Phase 1 GA Drawings Rest SheltersaravqwertyNo ratings yet

- 1TB01006 006C03 Moo RPT PM 0001 PDFDocument2 pages1TB01006 006C03 Moo RPT PM 0001 PDFmohamed makramNo ratings yet

- PP Jury FolioDocument37 pagesPP Jury FolioMOHAMMED AYAAN MOOSANo ratings yet

- Evh® 5150iii LBXDocument3 pagesEvh® 5150iii LBXДмитрийNo ratings yet

- HUG-98-104071-CS-2358-00001-0003-01Document1 pageHUG-98-104071-CS-2358-00001-0003-01anandNo ratings yet

- Modulo CHM FTLDocument9 pagesModulo CHM FTLNestor Zela MamaniNo ratings yet

- Raft Section A-A: 50 Thk. PCC 1:3:6 4 Thk. Water Proofing Membrane 100 Thk. PCC 1:4:8Document1 pageRaft Section A-A: 50 Thk. PCC 1:3:6 4 Thk. Water Proofing Membrane 100 Thk. PCC 1:4:8Omer HayatNo ratings yet

- HUG-98-104071-CS-2358-00001-0004-01Document1 pageHUG-98-104071-CS-2358-00001-0004-01anandNo ratings yet

- HUG-98-104071-CS-2358-00001-0005-01Document1 pageHUG-98-104071-CS-2358-00001-0005-01anandNo ratings yet

- 01 - General Tracker-1Document4 pages01 - General Tracker-1MAGED ELSADIGNo ratings yet

- MoBo SchematicDocument3 pagesMoBo SchematicAbd Al-KhataibNo ratings yet

- 03 - Daf - SDF - Rev 02BDocument10 pages03 - Daf - SDF - Rev 02BJhonnel PunzalanNo ratings yet

- Eng CD 2374900 A4-3077475Document4 pagesEng CD 2374900 A4-3077475Roger SuzanoNo ratings yet

- 380910-ESD-03 Specification For Outdoor Circuit Breaker (R0)Document19 pages380910-ESD-03 Specification For Outdoor Circuit Breaker (R0)Vinayak DeokarNo ratings yet

- Method of Statment CONCRETEDocument7 pagesMethod of Statment CONCRETESyed AtherNo ratings yet

- IGT Game King 044 Video CTRL Board Schematics (757-044-10)Document24 pagesIGT Game King 044 Video CTRL Board Schematics (757-044-10)Turko Alejandro50% (2)

- 4008-GE-LST-001 - B-Martabe Deliverable List - 20220314 - LOADED RESIN SCREEN PROJECT - HL UpdateDocument9 pages4008-GE-LST-001 - B-Martabe Deliverable List - 20220314 - LOADED RESIN SCREEN PROJECT - HL Updatethoriq ikhwanNo ratings yet

- MS 001 - Setting OutDocument6 pagesMS 001 - Setting OutChamux skalNo ratings yet

- CNOOC Zhejiang LNG Plant, Ningbo China: Ga DrawingDocument7 pagesCNOOC Zhejiang LNG Plant, Ningbo China: Ga Drawing李军No ratings yet

- Hmc1031ms8e Eval PCB SchematicDocument3 pagesHmc1031ms8e Eval PCB SchematicbaymanNo ratings yet

- Daily Wo 17 Februari 2024Document1 pageDaily Wo 17 Februari 2024agusNo ratings yet

- MEP Clearence - 20 Concrete Casting For MBBR Tank Wall Upto Level +26.80 Stage-07Document4 pagesMEP Clearence - 20 Concrete Casting For MBBR Tank Wall Upto Level +26.80 Stage-07sikandarkhan2828No ratings yet

- See Detail in Fabrication Work Schedule: (Overall)Document1 pageSee Detail in Fabrication Work Schedule: (Overall)Ye YintNo ratings yet

- Checkprint 1808795 4E701Document1 pageCheckprint 1808795 4E701fangrui maiNo ratings yet

- Peterbilt 362 Schematics Wiring DiagramDocument10 pagesPeterbilt 362 Schematics Wiring Diagramhamilton miranda100% (1)

- 154D3502AA D: Elementary DiagramDocument1 page154D3502AA D: Elementary DiagramYas AlbNo ratings yet

- 0080 D141 00001 - Rev.3 - C1Document2 pages0080 D141 00001 - Rev.3 - C1nuntaricherdchaiNo ratings yet

- Rev C MKR 370 DC Self Support Installation DrawingDocument1 pageRev C MKR 370 DC Self Support Installation DrawingPrasenjit DuttaNo ratings yet

- HUG-98-104071-CS-2358-00001-0006-01Document1 pageHUG-98-104071-CS-2358-00001-0006-01anandNo ratings yet

- Laporan Harian Produksi Domas Pt. Calvary Abadi Domas: U-Ditch & Cover CodeDocument1 pageLaporan Harian Produksi Domas Pt. Calvary Abadi Domas: U-Ditch & Cover Codefaradita alfiantiNo ratings yet

- G-102-01 (790DBBC) Al-Shahaniya: Qatar Armed ForcesDocument1 pageG-102-01 (790DBBC) Al-Shahaniya: Qatar Armed ForcesAslamNo ratings yet

- Dashboard - 02-May-2021Document1 pageDashboard - 02-May-2021AliNo ratings yet

- DF Safety Concept Wingd 2sDocument67 pagesDF Safety Concept Wingd 2ssestoubosNo ratings yet

- 0417 - 118T3293 Cooling Sealing AirDocument6 pages0417 - 118T3293 Cooling Sealing AirfaisalnadimNo ratings yet

- Sp3 MB A WPF Det - Typ 004-Rev A (Not in Use)Document1 pageSp3 MB A WPF Det - Typ 004-Rev A (Not in Use)Renaldo BunaidiNo ratings yet

- Hydrostor A-CAES - Heat Balance at Avg Conditions 002Document3 pagesHydrostor A-CAES - Heat Balance at Avg Conditions 002IbraDinceNo ratings yet

- V754749001XC (241 242) PDFDocument5 pagesV754749001XC (241 242) PDFErin JohnsonNo ratings yet

- HUG-98-104071-CS-2358-00001-0002-01Document1 pageHUG-98-104071-CS-2358-00001-0002-01anandNo ratings yet

- HUG-98-104071-CS-2358-00001-0001-01Document1 pageHUG-98-104071-CS-2358-00001-0001-01anandNo ratings yet

- Single Line DiagramDocument1 pageSingle Line DiagramNero ApawanNo ratings yet

- Sophos PerformanceDocument148 pagesSophos Performancefake fNo ratings yet

- PP Aaa PP1 101Document20 pagesPP Aaa PP1 101Rabah AmidiNo ratings yet

- HUG-98-104071-CS-2358-00001-0002-01-commentedDocument1 pageHUG-98-104071-CS-2358-00001-0002-01-commentedanandNo ratings yet

- Eng CD 1761987 C1Document2 pagesEng CD 1761987 C1ZorbanfrNo ratings yet

- HUG-98-104071-CS-2358-00001-0003-01-CommentedDocument1 pageHUG-98-104071-CS-2358-00001-0003-01-CommentedanandNo ratings yet

- CP201-SAJV-RSS-ALL-DRW-STG-06591 - 06608 RSS North Staircase Emergency Access 2 - GFC20220411Document20 pagesCP201-SAJV-RSS-ALL-DRW-STG-06591 - 06608 RSS North Staircase Emergency Access 2 - GFC20220411pupuk wahyuonoNo ratings yet

- R1 YankbDocument2 pagesR1 YankbmnsenalkanaNo ratings yet

- Prototype Print: 1 AT516772 1 Raw Weldment Painted Weldment, Lap Bar 2 T449786 1 Handlebar Lapbar OvermoldDocument1 pagePrototype Print: 1 AT516772 1 Raw Weldment Painted Weldment, Lap Bar 2 T449786 1 Handlebar Lapbar OvermoldLilian ChangNo ratings yet

- R1 YankbDocument4 pagesR1 YankbRizky TiensNo ratings yet

- R1 YankbDocument4 pagesR1 YankbRizky TiensNo ratings yet

- Ok DECAL, WIRING SCHEMATIC (Xe), SD, LVM, PORO, REMOTE ALARMDocument4 pagesOk DECAL, WIRING SCHEMATIC (Xe), SD, LVM, PORO, REMOTE ALARMMarcos LunaNo ratings yet

- CrankcaseDocument7 pagesCrankcaseCharlie BellNo ratings yet

- Algebra 3 Principles and Sample Problems: 3.1 Probability 3.2 Statistics 3.3 Problems For SolutionsDocument24 pagesAlgebra 3 Principles and Sample Problems: 3.1 Probability 3.2 Statistics 3.3 Problems For SolutionsKrisha Jean MacalinoNo ratings yet

- 12TH CS TERM 2 - PythonDocument8 pages12TH CS TERM 2 - PythonAnbuchelvan VKNo ratings yet

- Samsung CAC Duct S Brochure 20140729 0Document16 pagesSamsung CAC Duct S Brochure 20140729 0Callany AnycallNo ratings yet

- 1993 Engines Eurovan - 2.5L 5-CylinderDocument20 pages1993 Engines Eurovan - 2.5L 5-Cylinderfrancesco pavanNo ratings yet

- Intraoral ProjectionsDocument73 pagesIntraoral ProjectionsrespikNo ratings yet

- Metal-Catalyzed Epoxidations of Alkenes With Hydrogen PeroxideDocument18 pagesMetal-Catalyzed Epoxidations of Alkenes With Hydrogen PeroxidechidambaramrNo ratings yet

- Chapter 7: Advanced Modeling Techniques: Prof. Ming-Bo LinDocument42 pagesChapter 7: Advanced Modeling Techniques: Prof. Ming-Bo Linvimal_raj205No ratings yet

- Phs SelectionsDocument5 pagesPhs SelectionsadycrsNo ratings yet

- MagnusDocument26 pagesMagnussvsreeramaNo ratings yet

- Week 5 Lecture Pigeonhole Principle 1Document58 pagesWeek 5 Lecture Pigeonhole Principle 1CODING with ASAD.No ratings yet

- Water Properties & pH RegulationDocument19 pagesWater Properties & pH RegulationSumiya JssalbNo ratings yet

- Bank Statement QueryDocument13 pagesBank Statement QuerySiddiq MohammedNo ratings yet

- JBMO ShortLists-2001Document2 pagesJBMO ShortLists-2001OklaNo ratings yet

- Albert Einstein - What Is The Theory of RelativityDocument4 pagesAlbert Einstein - What Is The Theory of RelativityPPP100% (1)

- NSXT 30 AdminDocument1,028 pagesNSXT 30 AdminAlessandroNo ratings yet

- Smes - Lab3 - Systemc-TlmDocument3 pagesSmes - Lab3 - Systemc-TlmTulio GaldencioNo ratings yet

- Math8 - q1 - Mod5a - Multiplying and Dividing Rational Algebraic Expressions - 08092020Document34 pagesMath8 - q1 - Mod5a - Multiplying and Dividing Rational Algebraic Expressions - 08092020JaylanGalasi100% (4)

- Grade: Third Grade Unit Title: Matter Course/Subject: Science Approximate Time Required: 1 WeekDocument6 pagesGrade: Third Grade Unit Title: Matter Course/Subject: Science Approximate Time Required: 1 Weekapi-272854858No ratings yet

- K-Gamma and K-Beta FunctionDocument5 pagesK-Gamma and K-Beta FunctionketashiNo ratings yet

- Configure NTP Server on Cisco WLC via CLIDocument3 pagesConfigure NTP Server on Cisco WLC via CLImbayeNo ratings yet

- How To Draw Manga - Vegeta (Dragon Ball Z)Document7 pagesHow To Draw Manga - Vegeta (Dragon Ball Z)Constantino Paucar Vega100% (1)

- Getting Started with Anypoint Platform SetupDocument2 pagesGetting Started with Anypoint Platform SetupRRR180No ratings yet

- CFM To LFM CalculationDocument7 pagesCFM To LFM Calculationudilevy100% (1)

- DRT 105 - 1Document31 pagesDRT 105 - 1Sir ArtNo ratings yet

- Understanding Gases Through Kinetic TheoryDocument20 pagesUnderstanding Gases Through Kinetic TheoryJaimeNo ratings yet

- Enzymes ProbsDocument21 pagesEnzymes ProbsAnonymous sVNvV7Q100% (1)

- Relativistic Electrodynamics NotesDocument13 pagesRelativistic Electrodynamics NotesPritika SabharwalNo ratings yet

- Effect of Upstream Dam Geometry On Peak Discharge During Overtopping Breach in Noncohesive Homogeneous Embankment Dams Implications For Tailings DamsDocument22 pagesEffect of Upstream Dam Geometry On Peak Discharge During Overtopping Breach in Noncohesive Homogeneous Embankment Dams Implications For Tailings DamsHelvecioNo ratings yet