Professional Documents

Culture Documents

Emd Notes Int 1

Uploaded by

Balaji DhanabalOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Emd Notes Int 1

Uploaded by

Balaji DhanabalCopyright:

Available Formats

EMD

1. How design problems of electrical machines can be classified?

Electromagnetic design

Mechanical design

Thermal Design

Dielectric design

2. List the major considerations in electrical machine design?

The major considerations to achieve a good electrical machine are specific electric loading, specific

magnetic loading, temperature rise, efficiency, length of air gap and power factor.

3. Write short notes on standard specification?

The standard specifications are the specifications issued by the standards organization of a country. The

standard specification serves as guidelines for the manufacturers to produce quality products at economical

prices. The standard specifications for the electrical machines include Ratings, Types of Enclosure,

Dimensions of the conductors, Name plate details, performance indices, permissible temperature rise,

permissible loss, efficiency etc.,

4. Mention the main dimensions of a rotating machine.

The main dimensions of a rotating machine are the armature diameter or stator bore (D) and armature

or stator core length (L).

5. Define specific magnetic and electric loading.

The specific magnetic loading is defined as the total flux per unit area over the surface of the armature

periphery and is denoted by Bav also known as average flux density.

Specific magnetic loading (Bav) = total flux around the air gap / Area of flux path at the air gap

The specific electric loading is defined as the number of armature conductors per meter of armature

periphery at the air gap.

Specific electric loading (ac) = total number ampere conductors / armature periphery at air gap.

6. Define field form factor.

The filed form factor Kf is defined as the ratio of average gap density over the pole pitch to maximum flux

density in the air gap.

Kf = Bav / Bg

Kf ≈ ψ = pole arc/pole pitch

7. What is real and apparent flux density?

The real flux density is due to actual flux through a tooth. The apparent flux density is due to total flux that

has to be passed through the tooth. Since some of the flux passes through slot, the real flux density is

always less than the apparent flux density.

Bapp = Total flux in a slot pitch / Total area

Breal = Actual flux in a tooth / Total area

8. What is magnetic leakage and leakage coefficient?

The leakage flux is the flux passing through unwanted path. The leakage flux will not help either for transfer

or conversion of energy. The leakage coefficient is defined as the ratio of total flux to the useful flux.

1|Page Prepared by Mr.D.Balaji AP/EEE/MVIT

9. Define gap contraction factor (Kg).

The total gap contraction factor Kg, is defined as the ratio of reluctance of air gap of machines with slotted

armature & ducts to the reluctance of air gap in machines with smooth armature and without ducts. The

total gap contraction factor is equal to the product of gap contraction factors for slots and ducts.

10. State the properties which determine the suitability of material for insulating purpose of electrical

machines.

The insulating material should have the following properties. The material must have high mechanical strength

so that it carries the tension and weight of the conductors. They must have high dielectric strength. The

material is highly resistive for preventing the flow of leakage current from the conductor to earth. Cotton, silk,

paper without impregnation Cotton, silk, paper, suitably impregnated, coated or well immersed in dielectric

such as oil. Synthetic resins and enameled wires, cellulose, tri-acetate film, etc.

PART-B

Explain in detail about the heating and cooling curves.

HEATING AND COOLING CURVES

A machine can be considered as a homogeneous body developing heat internally at uniform rate and dissipating

heat proportionately to its temperature rise,

RELATION SHIP BETWEEN TEMPERATURE RISE AND TIME

Let,

Assume that a machine attains a temperature rise after the lapse of time t seconds.

In an element of time “dt” a small temperature rise “d” takes place.

Then,

Heat developed = p.dt

Heat stored = Gh.d

Heat dissipated = S. dt

Therefore, total heat developed=heat stored + heat dissipated

2|Page Prepared by Mr.D.Balaji AP/EEE/MVIT

Where is called as heating time constant and it has the dimensions of time.

Heating time constant

Heating time constant is defined as the time taken by the machine to attain 0.623 of its final steady temperature

rise.

The heating time constant of the machine is the index of time taken by the machine to attain its final steady

temperature rise.

The value of heating time constant is larger for poorly ventilated machines with large or totally enclosed machines,

the heating time constant may reach several hours or even days.

3|Page Prepared by Mr.D.Balaji AP/EEE/MVIT

When a hot body is cooling due to reduction of the losses developed in it, the temperature time curve is again an

exponential function.

If motor where disconnected from supply during cooling, there would be no losses taking place and hence, final

temperature reached will be the ambient temperature.

Cooling time constant

Cooling time constant is, therefore, defined as the time required cooling the machine down to 0.368 times the

initial temperature rise above ambient temperature.

4|Page Prepared by Mr.D.Balaji AP/EEE/MVIT

Calculate the mmf required for an air gap of dc machine with an axial length of 20 cm (no ducts) and a pole arc

of 18 cm, the slot pitch = 27 mm, slot opening = 12 mm, air gap = 6 mm, the useful flux / pole is 25 m Wb. Take a

Carter’s coefficient of slot is 0.3. (CO1, K3)

5|Page Prepared by Mr.D.Balaji AP/EEE/MVIT

Derive the relationship between real and apparent flux densities. (CO1, K2)

6|Page Prepared by Mr.D.Balaji AP/EEE/MVIT

State and explain the classification of insulating materials based on thermal consideration.

(CO1, K2)

Insulation materials somewhat less common in electrical machines are materials made of polyester fiber

(Dacron, Terylene, Diolen, Mylar), polyimide films (Kapton) and silicon resins employed in the

impregnation. Insulation can be roughly divided into two main categories: groundwall and conductor

insulation.

Classification of insulating materials based on thermal consideration

The insulation system (also called insulation class) for wires used in generators, motors

transformers and other wire-wound electrical components is divided into different classes according the

temperature that they can safely withstand.

As per Indian Standard (Thermal evaluation and classification of Electrical

Insulation,IS.No.1271,1985,first revision) and other international standard insulation is classified by

letter grades A,E,B,F,H (previous Y,A,E,B,F,H,C).

7|Page Prepared by Mr.D.Balaji AP/EEE/MVIT

Determine the apparent flux density in the teeth of a dc machine when real flux density is 2.15 Wb/m;

slot pitch 28 mm; slot width = 10 mm and gross core length = 0.35m. The number of ventilating ducts is 4, each

10 mm wide. The magnetizing force for the flux density of 2.15 Wb/m 2 is 55000 A/m. The iron stacking factor

is 0.9. (CO1, K3)

8|Page Prepared by Mr.D.Balaji AP/EEE/MVIT

You might also like

- 194 - EE6604 Design of Electrical Machines - Important QuestionsDocument28 pages194 - EE6604 Design of Electrical Machines - Important QuestionsNiteshNarukaNo ratings yet

- Design of Electrical Machine Unit 1 2 MarksDocument6 pagesDesign of Electrical Machine Unit 1 2 MarksVel MuruganNo ratings yet

- Ee1352 Electrical Machine Design 2 Marks Question Bank PDFDocument21 pagesEe1352 Electrical Machine Design 2 Marks Question Bank PDFvigneshwaran anguchamyNo ratings yet

- Ee1352 Electrical Machine Design-2 Marks Question BankDocument21 pagesEe1352 Electrical Machine Design-2 Marks Question BankAnnai Theresa100% (3)

- Predicting Temperature Rise of Ferrite Cored TransformersDocument5 pagesPredicting Temperature Rise of Ferrite Cored TransformersPhạm Văn TưởngNo ratings yet

- Lement of Lectrical Esign: General Design AspectsDocument84 pagesLement of Lectrical Esign: General Design AspectsKeval PatelNo ratings yet

- 12 Steps Design SMPS TransformersDocument11 pages12 Steps Design SMPS TransformersRnDES1 CMLNo ratings yet

- An Effective Cable Sizing Procedure Model For Industries and Commerial BuildingsDocument6 pagesAn Effective Cable Sizing Procedure Model For Industries and Commerial BuildingsRobNo ratings yet

- An Effective Cable Sizing Procedure Model For Industries and Commerial BuildingsDocument7 pagesAn Effective Cable Sizing Procedure Model For Industries and Commerial BuildingsOsama ElhadadNo ratings yet

- A Very High Density Heatsink Mounted Inductor For Automotive AppDocument7 pagesA Very High Density Heatsink Mounted Inductor For Automotive AppTrần Đức TrườngNo ratings yet

- Effective Cable Sizing Model For Building ElectricDocument8 pagesEffective Cable Sizing Model For Building ElectricNurul NaqiesyaNo ratings yet

- Types and Design Factors of Electrical BusbarsDocument7 pagesTypes and Design Factors of Electrical Busbarsgsantosh060% (1)

- Unit 1 PDFDocument6 pagesUnit 1 PDFrioNo ratings yet

- TEFC Motor End Region Cooling CFD StudyDocument5 pagesTEFC Motor End Region Cooling CFD StudyVitthal KhandagaleNo ratings yet

- F9000 GenInfo MotorCapsDocument10 pagesF9000 GenInfo MotorCapsAhmad Arif ZulfikarNo ratings yet

- Guide to Choosing Power Electronics CapacitorsDocument38 pagesGuide to Choosing Power Electronics CapacitorsSunil GeorgeNo ratings yet

- Dem Unit 1 2 3 4 5Document17 pagesDem Unit 1 2 3 4 5Revathy KannanNo ratings yet

- JKR Elektrik-Saiz CableDocument8 pagesJKR Elektrik-Saiz Cablearchery67% (3)

- Electrical Machine DesignDocument29 pagesElectrical Machine DesignMahmoud Fawzi100% (1)

- Design Electrical Machines SyllabusDocument26 pagesDesign Electrical Machines Syllabuskk8823No ratings yet

- Capacitor selection guide for motor applicationsDocument12 pagesCapacitor selection guide for motor applicationsZia urRehmanNo ratings yet

- Thermal Analysis of Electrical Machines Limits and Heat Transfer PrinciplesDocument2 pagesThermal Analysis of Electrical Machines Limits and Heat Transfer PrinciplesAnonymous sAmJfcVNo ratings yet

- Whitepaper: Accelerated Lifetime-Test For Metallized Film CapacitorsDocument24 pagesWhitepaper: Accelerated Lifetime-Test For Metallized Film CapacitorsccuevasarenasNo ratings yet

- Sizing Power Cables for Circuit Breaker Feeders (Part 1Document25 pagesSizing Power Cables for Circuit Breaker Feeders (Part 1akash_ing7683100% (1)

- Electrical Machine Design FactorsDocument8 pagesElectrical Machine Design FactorsHari SankarNo ratings yet

- Assignment:1: Hve Btee-802Document6 pagesAssignment:1: Hve Btee-802Er Pritpal S SNo ratings yet

- Cables (HT<) : Energy Estimation & Audit (15ee430)Document73 pagesCables (HT<) : Energy Estimation & Audit (15ee430)rohith mukkamalaNo ratings yet

- Sizing of Power Cables For Circuit Breaker Controlled FeedersDocument15 pagesSizing of Power Cables For Circuit Breaker Controlled FeedersAlmir Mahmutovic100% (1)

- MU040 - KRT EngHandbook Lowres PDFDocument24 pagesMU040 - KRT EngHandbook Lowres PDFRajendra Prasad ShuklaNo ratings yet

- Calc Temp Load Capable of Cable-Neher-McGrathDocument13 pagesCalc Temp Load Capable of Cable-Neher-McGrathmcavy100% (1)

- TafirifezaDocument2 pagesTafirifezazafrikhan875No ratings yet

- Jurnal 4Document16 pagesJurnal 4AnggiNo ratings yet

- Alcan Cable: A Growing TrendDocument3 pagesAlcan Cable: A Growing TrendCarlos Lino Rojas AgüeroNo ratings yet

- Neher Mcgrath1 PDFDocument13 pagesNeher Mcgrath1 PDFelmodeer9841No ratings yet

- Kerite Engineering Catalog PDFDocument20 pagesKerite Engineering Catalog PDFTIAGO3045No ratings yet

- Extra Losses Caused in High Current Conductors by Skin and Proximity EffectsDocument22 pagesExtra Losses Caused in High Current Conductors by Skin and Proximity Effectslbk50No ratings yet

- Pipe Insulation - Finding The Optimal ThicknessDocument5 pagesPipe Insulation - Finding The Optimal ThicknessmbsahgNo ratings yet

- Topic Assignment15Document8 pagesTopic Assignment15cuongakamarineNo ratings yet

- Charalambous 2011Document10 pagesCharalambous 2011FyhgiiuuNo ratings yet

- Cable SizerDocument5 pagesCable SizerShreenivas DevalmakkiNo ratings yet

- Ee1352 Electrical Machine Design-2 Marks Question Bank - Transformer - InductorDocument18 pagesEe1352 Electrical Machine Design-2 Marks Question Bank - Transformer - InductorSajad AliNo ratings yet

- Industrial InsulationDocument9 pagesIndustrial Insulationahad_shiraziNo ratings yet

- Pipe Insulation Finding The Optimal ThicknessDocument6 pagesPipe Insulation Finding The Optimal Thicknessthorem100% (1)

- Cable Selcetion2 Afte RM Rev4Document9 pagesCable Selcetion2 Afte RM Rev4Stephen BridgesNo ratings yet

- Variable Frequency Drive Installation Guide: Environmental RequirementsDocument12 pagesVariable Frequency Drive Installation Guide: Environmental RequirementsQOBITNo ratings yet

- Optimal Design Approach of Inductors For Mass Heating ProcessesDocument6 pagesOptimal Design Approach of Inductors For Mass Heating ProcessesInternational Journal of Application or Innovation in Engineering & ManagementNo ratings yet

- 1 s2.0 S0960148112000821 MainDocument6 pages1 s2.0 S0960148112000821 MainJaspreet Singh ChahalNo ratings yet

- Pre Lab 2Document5 pagesPre Lab 2Maaz HussainNo ratings yet

- Energy Station Post Insulator White PaperDocument10 pagesEnergy Station Post Insulator White PaperTravis WoodNo ratings yet

- Electrical Machine ProjectDocument18 pagesElectrical Machine ProjectrediNo ratings yet

- EE2355 Design of Electrical Machines NotesDocument24 pagesEE2355 Design of Electrical Machines Notesmadhes14No ratings yet

- Epcos China (TDK) ER - 35!20!11Document7 pagesEpcos China (TDK) ER - 35!20!11leoNo ratings yet

- Lab Manual PDFDocument40 pagesLab Manual PDFAngelline MalikNo ratings yet

- Grounding Calculation Report for 3500 TPD Cement PlantDocument8 pagesGrounding Calculation Report for 3500 TPD Cement Plantn2hhiepNo ratings yet

- Ee8002 - Dem - Question Bank - Unit 1Document8 pagesEe8002 - Dem - Question Bank - Unit 1DEVINo ratings yet

- 17 Measurements and Instrumentation Sep 2020Document2 pages17 Measurements and Instrumentation Sep 2020Balaji DhanabalNo ratings yet

- 18 Measurements and Instrumentation Jan 2022Document2 pages18 Measurements and Instrumentation Jan 2022Balaji DhanabalNo ratings yet

- 15 Measurements and Instrumentation May 2019Document2 pages15 Measurements and Instrumentation May 2019Balaji DhanabalNo ratings yet

- 11 Measurement and Instrumentation Apr 2017Document2 pages11 Measurement and Instrumentation Apr 2017Balaji DhanabalNo ratings yet

- 10 Measurement and Instrumentation-Nov 2016Document2 pages10 Measurement and Instrumentation-Nov 2016Balaji DhanabalNo ratings yet

- B.Tech. DEGREE EXAMINATION questions on electrical machine designDocument4 pagesB.Tech. DEGREE EXAMINATION questions on electrical machine designBalaji DhanabalNo ratings yet

- Machine Learning Assignment 1Document4 pagesMachine Learning Assignment 1Balaji DhanabalNo ratings yet

- 12 Measurments and Instrumentation Nov 2017Document2 pages12 Measurments and Instrumentation Nov 2017Balaji DhanabalNo ratings yet

- 1 Electrical Machine Design-Apr 2011Document2 pages1 Electrical Machine Design-Apr 2011Balaji DhanabalNo ratings yet

- 14 Electrical Machine Design-May 2016Document4 pages14 Electrical Machine Design-May 2016Balaji DhanabalNo ratings yet

- 4 Electrical MachineDesign-Apr 2012Document2 pages4 Electrical MachineDesign-Apr 2012Balaji DhanabalNo ratings yet

- 5 Pulse and Digital Circuits-Nov 2011Document2 pages5 Pulse and Digital Circuits-Nov 2011Balaji DhanabalNo ratings yet

- 4 Pulse and Digital Circuits-Apr 2011Document2 pages4 Pulse and Digital Circuits-Apr 2011Balaji DhanabalNo ratings yet

- 2 Electrical Machine Design-Nov 2011Document3 pages2 Electrical Machine Design-Nov 2011Balaji DhanabalNo ratings yet

- 2 Pulse and Digital Circuits-Nov 2010Document2 pages2 Pulse and Digital Circuits-Nov 2010Balaji DhanabalNo ratings yet

- 3 Pulse and Digital Circuits-Apr 2011Document2 pages3 Pulse and Digital Circuits-Apr 2011Balaji DhanabalNo ratings yet

- 1 Pulse and Digital Circuits-Apr 2010Document2 pages1 Pulse and Digital Circuits-Apr 2010Balaji DhanabalNo ratings yet

- Solar and renewable energy research document titlesDocument14 pagesSolar and renewable energy research document titlesBalaji DhanabalNo ratings yet

- ABB Price List 2017-2018Document218 pagesABB Price List 2017-2018Rafid A. Jassem Alashor100% (1)

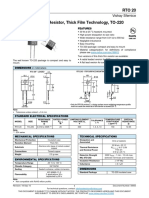

- Vishay Sfernice: FeaturesDocument5 pagesVishay Sfernice: FeaturesteoilcaNo ratings yet

- Power Factor PDFDocument14 pagesPower Factor PDFVictor SampaNo ratings yet

- Mechanical Engineering-Fluid Mechanics Important MCQDocument32 pagesMechanical Engineering-Fluid Mechanics Important MCQHarshal bansodeNo ratings yet

- Brune SynthesisDocument7 pagesBrune SynthesisPranjal RaiNo ratings yet

- Production 2Document22 pagesProduction 2Ramy MaamounNo ratings yet

- Energy-Efficient Electric Motors and Their Applications by Howard E. Jordan (Auth.)Document194 pagesEnergy-Efficient Electric Motors and Their Applications by Howard E. Jordan (Auth.)mylaptop VJethoseNo ratings yet

- Chapter 6 ThermochemistryDocument64 pagesChapter 6 ThermochemistryFABIO DE LIMANo ratings yet

- Boost ConvertorDocument6 pagesBoost ConvertorFaizan MalikNo ratings yet

- DC to AC InverterDocument13 pagesDC to AC Inverterejike123100% (1)

- CapacitorsDocument7 pagesCapacitorsAnkit RathoreNo ratings yet

- Tariff Schedule - 2013-14 PDFDocument37 pagesTariff Schedule - 2013-14 PDFSourabhThakurNo ratings yet

- PUMPFDNDocument9 pagesPUMPFDNSebastian Ramos GrilliNo ratings yet

- A Self-Consistent GE MR For CEoS Derivation and Fugacity CoefficientsDocument4 pagesA Self-Consistent GE MR For CEoS Derivation and Fugacity Coefficientsmurdanetap957No ratings yet

- Parameter EstimationDocument8 pagesParameter EstimationhezugNo ratings yet

- Finifinite Element Modeling DEDocument8 pagesFinifinite Element Modeling DETina HuangNo ratings yet

- Site Inspection & Test ProcedureDocument7 pagesSite Inspection & Test ProcedureNguyễn ĐứcNo ratings yet

- EE6508 - Power Quality - AG - Lecture - 4 - v2Document51 pagesEE6508 - Power Quality - AG - Lecture - 4 - v2wing fatt hiewNo ratings yet

- Kaled, A. - Modelling and Theoretical Analysis of Laminar Flow and Heat TransferDocument21 pagesKaled, A. - Modelling and Theoretical Analysis of Laminar Flow and Heat TransferElios SequiNo ratings yet

- Motion Problems WorksheetDocument2 pagesMotion Problems WorksheeticdjpNo ratings yet

- Introduction Mechatronics Sensors TransducersDocument102 pagesIntroduction Mechatronics Sensors TransducersArun ShalNo ratings yet

- NNSE618 L8 Transport PhenomenologyDocument11 pagesNNSE618 L8 Transport PhenomenologyBayanjargal ErdeneeNo ratings yet

- Prf-1150 1kw 13.56 MHZ Class eDocument20 pagesPrf-1150 1kw 13.56 MHZ Class eCesar MejíaNo ratings yet

- Physics EM Model Question PaperDocument16 pagesPhysics EM Model Question Paperedukondalubonthu805No ratings yet

- Rme Pec Module 3 - Sept 2015Document2 pagesRme Pec Module 3 - Sept 2015Bianca SañezNo ratings yet

- OilsistemDocument212 pagesOilsistemapi-2635664650% (2)

- Refrigeration and Air Conditioning SystemsDocument3 pagesRefrigeration and Air Conditioning SystemssivakrishnaNo ratings yet

- Physics Lesson on Work and PowerDocument4 pagesPhysics Lesson on Work and PowerJb Croft89% (9)

- Selec 800 Xu Timer CatalogDocument1 pageSelec 800 Xu Timer CatalogfarooquesherinNo ratings yet

- INDUSTRIAL DRYERS CLASSIFICATION AND PROBLEM SOLVINGDocument26 pagesINDUSTRIAL DRYERS CLASSIFICATION AND PROBLEM SOLVINGMei Lamfao100% (1)