Professional Documents

Culture Documents

Inspection & Testing For Pipeline Work

Inspection & Testing For Pipeline Work

Uploaded by

Neil Javier0 ratings0% found this document useful (0 votes)

6 views11 pagesOriginal Title

Inspection & testing for Pipeline work

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

6 views11 pagesInspection & Testing For Pipeline Work

Inspection & Testing For Pipeline Work

Uploaded by

Neil JavierCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 11

Inspection & Testing for Pipeline Works.

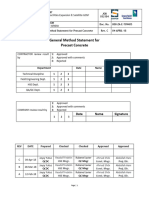

3 owas pa Parone ij apr | BIT

‘A [ONC Beste + getage | rc apr [708

Rev | Prepared By ‘hek/oritee By |NpprovedBy| Date

Tab

of Contents

4. PROCEDURE No.

2. SCOPE AND PURPOSE

3. APPLICABILITY

4. RESPONSIBILITY

GENERAL

6. DEFINITIONS

7. PROCEDURE

7A, Process Conti! for Pipeline Works

7.44. Matera

4.2. Wotiing Procedure Qualification

3. Weller Qualifications

4. Survey and Staking

5. R.O. Way Preparation

‘8. Ditch Preparation

7. Padding

8. Haul and String

9. Bending

40. Filting and Welding OF Line Pipe

‘1. Internal Cleaning and Gauging

12, Lowerand Lay

7.4.48. Temperature Tie-Ins

TA114, Backfiing

7.416. Cable, Pipe and Road Crossings

TA16, Pressure Testing Requirements

TAIT. Pressure Tesling Safety

7.1.18, Paintirg, Coating and Insulation

7.4.18. Concrete

7.1.20. Roadsand Paving

7.41.24. Structural Stee! Work

7.1.22. Fencing

7.128. Cathodie Protection

7.4.24. Electrical and Instrumentation

8. RECORDS

9. REFERENCES

4, PROCEDURE NO.

16a

2. SCOPE AND PURPOSE

‘The scope of this procedure is te define the construction phases for the process

Control of the pipelines works and o ensure that these processes ate carried out

under controlled corditions. Similarly this procedure shall define the manner of

installation in accordance with client and applicable specifications and standarde,

The purpose of this procedure is to detail the techniques fo be applied on the

sitferent activities relevant to the proper execution and installation of pipelines,

Glient specifications SATIP's and drawings shall supersede the techniques

\elailed in this procedure when they dif.

3, APPLICABILITY

All Aspects of Pipeline works (Supported by Specific Activity Documents)

4. RESPONSIBILITY

Project Manager

* Distipine Engineers

© Discipine Foremen

°

(QA Manager

QC Personne!

Material Controller

5. GENERAL |

This procedure covers field Process control of Pipeline Works. |

‘The construction phases for the pipeline will start with the mobilization of

personnel, equipment and camp facilities (when applicable) and shall continue

{throughout the pianned schedule up to the mechanical completion

documentation requirements and the county laws and regulations.

Unless otherwise indcated in the specifications, SATIP's or detalls shown on the

drawings the following detailed process shall apply

Equipment to be vsed shal be with vals documents in accordance with Chnt |

& — eHNTIONS

None

7. PROCEDURE

7.4, Inspection and Testing for Pipeline Works

TAA. Materia

Mateial shall be in accordance with Client specifications and

requirements. Material shall be oblained from Client approved

suppliers list. Purchasing procedure shall apply for material

procurement

7.12. Welding Procedure Qualification

‘As per SATIP-W-012.01, SAES-W.012 Sect 7 and Code

7.1.8, Welder Qualifications

‘As por SATIP-W-012-01, SAES-W-012 Sect 8 and Code

7.44. Survey and Staking

‘The surveyor shall estabish the final RO.W. route taking into

Consideration the soil conkitions, existing faites and installations.

‘And as per SATIP-L-450-01, SAES-A-100, SAES-L-450

‘The Surveyor shall take in evidence all particular points: roads

‘rossings, sol conditions, existing facilities ele. in such a manner, to

‘enable the Project Team to havo a better view of the overall Project

and its difficulties and consequently will be able to develop an

effective work plan

7.15. Right OfWay Preparation

Preparation and construction of the Right Of Way for the pipeline

will start taking into consideration the construction programme

requitements SATIP-L-450-01,5.0.W, and SAES-L-450,

C.A.7. wil construct and maintain through Project completion the

ecossary access ronds.

Blasting shall be executed as_per Client requirements,

specications and Country Laws and Regulations

Wher blasting is necessary proper safely measures will be

‘adopted to prevent accidents and damages to people, animals,

existing pipelines, facies and other properties.

7.4.6, Ditch Preparation

‘The trench routing shall be marked accurately as per the approved

plan and profile drawings, and the trench shall be excavated to the

proper dimensions, SATIPL-450.02, SAES1-450 and SAES-M-

100.

“The trenching activiy shal be in accordance with the procedure for

Civil and Earth Works, SATIP1-450-02, SAES-M-100, And SAES-L-

450.

The tenching actviies shall be executed by utilizing dliferent

excavation techniques according to the type of terrain encountered,

Prior to start any excavation a front-end crew will perform the ripping

survey for the tock identification. Backhoes wil then perform the

initial enching. The hard rock exposed by the backhoes may be

blasted with explosive or removed by rock breakers

Backhoes are used forthe final excavation of the trench,

In areas of loose soil the ditch wil be excavated by backhoes and

the sol shall be deposited on the spoil side of the ditch in a suitable

‘manner for subsequent iting, screening for padding, if required, and

for backing

7A. Paddirg

The trench will be pre-paded with approved paddling materials in

compliance with SAES-M-100 and SAES--450, the padding

rmatefals will be transported to the ste by dump trucks, if

necessary, and placed in the trench, Final Padding operations wil

continue until the pipe is totally covered to the requited depth. The

retaining trench wil then be backfilled with spoil materials fram the

‘trench, ulizing equipment such as loaders and dozers and as per

‘SATIP-L-450-02, SAES-M-100 and SAES-(-450,

‘The Ledding/padiding material wll be placed under and around the

pipe te cover the pipe to the depth specified in SAES-L-450

Particular care will be taken then during the subsequent backfiling

‘operation in order to place the material in a manner that will not

‘damage the sand pad,

‘Sand padding wil begin as ealy after lowering-n as practical.

‘The crown cover is at the pipeline centerline. The backfil material

shall meet the requirements of SAES-M-109,

74.8. Haul and String

‘The acivity shall be carried out in accordance with SAES-

‘SAES-_-450 Checklist SAIC-L-2132 shall be filled out.

74.10,

TAA

Pipes wil be off loaded from trailers using appropriate size sido

booms or cranes. Aluminum, Brass or other type padded hooks will

be used to eliminate damage to the pipe and bends.

‘The pipe shall be off loaded and strung on padded skids, sandbags

(F rubber tires for coated pipes. No padding is required for non-

‘coatec pipes.

Bending

From a study of the terrain or applicable contract drawings, a

qualified land surveyor prepares a bending schedule on a pipe

bendlrg dala sheet taking inlo consideration such factors as

limitation on bending radius, horizontal or vertical bending, bending

‘machine specs, ete

Cold eld bends will be made to conform to the profle of the

excavaied trench. GAT. shall utlize a conventional bending

‘machine with bending sets to ensure smooth bending and maintain

the sizing ofthe pipe. The bending sets are lined for coated pipes as

per SAES-H.200 Sec’5, Nylon slings will be used fer pipe handling

{to avoit damaging of pipe coating.

Bite stacing and bend per bite will be as SAES-L.450,

Fitting and Welding OF Line Pipe

Fiting of fine pipes for welding is made by experienced fitter

spacers under the supervision of the welding foreman according to

WPS, SAES-W-012, SATIP.W.012-01 and API 1104, Proper line

Up clamps is used for the diameter ofthe pipe to be welded,

Line welding proceeds as per WPS, SAES-W.012, SATIP-W.012-

Of and API 1104

‘Acceptance criteria for al fit up and completed welds are those by

applicable standards, Project revision.

N.D.E. and acceptance criteria will be as required by SAES-W.012

‘ond relovant SATIP's

‘A ground clamp or insulated strip of pipe with an exposed contact

point of same material as pipe is securely gripped on the previous

uncoated joint of the pipeline to provide the proper grounding

action

Inlemal Cleaning and Gauging _

‘Wher standard’ requires, a gauging plate approves by Client

(Diameter as per SAES-L°450) shall be attached to the inside disc

‘of scraper and pushed by compressed air.

TAA2,

7448.

rata

Lowerand Lay

Proper belts and cradles shail be used to lit and lower the section.

The rales of the cradles are lined with PVC to prevent damage to

coated pipes as per SAES-H-200, No lowering in wil be performed

in rary periods until the trench is dewatered / drained from any

accumulated water.

‘The trench bottom shall be properly padded to comply with SATIP-L-

450-04, SAES-L-450 & SAES-M-100,

During lower in a holiday detector previously checked against a

calibrated voltmeter is used set to the voltage called for in the scope

of work and SAES-H-200 Sect 7.

The holiday testing will be conducted once the pipe isin the ditch or

just as itis being lowered:in,

‘When holidays are detected, repairs are carried out. The type of

repair depends on size. For small repairs less than 2.254nch melt

sticks is used. For larger size holidays patching compounds are

Used. iFor reporting purposes use the attached FBE coating jeeping

record Both types of materials wil be as per Client standards,

Methods for repair of material other than F.B.E. wil be as

recommended by manufacturer

Temperature Tie-Ins

Temperature tie-ins occur at end of weld stings and al road

crossings and some pipe crossings. Temperature tie-ins will be

done during the hottest temperature of the day and in compliance

with SATIP-L-450:04, SAES-W.012 / SAES-450. The tie-in

temperature shall be above the minimum or within the range stated

in the Project Specification.

Racking

Pipe back fil shall be in accordance with SATIP-L-450-02, SAES-M-

100 & SAES-L-450.

Berm wil be placed in accordance with SAES1-450 and in @

‘manner to avoid disturbing sand paddling ofthe pipelines.

No coarse matarial shail be placed on top of sand pad or allow it to

ralldown-- ad

In sandy area, stabilization of the berm, if and when required, is by

having either weathered crude oil spread over the berm, with a

‘minimum penetration given in the specifications or by spreading ma

(on top of backfil. CAT shall cary out the temperature te-ins as per

the paragraph 16 of SAES--460,

7.4.46, Cable, Pipeline and Read Crossings

‘All Road/ Rail crossings actives shall be executed as per SATIP-L-

1480-04, SAES-1-460,

Cable and pipeline crossings shall be executed as per Client

specifications and as shown on the drawings and SATIP-P-107-01 &

SATIP-T-811-01. Pipeline crossing from the Area Classification 3 &

4 should go for under 100% RT.

‘Authorzations/Permissions shall be obtained ffom the local

‘competent authorities prior to start of work

Unless otherwise specified, the folowing shall appiy:

Paved road shall be open cut oF thrust bored as required by the

‘specifisations, in the fist case a by-pass may be required to keep

the traffic flowing, The pipe shall be positioned in accordance with

the drawings, The road shall then be backfiled, compacted and then

restored to its orginal condition. The traffic on the public road shall

then be resumes.

{road boring is required, the activity shall be subcontracted to a pro-

ualfied sub-contractor. C.AT. Sub-contractors Coordinator shall

fensute that works is executed as per the procedure, to the

applicable and Cent requited specifications,

Other crossings shal be executed by canrying-out the ditch

excavation by using mechanical means or by hand digging wien

necessary. The line pipe shall be instaled under the existing

facilis and then the backfling shall be conducted in a manner nol

ta distur the existing facts.

Ratiography will be made as called for in the scope of work relevant

SATIPS and SAES-W-0T2.

‘Sand pading will be applied as per Procedure for Ditch Preparation

and Process Control procedure for Civil and Earth Works F106.

Backfing will be in layers, unless specified otherwise, and

compacted to a density matching the surrounding soll

Cathodic Protection shall be carried out in accordance with

Procecure for Cathodic Protection, SATIP-X-600-02 and SAESX-

400

71.16.

74.47,

74.18

TAA9.

‘Sorapping and Flushing

Flushing shall be done witen required as per SAES-L-150 8 SAES-

A004,

Pressure Testing Requirements

AA pressure testing procedure will be completed and submitted for

approval as per GL0002.102, SAES-A.004, SAES1-180 and

folovant SATIP's, The procedure shall indude as a minimum the

following:-

‘© The flushing and cleaning requirements

+ Layup procedures (i applicable)

+ Alt of reference standards

‘© A section on test equipment to be used for the test, stating the

‘albration requirements

‘A section on safety requtements forthe test

entiation of water source

Pressurization

Description of the steps to be taken during the pressurization of

the system

Strength and tightness tests

‘A section containing the pressure test diagrams prepared by

Discipine Engineer will show as a minimum, the following

© Tost section breaks.

Location for filing

© Lising of test pressures and robiof valve setings

Location of pump, manifold, and chemical tank

Pressure Testing Safely

‘The pressure testing procedure as desciibed inthe previous section

Will contain sufficient safety considerations to ensure thatthe testis

‘conducted safely.

Paintirg, Coating and Insulation

The application methods and procedures used in painting on the

projects are as per scope of work, Client specications APCS s and

QArPt43,

7.4.20.

7.421,

74.22,

74.23,

7424,

7.428.

7.1.26,

RECORDS

Concrete

Unless otherwise specified the Concrete Works shall be as per the

Process Control Procedure for Concrete Works P133 and SAES-Q.

01

Roade and Paving

Unless otherwise specified the Paving Works shall be as per the

Process Control Procedure P47 for Roads and Paving Works and

SAES-0.006,

Structural Steet Work

‘As pe’ Process Control Procedure for Metal and Structural Stee!

Work P149, Standards, Codes and SAES-M-100

Fencing

‘As per the Process Control Procedure for Fencing, P140 SAES-O-

100, & 105

Cathodic Protection

{As per Process Control and Inspection and Testing Procedures for

Cathedic Protection, P134 and SAES-X-400

Electrical and Instrumentation

‘As pet, Process Control Procedures for, atemalivaly, Electrical

‘Works and Instrumentation Works, P136, P142, SAES-P- 104, 171,

122. SAES-J-002, 004, 005, 200,400, 505, 600. & N.E.C.

‘As Built Survey and Marked-Up Drawings

During construction, records will be maintained showing changes

‘and Iccations of underground installations that they may need

recording on aa-bult drawings according to specications, The

‘alignment drawings will be prepared as sections ofthe pipeline are

‘completed with the final as-bult drawings submitted for approval

‘They will eflect final grade and alignment,

All records relevant to above procedure shall be kept in the site office by the

QN/QG Supervisor for the duration of the project and transferred tothe Area Head

Office, atthe achieve nent of the Project, to be fled, archived and kept for a period

of Three years

9. REFERENCES

Inspection and Testing Procedures

Glient Specifications:

SAES-L-460, 180, 450, 110

SAES-H-200, 204

SAES-J-002, 002, O64, 005, 200, 400, 605, 600

SAES-M-100, 5

‘SAES-0-001, 006

‘SAES.0-100, 105

SAESP-104, 111, 118-124,

SAES.X-400

SAEP 1142

SATIP-H-002-10

SATIP-L450-04,

SATIP-L-450-02

SATIP-L-450-04

SATIP-P-107-01

SATIP-T-911-01

SATIPW.012.01

International Codes:

NEC.

APL 1104

AWS D1

Attachments:

None

You might also like

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5813)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (844)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- SA010-000-0804-SC-0029 - 01 Field Engineering Change Control Procedure r01Document6 pagesSA010-000-0804-SC-0029 - 01 Field Engineering Change Control Procedure r01Neil JavierNo ratings yet

- 133 SA010 00 0804 SC 0009 00 Leak Testing Procedure Procedure r00Document19 pages133 SA010 00 0804 SC 0009 00 Leak Testing Procedure Procedure r00Neil JavierNo ratings yet

- Hydrotesting ProcedureDocument6 pagesHydrotesting ProcedureNeil JavierNo ratings yet

- 91 SA010 00 5508 SC 0005 01 Method Statement For Handling Transportation and Storage of Pipes r01Document20 pages91 SA010 00 5508 SC 0005 01 Method Statement For Handling Transportation and Storage of Pipes r01Neil JavierNo ratings yet

- NSH-SAOMPP-QCP-CI-004 - 00 Coating Procedure For The Concrete SurfaceDocument20 pagesNSH-SAOMPP-QCP-CI-004 - 00 Coating Procedure For The Concrete SurfaceNeil JavierNo ratings yet

- NSH-SAOMPP-QCP-EL-003 - 01 Exothermic Welding For Grounding SystemDocument11 pagesNSH-SAOMPP-QCP-EL-003 - 01 Exothermic Welding For Grounding SystemNeil JavierNo ratings yet

- NSH-SAOMPP-QCP-IN-002 - 00 Fiber Optic Cable InstallationDocument16 pagesNSH-SAOMPP-QCP-IN-002 - 00 Fiber Optic Cable InstallationNeil JavierNo ratings yet

- General Method Statement For Epoxy Grout Rev NeilDocument9 pagesGeneral Method Statement For Epoxy Grout Rev NeilNeil JavierNo ratings yet

- NSH-SAOMPP-CMS-PI-005 - Intenal Cleaning & HydrotestingDocument12 pagesNSH-SAOMPP-CMS-PI-005 - Intenal Cleaning & HydrotestingNeil JavierNo ratings yet

- MPFM Hot Tap Procedure Rev B.2Document10 pagesMPFM Hot Tap Procedure Rev B.2Neil JavierNo ratings yet

- NSH-SAOMPP-CMS-PI-006-Gasket Installation & Bolt TorquingDocument48 pagesNSH-SAOMPP-CMS-PI-006-Gasket Installation & Bolt TorquingNeil JavierNo ratings yet

- Method of Statement For STOPAQ WrappingDocument12 pagesMethod of Statement For STOPAQ WrappingNeil JavierNo ratings yet

- Att-04 - Chemical Analysis ProcedureDocument1 pageAtt-04 - Chemical Analysis ProcedureNeil JavierNo ratings yet

- General Method Statement For Concrete Protective Coating For Immersion Service APCS-3 RevNeilDocument10 pagesGeneral Method Statement For Concrete Protective Coating For Immersion Service APCS-3 RevNeilNeil JavierNo ratings yet

- General Method Statement For Cathodic Protection Rev. CDocument12 pagesGeneral Method Statement For Cathodic Protection Rev. CNeil JavierNo ratings yet

- NSH SAOMPP CMS PI 007 ReinstatementDocument13 pagesNSH SAOMPP CMS PI 007 ReinstatementNeil JavierNo ratings yet

- SSCPF Gecat T 00083Document2 pagesSSCPF Gecat T 00083Neil JavierNo ratings yet

- UIPS QCP 003 Concrete Finishing Procedure After Pouring Concrete Rev 00 Sales Gas ProjectDocument8 pagesUIPS QCP 003 Concrete Finishing Procedure After Pouring Concrete Rev 00 Sales Gas ProjectNeil JavierNo ratings yet

- Waste Disposal Plan - CleaningDocument22 pagesWaste Disposal Plan - CleaningNeil JavierNo ratings yet

- General Method Statement For Cathodic Protection Rev.ADocument13 pagesGeneral Method Statement For Cathodic Protection Rev.ANeil JavierNo ratings yet

- NTPL-RGC-QASP-001 REV.01 Field Eng'g Change Control Proc-ApprovedDocument25 pagesNTPL-RGC-QASP-001 REV.01 Field Eng'g Change Control Proc-ApprovedNeil JavierNo ratings yet

- NTPL Waste Management PlanDocument17 pagesNTPL Waste Management PlanNeil JavierNo ratings yet

- SampleDocument5 pagesSampleNeil JavierNo ratings yet

- Zinc Ribbon Anode Installation Procedure - TPL WITH COMMENTSDocument18 pagesZinc Ribbon Anode Installation Procedure - TPL WITH COMMENTSNeil JavierNo ratings yet

- NSH-SAOMPP-CMS-PI-001 Piping FabricationDocument13 pagesNSH-SAOMPP-CMS-PI-001 Piping FabricationNeil JavierNo ratings yet

- CP Deep Anode Bed Method of StatementDocument11 pagesCP Deep Anode Bed Method of StatementNeil JavierNo ratings yet

- Galvanic Anode Installation Method of StatementDocument13 pagesGalvanic Anode Installation Method of StatementNeil JavierNo ratings yet

- NSH-SAOMPP-QCP-EL-004 - 02 Grounding System Installation and TestingDocument18 pagesNSH-SAOMPP-QCP-EL-004 - 02 Grounding System Installation and TestingNeil JavierNo ratings yet

- ALF-ZA-E-09612 Rev. BDocument96 pagesALF-ZA-E-09612 Rev. BNeil JavierNo ratings yet

- General Method Statement For Precast Concrete Rev.CDocument9 pagesGeneral Method Statement For Precast Concrete Rev.CNeil JavierNo ratings yet