Professional Documents

Culture Documents

Medical Gas System Management

Medical Gas System Management

Uploaded by

sajeda.nofalOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Medical Gas System Management

Medical Gas System Management

Uploaded by

sajeda.nofalCopyright:

Available Formats

Document Title: Medical Gas System Management

Document Type: Policy/Procedure Plan Guideline Clinical Practice Guideline Bylaw

Document Originating

21/10/2020

Date:

Document Effective Date: 3/6/2023

Revision Number: V.1

Originating Entity: Facility Management Department

Approved by: Facility Management Director, Chief Operation Officer

Document Ref: POLFM0005

Scope: Medical Gases Technicians at Abdali hospital

Next Revision Due Date: 6/2026

I. Purpose:

1.1 The purpose of this policy is to describe how can handle and store the medical gas cylinders.

II. Policy:

2.1 This policy applies to the supply, delivery, installation and maintenance of the medical gas

service from the point of supply, up to and including the terminal outlets.

2.2 This policy lays down the mandatory requirements for the activities associated within

medical gas pipeline systems for the supply of:

2.2.1 Medical Oxygen.

2.2.2 Nitrous Oxide.

2.2.3 Medical Compressed Air (4 Bar).

2.2.4 Surgical Compressed Air (7 Bar).

2.2.5 Medical Vacuum.

2.2.6 Anesthetic Gas Scavenging Systems.

2.3 This policy will cover handling and storage medical gas cylinders:

2.3.1 Carbon Dioxide Cylinders.

2.3.2 Compressed Air Cylinders.

2.3.3 Oxygen Cylinders.

2.3.4 Oxygen Crash Cart Cylinders.

2.3.5 Oxygen for Respirator/OR Cylinders.

Document Version 1 Date 3/6/2023 Page 1 of 7

POLFM0005

2.3.6 Oxygen Cylinder for PFT.

2.3.7 Nitrogen Cylinders.

III. Definition:

3.1 Medical gas systems: include the pipes, fixtures and other apparatus for medical gas, and

vacuum systems. These systems also include anesthetic gas scavenging system along with

medical air, nitrous oxide, oxygen, nitrogen, carbon dioxide, and other gas mixtures.

IV. Responsibilities:

4.1 It’s the responsibility of medical gas technician to follow the procedure inside this policy.

V. Procedure:

5.1 Liquid Oxygen System:

5.1.1 System Description: Oxygen is supplied from a tank located to operating rooms,

birthing center, recovery rooms, treatment rooms, emergency room, ICU, CCU and

other patient care areas via a central gas system. Complete medical gas distribution

drawings are found are located in the Engineering Department.

5.1.2 Normal Operation: In normal operation, the bulk storage tank supplies oxygen to

the hospital through a main valve located at the tank.

5.1.3 Backup Operation: cylinders back up on an automatic transfer manifold located on

the tank.

5.1.4 Alarms: A low-pressure set point of 3.8 bar has been established. A high-pressure set

point of 4.8 bar has been established. Upon an alarm condition, a visual and audible

alarm occurs at the local alarm panel. The departments involved shall notify

engineering department who will proceed to ascertain and correct the problem.

5.1.5 Test/Inspection/Maintenance: shall be checked daily for operation during daily

equipment rounds. The system is also inspected and maintained on a periodic basis

through the hospital’s preventive maintenance program. Records of repair shall be

kept in Engineering Department.

5.1.6 System Alarms Testing: The system alarms shall be tested dynamically by decreasing

the system pressure below the set point and check the all alarms parameters.

5.1.7 Results of Tests/Inspections: The results of the inspections, testing, or corrective

actions shall be recorded on the checklist PM sheets. The sheets shall be

documented in the engineering department.

Document Version 1 Date 3/6/2023 Page 2 of 7

POLFM0005

5.2 Nitrous Oxide System:

5.2.1 Normal Operation: In normal operation the nitrous oxide is delivered by a central

system from a manifold/cylinder bank located in the cylinder room at B1.

5.2.2 Alarms: which are audible, visual and linked to local control panel, will appear when

the system pressures drops/increases beyond the set point, and the departments

involved shall notify engineering department to take the necessary action.

5.2.3 Testing/Inspection/Maintenance: shall be inspected on daily basis. The system is

also inspected and maintained on a periodic basis through the hospital’s preventive

maintenance program. The checklists and repairs reports shall be recorded in the

Engineering Department.

5.2.4 Systems Alarms Testing: The nitrous oxide alarms shall be tested quarterly by

decreasing the system pressure below the set point and check the activation of

system alarms.

5.2.5 Testing Results: The results of inspections, tests, and corrective actions shall be

recorded on checklist sheets.

5.3 Carbon Dioxide System:

5.3.1 Normal Operation: In normal operation the carbon dioxide is delivered by a central

system from a manifold/cylinder bank located in the cylinder room at B1.

5.3.2 Alarms: which are audible, visual and linked to local control panel, will appear when

the system pressures drops/increases beyond the set point, and the departments

involved shall notify engineering department to take the necessary action.

5.3.3 Testing/Inspection/Maintenance: shall be inspected on daily basis. The system is

also inspected and maintained on a periodic basis through the hospital’s preventive

maintenance program. The checklists and repairs reports shall be recorded in the

Engineering Department.

5.3.4 Systems Alarms Testing: The nitrous oxide alarms shall be tested quarterly by

decreasing the system pressure below the set point and check the activation of

system alarms.

5.3.5 Testing Results: The results of inspections, tests, and corrective actions shall be

recorded on checklist sheets.

5.4 Medical Air System:

5.4.1 System Description: The medical air system is composed of quadruplex medical air

compressor systems.

Document Version 1 Date 3/6/2023 Page 3 of 7

POLFM0005

5.4.2 Normal Operation: In normal operation the quadruplex system, located in the

Basement 1, operate in rotation.

5.4.3 Backup Operation: cylinders back up on an automatic transfer manifold at the tank.

5.4.4 Equipment Maintenance: Medical air compression equipment shall be checked on

daily basis. The equipment is also inspected and maintained on a periodic basis

through the hospital’s preventive maintenance program. Records of repairs and

performed preventive maintenance shall be documented by the Engineering

Department.

5.4.5 Alarms: A low-pressure set point of 3.7 bar has been established. A high-pressure set

point of 5 bar has been established. Upon an alarm condition, a visual and audible

alarm occurs at the local alarm panel. The departments involved shall notify

engineering department who will proceed to ascertain and correct the problem.

5.4.6 Results of Testing: The results of inspections, testing, and corrective actions shall be

filed on the PM checklist sheets located in the Engineering Department.

5.5 Surgical air compressor plant:

5.5.1 System Description: The surgical air system is composed of simplex medical air

compressor systems.

5.5.2 Normal Operation: In normal operation the simplex system, located in the Basement

1, operate in rotation to equalize the operation hours of the compressors.

5.5.3 Backup Operation: cylinders back up on an automatic transfer manifold at the tank.

5.5.4 Equipment Maintenance: Medical air compression equipment shall be checked on

daily basis. The equipment is also inspected and maintained on a periodic basis

through the hospital’s preventive maintenance program. Records of repairs and

performed preventive maintenance shall be documented by the Engineering

Department.

5.5.5 Alarms: A low-pressure set point of 6.5 bar has been established. A high-pressure set

point of 7.5 bar has been established. Upon an alarm condition, a visual and audible

alarm occurs at the local alarm panel. The departments involved shall notify

engineering department who will proceed to ascertain and correct the problem.

5.5.6 Results of Testing: The results of inspections, testing, and corrective actions shall be

filed on the PM checklist sheets located in the Engineering Department.

5.6 Medical Vacuum System:

5.6.1 System Description: The medical vacuum system is composed of centrifugal

compressors for podium, main lab and tower.

Document Version 1 Date 3/6/2023 Page 4 of 7

POLFM0005

5.6.2 Normal Operation: Under normal conditions the vacuum pumps will be alternated

as duty to equalize the running working hours.

5.6.3 Alarms: A low alarm set point of (- 0.77 bar) has been established. The alarm

conditions exist and linked to local control panel. The Engineering Department shall

be notified of an alarm and shall proceed with the necessary action.

5.6.4 System Failure Procedures: In the event of a system-wide failure of all three vacuum

pumps, which will result in a vacuum outage of greater than 15 minutes, the

maintenance personnel will notify the PBX operator. The switchboard will in turn

notify Surgery, Maternity, ER, ICU, OR, CCU, and all nursing units. All units may

obtain portable suction equipment as needed.

5.6.5 Testing/Inspection/Maintenance: Vacuum pump equipment shall be checked daily

for operation during daily equipment rounds. The equipment is also inspected and

maintained on a periodic basis through the hospital’s preventive maintenance

program. Records of repair shall be kept in Engineering Department.

5.7 Compressed Gas Cylinders:

5.7.1 Medical gas cylinders should be stored in a purpose-built cylinder store to keep the

cylinders safe and proper stored.

5.7.2 Appropriate signage on the door to advise that gas cylinders are inside.

5.7.3 covered top store, preferably inside the building.

5.7.4 Avoid subjection to high temperature.

5.7.5 Keep the cylinders in dry, clean and well-ventilated store.

5.7.6 Good access for transportation.

5.7.7 The store shall be away from storage areas containing highly flammable liquids and

other combustible materials.

5.7.8 Empty cylinders shall be so identified and stored separately from full or partially full

cylinders. Small cylinders of oxygen or other nonflammable gas required during

patient transport may be used when safely affixed to the patient bed or stretcher.

5.7.9 Allow for strict rotation of full cylinders to enable the cylinders with the oldest filling

date to be used first.

5.7.10Have warning signs prohibiting smoking and naked lights within the vicinity of the

store.

Document Version 1 Date 3/6/2023 Page 5 of 7

POLFM0005

5.7.11Use of Cylinders:

5.7.11.1 Cylinders must be changed before the contents gauge drops into the red

zone, i.e. before the flow of gas stops due to the cylinder being empty.

5.7.11.2 Do not leave flow meters open if not in use with a patient. The cylinder

valve should always be closed when treatment is finished.

5.7.11.3 It is important that no part of the cylinder valve or equipment is either

lubricated or contaminated with oil or grease. This is due to the risk of

spontaneous combustion that can occur with high-pressure gases in the

presence of hydrocarbons.

5.8 Anesthetic Gas Scavenging System (AGSS):

5.8.1 Definition: AGSS system has been designed to remove exhaled anesthetic gas

mixtures from operating theatres, anesthetic rooms and recovery areas.

5.8.2 alarms: The alarm conditions exist and connected to local control panel, the

engineering department shall be notified of the alarms and shall take the necessary

action.

5.8.3 Testing/ Inspection/ Maintenance: the system shall be inspected and maintained on

a periodic basis through the hospital’s preventive maintenance program, the

performed preventive maintenance shall be recorded by engineering department.

VI. References:

6.1 External References: N/A

6.2 Quality References:

6.2.1 JCI (2020). Joint commission international accreditation standards for hospitals. 7th

edition. Joint Commission International

6.2.2 HCAC (2021). Healthcare Accreditation Hospital Manual.4th edition. Healthcare

Accreditation Council.

6.3 Cross Reference: N/A

VII. Performance Indicator:

7.1 Outcome Indicator: N/A

7.2 Process indicator: N/A

VIII. Appendix: N/A

Document Version 1 Date 3/6/2023 Page 6 of 7

POLFM0005

IX. Revision History and Tracking:

Date Révision Numbers Section Affected Details Approval Date

19/12/2020 V.0 All sections - 19/12/2020

3/6/2023 V.1 No section affected - 3/6/2023

Document Version 1 Date 3/6/2023 Page 7 of 7

POLFM0005

You might also like

- Spare Parts Inventory MEADocument161 pagesSpare Parts Inventory MEAGrupo ValoracionNo ratings yet

- HVAC Master Validation PlanDocument51 pagesHVAC Master Validation Plannavas197293% (30)

- Atmosphere Lesson PlanDocument7 pagesAtmosphere Lesson PlanJasmine DanaNo ratings yet

- PHSS Guidance Document For Cold Storage Temperature Monitoring and Mapping For Blood ProductsDocument24 pagesPHSS Guidance Document For Cold Storage Temperature Monitoring and Mapping For Blood ProductsAkuWilliamsNo ratings yet

- Environmental Crisis and Sustainable DevelopmentDocument62 pagesEnvironmental Crisis and Sustainable DevelopmentAnti Happy100% (1)

- BME FMS PolicyDocument17 pagesBME FMS Policynaresh100% (1)

- Fresenius 5008 Hemodialysis System - Service Manual PDFDocument168 pagesFresenius 5008 Hemodialysis System - Service Manual PDFTrung Nguyen100% (1)

- Sanitation and Pest Control ProcedureDocument6 pagesSanitation and Pest Control ProcedureEtta Jenee100% (1)

- SOP For Refrigeration PlantDocument37 pagesSOP For Refrigeration PlantGaurav Swarup67% (3)

- Lesson Plan in Science 7: Objectives A. Most Essential Learning Competency: (MELC) B. Code: C. Learning ObjectivesDocument6 pagesLesson Plan in Science 7: Objectives A. Most Essential Learning Competency: (MELC) B. Code: C. Learning ObjectivesLiezl BallesterosNo ratings yet

- Uninterruptible Power Supply (Ups) Systems Maintenance ProceduresDocument16 pagesUninterruptible Power Supply (Ups) Systems Maintenance ProceduresSuryaalaguNo ratings yet

- The Safety Critical Systems Handbook: A Straightforward Guide to Functional Safety: IEC 61508 (2010 Edition), IEC 61511 (2015 Edition) and Related GuidanceFrom EverandThe Safety Critical Systems Handbook: A Straightforward Guide to Functional Safety: IEC 61508 (2010 Edition), IEC 61511 (2015 Edition) and Related GuidanceRating: 5 out of 5 stars5/5 (2)

- The Manufacture of Sterile Pharmaceuticals and Liquid Medical Devices Using Blow-Fill-Seal Technology: Points to ConsiderFrom EverandThe Manufacture of Sterile Pharmaceuticals and Liquid Medical Devices Using Blow-Fill-Seal Technology: Points to ConsiderNo ratings yet

- 04.00MSHEM - Specific Awareness 04.00Document116 pages04.00MSHEM - Specific Awareness 04.00ShadifNo ratings yet

- Guidelines For Risk Management in Medical Electrical EquipDocument123 pagesGuidelines For Risk Management in Medical Electrical Equipmhenig0% (1)

- Htm2022 Ambulance Gases1Document26 pagesHtm2022 Ambulance Gases1احمد الجزار2007100% (1)

- DXC 700 Au User ManualDocument538 pagesDXC 700 Au User ManualAnas Tj100% (1)

- Operational Qualification For Compressed Air System.Document11 pagesOperational Qualification For Compressed Air System.BREWSKI50% (2)

- Maintenance of Fire Suppression SystemsDocument2 pagesMaintenance of Fire Suppression SystemsRaja Prathap SinghNo ratings yet

- Dynamic Equipment Maintenance SOPDocument3 pagesDynamic Equipment Maintenance SOPHasnain NiazNo ratings yet

- Pressure Relieving Device Inspection ProcedureDocument2 pagesPressure Relieving Device Inspection Procedurecamasa2011No ratings yet

- C4+ Maintenance ManualDocument28 pagesC4+ Maintenance Manualnorizam77100% (1)

- HTM 2022Document92 pagesHTM 2022masoodaeNo ratings yet

- Annex 1 Comments by Nissan CohenDocument15 pagesAnnex 1 Comments by Nissan CohenNarasimharao100% (1)

- White - Paper - Commissioning - and - QA - Experiances - With - Halcyon Rev 2.0 - MARC0595 ApprovedDocument25 pagesWhite - Paper - Commissioning - and - QA - Experiances - With - Halcyon Rev 2.0 - MARC0595 ApprovedMukhlishin bin muhammadNo ratings yet

- BS 2646-4-1991 - (2018-06-20 - 03-46-53 Am)Document10 pagesBS 2646-4-1991 - (2018-06-20 - 03-46-53 Am)Rankie ChoiNo ratings yet

- FOB2-3 TS - Technical Manual - Section 5 - MaintenanceDocument100 pagesFOB2-3 TS - Technical Manual - Section 5 - MaintenancemaghraouiNo ratings yet

- Sample Problem #4Document3 pagesSample Problem #4Dozdi100% (3)

- Industrial Hygiene - Hazard Control Ventilation RequirementsDocument3 pagesIndustrial Hygiene - Hazard Control Ventilation Requirementsh_mahdiNo ratings yet

- Medical Gas System Preventative Maintenance PrograDocument18 pagesMedical Gas System Preventative Maintenance PrograavinashNo ratings yet

- 1st MONTHDocument26 pages1st MONTHkaleabs321No ratings yet

- PaeoDocument14 pagesPaeomrms092004No ratings yet

- Cairosem09 Part 7Document7 pagesCairosem09 Part 7mohamed eissaNo ratings yet

- Good Weighing in Pharma - 3Document4 pagesGood Weighing in Pharma - 3RainMan75No ratings yet

- Planned Preventive MaintenanceDocument4 pagesPlanned Preventive MaintenanceMOHAMMAD AHMADNo ratings yet

- Israel Ski Standards PP TDocument17 pagesIsrael Ski Standards PP TVictor Akira Santos SatoNo ratings yet

- Maintenance Guide FA-120Document32 pagesMaintenance Guide FA-120Wolaé Mathurin Edmond Amegandjin100% (1)

- SW Presentation Kroening Medical GasDocument116 pagesSW Presentation Kroening Medical GasYudi Wahyudi WahyudiantoNo ratings yet

- Lfortis Bum 5855997-1en Rev3Document1,475 pagesLfortis Bum 5855997-1en Rev3The LamNo ratings yet

- Guide GMP Checklist 2.0Document57 pagesGuide GMP Checklist 2.0Jem VasquezNo ratings yet

- Micro Commissioning of Theatres HIS PaperDocument44 pagesMicro Commissioning of Theatres HIS PaperAbderrezak Merzak AbdouNo ratings yet

- Ventilator ICUDocument4 pagesVentilator ICUMohamed YounessNo ratings yet

- Analizador de Oxigeno Analytical (Ingles) PDFDocument18 pagesAnalizador de Oxigeno Analytical (Ingles) PDFSebastianSolisBolivarNo ratings yet

- 3 Module 2 - Pharmacy Medication ChecksDocument5 pages3 Module 2 - Pharmacy Medication ChecksSaman VithanageNo ratings yet

- How Flowmeters Perform Self-VerificationDocument6 pagesHow Flowmeters Perform Self-Verificationmuhammad adibNo ratings yet

- Manual Servicio cm200Document149 pagesManual Servicio cm200davidNo ratings yet

- ASA Publications Anesthesia Machine Obsolescence 20041Document7 pagesASA Publications Anesthesia Machine Obsolescence 20041Julio Corona100% (1)

- Vertical Separator Control and Instrumentation RepeatDocument12 pagesVertical Separator Control and Instrumentation RepeatklpiNo ratings yet

- trs961 Annex9 Supp10Document18 pagestrs961 Annex9 Supp10Shahrukh IslamNo ratings yet

- SOP For Sterilization Procedure For Production of Injection Serum According To Good Manufacturing PracticeDocument3 pagesSOP For Sterilization Procedure For Production of Injection Serum According To Good Manufacturing PracticefarNo ratings yet

- SOP For CAPA Handling ProcedureDocument17 pagesSOP For CAPA Handling Procedurelounes.asma30No ratings yet

- Critical Medical EquipmentDocument4 pagesCritical Medical Equipmentdeano80No ratings yet

- 30 Overview of An Eo ValidationDocument2 pages30 Overview of An Eo Validationskype2121100% (1)

- Man01 057Document118 pagesMan01 057Ramesh BabuNo ratings yet

- Annex 2 Qualification of GC EquipmentDocument11 pagesAnnex 2 Qualification of GC EquipmentBrian Williams100% (1)

- Process Performance Qual PDFDocument13 pagesProcess Performance Qual PDFDelvina GintingNo ratings yet

- Maintenance DetialsDocument9 pagesMaintenance DetialsAdura OgunnuNo ratings yet

- Fire System Testing RequirementsDocument21 pagesFire System Testing RequirementsAbdullah MunawirNo ratings yet

- AL09 23AnesthesiaGasModuleDocument8 pagesAL09 23AnesthesiaGasModuleSulay Avila LlanosNo ratings yet

- Regulatory Oversight of Ageing Management and Long Term Operation Programme of Nuclear Power PlantsFrom EverandRegulatory Oversight of Ageing Management and Long Term Operation Programme of Nuclear Power PlantsNo ratings yet

- Plantwide Control: Recent Developments and ApplicationsFrom EverandPlantwide Control: Recent Developments and ApplicationsGade Pandu RangaiahNo ratings yet

- GEAS Evaluation 6Document5 pagesGEAS Evaluation 6Denaiya Watton LeehNo ratings yet

- Tablas CeneguelDocument1 pageTablas CeneguelMargarito Robles KingNo ratings yet

- Tara Pharmacology PDF Medicalstudyzone - Com - CompressedDocument572 pagesTara Pharmacology PDF Medicalstudyzone - Com - Compressedunbridled.instinct.218No ratings yet

- Pathway To English SMA XI Wajib Chapter 7Document9 pagesPathway To English SMA XI Wajib Chapter 7Shabira NadaNo ratings yet

- Causes of Climate Change - Canada - CaDocument4 pagesCauses of Climate Change - Canada - CaChristine Jane Hansol ObutaNo ratings yet

- Protected Cultivation and Secondary Agriculture: Agricultural EngineeringDocument2 pagesProtected Cultivation and Secondary Agriculture: Agricultural Engineeringaditya singhNo ratings yet

- Chapter 7.1 DistillationDocument63 pagesChapter 7.1 Distillationamira nabillaNo ratings yet

- Cosumable Desember 2021Document66 pagesCosumable Desember 2021raiNo ratings yet

- APSC 252 Midterm Formula SheetDocument1 pageAPSC 252 Midterm Formula SheetYosloNo ratings yet

- Rashid Term 1 SyllabusDocument39 pagesRashid Term 1 SyllabusRashid AliNo ratings yet

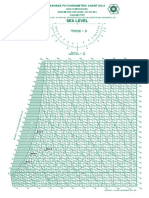

- Sea Level: Ashrae Psychrometric Chart No.3Document1 pageSea Level: Ashrae Psychrometric Chart No.3Tran KieuNo ratings yet

- Weather Systems in The CaribbeanDocument5 pagesWeather Systems in The CaribbeanAnthonyNo ratings yet

- 3.1 Earth SystemsDocument28 pages3.1 Earth SystemsCyraRenMarquezTagarinoNo ratings yet

- Energies: New HFC/HFO Blends As Refrigerants For The Vapor-Compression Refrigeration System (VCRS)Document20 pagesEnergies: New HFC/HFO Blends As Refrigerants For The Vapor-Compression Refrigeration System (VCRS)Jayakumar ANo ratings yet

- Wigley JupiterDocument2 pagesWigley JupiterPam WigleyNo ratings yet

- Science 4 CloudsDocument34 pagesScience 4 Cloudsmaryhope caneteNo ratings yet

- Kinetic Molecular Theory - Group 4Document49 pagesKinetic Molecular Theory - Group 4Mim MimNo ratings yet

- The Philippines Is Prone To Tropical CyclonesDocument4 pagesThe Philippines Is Prone To Tropical CyclonesfarhanieNo ratings yet

- English PPT ModalsDocument35 pagesEnglish PPT Modalssabrina az'zahraNo ratings yet

- Form 4 Biology Folio: Topic: The Causes and Effects of Global WarmingDocument4 pagesForm 4 Biology Folio: Topic: The Causes and Effects of Global WarmingCp SeowNo ratings yet

- Gpa04.hydrocarbons and Btex Pickup and Control From Amine SystemsDocument17 pagesGpa04.hydrocarbons and Btex Pickup and Control From Amine SystemsphostyNo ratings yet

- Uge1 Activity 4Document2 pagesUge1 Activity 4Vhon MisakiNo ratings yet

- Why Earth Is HabitableDocument26 pagesWhy Earth Is Habitablestormfury150% (2)

- Chemical Engineering 374: Fluid MechanicsDocument20 pagesChemical Engineering 374: Fluid Mechanicssathya prakashNo ratings yet

- Pref - 1 - Vocabulary 3.1 - Revisión Del IntentoDocument10 pagesPref - 1 - Vocabulary 3.1 - Revisión Del IntentoStephanny AriasNo ratings yet