DUCTILE IRON PIPE AND FITTINGS

TRANSPORT, LOADING, UNLOADING and STORAGE METHODS 1-

TRANSPORT

Pipes

Medium and large diameter pipes are transported alone.

Small diameter pipes are transported in bales.

Fittings

Large diameter attachments are transported alone.

Small diameter fittings are transported by crate.

216

� APPE

NDICE

S

A. GENERAL WARNINGS

a. Lifting

(1) Use of wire rope or polyester slings

Ensure that the weight of the pipe or fittings is

evenly distributed to prevent the wire rope or

polyester sling from slipping.

Pipes

When using steel wire ropes on pipes, use a

cushion to prevent damage to the pipe surface.

Do not lift the pipe with a single rope. The angle

between the two ropes carrying the pipe should

not exceed 60˚.

When placing the pipes on the planks, ensure

that each end of the pipe is approximately one

meter outside the planks. Make sure that there is

equal spacing between the pipes.

217

�DUCTILE IRON PIPE AND FITTINGS

Fittings:

Use polyester slings. To prevent sudden abrasion

on the polyester sling, use rubberized parts. For

flat parts, use rubberized hooks.

Pallets and crates:

Lift the pallet or crate from the bottom by placing

the steel ropes so that they pass through the

marked places.

(2) Hook Usage

Take care not to damage the pipe when using

the hook. Cover the hook with rubber material.

Make sure that the pointed end of the hook

does not damage the pipe.

218

� APPE

NDICE

S

b. Placement

Place the pipes that will be underneath slowly on

the planks to avoid sudden impacts.

Always protect the pipes against slipping and

falling with bumpers.

If you are stacking pipes in more than two rows in

the upward direction (like pyramid stacking),

support all pipes in the bottom row with bumpers

and secure the bumpers at the ends with staples.

Ensure that the two ends are approximately 1 meter each outside the planks. Take care to leave equal

spacing between the pipes.

219

�DUCTILE IRON PIPE AND FITTINGS

B. SAFETY WARNINGS

Wear a helmet, gloves and safety shoes for

safety.

Periodically inspect steel ropes and polyester

slings and replace damaged ones. Consider the

weight limits of ropes and similar equipment.

Never stand under a raised pipe.

220

� APPE

NDICE

S

When moving the pipe, m a k e sure that it

does not hit hard objects. Rough use of the crane

may cause the pipe to slip. If the rope is twisted,

the pipe may rotate.

When using the forklift, c o n s i d e r the

length of the pipe.

If you use planks during packing, always use

wedges to prevent the pipes from rolling.

221

�DUCTILE IRON PIPE AND FITTINGS

2. LOADING AND UNLOADING

A. UNLOADING THE SHIP

On deck In the warehouse

Use rubber coated hooks for lifting pipes.

When removing a pipe from a stack, avoid

movements that may affect other pipes. Use

cushioning (mat etc.) for the pipes underneath.

When picking up a pipe from the front or back

of the stack, first slide the pipe slowly and

carefully, then lift it up.

Stay away from the pipe while it is being

transported. Never stand under a lifted load.

222

� APPE

NDICE

S

B. LOADING ON TRUCK OR TRAILER

Place two or more planks on the floor.

Place the pipes on the planks and make sure to

protect them with wedges.

If you install more than one row of pipes, change

the direction of the pipe in each row.

223

�DUCTILE IRON PIPE AND FITTINGS

Loading on a trailer:

• Place the pipes in the bottom row with their muffled ends facing each other.

• Place wooden wedges between these pipes facing each other to prevent longitudinal movement.

Securing the pipes:

Place a protective cushion between the steel ropes

and the pipe.

Carefully secure all pipes using wire rope

and/or spandex. Check to make sure that all

pipes are secured.

224

� APPE

NDICE

S

C. UNLOADING THE TRUCK OR TRAILER

Check that all wedges are in place before releasing

the wire ropes.

Untie the ropes.

Pick up the pipes evenly from both sides so as

not to destabilize the vehicle.

Never throw pipes out of the truck or trailer.

225

�DUCTILE IRON PIPE AND FITTINGS

3. ARRANGEMENT OF M A T E R I A L S IN THE WAREHOUSE AREA

A. PREPARATIONS

Remove defects in the ground and level

the ground. Use a grader and road roller if

necessary.

Place the planks in the areas where the pipes will

be stacked.

Place the pipes on the planks and secure them

with wedges.

If more than one row is to be made, make sure that

the wide ends are between the narrow ends and vice

versa.

226

� APPE

NDICE

S

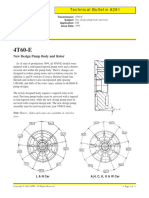

B. STACKING METHODS

(a) Quadrilateral Stacking

The pipes are placed in each row

perpendicular to the pipes in the previous

row.

(b) Pyramid Stacking

The number of pipes in each row decreases

as you move upwards. In pyramid stacking,

the bottom row is fixed with wedges and the

wedges at both ends are fixed by stapling.

(c) Stacking in Bundles

For stacking it is recommended to stack 2 or 3

bundles. There is no need for planks for the

bundles because the skids are connected

from the bottom.

227

�DUCTILE IRON PIPE AND FITTINGS

(d) Placement of Attachments

Place the fittings on the two planks.

(e) Placement of Pallets

Place the pallets on a flat surface.

(f) Placement of Safes

Place the crates on a flat surface. Store

the crates in a cool, dry place out of

direct sunlight.

228