Professional Documents

Culture Documents

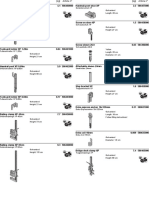

POST HOLE BORER SAFETY GUIDE

Uploaded by

RajendraOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

POST HOLE BORER SAFETY GUIDE

Uploaded by

RajendraCopyright:

Available Formats

POST HOLE BORER RISK ASSESSMENT

Likely Risk Issue Who/what may What Is the Rate Level? What Risk Control Action Needs To Be Taken? Time Frame

be harmed? (Rate risk as Low, Medium or High) (What needs to be considered so that the risks are identified and effectively controlled)

(Specific Persons)

Operating Risks Operator Severity of Risk (S)- 2 • Before using ensure there are no underground services at the bore position Every hire

Spectators Likelihood of Risk (L)- 2 • Make sure auger locking pin is installed correctly

Overall Risk (S x L)= 4 • Operator to check for fuel leaks and replace fuel cap firmly after filling

MEDIUM • Operator to ensure engine and control devices are not damaged

• Unit is best used on firm level ground

• Machine not to be left unattended especially when still running

• Operator to use both hands when machine is operating

• Regularly clear soil from auger bit to prevent jamming

• Operator to switch off machine and fuel after use

• Hearing protection, gloves, safety glasses, safety footwear and Hi-Vis shirt to be

worn

Transporting unit Operator Severity of Risk (S)- 2 • Machine to be lifted carefully to avoid damage to engine parts and control Every hire

Spectator Likelihood of Risk (L)- 1 mechanisms

Overall Risk (S x L)= 3 • Machine to be firmly secured in the upright position

LOW

Burns & other injuries Operator Severity of Risk (S)- 2 • Operator or other person to avoid touching hot engine Every hire

Spectator Likelihood of Risk (L)- 1 • No person is to go near auger bit when machine is operating

Overall Risk (S x L)= 3

LOW

Explosion or Fire Operator Severity of Risk (S)- 2 • Machine to be switched off before re-fuelling Every hire

when refueling Likelihood of Risk (L)- 2 • Avoid spillage especially onto hot engine parts

Overall Risk (S x L)= 4 • Tightly seal fuel tank cap after filling

MEDIUM

Slips, trips and falls Operator Severity of Risk (S)- 2 • Wear safety footwear Every hire

Spectators Likelihood of Risk (L)- 2 • Remove obstacles from operating area

Overall Risk (S x L)= 4 • Use extreme care in wet conditions

MEDIUM

Noise, fumes and Operator Severity of Risk (S)- 2 • Wear hearing protection Every hire

dust Spectators Likelihood of Risk (L)- 2 • Ensure abundant fresh air is available when operating in enclosed work spaces

Overall Risk (S x L)= 4 • Wear appropriate mask if work area is dusty

MEDIUM

Calculation of Risk Evaluation

Severity of Risk (S) is judged by evaluating the effects of the hazard if the risk occurs. This is evaluated as Minor = 1, Major = 2, Serious = 3

Risk Likelihood (L) - The likelihood of the harm occurring is evaluated on the basis of: Unlikely =1, Possible = 2, Likely = 3

Overall Risk is calculated by multiplying the figure for Severity (S) and Likelihood (L).

The overall risk figure calculated is related to the Risk Level of either Low: 1 to 3; Medium: 4 to 6 or High: 7 to 9

NB This is a generic risk assessment only. It is advisable to carry out a site-specific assessment prior to using this equipment.

September 2015 Issue //1 Pg 1 of 2

SAFE OPERATION OF A POST HOLE BORER

The instructions recommended within this document apply to normal risk conditions.

If the chainsaw is to be operated in a dangerous or hostile environment, the user/client is responsible for

conducting an appropriate risk analysis and applying suitable controls to mitigate those additional risks.

This instruction should be read in conjunction with

the Risk Assessment procedure for a Post Hole Borer

GENERAL SAFETY

• Wear safety footwear, safety gloves, hearing protection, eye protection and Hi-Vis jacket)

• The Post Hole Borer can only be operated if it is in a safe and sound operating condition and by a

competent operator.

• Work sites on roads must be separated from normal traffic flow

• Post Hole Borer activity should occur in a barricaded area to avoid entry of unauthorised persons.

• Unit is best operated on firm and reasonably level ground

• Ensure adequate fresh air is available if operating in an enclosed area

• A CHECK MUST BE MADE TO ENSURE THERE ARE NO UNDERGROUND SERVICES AT THE POINT

OF THE BORE

• The machine must not be left unattended when still operating

• Machine to be switched off before refuelling

TRANSPORT OF A POST HOLE BORER

• Ensure unit is firmly tied down on transport vehicle without damaging engine and fittings

OPERATING CONDITIONS

• Check fuel and oil levels

• Check for fuel and oil leaks. DO NOT OPERATE UNIT IF LEAKS ARE FOUND

• Ensure no slip/trip hazards are present in work area

• Avoid standing on loose ground

• Ensure auger lock pin is fitted correctly

• Turn on fuel valve

• Pull cord to start

• Operate drive control and ensure operating speed before starting a bore

• Bring revs to operating speed

• USE BOTH HANDS AT ALL TIMES

• Regularly withdraw auger from hole to clear debris

• NEVER LEAVE POST HOLE BORER RUNNING WHILE UNATTENDED

SHUT DOWN PROCEDURE

• Turn off fuel valve

• Move hand throttle back to start position when engine has stopped

INSPECTION AND MAINTENANCE

• Inspect fuel lines and tank for leaks.

• Ensure fuel valve and drive controls are functioning properly.

• Check auger bits and locking pin for damage

The above instructions must be followed at all times

If any of the instructions are not possible, contact the site supervisor

for an assessment of any safety requirements

September 2015 Issue //1 Pg 2 of 2

You might also like

- D25KS 245S ServiceDocument571 pagesD25KS 245S ServiceJesus CH100% (6)

- SCISSOR LIFT SAFETYDocument7 pagesSCISSOR LIFT SAFETYnatuan74No ratings yet

- Diesel GensetDocument2 pagesDiesel Gensetvega f ankaNo ratings yet

- D75KS Manual Servicio PDFDocument748 pagesD75KS Manual Servicio PDFSara100% (1)

- ATT400 Operation Maint 241384Document805 pagesATT400 Operation Maint 241384Hữu Dũng Nguyễn100% (8)

- Century t500 Parts 55145Document482 pagesCentury t500 Parts 55145Luis OrellanaNo ratings yet

- DRIVING - HEAVY EQUIPMENT SAFETYDocument9 pagesDRIVING - HEAVY EQUIPMENT SAFETYVidyesh Viswanathan NairNo ratings yet

- 360 Excavator Training ManualDocument14 pages360 Excavator Training ManualBiruk YifruNo ratings yet

- R F (H W C) :: Crushing & Screening Operations BDocument5 pagesR F (H W C) :: Crushing & Screening Operations Bkmohamedkeita906No ratings yet

- SOP SOP0007 Hitachi Electric Jack HammerDocument3 pagesSOP SOP0007 Hitachi Electric Jack HammerWidya BungaNo ratings yet

- 1 Training For HAMTANTOTOR  RTGs PDFDocument153 pages1 Training For HAMTANTOTOR  RTGs PDFAnonymous ahdhFMaNo ratings yet

- CTRA-23-STM-062-TK-95-001 - ManliftDocument3 pagesCTRA-23-STM-062-TK-95-001 - ManliftMohamed RizwanNo ratings yet

- D45KS HP Service C18 PDFDocument789 pagesD45KS HP Service C18 PDFPhong Le Xuan100% (2)

- Home 18 Knittable Projects To Keep You ComfyDocument100 pagesHome 18 Knittable Projects To Keep You ComfyRoxana Popa100% (3)

- R F (H W C) :: Operations & Screening CrushingDocument7 pagesR F (H W C) :: Operations & Screening Crushingkmohamedkeita906No ratings yet

- Crochet Bagrielle Snuggy PatternDocument7 pagesCrochet Bagrielle Snuggy PatternElena Filip-MuraruNo ratings yet

- The UAE Government Initiatives To Combat Covid 19Document45 pagesThe UAE Government Initiatives To Combat Covid 19RajendraNo ratings yet

- NR 18 - Aerial Lifts For ConstructionDocument44 pagesNR 18 - Aerial Lifts For ConstructionCPSSTNo ratings yet

- BHC Towage Risk Assessment Ed1 2018 PDFDocument42 pagesBHC Towage Risk Assessment Ed1 2018 PDFAndy BayuNo ratings yet

- Business ProposalDocument7 pagesBusiness ProposalMysha Tagle100% (1)

- GRP Installation GuideDocument13 pagesGRP Installation GuidepparreraNo ratings yet

- Manual de Partes RT-160Document622 pagesManual de Partes RT-160leogerguzNo ratings yet

- PG CaseDocument12 pagesPG CaseVivek PrakashNo ratings yet

- Fuel Assurance and Fuel-Related Reliability Risk Analysis For The Bulk Power SystemDocument39 pagesFuel Assurance and Fuel-Related Reliability Risk Analysis For The Bulk Power SystemRajendraNo ratings yet

- Fuel Assurance and Fuel-Related Reliability Risk Analysis For The Bulk Power SystemDocument39 pagesFuel Assurance and Fuel-Related Reliability Risk Analysis For The Bulk Power SystemRajendraNo ratings yet

- SOP SOP0022 Concrete Core DrillDocument3 pagesSOP SOP0022 Concrete Core Drillkristian08No ratings yet

- S Magazine 5 JuneDocument84 pagesS Magazine 5 JuneEmersonNo ratings yet

- d245s Hpil Op ManualDocument66 pagesd245s Hpil Op ManualJhair75% (4)

- Water Tank Risk AssessmentDocument2 pagesWater Tank Risk AssessmentHijikata Shiroi100% (3)

- Moonlightcrochet89 RubyDocument18 pagesMoonlightcrochet89 RubyMilagros Quintana100% (11)

- Job Hazard Analysis for SurveyingDocument1 pageJob Hazard Analysis for SurveyingYogesh Gowda100% (1)

- Palfinger ptm1800 ManualDocument113 pagesPalfinger ptm1800 ManualLisa Todd100% (1)

- DR460 Service QST30Document922 pagesDR460 Service QST30Cesar0% (1)

- PuwerDocument106 pagesPuwerBenny Salazar BotonesNo ratings yet

- Rapid Fire FulfillmentDocument55 pagesRapid Fire FulfillmentNeelesh Kamath100% (2)

- Basics of Equipment Guarding: Mining and Petroleum Training ServiceDocument51 pagesBasics of Equipment Guarding: Mining and Petroleum Training ServiceKim Lien TrinhNo ratings yet

- Rafhan Custard Powder - FinalDocument34 pagesRafhan Custard Powder - FinalAli Mohsin33% (3)

- Segment Wise Details of Markstrat at The End of Period 4Document17 pagesSegment Wise Details of Markstrat at The End of Period 4sazk070% (1)

- BCG Matrix of HULDocument7 pagesBCG Matrix of HULParesh Ghelani100% (1)

- Safety Procedure RammerDocument2 pagesSafety Procedure RammerAura SantosNo ratings yet

- Roller Safety ProceduresDocument4 pagesRoller Safety ProceduresRonald AranhaNo ratings yet

- Doc Honda Petrol GensetDocument3 pagesDoc Honda Petrol Gensetmanishadash009No ratings yet

- Electric Submersible PumpDocument2 pagesElectric Submersible Pumpneyazy abdelmonemNo ratings yet

- Oxy Welding/Cutting Equipment Risk Assessment: October 2014 //1Document2 pagesOxy Welding/Cutting Equipment Risk Assessment: October 2014 //1Alves EdattukaranNo ratings yet

- Ladder Risk AssessmentDocument3 pagesLadder Risk Assessmentvasanth pugazhendhiNo ratings yet

- Crane Truck Risk AssessmentDocument3 pagesCrane Truck Risk AssessmentMmamoraka Christopher MakhafolaNo ratings yet

- Risk Assessment For Grinding Work: Classic Builders and DevelopersDocument3 pagesRisk Assessment For Grinding Work: Classic Builders and DevelopersradeepNo ratings yet

- Welding Robots Technology System Issues and Applications - J Norberto PiresDocument76 pagesWelding Robots Technology System Issues and Applications - J Norberto PireshetpinNo ratings yet

- SOP SOP0003 Nail GunDocument2 pagesSOP SOP0003 Nail Gunjeevan georgeNo ratings yet

- SOP-22 AC Compressore Replacement WorkDocument4 pagesSOP-22 AC Compressore Replacement WorkNarendra SinghNo ratings yet

- Safe Operating Procedure Crane Truck: You Must Wear This Personal Protective Equipment When Doing This TaskDocument3 pagesSafe Operating Procedure Crane Truck: You Must Wear This Personal Protective Equipment When Doing This Taskr afriantoNo ratings yet

- 01-01b Safety BoomerDocument30 pages01-01b Safety BoomerJorge Luis Guerreros RamosNo ratings yet

- DR460 SP QST30 OpDocument90 pagesDR460 SP QST30 OpRamiro Joel Quiñonez RamosNo ratings yet

- 02 Safety_MT2200_enDocument28 pages02 Safety_MT2200_enjackNo ratings yet

- D25-D245 SandvikDocument86 pagesD25-D245 SandvikJesus CH100% (1)

- D45-50KS Maint Manual 732584 & Up (Rev. 7-09)Document92 pagesD45-50KS Maint Manual 732584 & Up (Rev. 7-09)Putra Dana100% (1)

- Operation 3120833 07-13-2015 CE Multi-LingualDocument260 pagesOperation 3120833 07-13-2015 CE Multi-LingualEdo RamNo ratings yet

- Safe Work Method Statement Rafter Fallguard (0004) : Job DetailsDocument11 pagesSafe Work Method Statement Rafter Fallguard (0004) : Job DetailsThandabantu MagengeleleNo ratings yet

- List Pre-Requisites Here: Importance Ranking Satisfactory or Needs WorkDocument19 pagesList Pre-Requisites Here: Importance Ranking Satisfactory or Needs WorkiZnoGouDmuzicNo ratings yet

- Weekly safety meeting covers aerial lift precautionsDocument1 pageWeekly safety meeting covers aerial lift precautionsFarhat SetharNo ratings yet

- ss10560 PDFDocument78 pagesss10560 PDFWilson GuzmanNo ratings yet

- Bobcat Excavator Risk AssessmentDocument4 pagesBobcat Excavator Risk AssessmentbugseNo ratings yet

- MINES VOCATIONAL TRAINING SAFETY TIPSDocument51 pagesMINES VOCATIONAL TRAINING SAFETY TIPSOmkar KurlekarNo ratings yet

- Industrial Safety Regulations for Machinery GuardingDocument4 pagesIndustrial Safety Regulations for Machinery GuardingMohamed AbdinNo ratings yet

- Installation Instructions: Power Take-Offs NH/4, NL/4 Versions B, CDocument19 pagesInstallation Instructions: Power Take-Offs NH/4, NL/4 Versions B, CAbhishek kumarNo ratings yet

- Machine Guarding - Machine Safeguarding PresentationDocument46 pagesMachine Guarding - Machine Safeguarding PresentationIns TaNo ratings yet

- Risk AssessmentDocument4 pagesRisk AssessmentThoufeer NETTERYNo ratings yet

- TVC - HOP Up Platform - Task SheetDocument3 pagesTVC - HOP Up Platform - Task SheetLeeJB09No ratings yet

- 7 - Machine Safety PDFDocument19 pages7 - Machine Safety PDFJohn Paulo Tacud100% (1)

- Haulotte Telescopic Booms 2008Document16 pagesHaulotte Telescopic Booms 2008daniel ortegaNo ratings yet

- Maintain Engine PlanDocument625 pagesMaintain Engine PlanArjun MenonNo ratings yet

- NR 18 Haulotte Compact 10dx 2008Document20 pagesNR 18 Haulotte Compact 10dx 2008CPSSTNo ratings yet

- RA082-C Grinding - ThornliebankDocument2 pagesRA082-C Grinding - Thornliebankloveson709No ratings yet

- (Co Cau Man Di Dong) 7Document1 page(Co Cau Man Di Dong) 7Ka KaNo ratings yet

- 189830Document3 pages189830RajendraNo ratings yet

- Snorkeling and Scuba Diving Safety EssentialsDocument21 pagesSnorkeling and Scuba Diving Safety EssentialsRajendraNo ratings yet

- Government of Telangana Rapid Covid Antigen Test Report: Date and Time of Reporting Sample IDDocument1 pageGovernment of Telangana Rapid Covid Antigen Test Report: Date and Time of Reporting Sample IDRajendraNo ratings yet

- BGC Packing InstructionsDocument8 pagesBGC Packing InstructionsRajendraNo ratings yet

- Sheet Pile RiskDocument24 pagesSheet Pile RiskNgọc NhiNo ratings yet

- COVID-19 Crew Safety Daily FormDocument1 pageCOVID-19 Crew Safety Daily FormRajendraNo ratings yet

- Health Record Guideline HighlightsDocument18 pagesHealth Record Guideline HighlightsragNo ratings yet

- Annexure CDocument2 pagesAnnexure CAsif ShaikhNo ratings yet

- Maritime Fire ProtDocument67 pagesMaritime Fire ProtKarenNo ratings yet

- Iosh Diving Presentation 001 Low Res Email Copy1Document49 pagesIosh Diving Presentation 001 Low Res Email Copy1RajendraNo ratings yet

- Importance of Risk Analysis and ManagementDocument30 pagesImportance of Risk Analysis and ManagementRajendraNo ratings yet

- Traffic ControlDocument15 pagesTraffic ControlDeepa LonerNo ratings yet

- SlideMembers FreePPTTemplateVRVirtualReality PS 4904Document6 pagesSlideMembers FreePPTTemplateVRVirtualReality PS 4904Jonathan SimanjuntajNo ratings yet

- Safety Practices Around Shuttle Cars and Scoops in Underground Coal MinesDocument24 pagesSafety Practices Around Shuttle Cars and Scoops in Underground Coal MinesRaviteja ThogataNo ratings yet

- Make Effective Presentations with Awesome BackgroundsDocument5 pagesMake Effective Presentations with Awesome BackgroundsmirzaNo ratings yet

- SlideMembers FreePPTTemplateFireExtinguisher PS 2398Document6 pagesSlideMembers FreePPTTemplateFireExtinguisher PS 2398RajendraNo ratings yet

- QUY150Document8 pagesQUY150RajendraNo ratings yet

- Click To Edit Master Title StyleDocument5 pagesClick To Edit Master Title StyleRajendraNo ratings yet

- Coronavirus Template 16x9Document5 pagesCoronavirus Template 16x9RajendraNo ratings yet

- Toolbox Talks: Driving in The Fog FactsheetDocument1 pageToolbox Talks: Driving in The Fog FactsheetRajendraNo ratings yet

- Spill ManagementDocument33 pagesSpill ManagementRajendraNo ratings yet

- Application For New Food Security Card - Application FormDocument2 pagesApplication For New Food Security Card - Application FormShirishaVijayapuram60% (10)

- Health & Safety Policy HSPol003 Feb2013Rev FinalDocument11 pagesHealth & Safety Policy HSPol003 Feb2013Rev FinalRajendraNo ratings yet

- Amana Cooktop AKT3040WWDocument12 pagesAmana Cooktop AKT3040WWjimmylovelyNo ratings yet

- In A Clothing Store A2Document3 pagesIn A Clothing Store A2Tena AvdicNo ratings yet

- 3 CDocument16 pages3 Cerosyor100% (1)

- Samsung SC9150Document16 pagesSamsung SC9150Andy SmithNo ratings yet

- Under Armour Marketing PlanDocument65 pagesUnder Armour Marketing PlanJoshua Casas50% (2)

- Consumer Perception Regarding Various Brands of Casual WearsDocument84 pagesConsumer Perception Regarding Various Brands of Casual WearsRuhi SinghNo ratings yet

- TE 3000-AVR: Operating Instructions en Mode D'emploi FR Manual de Instrucciones Es Manual de Instruções PTDocument18 pagesTE 3000-AVR: Operating Instructions en Mode D'emploi FR Manual de Instrucciones Es Manual de Instruções PTTony AlonsoNo ratings yet

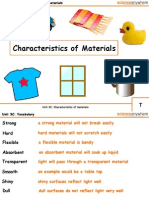

- Production, Uses and Care of FabricsDocument4 pagesProduction, Uses and Care of FabricsMaria ElizabethNo ratings yet

- Supply Chain Management of Hershey Foods CorporationDocument11 pagesSupply Chain Management of Hershey Foods CorporationShruti JainNo ratings yet

- Clio Awards 2012Document282 pagesClio Awards 2012Boris LoukanovNo ratings yet

- FRS2211IALDocument78 pagesFRS2211IALMihaela CaciumarciucNo ratings yet

- 02 Tourism ResourcesDocument111 pages02 Tourism ResourcesRtistNo ratings yet

- Rhetorical Analysis Essay FinalDocument5 pagesRhetorical Analysis Essay Finalapi-363883917No ratings yet

- اسس تصميم المطابخDocument22 pagesاسس تصميم المطابخMuhammad Jammal40% (5)

- TM-10-3530-205-14 1985 (C3-2005)Document457 pagesTM-10-3530-205-14 1985 (C3-2005)Gramma JoNo ratings yet

- Spanish DessertsDocument51 pagesSpanish DessertsCamilleNo ratings yet

- Trouser Top 10 DefectsDocument1 pageTrouser Top 10 DefectsSachin BansalNo ratings yet

- Chinar Final ReportDocument54 pagesChinar Final ReportBharat ShandilyaNo ratings yet

- Coca-Cola's Socio-Cultural Impact in IndiaDocument2 pagesCoca-Cola's Socio-Cultural Impact in IndiaLalima Bassi33% (3)

- ASC - Own Mocktail Recipes - Compiled, VN CorrectedDocument4 pagesASC - Own Mocktail Recipes - Compiled, VN CorrectedL4RRYNo ratings yet