Professional Documents

Culture Documents

ASTM E18 (2019) - Part23

ASTM E18 (2019) - Part23

Uploaded by

david42319930 ratings0% found this document useful (0 votes)

2 views1 pageOriginal Title

ASTM E18 (2019)_Part23

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

2 views1 pageASTM E18 (2019) - Part23

ASTM E18 (2019) - Part23

Uploaded by

david4231993Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 1

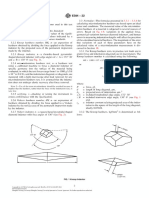

E18 − 19

A3.6 Class A Diamond Indenters A3.7 Reference Diamond Indenters

A3.6.1 Class A indenters are intended to be used for the A3.7.1 Reference diamond indenters are intended for the

standardization of Class B indenters in accordance with this standardization of Class A diamond indenters. The reference

Annex; the standardization of Rockwell hardness test blocks as indenter shall have tighter performance tolerances than Class A

described in Annex A4, and as a troubleshooting tool during and Class B indenters and shall be verified for performance by

the indirect verification of Rockwell hardness testing machines comparison to an indenter recognized as the national reference

in accordance with Annex A1. They are verified for correct indenter(s) of a national Rockwell hardness standardizing

geometry and performance in accordance with the schedule laboratory (see Note A3.3).

specified in Table A3.2. NOTE A3.3—In the United States, the national Rockwell hardness

A3.6.1.1 The instrument(s) used to verify the geometrical standardizing laboratory is the National Institute of Standards and

features shall be capable of measuring to the accuracies given Technology (NIST).

in Table A3.5.

A3.7.2 Geometric Requirements of Reference Diamond In-

A3.6.2 A Class A diamond indenter shall meet all of the denters:

manufacture and geometric requirements for a Class B dia- A3.7.2.1 Verification of the following geometric features of

mond indenter given in A3.5.2 with the following additional a Reference diamond spheroconical indenter shall be made at

requirements. See also Note A3.1. not less than eight approximately equally spaced full cross-

A3.6.2.1 The deviation from straightness of the generatric section profiles. For example, eight profiles would be spaced at

line of the diamond cone adjacent to the blend shall not exceed approximately 22.5 degree intervals.

0.002 mm over a minimum length of 0.40 mm.

A3.6.2.2 The angle between the axis of the indenter and the A3.7.3 A Reference diamond indenter shall meet all of the

axis normal to the seating surface of the indenter shall not manufacture and geometric requirements for a Class A dia-

exceed 0.5°. mond indenter given in A3.6.2. See also Note A3.1.

A3.6.3 Class A diamond indenters have tighter performance A3.7.4 Performance Verification of Reference Diamond In-

tolerances than Class B diamond indenters. The performance denters:

of each Class A indenter shall be verified by comparison to the A3.7.4.1 The performance comparison shall be performed

performance of a Reference indenter. by a national Rockwell hardness standardizing laboratory, and

A3.6.4 Perform the qualifying and verifying measurements shall meet the performance tolerances of Table A3.9.

as described in A3.5.3 for a Class B diamond indenter, except A3.7.4.2 Perform the qualifying and verifying measure-

that the qualifying measurements shall be made using a ments as described in A3.5.3 for a Class B indenter, except that

Reference diamond indenter on each test block from each at least four qualifying measurements shall be made using a

range defined in Table A3.8 for the type of indenter to be national reference indenter (see A3.7.1) on each test block

verified. from each range defined in Table A3.9 for the type of indenter

A3.6.4.1 For acceptability, the difference of the average of to be verified.

the three qualifying measurements and the average of the three A3.7.4.3 For acceptability, the difference of the average of

verifying measurements, H̄ Q 2H̄ V , shall be within the tolerance the five qualifying measurements and the average of the five

specified for Class A diamond indenters in Table A3.8. verifying measurements, H̄ Q 2H̄ V , shall be within the tolerance

specified for Reference indenters in Table A3.9 for each test

block used in the verification.

TABLE A3.8 Test Blocks to be Used for Class A Diamond

Indenter Performance Verifications and the Maximum Tolerance

on the Performance Relative to the Reference Indenter

TABLE A3.9 Test Blocks to be Used for Reference Indenter

Class A Performance Verifications and the Maximum Tolerance on the

Tolerance

Performance Relative to a National Reference Indenter

Ranges of as Compared

Indenter Type Required Test to Reference

Blocks Reference Indenter

Indenter Tolerance as

Ranges of

H̄ Q 2H̄ V Compared

Indenter Type Required Test

to a National

Regular Scales Diamond 80 to 83 HRA ± 0.3 HRA Blocks

Reference

22 to 28 HRC ± 0.4 HRC

Indenter

42 to 50 HRC ± 0.4 HRC

60 to 65 HRC ± 0.3 HRC H̄ Q 2H̄ V

Superficial Scales Diamond 88 to 94 HR15N ± 0.3 HR15N Regular Scales Diamond 22 to 28 HRC ± 0.3 HRC

60 to 69 HR30N ± 0.3 HR30N 62 to 65 HRC ± 0.3 HRC

42 to 50 HR30N ± 0.4 HR45N Superficial Scales Diamond 88 to 94 HR15N ± 0.3 HR15N

22 to 29 HR45N ± 0.4 HR45N 40 to 48 HR45N ± 0.3 HR45N

Combination Regular and 22 to 28 HRC ± 0.4 HRC Combination Regular and 20 to 28 HRC ± 0.3 HRC

Superficial Scales Diamond 60 to 65 HRC ± 0.3 HRC Superficial Scales Diamond 62 to 65 HRC ± 0.3 HRC

88 to 94 HR15N ± 0.3 HR15N 88 to 94 HR15N ± 0.3 HR15N

60 to 69 HR30N ± 0.3 HR30N 40 to 48 HR45N ± 0.3 HR45N

Copyright ASTM International

Provided by IHS Markit under license with ASTM

23

No reproduction or networking permitted without license from IHS

You might also like

- Astm A126Document3 pagesAstm A126banglvhNo ratings yet

- D448 PDFDocument3 pagesD448 PDFgrats_singcoNo ratings yet

- Weld Acceptance Criteria and Repair Procedures Drawn-Arc Welded Automotive Studs, Nuts and Brackets - SteelDocument8 pagesWeld Acceptance Criteria and Repair Procedures Drawn-Arc Welded Automotive Studs, Nuts and Brackets - SteelMuhammad AliNo ratings yet

- A327A327M-11 Standard Test Methods For Impact Testing of Cast IronsDocument4 pagesA327A327M-11 Standard Test Methods For Impact Testing of Cast IronsjuegyiNo ratings yet

- Copper-Clad Aluminum Bar For Electrical Purposes (Bus Bar)Document5 pagesCopper-Clad Aluminum Bar For Electrical Purposes (Bus Bar)Tuanbk NguyenNo ratings yet

- Ams 2175 Rev.Document22 pagesAms 2175 Rev.Johnny Oh100% (1)

- ASTM E18 (2019) - Part19Document1 pageASTM E18 (2019) - Part19david4231993No ratings yet

- ASTM E18 (2019) - Part24Document1 pageASTM E18 (2019) - Part24david4231993No ratings yet

- Table A3.4 Fig. A3.1 Fig. A3.1: DentersDocument10 pagesTable A3.4 Fig. A3.1 Fig. A3.1: DentersLaura Sofia AvellanedaNo ratings yet

- ASTM E18 (2019) - Part21Document1 pageASTM E18 (2019) - Part21david4231993No ratings yet

- Astm A126 PDFDocument3 pagesAstm A126 PDFCarlos DueñasNo ratings yet

- A 126 - 95 r01 Qteyni05nviwmqDocument3 pagesA 126 - 95 r01 Qteyni05nviwmqfekihassanNo ratings yet

- ASTM E18 (2019) - Part22Document1 pageASTM E18 (2019) - Part22david4231993No ratings yet

- ASTM E18 (2019) - Part25Document1 pageASTM E18 (2019) - Part25david4231993No ratings yet

- Surface orDocument2 pagesSurface orDaniel MaxNo ratings yet

- ASTM A438-80 Transverse Testing of Gray Cast IronDocument5 pagesASTM A438-80 Transverse Testing of Gray Cast IronTyson BoyceNo ratings yet

- Astm D 448 - 08Document3 pagesAstm D 448 - 08Laura VelozNo ratings yet

- ANSI Y14.1-1980v Drawing Sheet Size And: American National StandardsDocument23 pagesANSI Y14.1-1980v Drawing Sheet Size And: American National Standardsavr8784No ratings yet

- A126 PDFDocument3 pagesA126 PDFProduction DepartmentNo ratings yet

- Saudi Standards, Metrology and Quality Org. (SASO) : SASO-ASTM-A126 Standard NoDocument3 pagesSaudi Standards, Metrology and Quality Org. (SASO) : SASO-ASTM-A126 Standard NoSM DXBNo ratings yet

- Astm A615mDocument8 pagesAstm A615mKelvin100% (1)

- A 126 - 95 r01 - Qteyni1sruqDocument5 pagesA 126 - 95 r01 - Qteyni1sruqQaisir MehmoodNo ratings yet

- Details of Fillet Welds D15M-D15-2002 - Section - 2.1Document40 pagesDetails of Fillet Welds D15M-D15-2002 - Section - 2.1drac_dracNo ratings yet

- Steel Wire, Plain, For Concrete ReinforcementDocument6 pagesSteel Wire, Plain, For Concrete ReinforcementfekihassanNo ratings yet

- Engineering Standards: Material Specification Metals GM6435MDocument6 pagesEngineering Standards: Material Specification Metals GM6435MAkmal NizametdinovNo ratings yet

- Rail-Steel and Axle-Steel Deformed Bars For Concrete ReinforcementDocument5 pagesRail-Steel and Axle-Steel Deformed Bars For Concrete ReinforcementGerges RamzyNo ratings yet

- Gray Iron Castings: Standard Specification ForDocument6 pagesGray Iron Castings: Standard Specification Forsandeep acharNo ratings yet

- Copper Trolley Wire: Standard Specification ForDocument5 pagesCopper Trolley Wire: Standard Specification Fornicu1212No ratings yet

- Tolerances. Section 8 ANSI H35.2Document55 pagesTolerances. Section 8 ANSI H35.2Bá Lộc NguyễnNo ratings yet

- Astm A48 - 2003 - 2008Document6 pagesAstm A48 - 2003 - 2008Arnold Jose Batista RodriguezNo ratings yet

- A 48 - 94 Qtq4ltk0quuxDocument5 pagesA 48 - 94 Qtq4ltk0quuxFathia AlkelaeNo ratings yet

- Deformed and Plain Low-Alloy Steel Bars For Concrete ReinforcementDocument7 pagesDeformed and Plain Low-Alloy Steel Bars For Concrete ReinforcementSama UmateNo ratings yet

- Public Review Draft 2145Document21 pagesPublic Review Draft 2145AmeliaPrisiliaNo ratings yet

- Rail-Steel and Axle-Steel Deformed Bars For Concrete ReinforcementDocument5 pagesRail-Steel and Axle-Steel Deformed Bars For Concrete ReinforcementDarwin DarmawanNo ratings yet

- Astm B648-23Document4 pagesAstm B648-23zuqin bianNo ratings yet

- Cast Aluminum Alloy Railing Posts: Standard Specification ForDocument2 pagesCast Aluminum Alloy Railing Posts: Standard Specification ForFRANZ RICHARD SARDINAS MALLCONo ratings yet

- A126-04 (2014) Gray Iron Castings For Valves, Flanges, and Pipe FittingsDocument3 pagesA126-04 (2014) Gray Iron Castings For Valves, Flanges, and Pipe FittingsJosh HansenNo ratings yet

- A 184 - A 184M - 01 Qte4nc9bmtg0tq - PDFDocument3 pagesA 184 - A 184M - 01 Qte4nc9bmtg0tq - PDFfekihassanNo ratings yet

- Deformed and Plain, Low-Carbon, Chromium, Steel Bars For Concrete ReinforcementDocument5 pagesDeformed and Plain, Low-Carbon, Chromium, Steel Bars For Concrete ReinforcementMarcons Jon Maturan CasabaNo ratings yet

- Rockwell Hardness of Metallic Materials: Standard Test Methods ForDocument38 pagesRockwell Hardness of Metallic Materials: Standard Test Methods ForochableNo ratings yet

- Astm E18Document38 pagesAstm E18Danish HandaNo ratings yet

- PCI-MNL-116-99-Structural-QC-Manual - Test Percentage of Welding For PrecastDocument2 pagesPCI-MNL-116-99-Structural-QC-Manual - Test Percentage of Welding For PrecastEng-TaYsEeRNo ratings yet

- Abstract of ASTM A307 2000Document7 pagesAbstract of ASTM A307 2000Jesse ChenNo ratings yet

- Aws A5.2-1992Document8 pagesAws A5.2-1992abastosuaptNo ratings yet

- Gray Iron Castings: Standard Specification ForDocument6 pagesGray Iron Castings: Standard Specification Forsharon blushteinNo ratings yet

- 01-Astm A 615-A615m-2022Document8 pages01-Astm A 615-A615m-2022rdx6zqftnrNo ratings yet

- A184 PDFDocument3 pagesA184 PDFluisNo ratings yet

- Rockwell Hardness of Graphite Materials: Standard Test Method ForDocument3 pagesRockwell Hardness of Graphite Materials: Standard Test Method ForLabeed ShamilNo ratings yet

- Evaluating The Microstructure of Graphite in Iron Castings: Standard Test Method ForDocument13 pagesEvaluating The Microstructure of Graphite in Iron Castings: Standard Test Method ForMarlon VillarrealNo ratings yet

- Astm A48 A48m-03 (R2008)Document7 pagesAstm A48 A48m-03 (R2008)Vũ Nhân Hòa100% (1)

- A 247 - 17 PDFDocument13 pagesA 247 - 17 PDFأسامة وحيد الدين رمضانNo ratings yet

- Astm A48Document6 pagesAstm A48ÓscarAranda100% (1)

- Astm A 615 PDFDocument6 pagesAstm A 615 PDFVo Hong Kiet0% (1)

- ASME Section II Part A - Ferrous Material SpecificationsDocument8 pagesASME Section II Part A - Ferrous Material SpecificationsGato Sesa100% (1)

- Sizes of Aggregate For Road and Bridge ConstructionDocument3 pagesSizes of Aggregate For Road and Bridge ConstructionRicardoNo ratings yet

- F2832-11 (Reapproved 2016)Document5 pagesF2832-11 (Reapproved 2016)Mohammed EldakhakhnyNo ratings yet

- Structural Steel Design to Eurocode 3 and AISC SpecificationsFrom EverandStructural Steel Design to Eurocode 3 and AISC SpecificationsNo ratings yet

- Flow Measurement: By Square-Edged Orifice Plate Using Corner TappingsFrom EverandFlow Measurement: By Square-Edged Orifice Plate Using Corner TappingsRating: 5 out of 5 stars5/5 (1)

- Pressuremeter Testing: Methods and InterpretationFrom EverandPressuremeter Testing: Methods and InterpretationRating: 5 out of 5 stars5/5 (2)

- ASTM E384 (2022) - Part8Document1 pageASTM E384 (2022) - Part8david4231993No ratings yet

- ASTM E384 (2022) - Part6Document1 pageASTM E384 (2022) - Part6david4231993No ratings yet

- ASTM E18 (2019) - Part39Document1 pageASTM E18 (2019) - Part39david4231993No ratings yet

- ASTM E384 (2022) - Part9Document1 pageASTM E384 (2022) - Part9david4231993No ratings yet

- ASTM E18 (2019) - Part38Document1 pageASTM E18 (2019) - Part38david4231993No ratings yet

- ASTM E384 (2022) - Part1Document1 pageASTM E384 (2022) - Part1david4231993No ratings yet

- ASTM E384 (2022) - Part2Document1 pageASTM E384 (2022) - Part2david4231993No ratings yet

- ASTM E18 (2019) - Part36Document1 pageASTM E18 (2019) - Part36david4231993No ratings yet

- ASTM E18 (2019) - Part34Document1 pageASTM E18 (2019) - Part34david4231993No ratings yet

- ASTM E18 (2019) - Part33Document1 pageASTM E18 (2019) - Part33david4231993No ratings yet

- ASTM E18 (2019) - Part35Document1 pageASTM E18 (2019) - Part35david4231993No ratings yet

- ASTM E18 (2019) - Part29Document1 pageASTM E18 (2019) - Part29david4231993No ratings yet

- ASTM E18 (2019) - Part22Document1 pageASTM E18 (2019) - Part22david4231993No ratings yet

- ASTM E18 (2019) - Part20Document1 pageASTM E18 (2019) - Part20david4231993No ratings yet

- ASTM E18 (2019) - Part27Document1 pageASTM E18 (2019) - Part27david4231993No ratings yet

- ASTM E18 (2019) - Part18Document1 pageASTM E18 (2019) - Part18david4231993No ratings yet

- ASTM E18 (2019) - Part17Document1 pageASTM E18 (2019) - Part17david4231993No ratings yet

- ASTM E18 (2019) - Part2Document1 pageASTM E18 (2019) - Part2david4231993No ratings yet

- ASTM E18 (2019) - Part11Document1 pageASTM E18 (2019) - Part11david4231993No ratings yet

- ASTM E18 (2019) - Part3Document1 pageASTM E18 (2019) - Part3david4231993No ratings yet

- Effects of Shear Deformation and Rotatory Inertia OnDocument33 pagesEffects of Shear Deformation and Rotatory Inertia OnJimoh SULE AdekunleNo ratings yet

- Control Valve Datasheet & BOQ PDFDocument4 pagesControl Valve Datasheet & BOQ PDFFireNo ratings yet

- On Stability Analysis of Slurry-Wall Trenches: Plaxis PracticeDocument6 pagesOn Stability Analysis of Slurry-Wall Trenches: Plaxis PracticeVetriselvan ArumugamNo ratings yet

- W8,9,10 Chapter 5-Statically Determinate TrussesDocument38 pagesW8,9,10 Chapter 5-Statically Determinate TrussesNor HakimNo ratings yet

- Content: - What Is Energy Audit? - It's Importance in Industries. - List of Different Instruments Used For Energy AuditDocument9 pagesContent: - What Is Energy Audit? - It's Importance in Industries. - List of Different Instruments Used For Energy AuditDarshit KananiNo ratings yet

- Max Shear Stress Shape FactorDocument4 pagesMax Shear Stress Shape FactorRajnikanth GedhadaNo ratings yet

- Design of Spur Gearing Using Agma Standard. Verificationg With Finite Element Analysis (Fea)Document77 pagesDesign of Spur Gearing Using Agma Standard. Verificationg With Finite Element Analysis (Fea)Arthanari VaidyanathanNo ratings yet

- 3rd ChapterDocument10 pages3rd ChapterDeepak BhaskaranNo ratings yet

- Appendix Technical Data & Dimensions: Multistrand Post-TensioningDocument18 pagesAppendix Technical Data & Dimensions: Multistrand Post-TensioningCamilo Andres TorresNo ratings yet

- Saturation Pressure Apparatus TH3 PDFDocument17 pagesSaturation Pressure Apparatus TH3 PDFFrank.JNo ratings yet

- Esolutions Manual - Powered by CogneroDocument13 pagesEsolutions Manual - Powered by CogneroasdasdasdasdasdNo ratings yet

- 1 s2.0 S0016236114002701 MainDocument8 pages1 s2.0 S0016236114002701 Maindorian.axel.ptNo ratings yet

- PH 304 Final 03Document13 pagesPH 304 Final 03Ana SultanNo ratings yet

- Assignment 5: IC260 - IIT MandiDocument3 pagesAssignment 5: IC260 - IIT MandiSourav SamantNo ratings yet

- Engineering Material Specification: Printed Copies Are UncontrolledDocument8 pagesEngineering Material Specification: Printed Copies Are UncontrolledaldairlopesNo ratings yet

- QL40-ELOG Electrical ResistivityDocument5 pagesQL40-ELOG Electrical ResistivityJhon Antony LizanaNo ratings yet

- Discrete Structures: Dr. Nirnay GhoshDocument18 pagesDiscrete Structures: Dr. Nirnay Ghoshalok_bNo ratings yet

- Properties: EM 1110-2-2006 15 Jan 00Document11 pagesProperties: EM 1110-2-2006 15 Jan 00aminsuhadiNo ratings yet

- Structure of Atom Part-4Document25 pagesStructure of Atom Part-4ARYANNo ratings yet

- NotesDocument20 pagesNotesAkashNo ratings yet

- De Cuong Mon Hoc DSTT - MA003 - MAU MOIDocument8 pagesDe Cuong Mon Hoc DSTT - MA003 - MAU MOIK.No ratings yet

- Me172 TSDocument2 pagesMe172 TSalex.waker.proNo ratings yet

- Gtu MCQ: Dynamics of Machinery (3151911)Document2 pagesGtu MCQ: Dynamics of Machinery (3151911)kannu19802550No ratings yet

- Exp-6 Melde's ExpDocument7 pagesExp-6 Melde's ExpBerlinNo ratings yet

- 1 s2.0 S0038092X12002150 MainA Cell To Module To Array Detailed Model For Photovoltaic PanelsDocument12 pages1 s2.0 S0038092X12002150 MainA Cell To Module To Array Detailed Model For Photovoltaic PanelsRendy Adhi RachmantoNo ratings yet

- Adaptive Sliding Mode Control of Ball and Plate Systems For Its Practical ApplicationDocument5 pagesAdaptive Sliding Mode Control of Ball and Plate Systems For Its Practical Application미끄덩No ratings yet

- Journal of Adhesion Science and Technology: Click For UpdatesDocument13 pagesJournal of Adhesion Science and Technology: Click For UpdatesDjm AlgNo ratings yet

- An Experimental Study On Map Projection TransformaDocument17 pagesAn Experimental Study On Map Projection TransformaMaharina NrsaifNo ratings yet

- NOTES SeviceabilityDocument81 pagesNOTES Seviceabilitydileep 443No ratings yet

- 1.two Way Slab Design (USD)Document16 pages1.two Way Slab Design (USD)kashemNo ratings yet