Professional Documents

Culture Documents

ASTM E18 (2019) - Part25

ASTM E18 (2019) - Part25

Uploaded by

david4231993Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

ASTM E18 (2019) - Part25

ASTM E18 (2019) - Part25

Uploaded by

david4231993Copyright:

Available Formats

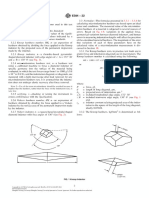

E18 − 19

stating the Rockwell hardness scales that are covered by the A4.5.3 The standardization procedure involves making

accreditation, and the standards to which the test block hardness measurements on the test block surface using the

standardizations are traceable. forces and type of indenter that are appropriate for the hardness

scale.

A4.3 Manufacture A4.5.3.1 Make at least five measurements distributed uni-

A4.3.1 The attention of the manufacturer of test blocks is formly over the test surface.

drawn to the need to use material and a manufacturing process A4.5.4 Determine the nonuniformity range HR of the mea-

which will give the necessary homogeneity, stability of surements as:

structure, and uniformity of surface hardness. For quality

control purposes, test blocks should be examined for homoge- H R 5 H max 2 H min (A4.1)

neity and uniformity of surface hardness in accordance with a where:

statistically acceptable sampling procedure. Hmax = highest hardness value, and

A4.3.2 The test blocks, if of steel, shall be demagnetized at Hmin = lowest hardness value.

the end of the manufacturing process. A4.5.4.1 The nonuniformity range HR of the standardizing

A4.3.3 To assure that material is not removed from the test measurements provides an indication of the non-uniformity of

surface after standardization, an identifying mark shall be the test block hardness. For acceptability, the nonuniformity

made on the test surface. The mark shall be such that it can not range HR shall be within the tolerances of Table A4.2.

be removed by any method other than removal of test block A4.5.5 The standardized value of the test block is defined as

material. the average of the standardization measurements H̄.

A4.3.4 The standardized test block shall meet the physical A4.5.6 In some cases, a more accurate standardized value

requirements of Table A4.1. for the test block may be obtained by correcting the measured

A4.4 General Requirements average hardness value by a performance offset value for the

standardizing machine. The offset value may be based on the

A4.4.1 The standardizing laboratory environment, the stan- error E values measured during the last indirect verification of

dardizing machine, and the standardizing test cycle shall the standardizing machine. For example, an appropriate offset

satisfy the requirements of Annex A2. correction curve for each standardizing machine may be

A4.4.2 All instruments used to make measurements re- calculated for a specific Rockwell scale by fitting a linear line

quired by this Annex shall have been calibrated traceable to to the error values measured during the indirect verification.

national standards where a system of traceability exists, except The laboratory should be cautioned that the validity of calcu-

as noted otherwise. lating a correction curve in this way is dependent on the

linearity of the fit of the offset data across the entire scale.

A4.5 Standardization Procedure

A4.5.1 A test block is standardized by calibrating the

average hardness of the test surface to a specific Rockwell

hardness standard. Only one surface of the test block shall be TABLE A4.2 Maximum Nonuniformity for Standardized

calibrated. When possible, the test blocks should be calibrated Test Blocks

traceable to national Rockwell standards (see Note A4.1). The Max.

Rockwell standard to which the test blocks are traceable shall Nonuniformity

Nominal Hardness of Range,

be stated in the certification. Standardized Test Block HR

NOTE A4.1—In the United States, the national Rockwell hardness (HR

standardizing laboratory is the National Institute of Standards and units)

Technology (NIST), Gaithersburg, MD 20899. HRA $20 and <80 1.0

NOTE A4.2—Primary standardized test blocks are available as Standard $80 and <92 0.5

Reference Material from NIST, Gaithersburg, MD 20899. HRBW $0 and <45 1.5

$45 and <100 1.0

A4.5.2 Class A ball indenters and Class A or Reference HRC $20 and <60 1.0

diamond indenters as described in Annex A3 (see Note 3) shall $60 and <70 0.5

be used for the standardization of test blocks. HRD $40 and <60 1.0

$60 and <87 0.5

HREW, HRFW, HRGW, HRHW, 1.0

TABLE A4.1 Physical Requirements of Standardized Test Blocks HRKW, HRLW, HRMW, HRPW,

HRRW, HRSW, HRVW

Test Block Parameter Tolerance HR15N $69 and <90 1.0

Thickness $6.0 mm (0.236 in.) $90 and <97 0.7

#16.0 mm (0.630 in.) HR30N $41 and <77 1.0

Test surface area #2600 mm2 (4 in.2) $77 and <92 0.7

Deviation from surface flatness #0.005 mm (0.0002 in.) HR45N $19 and <66 1.0

(test & bottom) $66 and <87 0.7

Deviation from surface parallelism #0.0002 mm per mm HR15TW, HR30TW, HR45TW 1.0

(test & bottom) (0.0002 in. per in.) HR15WW, HR30WW, HR45WW, 1.0

Mean surface roughness Ra # 0.003 mm (12 µin.) HR15XW, HR30XW, HR45XW,

(test & bottom) center line average HR15YW, HR30YW, HR45YW

Copyright ASTM International

Provided by IHS Markit under license with ASTM

25

No reproduction or networking permitted without license from IHS

You might also like

- Astm E18-2020Document39 pagesAstm E18-2020Andrés Bernal De la Ossa90% (10)

- Astm D 732 - 02 PDFDocument4 pagesAstm D 732 - 02 PDFJimmyJohanTapiaVasquez100% (1)

- Astm D2095 PDFDocument3 pagesAstm D2095 PDFTaher Hama AmeenNo ratings yet

- Procedure For Determining Conformance To Steel Profile/Surface Roughness/Peak Count RequirementsDocument7 pagesProcedure For Determining Conformance To Steel Profile/Surface Roughness/Peak Count Requirementssarath100% (1)

- ASME Y14.5 2009 Vs 2018 Comparison ChartDocument1 pageASME Y14.5 2009 Vs 2018 Comparison ChartShiban TripathyNo ratings yet

- Astm E18 Pdqv6897Document14 pagesAstm E18 Pdqv6897Nayth Andres GalazNo ratings yet

- Sspc-Pa 17-2012Document7 pagesSspc-Pa 17-2012ALEXIS MARTINEZ100% (1)

- C116 90Document3 pagesC116 90Kemal YücelNo ratings yet

- (Universitext) Hans Wilhelm Alt (Auth.) - Linear Functional Analysis - An Application-Oriented Introduction (2016, Springer)Document446 pages(Universitext) Hans Wilhelm Alt (Auth.) - Linear Functional Analysis - An Application-Oriented Introduction (2016, Springer)Steven DubnerNo ratings yet

- OrmatioDocument1 pageOrmatioMechanicalNo ratings yet

- B294-10 Standard Test Method For Hardness Testing of Cemented Carbides PDFDocument8 pagesB294-10 Standard Test Method For Hardness Testing of Cemented Carbides PDFdiego rodriguezNo ratings yet

- Standard Methods For Mechanical Testing of Welds: 1. ScopeDocument51 pagesStandard Methods For Mechanical Testing of Welds: 1. ScopePaola CernaNo ratings yet

- ASTM A833-08aDocument3 pagesASTM A833-08aАртем ТитовNo ratings yet

- Pre ASTM E18-20Document5 pagesPre ASTM E18-20Ranga100% (1)

- B769 112021 2 02 Standard Test Method For Shear Testing of AluminumDocument4 pagesB769 112021 2 02 Standard Test Method For Shear Testing of AluminumShodji MabungaNo ratings yet

- ASTM D2228 Rubber Prop-Abrasion Resistance TestingDocument9 pagesASTM D2228 Rubber Prop-Abrasion Resistance TestingJesse KrebsNo ratings yet

- Astm C748.10372Document3 pagesAstm C748.10372Luis Felipe Cam ChiangNo ratings yet

- Rockwell Hardness of Graphite Materials: Standard Test Method ForDocument3 pagesRockwell Hardness of Graphite Materials: Standard Test Method ForMuhammad NaumanNo ratings yet

- ASTM E18 (2019) - Part24Document1 pageASTM E18 (2019) - Part24david4231993No ratings yet

- Rockwell Hardness of Metallic Materials: Standard Test Methods ForDocument39 pagesRockwell Hardness of Metallic Materials: Standard Test Methods ForSandipGangurdeNo ratings yet

- Rockwell Hardness of Metallic Materials: Standard Test Methods ForDocument39 pagesRockwell Hardness of Metallic Materials: Standard Test Methods ForrugthierNo ratings yet

- Rockwell Hardness of Graphite Materials: Standard Test Method ForDocument3 pagesRockwell Hardness of Graphite Materials: Standard Test Method ForLabeed ShamilNo ratings yet

- F-0606 - Standard Test Method For Determining The Mechanical Properties of Externally and Internally Threaded Fasteners, Washers, and RivetsDocument12 pagesF-0606 - Standard Test Method For Determining The Mechanical Properties of Externally and Internally Threaded Fasteners, Washers, and RivetsEwan SutherlandNo ratings yet

- Tensile ASTM C749Document13 pagesTensile ASTM C749hamidrezaghezelNo ratings yet

- Astm A-833-17Document5 pagesAstm A-833-17Mos Peerapat100% (2)

- Lab 368 - Astm E18Document39 pagesLab 368 - Astm E18yessicaNo ratings yet

- Sast1453 01Document3 pagesSast1453 01jose miguelNo ratings yet

- Rubber Property-Relative Abrasion Resistance by Pico Abrader MethodDocument9 pagesRubber Property-Relative Abrasion Resistance by Pico Abrader MethodMaxNo ratings yet

- Simulated Service Testing of Wood and Wood-Based Finish FlooringDocument11 pagesSimulated Service Testing of Wood and Wood-Based Finish Flooringalejo-peñaNo ratings yet

- Astm D4475-02 - 2008Document4 pagesAstm D4475-02 - 2008Siu Hei LauNo ratings yet

- ASTM E18 (2019) - Part19Document1 pageASTM E18 (2019) - Part19david4231993No ratings yet

- Rockwell Hardness of Metallic Materials: Standard Test Methods ForDocument39 pagesRockwell Hardness of Metallic Materials: Standard Test Methods ForsajalNo ratings yet

- Astm A 833Document2 pagesAstm A 833AHMED ALJAAFARNo ratings yet

- Resistance To Deformation and Cohesion of Bituminous Mixtures by Means of Hveem ApparatusDocument7 pagesResistance To Deformation and Cohesion of Bituminous Mixtures by Means of Hveem ApparatusROHITNo ratings yet

- Rockwell Hardness of Metallic Materials: Standard Test Methods ForDocument39 pagesRockwell Hardness of Metallic Materials: Standard Test Methods ForLinda Julieth PinzónNo ratings yet

- E18.3534 - Rockwell Hardness PDFDocument39 pagesE18.3534 - Rockwell Hardness PDFDennis Cruz100% (1)

- ASTM B557 15 Standard Test Methods For Tension Testing Wrought and Cast Aluminum and Magnesium Alloy ProductsDocument32 pagesASTM B557 15 Standard Test Methods For Tension Testing Wrought and Cast Aluminum and Magnesium Alloy ProductsPuchi Ceballo100% (1)

- Rockwell Hardness of Metallic Materials: Standard Test Methods ForDocument10 pagesRockwell Hardness of Metallic Materials: Standard Test Methods ForDiego VargasNo ratings yet

- Rockwell Hardness of Metallic Materials: Standard Test Methods ForDocument39 pagesRockwell Hardness of Metallic Materials: Standard Test Methods ForJones Pereira NetoNo ratings yet

- Astm C748Document2 pagesAstm C748정호철No ratings yet

- N.004 - ASTM B557 - Standard Methods of Tension Testing Wrought and Cast Aluminum - and Magnesium - Alloy ProductsDocument20 pagesN.004 - ASTM B557 - Standard Methods of Tension Testing Wrought and Cast Aluminum - and Magnesium - Alloy ProductsAdriene SantosNo ratings yet

- ASTM E18 (2019) - Part23Document1 pageASTM E18 (2019) - Part23david4231993No ratings yet

- E566 - Eddy Current Sorting FerrousDocument5 pagesE566 - Eddy Current Sorting Ferrousshunmu_scribNo ratings yet

- ASTM E18 (2019) - Part26Document1 pageASTM E18 (2019) - Part26david4231993No ratings yet

- ASTM D 5 - 05 Standard Test Method For Penetration of Bituminous MaterialsDocument4 pagesASTM D 5 - 05 Standard Test Method For Penetration of Bituminous MaterialsEdison QuinapalloNo ratings yet

- Astm A956 A956m 22Document7 pagesAstm A956 A956m 22Mohamed KANENo ratings yet

- Norme - Astm - D 3846 - 02Document3 pagesNorme - Astm - D 3846 - 02Ryan DrakeNo ratings yet

- Penetration of Bituminous Materials: Standard Test Method ForDocument4 pagesPenetration of Bituminous Materials: Standard Test Method ForAnonymous qabSVjzrANo ratings yet

- Norma ASTM D5 PDFDocument4 pagesNorma ASTM D5 PDFBryan Santiago VásquezNo ratings yet

- A304 PDFDocument49 pagesA304 PDFSamuel PeterNo ratings yet

- D242D242M-09 (2014) Standard Specification For Mineral Filler For Bituminous Paving MixturesDocument2 pagesD242D242M-09 (2014) Standard Specification For Mineral Filler For Bituminous Paving MixturesAlabbas FadhelNo ratings yet

- D 4146 - 96 R03 - RdqxndyDocument4 pagesD 4146 - 96 R03 - RdqxndyEmre DalgicNo ratings yet

- F 606 - 00 - Rjywni0wmaDocument14 pagesF 606 - 00 - Rjywni0wmaEYBER ALEXANDER GARNICA TRUJILLONo ratings yet

- Astm b637 PDFDocument6 pagesAstm b637 PDFRobert SumińskiNo ratings yet

- Resistance To Deformation and Cohesion of Bituminous Mixtures by Means of Hveem ApparatusDocument7 pagesResistance To Deformation and Cohesion of Bituminous Mixtures by Means of Hveem ApparatusFanny SiregarNo ratings yet

- ASTM A1038 Hardness UltrsonicDocument7 pagesASTM A1038 Hardness Ultrsonicjohnrojas950% (2)

- ASTM D2228 04 - Standard Test Method For Rubber Property-Relative Abrasion Resistance by Pico Abrader MethodDocument9 pagesASTM D2228 04 - Standard Test Method For Rubber Property-Relative Abrasion Resistance by Pico Abrader MethodAndre Rodriguez Spirim100% (1)

- Shear Testing of Aluminum Alloys: Standard Test Method ForDocument4 pagesShear Testing of Aluminum Alloys: Standard Test Method ForMarcos Verissimo Juca de PaulaNo ratings yet

- Plastics Testing and Characterization: Industrial ApplicationsFrom EverandPlastics Testing and Characterization: Industrial ApplicationsNo ratings yet

- Adaptive Tests of Significance Using Permutations of Residuals with R and SASFrom EverandAdaptive Tests of Significance Using Permutations of Residuals with R and SASNo ratings yet

- Building a Successful Board-Test StrategyFrom EverandBuilding a Successful Board-Test StrategyRating: 4 out of 5 stars4/5 (1)

- ASTM E384 (2022) - Part8Document1 pageASTM E384 (2022) - Part8david4231993No ratings yet

- ASTM E384 (2022) - Part6Document1 pageASTM E384 (2022) - Part6david4231993No ratings yet

- ASTM E18 (2019) - Part39Document1 pageASTM E18 (2019) - Part39david4231993No ratings yet

- ASTM E384 (2022) - Part9Document1 pageASTM E384 (2022) - Part9david4231993No ratings yet

- ASTM E18 (2019) - Part38Document1 pageASTM E18 (2019) - Part38david4231993No ratings yet

- ASTM E384 (2022) - Part1Document1 pageASTM E384 (2022) - Part1david4231993No ratings yet

- ASTM E384 (2022) - Part2Document1 pageASTM E384 (2022) - Part2david4231993No ratings yet

- ASTM E18 (2019) - Part36Document1 pageASTM E18 (2019) - Part36david4231993No ratings yet

- ASTM E18 (2019) - Part34Document1 pageASTM E18 (2019) - Part34david4231993No ratings yet

- ASTM E18 (2019) - Part33Document1 pageASTM E18 (2019) - Part33david4231993No ratings yet

- ASTM E18 (2019) - Part35Document1 pageASTM E18 (2019) - Part35david4231993No ratings yet

- ASTM E18 (2019) - Part29Document1 pageASTM E18 (2019) - Part29david4231993No ratings yet

- ASTM E18 (2019) - Part22Document1 pageASTM E18 (2019) - Part22david4231993No ratings yet

- ASTM E18 (2019) - Part20Document1 pageASTM E18 (2019) - Part20david4231993No ratings yet

- ASTM E18 (2019) - Part27Document1 pageASTM E18 (2019) - Part27david4231993No ratings yet

- ASTM E18 (2019) - Part18Document1 pageASTM E18 (2019) - Part18david4231993No ratings yet

- ASTM E18 (2019) - Part17Document1 pageASTM E18 (2019) - Part17david4231993No ratings yet

- ASTM E18 (2019) - Part2Document1 pageASTM E18 (2019) - Part2david4231993No ratings yet

- ASTM E18 (2019) - Part11Document1 pageASTM E18 (2019) - Part11david4231993No ratings yet

- ASTM E18 (2019) - Part3Document1 pageASTM E18 (2019) - Part3david4231993No ratings yet

- Lecture 1 - The Quantum WorldDocument7 pagesLecture 1 - The Quantum WorldMartin MaguNo ratings yet

- Inverse Trigonometric Functions: PrefaceDocument11 pagesInverse Trigonometric Functions: PrefaceBharti Pant GahtoriNo ratings yet

- MATH225 Abstract Algebra Notes Part IDocument112 pagesMATH225 Abstract Algebra Notes Part IThrow AwayNo ratings yet

- Calculus For The Life Sciences 2nd Edition Greenwell Solutions ManualDocument26 pagesCalculus For The Life Sciences 2nd Edition Greenwell Solutions ManualSharonPerezozqy100% (60)

- (ARTIGO) Energy Harvesting by Means of Flow-Induced Vibrations On Aerospace VehiclesDocument35 pages(ARTIGO) Energy Harvesting by Means of Flow-Induced Vibrations On Aerospace VehiclesCorsini EngenhariaNo ratings yet

- Article in Press: Powder Coating of Veneered Particle Board Surfaces by Hot PressingDocument7 pagesArticle in Press: Powder Coating of Veneered Particle Board Surfaces by Hot PressingDelovita Ginting -No ratings yet

- Solid Geometry: - Area and Perimeter - Solid and VolumeDocument12 pagesSolid Geometry: - Area and Perimeter - Solid and VolumeJames Chua Hong KhengNo ratings yet

- Conversation Kelompok 1Document5 pagesConversation Kelompok 1Yeni Sutriana.NNo ratings yet

- Metrum Cryoflex Twist 1940 Evlt enDocument4 pagesMetrum Cryoflex Twist 1940 Evlt enBeata SviantickaNo ratings yet

- Online Laboratory (E-Lab) Instruction For: Mechanics of Materials (Mom)Document18 pagesOnline Laboratory (E-Lab) Instruction For: Mechanics of Materials (Mom)amiraNo ratings yet

- Report Pengolahan Bendungan Mamak PDFDocument4 pagesReport Pengolahan Bendungan Mamak PDFSurvei Sumbawa5No ratings yet

- Adekanol Uh-420: Thickener Rheology ModifiersDocument6 pagesAdekanol Uh-420: Thickener Rheology ModifierszxcvxcvxzcvNo ratings yet

- Development of A Multifunctional Intelligent Elbow Brace (MIEB) Using A Knitted Textile Strain SensorDocument9 pagesDevelopment of A Multifunctional Intelligent Elbow Brace (MIEB) Using A Knitted Textile Strain SensorhawNo ratings yet

- CML 2017 Paper Oh4eDocument19 pagesCML 2017 Paper Oh4eVishal ParekhNo ratings yet

- Consistent Mesoscopic Mechanical Behaviour Model For Woven Composite Reinforcements in Biaxial TensionDocument17 pagesConsistent Mesoscopic Mechanical Behaviour Model For Woven Composite Reinforcements in Biaxial TensionFederico LamonNo ratings yet

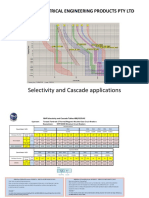

- NHP 2014 Selectivty & Cascading TablesDocument22 pagesNHP 2014 Selectivty & Cascading Tablesarllanbd4706No ratings yet

- GCSE Paper 1 Memory TestDocument4 pagesGCSE Paper 1 Memory TestArsh TewariNo ratings yet

- Lecture 6 - Groundwater Flow-UnsteadyDocument24 pagesLecture 6 - Groundwater Flow-Unsteadyph4318No ratings yet

- Adaptive Sliding Mode Control of Ball and Plate Systems For Its Practical ApplicationDocument5 pagesAdaptive Sliding Mode Control of Ball and Plate Systems For Its Practical Application미끄덩No ratings yet

- RESEARCH123Document12 pagesRESEARCH123Vedant MankarNo ratings yet

- Tuned Liquid Dampers Simulation For EarthquakeDocument18 pagesTuned Liquid Dampers Simulation For EarthquakedaahdadaNo ratings yet

- Lib-Dating-Fossils-53740-Article - and - QuizDocument7 pagesLib-Dating-Fossils-53740-Article - and - QuizRim YazidNo ratings yet

- 11.06.23 X (Cbse) Science Paper (CH - Light + Human Eye and Colourful World)Document2 pages11.06.23 X (Cbse) Science Paper (CH - Light + Human Eye and Colourful World)Mr.Saksham YadavNo ratings yet

- Science Chapter 12 Solar SystemDocument23 pagesScience Chapter 12 Solar Systemg-32347797No ratings yet

- WTE1501 Assessment 1Document4 pagesWTE1501 Assessment 1shalona behariNo ratings yet

- MYYMDocument2 pagesMYYMcatalin.nerajeanu2No ratings yet

- June 2019 BTEC EngineeringDocument20 pagesJune 2019 BTEC Engineeringshyam.n.rNo ratings yet

- Thermo Mid Term 2022-RevisedDocument4 pagesThermo Mid Term 2022-RevisedJeet VyasNo ratings yet