Professional Documents

Culture Documents

HPS Centurion D DVDT Series - Brochure

Uploaded by

Gustavo PérezOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

HPS Centurion D DVDT Series - Brochure

Uploaded by

Gustavo PérezCopyright:

Available Formats

CENTURION D

dV/dT Filters

hammondpowersolutions.com Energizing Our World

HPS Centurion D dV/dT Filters

HPS dV/dT Filters

The HPS dV/dT filters are designed for use between variable frequency drives (VFD’s) and

motors when long cable lengths are used.

The HPS Centurion D1 dV/dT filter (D1) combines an inductor and parallel resistor network to

mitigate both high frequency ringing and voltage spikes between the VFD and motor and

within the motor’s windings.

The D1 can mitigate the effects of reflected wave voltages greater than what a reactor alone

can accomplish. The D1 filter provides protection to the motor by slowing down the rate of

voltage increase (dV/dT) and minimizes the damaging peak voltages that occur within the

motor’s windings and along the length of cables feeding the motor.

HPS dV/dT Operation Principle

The term “dV/dT” refers to the change in voltage over change in time. With regards to VFD’s, dV/dT is explained as the rapid change in

voltage at the beginning or end of the square wave pulses that make up the pulse width modulated (PWM) output of a VFD that powers

the motor. As the square wave pulses travel the electrical cable to the motor, the differences in impedance between the cable and motor

windings cause some energy in the pulse to be “reflected”. In applications where the distance between the motor and VFD is long, the

voltage of two pulses can combine in the cable or motor windings. This creates voltage spikes that can be more than twice the VFD’s DC

bus voltage. Applications with long cables between the VFD and the motor can experience peak voltages up to 1600V in a 480V system

and up to 2100V in a 600V system. These high peak voltages will cause premature motor insulation failures resulting in down time and lost

revenue.

VFD HPS

HPSCenturion

Centurion D1D1 Motor

VFD Motor

dV/dT Filter

dV/dT Filter

Applications

The HPS Centurion D1 series dV/dT filters are designed for applications with long cables between the VFD and the

motor. VFD manufacturers often have recommendations on when to use dV/dT filters within their manuals. They

should always be installed close to the VFD. Typical applications include:

• Oil & Gas Pumps

• Wastewater Treatment Plants

• HVAC Systems

• Pulp & Paper

• Irrigation Fields

2 Data Subject to Change Without Notice hammondpowersolutions.com

The Reflected Wave Phenomenon

The reflected wave phenomenon in motor drives systems refers to the overvoltage at the motor or along the cables feeding it. The

reflected wave phenomena occurs due to a mismatch between the cable’s characteristic impedance and the motor’s surge impedance.

In addition, the high switching frequency and the fast rise time of the switching devices (IGBT) of the variable frequency drive (VFD)

increase the magnitude of the reflected wave’s voltage. The high rate of change in voltage with respect to time (dV/dT) of the IGBTs causes

a high voltage to be developed in the windings of motors, resulting in motor insulation stress.

Motor Voltage - No Filter

Motor Voltage (V)

Time (ms)

Motor Voltage - HPS Centurion D1 Filter

Motor Voltage (V)

Time (ms)

HPS Centurion D1 Series dV/dT filter is engineered to mitigate reflected wave by reducing:

• Peak voltage seen by the motor

• Rise time of the pulses

• Pulses ringing

Motor Voltage - No Filter Motor Voltage - HPS Centurion D1 Filter

Motor Voltage (V)

Motor Voltage (V)

Time (ms) Time (ms)

Energizing Our World Data Subject to Change Without Notice 3

HPS Centurion D dV/dT Filters

Typical Performance

Electrical Product Characteristics

System Voltage Rating: up to 600V (480V-600V applications)

Current Rating: 2A to 108A (consult HPS for higher ratings)

Technical Product Characteristics

Inverter Switching Frequency: 2kHz to 4kHz (consult HPS for higher switching frequency)

Inverter Operating Frequency: up to 60Hz

Insulation System: 130oC (2A - 54A), 180oC (>55A)

Voltage Drop: <3%

Motor Lead Length: Up to 1000ft (600ft & 1000ft models available)1, 2

Peak Voltage At Motor: 150% of DC bus voltage

Approvals: cUL Listed

Notes:

1

VFD rated cable recommended

2

Maximum motor cable size to achieve 5% voltage drop (including 2% from the filter)

Maximum lead length and carrier frequency can vary depending on motor cable type

Environmental Conditions

Open Style: Up to 50°C

Ambient Operating Temperature:

Enclosed Style: Up to 40°C

Altitude: <1000M

Cooling Method: Natural convection

Enclosure Type: Open, Type 1 (Type 3R available upon request)

4 Data Subject to Change Without Notice hammondpowersolutions.com

Part Number Guide

Product Cable

Type Model Voltage Current Rating Enclosure

Line Length

Example C D 1 X 0 0 2 5 F 1

Family Model Voltage Current Rating (Amps) Enclosure 600 ft*

C - Centurion 1 - D1 Model X - up to 3A to 108A F - Open

1 - 1000 ft

600V (480V Frame

Type

& 600V ap- 3A 0003 E - Type 1

D - dV/dT Filter plications) 17A 0017

108A 0108

*Default options - ignore if all following characters are default values.

Selection Guide

System Voltage, the input voltage to the VFD, has a major effect on the reflected wave phenomenon. Typically, the reflected wave is twice

of the DC bus voltage.

√2*System Voltage=DC Bus Voltage

√2=>1.414*480 VAC=679 VDC Bus

Reflected Wave=2*679 Volts ~ 1360 volts

Modern motor insulation systems can typically handle reflected wave issues from 208 VAC and 240 VAC systems due to the lower DC bus

voltage. North American 480 VAC and 600 VAC systems can experience motor damage from reflected waves. Please consult with HPS

for any application that may require the use of dV/dT filters at voltages below 480V or output carrier frequencies above 4kHz. In addition

to mitigating reflective wave issues, dV/dT filters can also lower the VFD’s output voltage rise time and reduce the peak voltage seen by

the motor and cabling. This can have the added benefit of reducing the motors temperature rise and audible noise.

Select the filter based on Full Load Amps (FLA) of the motor.

1000 ft Cable Length

NEC NEC Part HPS Amp Weight Overall Dimensions - Inches [mm] Watts Dim. Enclosed

480 HP 600 HP Number Rating Lbs. [kg] Loss* Fig. # Figure

Width Depth Height

0.5-1.5 0.5-2 CD1X0003F1 3 4.0 [1.8] 8.00 [203.20] 6.00 [152.40] 5.50 [139.70] 50 1 N1

2 3 CD1X0004F1 4 4.0 [1.8] 8.00 [203.20] 6.00 [152.40] 5.50 [139.70] 52 1 N1

3 5 CD1X0007F1 7 4.0 [1.8] 8.00 [203.20] 6.00 [152.40] 5.50 [139.70] 58 1 N1

5 7.5 CD1X0009F1 9 6.0 [2.7] 8.00 [203.20] 6.00 [152.40] 5.50 [139.70] 54 1 N1

7.5 10 CD1X0012F1 12 6.0 [2.7] 8.00 [203.20] 6.00 [152.40] 5.50 [139.70] 57 1 N1

10 15 CD1X0017F1 17 6.0 [2.7] 8.00 [203.20] 6.00 [152.40] 5.50 [139.70] 64 1 N1

15 20 CD1X0022F1 22 6.0 [2.7] 8.00 [203.20] 6.00 [152.40] 5.50 [139.70] 76 1 N1

20 25 CD1X0027F1 27 14.0 [6.2] 8.00 [203.20] 6.00 [152.40] 7.25 [184.15] 37 2 N1

25 30 CD1X0035F1 35 14.0 [6.2] 8.00 [203.20] 6.00 [152.40] 7.25 [184.15] 47 2 N1

30 40 CD1X0045F1 45 14.0 [6.2] 8.00 [203.20] 6.00 [152.40] 7.25 [184.15] 57 2 N1

40 50 CD1X0054F1 54 14.0 [6.2] 8.00 [203.20] 6.00 [152.40] 7.25 [184.15] 70 2 N1

50 60 CD1X0065F1 65 28.0 [12.4] 9.00 [228.60] 7.50 [190.50] 7.00 [177.80] 89 3 N2

60 75 CD1X0080F1 80 28.0 [12.4] 9.00 [228.60] 7.50 [190.50] 7.00 [177.80] 108 3 N2

75 100 CD1X0108F1 108 28.0 [12.4] 9.00 [228.60] 7.50 [190.50] 7.00 [177.80] 158 3 N2

*Typical watt losses at 480V system, 2kHz switching frequency, 60Hz

Energizing Our World Data Subject to Change Without Notice 5

HPS Centurion D dV/dT Filters

Selection Guide Continued

600 ft Cable Length

NEC NEC Part HPS Amp Weight Overall Dimensions - Inches [mm] Watts Dim. Enclosed

480 HP 600 HP Number Rating Lbs. [kg] Loss* Fig. # Figure

Width Depth Height

0.5-1.5 0.5-2 CD1X0003F 3 4.0 [1.8] 8.00 [203.20] 6.00 [152.40] 5.50 [139.70] 38 1 N1

2 3 CD1X0004F 4 4.0 [1.8] 8.00 [203.20] 6.00 [152.40] 5.50 [139.70] 40 1 N1

3 5 CD1X0007F 7 4.0 [1.8] 8.00 [203.20] 6.00 [152.40] 5.50 [139.70] 46 1 N1

5 7.5 CD1X0009F 9 6.0 [2.7] 8.00 [203.20] 6.00 [152.40] 5.50 [139.70] 42 1 N1

7.5 10 CD1X0012F 12 6.0 [2.7] 8.00 [203.20] 6.00 [152.40] 5.50 [139.70] 45 1 N1

10 15 CD1X0017F 17 6.0 [2.7] 8.00 [203.20] 6.00 [152.40] 5.50 [139.70] 53 1 N1

15 20 CD1X0022F 22 6.0 [2.7] 8.00 [203.20] 6.00 [152.40] 5.50 [139.70] 66 1 N1

20 25 CD1X0027F 27 14.0 [6.2] 8.00 [203.20] 6.00 [152.40] 7.25 [184.15] 32 2 N1

25 30 CD1X0035F 35 14.0 [6.2] 8.00 [203.20] 6.00 [152.40] 7.25 [184.15] 42 2 N1

30 40 CD1X0045F 45 14.0 [6.2] 8.00 [203.20] 6.00 [152.40] 7.25 [184.15] 52 2 N1

40 50 CD1X0054F 54 14.0 [6.2] 8.00 [203.20] 6.00 [152.40] 7.25 [184.15] 65 2 N1

50 60 CD1X0065F 65 28.0 [12.4] 9.00 [228.60] 7.50 [190.50] 7.00 [177.80] 78 3 N2

60 75 CD1X0080F 80 28.0 [12.4] 9.00 [228.60] 7.50 [190.50] 7.00 [177.80] 97 3 N2

75 100 CD1X0108F 108 28.0 [12.4] 9.00 [228.60] 7.50 [190.50] 7.00 [177.80] 147 3 N2

*Typical watt losses at 480V system, 2kHz switching frequency, 60Hz

NOTE: The motor HP ratings above are for reference only.

CORE & COIL DRAWINGS

Fig. # 1 Fig. # 2

Fig. # 3

6 Data Subject to Change Without Notice hammondpowersolutions.com

TYPE 1 ENCLOSED DRAWINGS

‘N1’ SERIES ENCLOSURE ‘N2’ SERIES ENCLOSURE

4 - Raised Mounting Feet with ø0.188 [4.78]

4 - Raised Mounting Feet with ø0.188 [4.78]

0.125 [3.18]

0.13 [3.31]

0.75 [19.05]

1.50 [38.10]

1.75 [44.45]

8.00 [203.20]

2.00 [50.80]

12.00 [304.80]

mounting hole in center.

mounting hole in center.

7.0 1 0.

0[ 00

1 0. 17 7 0] [25 0]

00 .80

165

.1 14 . 6.7

[25 ] 00 4

[35 .00] [26 0]

] 0[ . 20 5 .6

4 .0 6.5 3 5 .6 .50 [35

0] [20 10

.0 0

0]

14 .0 0

8

All dimension in inches [mm] All dimension in inches [mm]

Conduit Size vs. Actual Knockout Size Reference Table

Standard Conduit Size Actual Knockout Diameter

0.50 [12.70] 0.88 [22.23]

0.75 [19.05] 1.13 [28.58]

1.00 [25.40] 1.38 [34.93]

1.25 [31.75] 1.75 [44.45]

1.50 [38.10] 2.00 [50.80]

2.00 [50.80] 2.50 [63.50]

2.50 [63.50] 3.00 [76.20]

3.00 [76.20] 3.63 [92.08]

3.50 [88.90] 4.13 [104.78]

Please note the above table is not applicable for Stainless Steel enclosures.

All dimension in inches [mm]

Termination Details

AMP Rating Terminal Detail AMP Rating Terminal Detail

3 13-10 AWG 27 10-2 AWG

4 13-10 AWG 35 10-2 AWG

7 13-10 AWG 45 10-2 AWG

9 12-8 AWG 54 10-2 AWG

1A = 0.28” Dia.

12 12-8 AWG 65 1A

17 12-8 AWG 80 1A

DIAGRAM 1 22 12-8 AWG 108 1A

Energizing Our World Data Subject to Change Without Notice 7

CANADA

Hammond Power Solutions

595 Southgate Drive

Guelph, Ontario N1G 3W6

Tel: (519) 822-2441 | Fax: (519) 822-9701

Toll Free: 1-888-798-8882

CANADA

sales@hammondpowersolutions.com

UNITED STATES

Hammond Power Solutions

1100 Lake Street

Baraboo, Wisconsin 53913-2866

Tel: (608) 356-3921 | Fax: (608) 355-7623

Toll Free: 1-866-705-4684

UNITED STATES

sales@hammondpowersolutions.com

MEXICO

Hammond Power Solutions Latin America S.

Av. No. 800,

Parque Industrial Guadalupe

Guadalupe, NL, Mexico, C.P. 67190.

Tel: (819) 690-8000

MEXICO

sales@hammondpowersolutions.com

ASIA

Hammond Power Solutions Pvt. Ltd.

Plot No 6A, Phase -1, IDA,

Pashamylaram, Patancheru (M)

Sangareddy, 502 307, India

Tel: +91-994-995-0009

ASIA

marketing-india@hammondpowersolutions.com

EMEA (SALES OFFICE)

Hammond Power Solutions SpA

Tel: +49 (152) 08800468

sales-emea@hammondpowersolutions.com

hammondpowersolutions.com CENTDP-BBH2-EN

July 2023

You might also like

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2No ratings yet

- MotorShield BrochureDocument2 pagesMotorShield BrochuresalvorgNo ratings yet

- Reflective Wave Phenomena Defined Design Considerations For VFD Applications-2Document4 pagesReflective Wave Phenomena Defined Design Considerations For VFD Applications-2Asistencia Técnica JLFNo ratings yet

- BR20170505 Conext CL 60 String Inverter 1Document4 pagesBR20170505 Conext CL 60 String Inverter 1powerabsolut myanmarNo ratings yet

- Altivar 1260 Technical SpecsDocument16 pagesAltivar 1260 Technical SpecsneckitoNo ratings yet

- Applying DV/DT Fi Lters With Afds: Application Paper Ap043001EnDocument4 pagesApplying DV/DT Fi Lters With Afds: Application Paper Ap043001EnSuperhypoNo ratings yet

- BR20170406 Conext CL 60 String InverterDocument4 pagesBR20170406 Conext CL 60 String InverterAnonymous FaqNSHEtNo ratings yet

- Schneider Electric - Altivar-Process-ATV6000 - ATV6000M125A1111NA3Document5 pagesSchneider Electric - Altivar-Process-ATV6000 - ATV6000M125A1111NA3Shivam MoreNo ratings yet

- Capacitor - Data Sheet - CircutorDocument6 pagesCapacitor - Data Sheet - CircutorMd.SafwanNo ratings yet

- FN 5040 FN 5045Document8 pagesFN 5040 FN 5045Oscar SuarezNo ratings yet

- ATV23Document3 pagesATV23Vinny RathNo ratings yet

- 1-10-020-15 ThyristorDocument9 pages1-10-020-15 ThyristornishantpsbNo ratings yet

- Inverter SchneiderDocument2 pagesInverter SchneiderjuanNo ratings yet

- 500kVA K600C Rigsafe Diesel Generator Flyer PDFDocument2 pages500kVA K600C Rigsafe Diesel Generator Flyer PDFMd MkNo ratings yet

- Variable Frequency Drive : Ravikumar .M M.Tech 3 SEM C.A.I.DDocument22 pagesVariable Frequency Drive : Ravikumar .M M.Tech 3 SEM C.A.I.Davi013No ratings yet

- SMA Core1Document2 pagesSMA Core1Syed Umair AliNo ratings yet

- Altivar Process ATV600 - ATV630D37N4Document13 pagesAltivar Process ATV600 - ATV630D37N4Ichsan RosidinNo ratings yet

- Conext Core XC-NA Spec SheetDocument2 pagesConext Core XC-NA Spec Sheetbianca7sallesNo ratings yet

- Schneider Electric - Altivar-Process-ATV600 - ATV650D75N4Document15 pagesSchneider Electric - Altivar-Process-ATV600 - ATV650D75N4GabrielNo ratings yet

- Schneider Electric - Altivar-Process-ATV600 - ATV630D45N4Document16 pagesSchneider Electric - Altivar-Process-ATV600 - ATV630D45N4JohnNo ratings yet

- Altivar Process ATV900 - ATV9B0M12Q6Document4 pagesAltivar Process ATV900 - ATV9B0M12Q6SándorRónyaiNo ratings yet

- LoRes DKDDPFO615A202 Dudt Filter MCC102Document2 pagesLoRes DKDDPFO615A202 Dudt Filter MCC102nsmikleNo ratings yet

- Chloride CP 70z Ds en GL 0516 Rev7Document2 pagesChloride CP 70z Ds en GL 0516 Rev7arifirmansyahtingtingNo ratings yet

- Schaffner Datasheet FN5060HVDocument5 pagesSchaffner Datasheet FN5060HVRomy GeorgeNo ratings yet

- PowerFlex 6000Document20 pagesPowerFlex 6000Tien Tran Kha Tien100% (1)

- LC Sine Wave Filter Technical Specifications: SmisenDocument6 pagesLC Sine Wave Filter Technical Specifications: Smisenrajabharath12No ratings yet

- Schneider Conext CL E 20 25 Datasheet (20141002) - ENGDocument2 pagesSchneider Conext CL E 20 25 Datasheet (20141002) - ENGmidas33No ratings yet

- Altivar Process ATV600 - ATV630D75N4Document13 pagesAltivar Process ATV600 - ATV630D75N4Md. Morshed JahanNo ratings yet

- Altivar Process ATV600 - ATV630D75N4Document14 pagesAltivar Process ATV600 - ATV630D75N4kpeNo ratings yet

- SMA-Sunny Highpower Peak3Document2 pagesSMA-Sunny Highpower Peak3Omar ChaconNo ratings yet

- Chloride 80-NET: UPS CatalogueDocument36 pagesChloride 80-NET: UPS CataloguesaidazzNo ratings yet

- ST548KWH-250: Storage SystemDocument2 pagesST548KWH-250: Storage Systemsubkhan100% (1)

- Chloride 80-NET 60-500 KVA enDocument34 pagesChloride 80-NET 60-500 KVA enOmnhickNo ratings yet

- Sunny Highpower Peak3 125-Us / 150-UsDocument2 pagesSunny Highpower Peak3 125-Us / 150-UsGregorio VillarrealNo ratings yet

- Altivar Process ATV600 - ATV630D75N4ZDocument13 pagesAltivar Process ATV600 - ATV630D75N4ZPhaniNo ratings yet

- Stpcore1 Dus174016wDocument2 pagesStpcore1 Dus174016wMohamed MourtagaNo ratings yet

- AEG Protect8.33 InfoDocument4 pagesAEG Protect8.33 InfoAllan T.No ratings yet

- REFUstore 50K... 100K Datasheet EN V06 ScreenDocument6 pagesREFUstore 50K... 100K Datasheet EN V06 Screencmaftei.505No ratings yet

- Modular Inverter Datasheet Media TSI 48Vdc - 230vac - 1.5kVA EN v1.3Document2 pagesModular Inverter Datasheet Media TSI 48Vdc - 230vac - 1.5kVA EN v1.3Charmer JiaNo ratings yet

- CET Multidirectional Converter Datasheet Sierra 10-48-230 en v1.2Document2 pagesCET Multidirectional Converter Datasheet Sierra 10-48-230 en v1.2dfghjkNo ratings yet

- Altivar Process ATV900 - ATV930D75N4Document14 pagesAltivar Process ATV900 - ATV930D75N4alexis roblesNo ratings yet

- Columna de Burbujeos PDFDocument6 pagesColumna de Burbujeos PDFKarin ParraNo ratings yet

- LV Alternator (730kVA)Document12 pagesLV Alternator (730kVA)AfiqNo ratings yet

- Marathon MX-1030-4Document7 pagesMarathon MX-1030-4YuriyNo ratings yet

- P1000 Industrial Fan and Pump Drive: 240V Class: To 175 HP 480V Class: 1 To 1000 HP 600V Class: 1 To 250 HPDocument2 pagesP1000 Industrial Fan and Pump Drive: 240V Class: To 175 HP 480V Class: 1 To 1000 HP 600V Class: 1 To 250 HPlordsethdarknessNo ratings yet

- BrochureDocument11 pagesBrochureparthasarathipalNo ratings yet

- Datasheet - DeLTA Power System DPS 600B-48-2Document2 pagesDatasheet - DeLTA Power System DPS 600B-48-2Jose VazNo ratings yet

- MediaDocument20 pagesMediaKarthikeyan GuruNo ratings yet

- High Voltage Spike (DV - DT) and Motor Protection MethodsDocument5 pagesHigh Voltage Spike (DV - DT) and Motor Protection MethodsAnonymous V6y1QL6hnNo ratings yet

- 001 004 Rev 00Document11 pages001 004 Rev 00Muhammad Asif IqbalNo ratings yet

- EM-PME375-T200: Electric Machine, Permanent Magnet ExternalDocument5 pagesEM-PME375-T200: Electric Machine, Permanent Magnet ExternalÖzgür AkayNo ratings yet

- AQT 2500 EditDocument3 pagesAQT 2500 EditbassemNo ratings yet

- Gt3 Series On-Grid PV Inverter: Superior EfficiencyDocument2 pagesGt3 Series On-Grid PV Inverter: Superior EfficiencyJose Luis Diaz BolivarNo ratings yet

- FCP104N60 D-2312015Document11 pagesFCP104N60 D-2312015Electronica Analogica Y DigitalNo ratings yet

- Contax ContactorDocument4 pagesContax Contactorheri fauziNo ratings yet

- 01 Technical Specification For 160MVA 220 132 33KV Power TransformerDocument88 pages01 Technical Specification For 160MVA 220 132 33KV Power Transformerk. harikarasudhan33% (3)

- Altivar Process ATV600 - ATV630U15N4Document13 pagesAltivar Process ATV600 - ATV630U15N4muhamedNo ratings yet

- ULTRA-750/1100/1500 750kW To 1560kW: ABB Central InvertersDocument6 pagesULTRA-750/1100/1500 750kW To 1560kW: ABB Central InvertersInam MemonNo ratings yet

- Altivar Process ATV600 - ATV650U30N4Document11 pagesAltivar Process ATV600 - ATV650U30N4Hoà Đặng Lê NgọcNo ratings yet

- Model 351 High Frequency Pulse Generator: DescriptionDocument2 pagesModel 351 High Frequency Pulse Generator: DescriptioncavendiNo ratings yet

- HPS Express G - 2020pdfDocument13 pagesHPS Express G - 2020pdfstarmd3No ratings yet

- PREVENTA Machine Safety Products Catalogue 2014Document568 pagesPREVENTA Machine Safety Products Catalogue 2014Gustavo PérezNo ratings yet

- "Watts Current" Technical Bulletin ... Choosing The Right Ground Resistance Ester - Chauvin ArnouxDocument19 pages"Watts Current" Technical Bulletin ... Choosing The Right Ground Resistance Ester - Chauvin ArnouxGustavo PérezNo ratings yet

- HPS Sentinel Comparison Flyer (SENCOM)Document2 pagesHPS Sentinel Comparison Flyer (SENCOM)Gustavo PérezNo ratings yet

- HPS Full Load Dry-Type Transformer Current CardsDocument2 pagesHPS Full Load Dry-Type Transformer Current CardsGustavo PérezNo ratings yet

- Find Your Competitive AdvantageDocument12 pagesFind Your Competitive AdvantageGustavo PérezNo ratings yet

- Preventa XPS Universal XPSUAF13AP DatasheetDocument7 pagesPreventa XPS Universal XPSUAF13AP DatasheetGustavo PérezNo ratings yet

- Zelio Control Relays Probe RM79696043 DatasheetDocument1 pageZelio Control Relays Probe RM79696043 DatasheetGustavo PérezNo ratings yet

- Catalog Harmony Electromechanical Relays 2021Document45 pagesCatalog Harmony Electromechanical Relays 2021Gustavo PérezNo ratings yet

- Harmony Electromechanical Relays Catalog 2020Document45 pagesHarmony Electromechanical Relays Catalog 2020Gustavo PérezNo ratings yet

- Your ZELIO Relay Guide 2016Document6 pagesYour ZELIO Relay Guide 2016Gustavo PérezNo ratings yet

- Catalog Harmony Control Relays 2021Document72 pagesCatalog Harmony Control Relays 2021Gustavo PérezNo ratings yet

- Zelio Control Relays RM35LM33MW DatasheetDocument6 pagesZelio Control Relays RM35LM33MW DatasheetGustavo PérezNo ratings yet

- What Is The Power Consumption in PTC Probe Connected To LT3SMDocument1 pageWhat Is The Power Consumption in PTC Probe Connected To LT3SMGustavo PérezNo ratings yet

- Relevador SquareDocument5 pagesRelevador Squarejesus chumaceroNo ratings yet

- Protection of Solid State Relay Circuits... Fuse SelectionDocument4 pagesProtection of Solid State Relay Circuits... Fuse SelectionGustavo PérezNo ratings yet

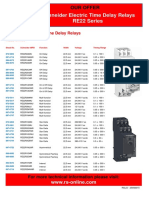

- RE22 Series Timing RelaysDocument1 pageRE22 Series Timing RelaysGustavo PérezNo ratings yet

- RE22R1AMR DatasheetDocument6 pagesRE22R1AMR DatasheetGustavo PérezNo ratings yet

- RE7RL13BU OFF DELAY Timing Relay DatasheetDocument7 pagesRE7RL13BU OFF DELAY Timing Relay DatasheetGustavo PérezNo ratings yet

- RM35BA10: Product Data SheetDocument7 pagesRM35BA10: Product Data SheetGustavo PérezNo ratings yet

- RE22R1KMR DatasheetDocument6 pagesRE22R1KMR DatasheetGustavo PérezNo ratings yet

- Analog Converter 0 - 5 A - RMCA61BDDocument5 pagesAnalog Converter 0 - 5 A - RMCA61BDGustavo PérezNo ratings yet

- How To Select A SSRDocument4 pagesHow To Select A SSRGustavo PérezNo ratings yet

- Radiador SSRHP07 DatasheetDocument2 pagesRadiador SSRHP07 DatasheetGustavo PérezNo ratings yet

- How To Select The Suitable HeatsinkDocument4 pagesHow To Select The Suitable HeatsinkGustavo PérezNo ratings yet

- SSP1A4125M7 DataSheetDocument2 pagesSSP1A4125M7 DataSheetGustavo PérezNo ratings yet

- RM79696043 Liquid Level Probe DatasheetDocument1 pageRM79696043 Liquid Level Probe DatasheetGustavo PérezNo ratings yet

- RSB Auxiliary RelaysDocument7 pagesRSB Auxiliary RelaysGustavo PérezNo ratings yet

- SSP1A475M7 DataSheetDocument4 pagesSSP1A475M7 DataSheetGustavo PérezNo ratings yet

- RM17UAS15 DatasheetDocument7 pagesRM17UAS15 DatasheetGustavo PérezNo ratings yet

- N 501Document47 pagesN 501cruzcelestinacecilia3No ratings yet

- D IODESDocument62 pagesD IODESCllyan Reyes0% (1)

- NR24A-SR Datasheet En-Gb PDFDocument3 pagesNR24A-SR Datasheet En-Gb PDFWagesusilo23121986_No ratings yet

- Job Sheet Resistance MeasurementDocument32 pagesJob Sheet Resistance MeasurementRonald Adi SaputraNo ratings yet

- Project: Place of InstallationDocument34 pagesProject: Place of InstallationDaniel MuratallaNo ratings yet

- SF6 Gas For 500kV CBDocument4 pagesSF6 Gas For 500kV CBJawad AmjadNo ratings yet

- Experiment - 4: © MEC, BikanerDocument5 pagesExperiment - 4: © MEC, Bikanersahumanish9240No ratings yet

- Pocket Book Complete WAPDADocument191 pagesPocket Book Complete WAPDAomerscheenNo ratings yet

- Magnetically Coupled CircuitsDocument10 pagesMagnetically Coupled CircuitsMohamed IsmailNo ratings yet

- Nvis6000 Electricity Lab KitDocument53 pagesNvis6000 Electricity Lab Kitbernardmwangi055No ratings yet

- Rectifier Diode Avalanche Diode PDFDocument1 pageRectifier Diode Avalanche Diode PDFIsrar Ul HaqNo ratings yet

- Hindle Group I Operating Manual (6 25 Adc)Document100 pagesHindle Group I Operating Manual (6 25 Adc)Rony NasrNo ratings yet

- Resumen C37 010 Aplicacion de Breaker Disenados IC Simetrica PDFDocument9 pagesResumen C37 010 Aplicacion de Breaker Disenados IC Simetrica PDFglendathais100% (1)

- Dm542 ManualDocument5 pagesDm542 ManualJulio RuizNo ratings yet

- Latch Up Failure in IGBTDocument3 pagesLatch Up Failure in IGBTgetssyNo ratings yet

- Ee 1403 - Design of Electrical ApparatusDocument9 pagesEe 1403 - Design of Electrical ApparatusskrtamilNo ratings yet

- EIM 6 Lesson 1Document19 pagesEIM 6 Lesson 1Victor Rosales100% (1)

- Piezo SwitchDocument11 pagesPiezo SwitchPedro GonzálezNo ratings yet

- Uni-Semi-U3115s C400130Document9 pagesUni-Semi-U3115s C400130Emanuel SantilloNo ratings yet

- Fastest Finger Press Quiz Buzzer: Block DiagramDocument1 pageFastest Finger Press Quiz Buzzer: Block DiagramShreerama Samartha G BhattaNo ratings yet

- DS 20220523 SG6600UD-MV 8800UD-MV Datasheet V13 ENDocument2 pagesDS 20220523 SG6600UD-MV 8800UD-MV Datasheet V13 ENRony ZeaNo ratings yet

- Disassembly & ReassemblyDocument4 pagesDisassembly & ReassemblyGilbertoAdonayGutierrezNo ratings yet

- Manufacturers of CTS, PTS, SMC LT DB, MS Sheet LT DB, Isolators, DO Fuse Set, AB Switch, Transmission Line Hardware Fittings, Control PanelsDocument13 pagesManufacturers of CTS, PTS, SMC LT DB, MS Sheet LT DB, Isolators, DO Fuse Set, AB Switch, Transmission Line Hardware Fittings, Control PanelsSharafatNo ratings yet

- Review of Sys GroundingDocument38 pagesReview of Sys GroundingChilamkurti Siva Sankara RaoNo ratings yet

- MC1 MC1: User / Installer ManualDocument18 pagesMC1 MC1: User / Installer ManualGaby TanyNo ratings yet

- Asynchronous and Synchronous Machines (EL-208) (IV SEM EL Session 2017-18) Tutorial Sheet 1 (Dated 08.01.2018) (3 Phase Induction MotorsDocument10 pagesAsynchronous and Synchronous Machines (EL-208) (IV SEM EL Session 2017-18) Tutorial Sheet 1 (Dated 08.01.2018) (3 Phase Induction MotorsKushagra BhatiaNo ratings yet

- Tbea Inverter Comissioning Check ListDocument3 pagesTbea Inverter Comissioning Check ListelxgiiuseppeNo ratings yet

- n07v K EngDocument1 pagen07v K EngJUANQUIREALNo ratings yet

- (Moulded Case Circuit Breaker) : Submitted by VIPIN KUMAR (1505220056)Document15 pages(Moulded Case Circuit Breaker) : Submitted by VIPIN KUMAR (1505220056)amit shukla100% (1)

- Altec 458ADocument4 pagesAltec 458AjoeeNo ratings yet