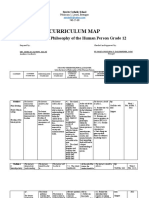

Professional Documents

Culture Documents

Heating Microscopy and Its Applications

Uploaded by

amannigam19940914Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Heating Microscopy and Its Applications

Uploaded by

amannigam19940914Copyright:

Available Formats

https://doi.org/10.

1017/S1551929510001185 Published online by Cambridge University Press

Heating Microscopy and its Applications

Chiara Venturelli

Expert System Solutions, Viale Virgilio 58/L, 41123 Modena, Italy

c.venturelli@expertsystemsolutions.it

Introduction kept at the desired temperature and, thanks to a motorized slit,

Heating microscopes were commercially introduced 60 in a few seconds the kiln moves over the sample, which is at

years ago, and they immediately gained an important role in room temperature.

material science and engineering thanks to their wide field Methods

of application [1]. Nowadays, these instruments are used in The Heating Microscope Misura HSM produced by

both industry and research in many sectors: traditional and Expert System Solutions (see Figure 1a) consists of three

advanced ceramic industries, the glass industry, power plants, principal units mounted on an optical bench: a halogen

the metallurgical sector, and, generally, in all fields where the lamp light source, an electric furnace (100 mm in length

melting behavior of materials has to be determined. Heating and 20 mm in diameter) with sample carriage, and an

microscopy techniques can be successfully applied to the

observation unit with microscope and recording facility.

direct characterization of glazes, glasses, frits, ashes, mold

The sample is placed on a small alumina plate at the end

powders for continuous casting, coals, slags, etc.—during a

of a thermocouple. Figure 1b represents a sample inside

heat treatment.

the kiln during a test. The microscope projects the image

A full understanding of the physical–chemical behaviors

of the sample situated in the furnace at ~5× magnification

of these materials is often out of reach because of their

through a quartz window and onto the recording camera

complexity. To cite an example, a ceramic glaze may contain

more than 20 chemical elements. This makes it almost [2]. This instrument is able to acquire images of a specimen

impossible to obtain meaningful results ab initio, that is, subjected to a heating cycle, at predetermined time or

beginning from the fundamental properties of the single temperature intervals, while all the dimensional parameters

components forming the material, especially when new phases (height, length, etc.) are measured automatically during the

develop during the process. Experimental methods prove to be test, in order to identify and measure certain characteristic

most effective for the study of the behavior of these materials parameters of the material.

during firing, allowing a good comprehension of behavior in The system software automatically analyzes the sample

an actual industrial firing cycle, thanks to direct observation images acquired during the test. Thanks to calculations using

of the sample. geometric parameters based on the shape of the test piece

When heating microscopes first appeared, manual analysis (height, width, contact angle), it is able to determine the

was extremely laborious and was often limited to recording characteristic points of the material. All such data are available

the “softening temperature,” and, in any case, they gave very in graphic form immediately after the test.

subjective measurements. Furthermore, with the old manual The most important features of this analytical technique

heating microscopes it was not possible to reach high heating are the capacity to follow the behavior of materials at the same

rates. The new generation models are completely automatic temperature gradient, as well as in the industrial kiln, without

and can simulate industrial heat treatments up to 1600°C, entering and having to contact the sample. The use of small

with heating rates as high as 80°C/min or even “flash” heating. samples allows very high heating rates and ensures a homoge-

“Flash” or instantaneous heating means that the kiln is always neous heating of the specimen.

Figure 1: (a) The heating microscope Misura® HSM, and (b) the sample inside the furnace.

20 doi:10.1017/S1551929510001185 www.microscopy-today.com • 2011 January

https://doi.org/10.1017/S1551929510001185 Published online by Cambridge University Press

https://doi.org/10.1017/S1551929510001185 Published online by Cambridge University Press

Heating Microscopy

Results • Deformation temperature: the first sign of ash deforma-

Analysis of fuel ash samples according to DIN 51730. tion (rounding of the edges, start of swelling)

The definition of characteristic parameters identifiable with • Sphere temperature: the edges of the sample become

the heating microscope is contained in the German rule DIN completely round, with H=W

51730, referring to a specific ash fusibility test of fuel. This test is • Hemisphere temperature: the sample is approximately

important in power plants because the maximum temperature hemispherical, with W=2H

of the combustion chamber must be regulated to be always lower • Flow temperature: the sample has spread out such that its

than the softening temperature of ash. If the temperature is too height is one-third that of the hemisphere temperature.

high, ash will start to melt and stick on the walls of the chamber, With the addition of some water drops for increasing the

damaging the burner. This rule was published for the first time plasticity, the ground ash was pressed with a manual press to

in 1954, and it is widely used [1]. The specified specimen shapes obtain a cylinder 3 mm high and 3 mm in diameter, which is

are: cylinder 3 mm high and 3 mm in diameter; cube with an then placed on an alumina plate. Data acquisition intervals are

edge length of 3 mm, or truncated cone. Equivalent American temperature-based, every 5°C. The results are shown in Figure 3,

rules ASTM D 1857 and the International Standard ISO 540 where the dimensional variations of the specimen are expressed

are additional common norms for ash and use test pieces with as a percentage with respect to its initial size (taken as 100%)

sharp edges to facilitate the typical shapes observed (generally and reported as a function of the temperature. The deformation

pyramidal shapes with height up to 19 mm or cubic samples point is identified as the onset of swelling. During the test the

up to 7 mm on a side). The heating microscope Misura ash sample, in fact, develops a non-negligible quantity of gas.

HSM is designed to respect all Analysis of glazes, glasses, and frits. In the ceramic

these international standard sector, heating microscope testing has never been ruled by a

test methods for the determi- specific law, even though since the first years of its introduction

nation of ash melting behavior. on the market, a standard analysis method has been sought [1].

Here, the melting behavior The aim of the study of Paganelli in 1997 [3] was understand-

of fuel ash is studied with the ing if the common practice of running laboratory tests with

heating microscope Misura 3-mm high, 2-mm diameter samples at 50°C/min can provide

Figure 2: Cylindrical specimen

HSM, using the DIN 51730 valuable information about the behavior of the samples in

(3 mm high, 3 mm in diameter) standard. Referring to this industrial firing conditions. All tests were performed using

used for the determination of ash standard and Figure 2, it is the heating microscope MISURA HSM. Paganelli found

melting behavior according to the

possible to define the following that the test method is quite reliable because it gives results

German standard DIN 51730.

characteristic temperatures: within a very narrow range, even comparing industrial firing

cycles with a typical labora-

tory cycle at a constant heat-

ing rate. The sample size

was developed considering

the balance between gravita-

tional, viscous, and surface

tension forces acting on the

glaze during the melting

process.

The cylindrical sample

was chosen because this is

the only shape that enables

the microscope to focus on

a plane that does not change

during the shape transfor-

mations induced by heating.

The use of prismatic samples

should be avoided because

they require continuous

changes of the focus.

The characteristic points

typical of glasses, glazes,

and frits identifiable with

the heating microscope are

defined in Table 1. Figure 4

shows the comparison be-

tween the curves obtained

Figure 3: Heating microscope data curve obtained for a fuel ash sample. Characteristic points are identified according to

DIN 51730.

for two different ceramic frits

subjected to a heating rate of

22 www.microscopy-today.com • 2011 January

https://doi.org/10.1017/S1551929510001185 Published online by Cambridge University Press

Heating Microscopy

Table 1: Definition of characteristic points for glasses, glazes, and frits identifiable with the heating microscope Misura HSM.

Onset of data acquisition:

The image analyzer automatically takes as 100% the height of the sample, measured considering

the sample holder (alumina support) as a base reference.

Sintering:

As the temperature increases, the viscous flow activation threshold is overcome and the material

undergoes the sintering phase: the sample decreases in size, but its shape does not substantially

change. In the case of glasses, glazes, and frits, the driving force of the sintering process is the

surface tension of the vitreous phases. The sintering phase ends when the sample reaches its

maximum density. The sintering temperature identified by the instrument is the temperature at

which the sample has reached a dimensional variation corresponding to the 5% with respect to

the first image acquired, which is taken to be 100%.

Softening:

The softening point is reached when liquid phases appear on the surface of the sample. From this

point on, the shape of the sample undergoes substantial changes caused by the surface tension of

the liquid phases. To find this point, the rounding of the corners of the sample and the smoothing

of the upper part of the walls of the sample are taken into consideration.

Sphere:

At the sphere temperature the sample is formed almost entirely of liquid phases, and the shape

of the sample is controlled by the surface tension. While the surface tension tends to reduce the

surface to a minimum forming a sphere, the hydrostatic pressure related to the density of the

liquid phase tends to flatten the shape. Some glasses do not reach the sphere point: for example,

glasses with a high density and a low surface tension (lead silicates).

In detecting the sphere temperature, every image analyzed is compared with a theoretical

sphere.

Half Sphere:

The half sphere temperature is reached when the height of the sample is half the width of the base.

If the glass behaves normally, at the half sphere temperature the contact angle is approximately

90°. However, at this temperature the contact angle is often much higher, and in some cases the

shape of the sample can resemble a bell. These anomalies can be attributed to the formation of

non-homogenous phases inside the sample, such as crystallization or glass-glass separations.

Melting:

When the height of the sample shrinks to under a third of the base, it is assumed that the sample

has completely liquified and has reached the melting point.

50°C/min. The cylindrical samples (3 mm high and 2 mm in the curve. The sample dimensions remain constant for a

diameter) were obtained pressing the powders with a manual certain temperature interval (770–840°C) even if the sample

press into a cavity of suitable dimensions with some water. continues to be heated. As the temperature increases further,

Glassy frit (Figure 4, black curve): Between 650 and the surface tension does not vary much, but the viscosity of

750°C, the first shrinkage in the sample occurs. This is the glassy phase decreases exponentially. When the viscosity

the sintering phase, during which the sample dimensions reaches a sufficiently low value to allow the glassy phases to

decrease, but the specimen shape remains unchanged. As the wet the external surface of the specimen, the material is at the

maximum density is achieved, the sintering process cannot softening point (840°C). Beyond this point the glass begins

proceed anymore and this causes a “sintering plateau” on to behave as a liquid, and the surface tension decreases the

2011 January • www.microscopy-today.com 23

https://doi.org/10.1017/S1551929510001185 Published online by Cambridge University Press

Heating Microscopy

not change dimension between

950°C and 1250°C). This means

that crystallization is taking

place inside the material. As the

temperature increases (between

1230°C and 1300°C), the material

does not behave like a glass (does

not exhibit spherical shapes) but

melts with the typical behavior of

a crystalline material.

Analysis of ceramic mold

powders for continuous casting.

The application of different heating

rates (30°C/min, 80°C/min, “flash”

heating) causes different effects on

the melting behavior of a material.

The example in Figure 5 shows this

phenomenon for the case of mold

powders for continuous casting.

Mold powders, initially fly ash

based, were introduced about 40

years ago in the steel continuous

casting process. Today synthetic

powders consisting of mixtures

Figure 4: Comparison of data curves for two different ceramic frits: glassy frit (black curve) and crystallizing frit

(red curve). of various minerals are also

used. Considering the chemical

composition, the powders are

made up of complex mixtures of

carbon, some oxides (SiO2 , Al 2O3,

Na 2O, CaO) and other materials.

The aims of the powders, when

added to the free surface of the

liquid steel in the mold, can be

summarized as follows: (a) thermal

isolation of the steel surface, in

order to prevent its solidification;

(b) protection of the steel surface

from the oxidation; (c) lubrica-

tion and heat transfer control

between the mold wall and the

solid steel shell; and (d) absorption

of non-metallic inclusions coming

from the steel [4].

When a low heating rate

(30°C/min) is applied, a horizontal

plateau is observed between 1000

and 1100°C. During this period,

specimen dimensions remain

constant as the temperature varies.

This indicates that a crystallization

Figure 5: Curves obtained for a sample of mold powders for continuous metal casting applying different heating process is occurring inside the

rates. material, which is transforming.

The melting temperature of this

surface area to a minimum, causing the formation of a sphere. specimen was identified as 1150°C. The same powder melts

The specimen shape rapidly becomes spherical (920°C) and at a lower temperature when a higher heating rate is applied.

then hemispherical (1005°C). Finally, the melting point is This is because the elements that constitute the material do

reached at 1095°C. not have sufficient time to react to compounds with higher

Crystallizing frit (Figure 4, red curve): After the sintering melting temperatures. The “flash” or instantaneous heating is

phase, this curve shows a long plateau. (The sample does the heating rate that best reproduces the thermal stresses that

24 www.microscopy-today.com • 2011 January

https://doi.org/10.1017/S1551929510001185 Published online by Cambridge University Press

Heating Microscopy

actually occur in a mold. The melting temperature obtained

for a material heated under industrial conditions may be

different from the results obtained in a laboratory because the

heating rates are likely to be lower in the latter.

Conclusions

Automatic image analysis provided by the heating

microscope Misura HSM allows an accurate measurement

of the thermal behavior of ceramics and glasses during

heating. This microscope also allows the possibility of applying

instantaneous heating to better simulate certain industrial

conditions. This new generation of microscopes continues to

represent one of the most effective and helpful tools for charac-

terizing thermally induced shape changes.

References

[1] Anonymous, International Ceramic Journal 1 (2002)

61–62.

[2] M Paganelli and D Sighinolfi, Ceramic Forum

International (Berichte der Deutschen Keramischen

Gesellshaft) 86 (5) (2009) E18–E21.

[3] M Paganelli, Industrial Ceramics 17(2) (1997)

69–73.

[4] KC Mills: “Chapter 8: Mold powders for continuous

casting,” in The Making, Shaping and Treating of Steel,

11th ed., Casting Volume, AISE Steel Foundation,

Pittsburgh, 2003.

2011 January • www.microscopy-today.com 25

You might also like

- 16MnCr5 PropertyDocument7 pages16MnCr5 PropertyGuru SamyNo ratings yet

- Aec3414 Philosophy FinalDocument5 pagesAec3414 Philosophy Finalapi-532996380No ratings yet

- Mold Powders Continuous CastingDocument6 pagesMold Powders Continuous CastingJose Marval RodriguezNo ratings yet

- Interpretation of DSC Curves in Polymer Analysis 2000 - ToledoDocument0 pagesInterpretation of DSC Curves in Polymer Analysis 2000 - ToledoyrecoverNo ratings yet

- Thermal Conductivity Measurements On Challenging Samples by The 3 Omega MethodDocument6 pagesThermal Conductivity Measurements On Challenging Samples by The 3 Omega MethodTriều Huỳnh NhậtNo ratings yet

- Silicon Hotplates For Metal Oxide Gas Sensor ElementsDocument8 pagesSilicon Hotplates For Metal Oxide Gas Sensor ElementsshobiiiscNo ratings yet

- Control Continuous Annealing Copper Strips ModellingDocument18 pagesControl Continuous Annealing Copper Strips ModellingKUNAL GUPTANo ratings yet

- 2022 BSE Fire Lab NotesDocument7 pages2022 BSE Fire Lab NotesTsz Sang IpNo ratings yet

- 81 - Comparative Analysis of Different Methods - F.asbdrubali 2010Document5 pages81 - Comparative Analysis of Different Methods - F.asbdrubali 2010libecen289No ratings yet

- Experiment B Temperature Measurement and Control: ObjectivesDocument11 pagesExperiment B Temperature Measurement and Control: ObjectivesVishalNo ratings yet

- ExperimentDocument9 pagesExperimentshaina.planco4No ratings yet

- Calorimeter in The Cement IndustryDocument5 pagesCalorimeter in The Cement IndustryDavid SimanungkalitNo ratings yet

- Introduction To Valve TraysDocument7 pagesIntroduction To Valve TraysJoel OkohNo ratings yet

- Drying Stages During The Heating of High-Alumina, Ultra-Low-Cement Refractory CastablesDocument4 pagesDrying Stages During The Heating of High-Alumina, Ultra-Low-Cement Refractory CastablesAnthony MarasiganNo ratings yet

- Transient Heat Transfer Analysis of Induction Furnace by Using Finite Element AnalysisDocument5 pagesTransient Heat Transfer Analysis of Induction Furnace by Using Finite Element AnalysisMilion dugumaNo ratings yet

- Martínez Martínez 2010b InTechDocument17 pagesMartínez Martínez 2010b InTechJohanNo ratings yet

- Article 3 2004 WeigleDocument8 pagesArticle 3 2004 Weigleuamiranda3518No ratings yet

- Assessment of The Thermal Performance of Plastering Mortars Within Controlled Test CellsDocument10 pagesAssessment of The Thermal Performance of Plastering Mortars Within Controlled Test CellsToàn nguyễn HữuNo ratings yet

- Noriega 2015 J. Phys.: Conf. Ser. 582 012029Document7 pagesNoriega 2015 J. Phys.: Conf. Ser. 582 012029Anonymous GUitcVONo ratings yet

- BF 02428171Document7 pagesBF 0242817120201056No ratings yet

- Paper Finale Asdrubali Et AlDocument5 pagesPaper Finale Asdrubali Et AlAlyNo ratings yet

- Microwave Sintering of Hydroxyapatite Ceramics PDFDocument8 pagesMicrowave Sintering of Hydroxyapatite Ceramics PDFfishvalNo ratings yet

- ++onlinemonitoringofwaxdepositioninsub Seapipelines Published 2011 05 22v2Document14 pages++onlinemonitoringofwaxdepositioninsub Seapipelines Published 2011 05 22v2Sahin İmanovNo ratings yet

- Experimental Study AND Numerical Simulation OF Preform Infrared Radiative HeatingDocument8 pagesExperimental Study AND Numerical Simulation OF Preform Infrared Radiative HeatingRafael Calle Napoleon LuisNo ratings yet

- Extruder Melt Temperature Control With F PDFDocument6 pagesExtruder Melt Temperature Control With F PDFAutogreder100% (1)

- Simulation of The Firebox ofDocument6 pagesSimulation of The Firebox ofAli DarvishiNo ratings yet

- Effect of Post-Mold Curing On Package Reliability: Anfred EngelDocument11 pagesEffect of Post-Mold Curing On Package Reliability: Anfred EngelGoh Kae HorngNo ratings yet

- Practical 18,19,20Document9 pagesPractical 18,19,20Muhammad AwaisNo ratings yet

- Rotary Cement Kiln Coating Estimator: Integrated Modelling of Kiln With Shell Temperature MeasurementDocument10 pagesRotary Cement Kiln Coating Estimator: Integrated Modelling of Kiln With Shell Temperature MeasurementDiego MorenoNo ratings yet

- Engineers Handbook of Industrial Microwave Heating Industrial Microwave Oven Manufacturers Large Microwaves PDFDocument9 pagesEngineers Handbook of Industrial Microwave Heating Industrial Microwave Oven Manufacturers Large Microwaves PDFMustafa Demircioğlu100% (1)

- Grain Growth in Millimeter Wave Sintered Alumina Ceramics: S. Mitsudo, S. Inagaki, I.N. Sudiana, K. KuwayamaDocument4 pagesGrain Growth in Millimeter Wave Sintered Alumina Ceramics: S. Mitsudo, S. Inagaki, I.N. Sudiana, K. KuwayamaGusti EricsandraNo ratings yet

- Thermal Conductivity of Aloji Fireclay As Refractory MaterialDocument5 pagesThermal Conductivity of Aloji Fireclay As Refractory MaterialArief M FirdausNo ratings yet

- Review Paper On Numerical Analysis of Induction Furnace: Nihar BaraDocument7 pagesReview Paper On Numerical Analysis of Induction Furnace: Nihar BaraUma KoduriNo ratings yet

- Rotary Cement Kiln Coating Estimator: Integrated Modelling of Kiln With Shell Temperature MeasurementDocument10 pagesRotary Cement Kiln Coating Estimator: Integrated Modelling of Kiln With Shell Temperature MeasurementJenkeiz KhanNo ratings yet

- Swimmetal Int JThermophysics VIGDocument16 pagesSwimmetal Int JThermophysics VIGsalihguvensoy1No ratings yet

- Heat Treat and Creep of Ni Super AlloyDocument6 pagesHeat Treat and Creep of Ni Super AlloyHarish KPNo ratings yet

- Remnant Life Assessment of Platformer Heater T9 Tubes Using Api 579 Omega MethodDocument9 pagesRemnant Life Assessment of Platformer Heater T9 Tubes Using Api 579 Omega Methodsanu patilNo ratings yet

- Twtmeasurement Bestpractices 131212155525 Phpapp01 PDFDocument10 pagesTwtmeasurement Bestpractices 131212155525 Phpapp01 PDFwasayNo ratings yet

- Adiabatic and Semi-Adiabatic Calorimetry ToDocument14 pagesAdiabatic and Semi-Adiabatic Calorimetry TopedroNo ratings yet

- EPA 1030 Ignitability of SolidsDocument13 pagesEPA 1030 Ignitability of SolidsdcardonasterNo ratings yet

- 2013 Jaunich Raw Mat and Appl Low Temperature Properties of Rubber SealsDocument6 pages2013 Jaunich Raw Mat and Appl Low Temperature Properties of Rubber SealslienhartviktorNo ratings yet

- Experimental and Theoretical Study of Pool BoilingDocument11 pagesExperimental and Theoretical Study of Pool Boilingvaibhav pawarNo ratings yet

- Construction and Building Materials: S. Djaknoun, E. Ouedraogo, A. Ahmed BenyahiaDocument11 pagesConstruction and Building Materials: S. Djaknoun, E. Ouedraogo, A. Ahmed BenyahiaEhasanul HaqueNo ratings yet

- Highly Preheated Air Combustion Research in Sweden: Blasiak W, Dong W, Lille SDocument18 pagesHighly Preheated Air Combustion Research in Sweden: Blasiak W, Dong W, Lille SSaptarshi SenguptaNo ratings yet

- Review On Thermomechanical Anlysis of Nano Composites: Y.Sowjany A, V.Jayaprasa D, K.Dileep Kuma R, N.Mohanra oDocument6 pagesReview On Thermomechanical Anlysis of Nano Composites: Y.Sowjany A, V.Jayaprasa D, K.Dileep Kuma R, N.Mohanra olydiaNo ratings yet

- Optimization of A Pusher Type Reheating Furnace: An Adaptive Model Predictive Control ApproachDocument6 pagesOptimization of A Pusher Type Reheating Furnace: An Adaptive Model Predictive Control ApproachNoman AliNo ratings yet

- Extension and Optimization of A Three-Layer Method For The Estimation of Thermal Conductivity of Super-Insulating MaterialsDocument10 pagesExtension and Optimization of A Three-Layer Method For The Estimation of Thermal Conductivity of Super-Insulating MaterialsSalifou GarbaNo ratings yet

- Numerical Simulation of The Flow Streams Behavior in A Self-Regenerative Crucible FurnaceDocument7 pagesNumerical Simulation of The Flow Streams Behavior in A Self-Regenerative Crucible FurnaceperulesNo ratings yet

- Validating Numerical Calculations Against Guarded Hot Box MeasurementsDocument9 pagesValidating Numerical Calculations Against Guarded Hot Box MeasurementsJayaminNo ratings yet

- Heat Transfer Enhancement Using Nanoparticles (Al2o3)Document6 pagesHeat Transfer Enhancement Using Nanoparticles (Al2o3)IJRASETPublicationsNo ratings yet

- Investigation of Process Affected ZoneDocument9 pagesInvestigation of Process Affected Zonetawsif mahmoodNo ratings yet

- Geaman V - 09Document4 pagesGeaman V - 09Bala SubramanianNo ratings yet

- Innovative Instrumentation and Analysis of The Temperature Measurement For High Temperature GasificationDocument41 pagesInnovative Instrumentation and Analysis of The Temperature Measurement For High Temperature GasificationMohammed Al-MislimmawwyNo ratings yet

- Icsoba-45, 391-400, 2016Document10 pagesIcsoba-45, 391-400, 2016Debashis DashNo ratings yet

- Oxidation Mass Loss of Manufactured Carbon and Graphite Materials in AirDocument4 pagesOxidation Mass Loss of Manufactured Carbon and Graphite Materials in AirMuhannad NasifNo ratings yet

- An Experimental Technique For The Measurement of Temperature Fields For The Orthogonal Cutting in High Speed MachiningDocument9 pagesAn Experimental Technique For The Measurement of Temperature Fields For The Orthogonal Cutting in High Speed MachiningTEJ SAKPALNo ratings yet

- Fire Safety Journal: Giovanni Muciaccia, Luigi BiolziDocument11 pagesFire Safety Journal: Giovanni Muciaccia, Luigi BiolziMatheus CiveiraNo ratings yet

- Report Proposal (Oven)Document12 pagesReport Proposal (Oven)Victor NudanuNo ratings yet

- Kobayashi 2002Document13 pagesKobayashi 2002Abdulaziz Ali M AlahmadiNo ratings yet

- Cellular and Porous Materials: Thermal Properties Simulation and PredictionFrom EverandCellular and Porous Materials: Thermal Properties Simulation and PredictionNo ratings yet

- Flow, Mixing and Heat Transfer in Furnaces: The Science & Applications of Heat and Mass Transfer Reports, Reviews & Computer ProgramsFrom EverandFlow, Mixing and Heat Transfer in Furnaces: The Science & Applications of Heat and Mass Transfer Reports, Reviews & Computer ProgramsK. H. KhalilNo ratings yet

- GGFHJDocument1 pageGGFHJanon_791172439No ratings yet

- Exceptions and Limitation of Patent Rights and Its Enforcement in IndiaDocument8 pagesExceptions and Limitation of Patent Rights and Its Enforcement in IndiaVyas NikhilNo ratings yet

- Microsoft Excel - Class 1Document12 pagesMicrosoft Excel - Class 1Carllouie De LaraNo ratings yet

- Principles of PaleontologyDocument10 pagesPrinciples of Paleontologyvitrinite50% (2)

- SMPS FundamentalsDocument53 pagesSMPS FundamentalsRahul Gupta100% (2)

- List of Engineering Colleges in PakistanDocument7 pagesList of Engineering Colleges in PakistanFahad Bin ImtiazNo ratings yet

- To FrameDocument5 pagesTo FrameMuhaimin RohizanNo ratings yet

- Gas Cutting - by KiranDocument40 pagesGas Cutting - by KiransridharchebroluNo ratings yet

- Curriculum Map in Introduction To The World ReligionDocument7 pagesCurriculum Map in Introduction To The World ReligionRaizza Vanizza SiguenzaNo ratings yet

- Stuart Hall - Who Dares, FailsDocument3 pagesStuart Hall - Who Dares, FailsdNo ratings yet

- Valtra A114 HitechDocument31 pagesValtra A114 Hitechhicev32274No ratings yet

- Qualities of A Good PresenterDocument2 pagesQualities of A Good PresenterMuhammad Umair KhanNo ratings yet

- System: Priscila Leal, Graham V. CrookesDocument11 pagesSystem: Priscila Leal, Graham V. CrookesShaimoz Ithe WatuirituNo ratings yet

- CIRPs Ending in Resolution - 30sept 2022Document10 pagesCIRPs Ending in Resolution - 30sept 2022dip downNo ratings yet

- 7.0 Overview of Vibrational Structural Health Monitoring With Representative Case StudiesDocument9 pages7.0 Overview of Vibrational Structural Health Monitoring With Representative Case Studiesankurshah1986No ratings yet

- May DAY EVE LessonsDocument4 pagesMay DAY EVE LessonsFerdinand Pinon100% (1)

- Remote Sensing GeologyDocument438 pagesRemote Sensing GeologyStalin Bryan100% (2)

- Shaker SK L180 SDocument1 pageShaker SK L180 SUPT LABKESDA KAB PADANG PARIAMANNo ratings yet

- The Good Governance Concept Revisited PDFDocument16 pagesThe Good Governance Concept Revisited PDFPritam AnantaNo ratings yet

- Prosperity Power Signature PDFDocument31 pagesProsperity Power Signature PDFOscar NygrenNo ratings yet

- Ground Effect Aerodynamics PDFDocument12 pagesGround Effect Aerodynamics PDFChegrani Ahmed100% (1)

- The Problem of Authenticity or External CriticismDocument30 pagesThe Problem of Authenticity or External CriticismKen StarNo ratings yet

- BiometricsDocument10 pagesBiometricsKrishna Murthy PNo ratings yet

- Practical Questions BookletDocument37 pagesPractical Questions BookletPrecious ChirangareNo ratings yet

- Reference Manual - Model 6487 Picoammeter/Voltage SourceDocument338 pagesReference Manual - Model 6487 Picoammeter/Voltage SourceRanilson AngeloNo ratings yet

- FINALby REDAZADocument3 pagesFINALby REDAZANoreen RedazaNo ratings yet

- Kidstone Mines Start UpDocument5 pagesKidstone Mines Start UpCraftychemistNo ratings yet

- Course Policy Che 406 S2020Document2 pagesCourse Policy Che 406 S2020Ahmad IjazNo ratings yet

- Heat Transfer EquipmentDocument28 pagesHeat Transfer Equipmentdeepak.dce.meNo ratings yet