Professional Documents

Culture Documents

Caterham Buildpage

Uploaded by

rat_520Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Caterham Buildpage

Uploaded by

rat_520Copyright:

Available Formats

Caterham 7 Gearbox Upgrade - Ford T9 to BGH-E7

Gear ratio's in the Type 9 Ford Sierra gearbox are good, except for 1st gear. The 3.36 ratio is designed to work with the much heavier Ford

Sierra car and is unsuitable for a Seven: With engines with > 110..120ftlbs of torque, it's difficult to take off without spinning the wheels.

Second, the 1st to 2nd gap is too large, which with a tuned engine causes it to drop off the cam. BGH transmission specialists, but also

Quaife offer alternate ratio's for this Ford Type 9 box. Regarding horsepower, torque and rpm capacity of the T9.. it's fine up to

Main Page 160..180ftlbs, and a taller 1st gear (lower ratio), will reduce internal stresses as well as the load on the differential. Lubrication is a critical

point and Brian Hill and team have developed several modifications to improve this. At a minimum I'd suggest to switch to Redline MTL,

which I've used now for some time with great result - great synchromesh action (no more 2-3 crunching during track days).

What's a Seven? Brian Hill's recommended E7 set includes a layshaft with a different input gear. This changes all the gears on the layshaft (not 4th) and in

order to get practical ratio's both 1st and 5th on the output shaft are also changed to suit. 1st is intended to get to the 2.75 ratio, whereas 5th

Driving is intended to return to a ratio close to .85. If not, the resultant 5th would be .79, which is too tall for track work, but could be fine for long

trips.

Build page story

Build page pics For my own car, the motivation for changing ratio's became clear when I put the 200HP Zetec in. Also, during spirited driving and track day

running, 3rd gear shifts had become a bit crunchy, indicating wear on the 3rd gear baulk ring. These reasons provided ample justification to

Zetec vs. X-Flow go ahead and open that gearbox!

Conversion to Zetec September 2005, my wife and I made a sightseeing tour to England and Scotland, starting from Gatwick. I had spoken with the BGH team

before over the phone, but Wisconsin is just too far away, so I concluded an in-person visit would be better and if anything more

Maintenance Log entertaining. Hence the first stop on our tour was BGH Geartech in Cranbrook, Kent. The country side in South Eastern England is always

one of our favorite areas for touring and we somehow have always been lucky with the weather there, at least this is how I sold it to my

USA7-777 wife, who's a very good sport! The roads themselves are absolutely fantastic. We had rented a Ford Focus, but I kept thinking 7...

Gallery

Brian's shop is composed of several workspaces. Suspended off the ceiling of one of these, is the original prototype of the 6 speed

Anecdotes Caterham gearbox, that he developed for them. During the tour through Brian's shop it became clear that his team can do anything with

gears, from specifying and cutting special profiles to creating custom solutions. Their world wide reputation as gearbox experts is very

Registration much justified!

Books Andy, one of the BGH team members was kind enough to walk me through the disassembly process. For my own reference, I video taped

the dismantling of a T9 box, which took him only 20 minutes, pointing out potential pitfalls. There are some differences between the older

Links and newer Type 9 gearboxes, that require some attention, such as the layshaft stub shaft, vs. the full countershaft that is deployed in the

older boxes. The shifter mechanism (half of which is housed in the tail), is different as well. E.g. there is no pin / spring under the 5th gear

e-Mail shifter location cover.

Later, back in Wisconsin when I disassembled my own box, I first thought this pin was missing, but it's absence it's one of those remnants

of the earlier design.

We left BGH with a suit case full of parts, rings, layshaft, bearings etc. The return trip back to the US was interesting to say the least. We

should have flown non-stop, but either way, the stop over in Philly was "special". One of the guards freaked out upon seeing the layshaft in

my hand luggage. I had kept it there as I was concerned it'd work it's way through a checked suitcase, just because of it's mass. So, she was

prancing it around claiming it to be a "blungeoning tool"... good grief... fortunately one of her more sane colleges was a carguy and

recognized that it wasn't. An hour later we were let go with our stuff, but the delay forced us to take another flight to make it back to

Wisconsin. The following week I started the swap, as the driving season was getting short and I wanted to at least experience the improved

ratio's before parking it for the annual "Wisconsin ice-season".

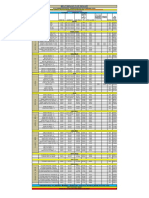

Gear ratio's 1st 2nd 3rd 4th 5th General notes on the Type 9:

Standard 3 shaft design, with an input (clutch) shaft containing the

common or input gear.

Standard Layshaft with the matching input counter gear and 3rd, 2nd, reverse 1st

range = 4.07 : 1 3.36 1.81 1.26 1.00 .825 and 5th

Output or mainshaft with 3rd, 2nd, Reverse, 1st and 5th gear. The end

of this shaft spins in a needle bearing in the input shaft. The other side is

supported by a bearing in a sandwich plate , between the main case and

Modified (E7)

the tail housing, and at the far end by a sleeve bearing that is formed by

range = 3.23 : 1 2.75 1.75 1.21 1.00 .85

the outer surface of the drive shaft that is spline fitted onto the mainshaft.

Note: in this design, when the clutch is engaged, even in neutral, all gears are

rotating. However, when (lift front) towing this car, no gears are rotating, i.e. no

lubrication, but the output shaft will be rotating inside the stationary gears (1,2,3 & 5)

and the pilot inside the input shaft.

Not recommended for long distance lift-front towing.

Lia's relaxing at a road stop in Kent, September 2005. Back home in Wisconsin, it's winter and Tail housing off, showing on the mainshaft

but... we both went to BGH! Brian Hill and the 6speed March '06 and at last it's time to take from L to R : 4-3 gears / shift-selector main /

gearbox Caterham prototype the box out of the car 2-1 gears / bearings in sandwhich plate /

5th gear / shift selector secondary

T9 (Scorpio) Gearbox disassembly and re-assembly

As mentioned above, the 3.36:1 1st gear ratio replacement was something I had been wanting to do for a long time, esp. because of the 2.0ltr Zetec's torque.

As far as a do-it-at-home project, this is quite doable without major tools. Some key items you'll need are a clean place to work (I use a small wooden

platform on wheels), and lots of trays for parts. Be careful of the sychromesh assemblies and keep them "in-tact" if you can. If the springs and keys do come

out, clean and dry your hands otherwise on reinsertion the keys may fly all over the place. Note they are gear specific.You will be greatly helped by having an

air compressor and airwrench - 70..80psi / 1/2". Get the best snap ring tool(s) you can get, the box is designed around these, inside, outside, eyed, they are all

there and there are many of them.

For the friction fitted speedo gear removal, you'll need to modify a standard

gear puller with some extensions - I used four strips to extend the puller arms.

Make sure to note the exact gear location, as it's a friction fit, and it needs to go

back exactly where you found it.

To get the bearing / sandwhich plate to come off, after removing the snapring

(!), you will need two fabricated 3/16" rods, shaped as shown. Flatten the ends

like blades as shown, as well as the small Z-bends. Dimensions are about 8..9 inches per side.

To replace the Torrington bearing (layshaft / output side), the outer ring just slips off, once the large nut has

been removed from 5th gear. Engage 2 & 3th gear or 1st and 3rd and use a 1/2" air wrench for this, 70..80psi. Then a heavy duty puller will be needed to get

5th gear to come off. I used a little stub (see pic) under the puller to insert into the hollow layshaft with .780" diameter on the small end, but a 3/4" socket

extension will work as well. Remove the synchromesh before removing the 5th gear nut to avoid damage to the synchro. The 5th gear nut requires a 12pt

socket. The gear will likely have hammered in a bit onto the splines. When using the airwrench to remove it go easy, as 12pt sockets are never robust. To get

the gear off, properly place the puller hooks, but avoid the gear teeth to avoid burring. It'll take some force.

For lubrication, I've tried a number of different brands and viscosities, but settled on Redline MTL, which is a special blend of lightweight oil with

synchromesh action promoting behaviour! This is critical, and really helps in a 7 where you'd be likely to shift quick. It stops the notorious 2-3 crunches when

the box gets hot (Mobile 75/90 synthetic gear-oil lets go here) on the track. I also put this in my old '84 Esprit and it transformed that gearbox. It's well worth

the added cost (about 2x that of regular synthetic gear oil).

Anything I'd do different: I'd certainly avoid machining past the end of the case like I did. In retrospect Brian Hill's notes were clear, but I misinterpreted his

drawing. Of course after it's all done, it's all clear as always. No problem really, as my alternate solution with the oilite thrust washer has been working fine for

thousands of miles and some track time. Meanwhile, it's winter of '06/'07 now and BGH was good enough to sell me another T9 Scorpio case and I'll be

putting that in, as soon as it warms up here a bit. We've been below -15C for over a month now, and working in the non-heated garage is challenging. Once it

get's warm here, like anything above -5C, I'll go back in there and replace the case, to make it all proper again. Nevertheless, the upgrade has been excellent

and it's well worth the time and $ spent on it.

The pictorial log for my 2005 winter upgrade

5th gear pair & Shift mechanism. Complete shifter mechanism.

- Top shaft left-of-center, the brass

disc/disc-arm & coil spring Left to Right:

arrangement provide the left-right - Far-left on-shaft - indentations for:

location of the shift lever for the [2-4], [Neutral], [R-1-3-5]

for-aft planes for Reverse / 1-2 / 3-4 - 4-3 shift fork, lockout disc

/ 5th. The brass arm straddles or (disc is located by the cover

forks a pin in the tail housing. plate)

- 2-1 shift fork, 5th shift fork

- The steel sleeve and disc on the - 5th gear lockout disc

top shaft, right-of-center allows for - L/R plane springload fork (far right)

selection of 5th gear and provides (the spring reference is located by a

speedo gear, and 5th gear/synchro are lockout when other gears are pin in the tailhousing)

located in the tail section engaged.

Lower-left in the pie-tin: Mainshaft ( = output shaft):

pin&spring for locating shifter- Left to Right:

shaft. - Synchro slider 3-4 gear

Center-right: speedo gear (194mm - baulk ring 3rd gear - 3rd gear

from gear back to sandwich plate - 2nd gear - baulk ring 2nd

face). Pull off with extended - 1-2 shift ring (accepts shift fork) /

(fabricated) puller. Rev. gear teeth

- baulk ring 1st - 1st gear

Low-center: get the best clip/snap - Sandwich plate (holds bearings)

ring pliers you can find!! This box - cleaned off output shaft (5th &

has many external and internal snap speedo removed)

rings.

Note: 5th gear shift cone engages

by moving away from 5th gear, as

it's plane is with gears 1/3/5. The

cuff rides on an extension of 5th

gear.

First the layshaft stub shaft must Input shaft (left).

be removed, by pounding it out Showing the input shaft, main bearing

through the hollow layshaft. I used and input gear, and 4th gear synchro

a 10" 1/2" socket wrench teeth & cone.

extension. Note: the 4th gear synchro connects

To remove the layshaft (center / the input shaft with the output shaft,

vertical), the outer race and rollers for a 1:1 ratio.

of the torrington bearing in the s.w.

plate have to be pushed out. With Also, in the left tray are synchro

two L-shaped 1/4" steel rods spring, blocker pins and a baulk ring.

(Brian's suggestion), with the ends

about 1" long and the "handles" In the right tray, some snap rings and

about 9" long, the bearing outer the layshaft stub shaft. A roller

race edge can be pushed out bearing in the layshaft runs on that.

between the s.w. plate and the case.

The s.w. plate can be moved out,

about 1/2" inch. Then the layshaft

can be lowered and the input shaft

removed. Up to this point it's been

caught behind the layshaft input

gear.

Showing the old 3.36 1st gear and Main case (cast iron).

layshaft meshed. Note the input Note round disc magnet at the bottom

shaft is on the left, then the of the case.

common (input) gear pair drives the The reverse idler gear has not been

layshaft permanently, as the output removed yet.

shaft is referenced via a pilot

bearing right next to the common

gear.

The 1st gear pair is on the right.

Gears on layshaft:

Common - 3 - 2 - R - 1 (5th is

removed).

This side mates with the sandwich Case inside view after machining.

(bearing) plate, and requires some Note material removal at the bottom

machining: The larger 1st gear on (low-center in pic).

the layshaft (bottom opening) Need to be careful with the small

interferes with the edge of the lower reverse gear stop, that can easily be

opening, as well as with some ribs nicked during the grinding process.

on the inside just below the reverse The spring on the reverse idler gear

gear stop. fork, keeps the idler gear located

I used a boring bar set to 2.5" towards the rear of the box, against

diameter. as suggested by BGH, the stop.

and then cut material side to side by

.15"

After machining. Test fit of the layshaft. I used teflon

After washing the box, it's ready for tape to protect the inner race of the

test fitting and reassembly. Torrington bearing which was heat

---- Ok, something went wrong here, as I shrunk onto the layshaft (thanks to

machined out the thrust surface for the John H. for calculating the correct

torrington bearing, the one that sits on the temperature, and use of his oven!).

layshaft in the sandwhich plate. It is held Note the rear side of the input shaft

captive by the snapring in the sandwhich

on top.

plate and the case on the other side. But

since I machined it out to the full thickness, The layshaft stub shaft is used on the

no edge remains for the bearing to rest other side, to position the layshaft

against - my solution is a new thrust more or less in the correct location.

surface made with a bronze washer and

stainless shim at the other end of the

layshaft - pics to follow below - yup, I

screwed up, but it's fixed ....(see below)

Another testfit view from the top, Main shaft cluster, left to right:

showing the input shaft more 3/4 shifter cuff hub then 3rd gear,

clearly. 2nd gear

Mainshaft shown in the top of the Reverse on top of 1/2 shift cuff

picture. note: engaging R is accomplished by sliding

the

Reverse idler gear, not this 2/3 cuff.

Next is the new 1st gear.

New brass baulk rings are in place for

1/2/3rd. The 4th and 5th showed no

measurable wear and mated well.

Reassembled, new 1st and 5th gear, New alloy cover with top filler and

overall slightly closer ratio's for 2 oil level dipstick (see threaded entry

and 3 as well, due to the changed top right of the cover in this pic).

input gear on the layshaft.

Note the slotted guide for the shift

New synchro rings (brass baulk mechanism disc in the center of the

rings) as well as fresh bearings. top plate, which means test shifting

Turned out the bearings were like without the cover in place, requires

new. I wasn't sure what state they some care.

would be in as at the point of

dissassembly I had put 60k miles on

the box (and the car :-).

Ok, I tried to find another gear case, The layshaft input side bearing in the I would think (I need to test this some

so now I'm making it right again - but in the US no-one appears to older case is a set of roller pins, which day) that a later style tail and

following a couple pics of the new have one. have to be temporarily glued into the sandwhich plate should fit with an

thrust washer solution. Better would The main difference between these layshaft with some thick bearing older case. So, if my thrust bearing

have probably been, not to machine out boxes is that the older style has a grease. The newer vesion uses a caged solution wears out prematurely, that's

the whole opening, but this is certainly support shaft running through the roller bearing that is pressed into the what I'll try do.

a lot more fun! layshaft, which then runs on that. In end of the layshaft. I believe this

Also note that late(r) model T9 the newer (Ford Scorpio style) box, bearing actually works both for the

(Scorpio) gearboxes are very hard to the layshaft hangs on a small stub newer as well as the older boxes. Then,

come by in the US. shaft (see below). the other big difference is the 5th gear

selector blocker which is much

- 1/07 - Got another case - I'll swap simplified in the newer box.

it in sometime in the coming

months. Right. Way way too busy. I

really should retire sometime.

note: it's almost 2011 and that fresh

case still sits under a desk.

meanwhile the gearbox is still fine.

Left to Right: Same as on the left, but showing the

relative position of the washers. The

a. Layshaft with inserted caged .010" stainless shim / washer will rest

roller bearing against the raised area on the case that

b. bronze oillite .062" washer exists where the stub shaft protrudes

- with it's ID milled out to .950" the front panel of the gearcase inside

c. stainless shim washer .010" the box.

d. stub shaft that bolts to the front The gap is where the case wall will be

of the case. (ok, that sounds confusing...). Note

the three bolts will be outside on the

front face of the gearbox.

Purpose of the .010" washer is to

provide a smooth running surface for

Note: the plate with the three holes will

the bronze washer. The oil feed is

be shimmed on the outside, to allow for

from the opposite end of the hollow

the slight laternal shift created by the

layshaft and thus these washers will

washers. The longitudinal force is run semi-submerged in oil.

taken between the layshaft / washers /

inside gearbox wall, instead of the

torrington bearing, which resting-edge

I accidentially machined away..

You might also like

- Checkball Domestic Volume 1atsgDocument120 pagesCheckball Domestic Volume 1atsgJorge GallardoNo ratings yet

- A Book of Helpful Tips on Overhauling a Vintage Engine - Including Car, Motorbike and Lawn Mower EnginesFrom EverandA Book of Helpful Tips on Overhauling a Vintage Engine - Including Car, Motorbike and Lawn Mower EnginesRating: 5 out of 5 stars5/5 (1)

- Legend Car Setup 2001Document7 pagesLegend Car Setup 2001Eric KramerNo ratings yet

- An Illustrated Guide to Making Mobile Toys - Scooter, Tricycle, Two Utility Carts and Wooden Land RoverFrom EverandAn Illustrated Guide to Making Mobile Toys - Scooter, Tricycle, Two Utility Carts and Wooden Land RoverNo ratings yet

- Suitcase PowercycleV2Document13 pagesSuitcase PowercycleV2Jim67% (3)

- Train Backyard ToyDocument12 pagesTrain Backyard ToyJim100% (17)

- 3 Wheel Dune BuggyDocument5 pages3 Wheel Dune BuggyyukitadaNo ratings yet

- Yard-Dozer MidgetDocument5 pagesYard-Dozer MidgetOlin Stej80% (5)

- Midgettractor PSMar 54Document7 pagesMidgettractor PSMar 54JimNo ratings yet

- PowerCycle With SideCarDocument7 pagesPowerCycle With SideCarJim100% (2)

- Type - 9 - Gearbox To Essex v6Document11 pagesType - 9 - Gearbox To Essex v6aakk75No ratings yet

- Construction - Bicycles, Dicycles Or Otto Type Machines And TricyclesFrom EverandConstruction - Bicycles, Dicycles Or Otto Type Machines And TricyclesNo ratings yet

- MG - MGA - Workshop Manual - 1955 - 1955Document5 pagesMG - MGA - Workshop Manual - 1955 - 1955Jan Svein HammerNo ratings yet

- BMW ECU ListDocument9 pagesBMW ECU ListTomica TišljarićNo ratings yet

- Suburban Tractor: Here's What It CostsDocument11 pagesSuburban Tractor: Here's What It CostsWojtek WywiałNo ratings yet

- 980G Electric SchematicDocument2 pages980G Electric SchematicJose nildo lobato Mendes Mendes100% (1)

- PLANOS AutogiroDocument11 pagesPLANOS Autogirorobochoa100% (1)

- Tote All ScooterDocument7 pagesTote All ScooterJimNo ratings yet

- By Emile Alline: Technical Art by Fred WolffDocument4 pagesBy Emile Alline: Technical Art by Fred WolffJim100% (3)

- Warehouse Construction Guide PDFDocument10 pagesWarehouse Construction Guide PDFRyan100% (1)

- T7.170, T7.185, T7.200, T7.210 Range-Power Command, T7.170, T7.185, T7.200, T7.210 Auto Command - 84477609A-Linked PDFDocument3,129 pagesT7.170, T7.185, T7.200, T7.210 Range-Power Command, T7.170, T7.185, T7.200, T7.210 Auto Command - 84477609A-Linked PDFДмитрий Викторович Панихидин100% (1)

- Roach Runner 518 TransmisionDocument5 pagesRoach Runner 518 Transmisiond72hemiNo ratings yet

- Vehicle: /rfdwlrqs L - R L5/6 - CKP Sensor: Left Rear of Engine, at Ring Gear, Above StarterDocument19 pagesVehicle: /rfdwlrqs L - R L5/6 - CKP Sensor: Left Rear of Engine, at Ring Gear, Above StarterrodolfodiazNo ratings yet

- Building One Lung KartsDocument7 pagesBuilding One Lung KartsJim100% (5)

- The Marmo Method Modelbuilding Guide #2: Building A Transtar/Peerless Logging RigFrom EverandThe Marmo Method Modelbuilding Guide #2: Building A Transtar/Peerless Logging RigNo ratings yet

- 5 R 110 WDocument4 pages5 R 110 WNuman2100% (1)

- Bridge Design Requirements DocumentDocument105 pagesBridge Design Requirements DocumentRestie TeanoNo ratings yet

- OvalCrewChief101 v5Document7 pagesOvalCrewChief101 v5darakof258No ratings yet

- Chassis Setup GuideDocument22 pagesChassis Setup GuideAline Zambolim ZambolimNo ratings yet

- RA No. 10642 - Lemon Law (Trans)Document3 pagesRA No. 10642 - Lemon Law (Trans)Khent Daryl FranciscoNo ratings yet

- Arctic Cat 2011 DVX 300 and 300 Utility Service ManualDocument10 pagesArctic Cat 2011 DVX 300 and 300 Utility Service ManualEvan98% (47)

- Road & Track Iconic Cars: CamaroFrom EverandRoad & Track Iconic Cars: CamaroLarry WebsterNo ratings yet

- Getrag En1 PDFDocument6 pagesGetrag En1 PDFJeremías EspinozaNo ratings yet

- SEAT Altea Freetrack BrochureDocument27 pagesSEAT Altea Freetrack BrochureScribbleCrewNo ratings yet

- Getrag En1 PDFDocument6 pagesGetrag En1 PDFBen MuisNo ratings yet

- Bede BD5Document4 pagesBede BD5Alfredo Arnéz Paz SoldánNo ratings yet

- 3 Wheel Go KartDocument5 pages3 Wheel Go KartLucas BrasilNo ratings yet

- New Problems Facing The 09G: Fun TransmissionsDocument8 pagesNew Problems Facing The 09G: Fun TransmissionsWelquer Andrade SilvaNo ratings yet

- Dependable Frame and Fork: Arrived at Road - CCDocument13 pagesDependable Frame and Fork: Arrived at Road - CCkhairiNo ratings yet

- U660e Case BoreDocument8 pagesU660e Case BoretejonmxNo ratings yet

- Crab FrameDocument3 pagesCrab FrameJock HedderwickNo ratings yet

- 1988 Haro CatalogDocument16 pages1988 Haro CatalogJose Leonardo Barboza PerezNo ratings yet

- Easy Fork Fixes You Can Do at HomeDocument8 pagesEasy Fork Fixes You Can Do at HomeKarsa SambasNo ratings yet

- ManualDocument20 pagesManualSean “the sean crabtree show” CrabtreeNo ratings yet

- Commodore - S Garage #8 - Coil Binding - IracingDocument5 pagesCommodore - S Garage #8 - Coil Binding - IracingHitesh VashistNo ratings yet

- Adaptação Da Caixa de Redução DewaltDocument6 pagesAdaptação Da Caixa de Redução DewaltcentraltechgvNo ratings yet

- 2015 Cervelo R5 Cyclist PDFDocument3 pages2015 Cervelo R5 Cyclist PDFAllan Dalton50% (2)

- Fae 090322Document6 pagesFae 090322Luis LoachaminNo ratings yet

- Turbocharging The Champ Flathead Six: by Greg MeyersDocument7 pagesTurbocharging The Champ Flathead Six: by Greg MeyersWilmer Howard BenderNo ratings yet

- Manual Qs Rc5Document1 pageManual Qs Rc5Director Tecnico AdministrativoNo ratings yet

- Unit 3 Steering System Tyres & Wheels Steering SystemDocument22 pagesUnit 3 Steering System Tyres & Wheels Steering SystemPrashant BhumireddyNo ratings yet

- Wheels: TvresDocument22 pagesWheels: TvresAviral DalalNo ratings yet

- LepelletierDocument4 pagesLepelletierSaveli Paul FlorinNo ratings yet

- P-51 Mustang Construction DetailsDocument1 pageP-51 Mustang Construction DetailsDeepak Paul Tirkey100% (1)

- English WorksheetDocument4 pagesEnglish WorksheetFelipeCataldoAleitteNo ratings yet

- Panda Stocker Review - Rcca-August-1989Document4 pagesPanda Stocker Review - Rcca-August-1989Rully LlamaNo ratings yet

- Elan 5 SPDDocument6 pagesElan 5 SPDslipsittinNo ratings yet

- Revista ModelismoDocument8 pagesRevista ModelismoAlan Ferreira De Sousa100% (1)

- AeroplaneDocument12 pagesAeroplaneNishant DeyNo ratings yet

- Shipping Instructions For Ge787 and Ge788 Motorized Wheel: GEK-91671ADocument4 pagesShipping Instructions For Ge787 and Ge788 Motorized Wheel: GEK-91671Aait mimouneNo ratings yet

- CV 508 - Single PagesDocument18 pagesCV 508 - Single PagesBharatiyulamNo ratings yet

- DL 2602gb IngDocument11 pagesDL 2602gb IngKamanziNo ratings yet

- Falco F8LDocument13 pagesFalco F8LPredrag PavlovićNo ratings yet

- GM IFS InfoDocument3 pagesGM IFS InfoartdbritoNo ratings yet

- 1a. The Input Shaft On The EA-series Transmissions Are About A 1/2" Longer Than Those On The EJ-series Ones. andDocument25 pages1a. The Input Shaft On The EA-series Transmissions Are About A 1/2" Longer Than Those On The EJ-series Ones. andjibshot69No ratings yet

- TOTAL StearmanDocument10 pagesTOTAL Stearmanmike_hobbs_6No ratings yet

- Dimensionais Redutor CicloiodalDocument15 pagesDimensionais Redutor CicloiodalVendedorNo ratings yet

- XRAY XT8 - 2009 Specs Review in Radio Race Car (UK) - NEWDocument6 pagesXRAY XT8 - 2009 Specs Review in Radio Race Car (UK) - NEWtxrxrsNo ratings yet

- Esab Cab 460MDocument2 pagesEsab Cab 460MSadashiva sahooNo ratings yet

- The Wendiu - Herlian PrincipleDocument4 pagesThe Wendiu - Herlian PrincipleCitrei KimNo ratings yet

- OHSCodeDocument555 pagesOHSCodeawais719No ratings yet

- Merritt Morning Market 3821 - Apr 26Document2 pagesMerritt Morning Market 3821 - Apr 26Kim LeclairNo ratings yet

- PathCross Service ManualDocument311 pagesPathCross Service ManualcastelodebubalNo ratings yet

- KG - Hyundai CSD Price ListDocument1 pageKG - Hyundai CSD Price Listsourav modakNo ratings yet

- Improvement in Low Temperature-Properties of Reclaimed Asphalt Binder Using Waste Engine OilDocument3 pagesImprovement in Low Temperature-Properties of Reclaimed Asphalt Binder Using Waste Engine OilGerald CasabarNo ratings yet

- (Ccu) (Ixb)Document1 page(Ccu) (Ixb)Mr David SarkarNo ratings yet

- Types of TrainsDocument12 pagesTypes of TrainsMostafa AfifyNo ratings yet

- National Highway Pre-Cast Concrete Policy 08-04-2022Document2 pagesNational Highway Pre-Cast Concrete Policy 08-04-2022Arun SethiNo ratings yet

- The Distant Sound of Engines: Algis BudrysDocument4 pagesThe Distant Sound of Engines: Algis BudrysPloop2000No ratings yet

- W156Document2 pagesW156Phillipe SabinoNo ratings yet

- Report IvecoDocument14 pagesReport Ivecoacb . bNo ratings yet

- Disc BrakesDocument4 pagesDisc BrakesNavam JainNo ratings yet

- 25.0 Powerscreen Phoenix 2100 Tech Spec RevX 16-05-2011 PhoenixDocument8 pages25.0 Powerscreen Phoenix 2100 Tech Spec RevX 16-05-2011 PhoenixbogdanmichaelNo ratings yet

- Factors Affecting Road Transport in UgandaDocument98 pagesFactors Affecting Road Transport in Ugandakeneth kaundaNo ratings yet

- Sae Technical Paper Series: Isaya Matsuo, Shinsuke Nakazawa, Hiromasa Maeda and Eiji InadaDocument11 pagesSae Technical Paper Series: Isaya Matsuo, Shinsuke Nakazawa, Hiromasa Maeda and Eiji InadaJawad AhmedNo ratings yet

- Muratori 2021 Prog. Energy 3 022002Document35 pagesMuratori 2021 Prog. Energy 3 022002Shubh HanspalNo ratings yet

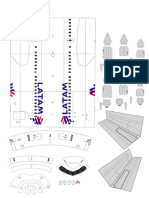

- A321neo Latam PapercraftDocument5 pagesA321neo Latam PapercraftshinoypuntoNo ratings yet

- Essay: Banking University of Ho Chi Minh CityDocument30 pagesEssay: Banking University of Ho Chi Minh CityNguyễn Hoàng ThơNo ratings yet

- Eactros FlyerDocument4 pagesEactros FlyerJDNo ratings yet