Professional Documents

Culture Documents

Charging

Uploaded by

jasonphxCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Charging

Uploaded by

jasonphxCopyright:

Available Formats

CHARGING

CHARGING SYSTEM . . . . . . . . . . . . . . . . . . . . CH–1

ALTERNATOR . . . . . . . . . . . . . . . . . . . . . . . . . . . CH–5

CH–1

CHARGING – CHARGING SYSTEM

CHARGING SYSTEM

CH07B–01

PRECAUTION

S Check that the battery cables are connected to the correct terminals.

S Disconnect the battery cables when the battery is given a quick charge.

S Do not perform tests with a high voltage insulation resistance tester.

S Never disconnect the battery while the engine is running.

LEXUS RX300 (RM785E)

CH–2

CHARGING – CHARGING SYSTEM

CH0G5–01

ON–VEHICLE INSPECTION

1. CHECK BATTERY ELECTROLYTE LEVEL

Check the electrolyte quantity of each cell.

If under the lower level, replace the battery (or add distilled wa-

ter if possible). Check the charging system.

2. CHECK BATTERY VOLTAGE

(a) After having driven the vehicle and in the case that 20

Voltmeter

minutes have not passed after having stopped the en-

gine, turn the ignition switch ON and turn on the electrical

system (headlight, blower motor, rear defogger etc.) for

60 seconds to remove the surface charge.

(b) Turn the ignition switch OFF and turn off the electrical sys-

tems.

B04633

(c) Measure the battery voltage between the negative (–)

and positive (+) terminals of the battery.

Standard voltage:

12.5 – 12.9 V at 20°C (68°F)

If the voltage is less than specification, charge the battery.

HINT:

Check the indicator as shown in the illustration.

Blue White Red

3. CHECK BATTERY TERMINALS, FUSIBLE LINK AND

FUSES

(a) Check that the battery terminals are not loose or cor-

roded.

OK Charging Insufficient If the terminals are corroded, clean the terminals.

Necessary Water (b) Check the fusible link, H–fuses, M–fuse and fuses for

Z11580 continuity.

4. INSPECT DRIVE BELTS

(a) Visually check the drive belt for excessive wear, frayed

cords etc.

If any defect has been found, replace the drive belt.

HINT:

Cracks on the rib side of a drive belt are considered acceptable.

If the drive belt has chunks missing from the ribs, it should be

replaced.

Z00015

LEXUS RX300 (RM785E)

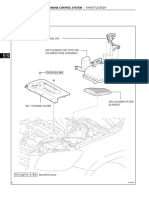

CH–3

CHARGING – CHARGING SYSTEM

(b) Check the drive belt deflection by peressing on the belt at

Ideller Pulley

the points indicated in the illustration with 98 N (10 kgf, 22

Water Pump lbf) of pressure.

New belt 8.0 – 9.0 mm (0.35 – 0.47 in.)

Used belt 12.0 – 14.0 mm (0.43 – 0.59 in.)

Crank Pulley

Compressor

:Measure point for belt looseness and

tension N17028

HINT:

S ”New belt” refers to a belt which has been used less than

5 minutes on a running engine.

S ”Used belt” refers to a belt which has been used on a run-

ning engine for 5 minutes or more.

S After installing a belt, check that it fits properly in the

CORRECT WRONG

ribbed grooves.

S Check with your hand to confirm that the belt has not

CH0086 slipped out of the groove on the bottom of the pulley.

S After installing a new belt, run the engine for about 5 min-

utes and recheck the belt tension.

(c) Reference:

Using a belt tension gauge, measure the belt tension.

Belt tension gauge:

DENSO BTG–20 (95506–00020)

Drive belt tension:

New belt 756 – 801 N (77 – 82 kgf)

Used belt 422 – 601 N (43 – 61 kgf)

If the belt tension is not as specified, adjust it.

I02495

5. VISUALLY CHECK ALTERNATOR WIRING AND LIS-

TEN FOR ABNORMAL NOISES

(a) Check that the wiring is in good condition.

(b) Check that there is no abnormal noise from the alternator

while the engine is running.

LEXUS RX300 (RM785E)

CH–4

CHARGING – CHARGING SYSTEM

6. CHECK DISCHARGE WARNING LIGHT CIRCUIT

(a) Warm up the engine and then turn it off.

(b) Switch off all accessories.

(c) Turn the ignition switch ”ON”. Check that the discharge

warning light is lit.

(d) Start the engine. Check that the light goes off.

If the light does not go off as specified, troubleshoot the dis-

charge light circuit.

Ammeter 7. INSPECT CHARGING CIRCUIT WITHOUT LOAD

HINT:

Disconnect Wire

from Terminal B If a battery/alternator tester is available, connect the tester to

the charging circuit as per manufacturer’s instructions.

Battery Voltmeter (a) If a tester is not available, connect a voltmeter and amme-

ter to the charging circuit as follows:

S Disconnect the wire from terminal B of the alterna-

Alternator

tor, and connect it to the negative (–) tester probe

Z03473 of the ammeter.

S Connect the positive (+) tester probe of the amme-

ter to terminal B of the alternator.

S Connect the positive (+) tester probe of the voltme-

ter to terminal B of the alternator.

S Ground the negative (–) tester probe of the voltme-

ter.

(b) Check the charging circuit as follows:

With the engine running from idling to 2,000 rpm, check

the reading on the ammeter and voltmeter.

Standard amperage:

10 A or less

Standard voltage:

13.2 – 14.0 V

If the voltmeter reading is more than standard voltage, replace

the coil assembly.

8. INSPECT CHARGING CIRCUIT WITH LOAD

(a) With the engine running at 2,000 rpm, turn on the high

beam headlights and place the heater blower switch at

”HI”.

(b) Check the reading on the ammeter.

Standard amperage:

30 A or more

If the ammeter reading is less than the standard amperage, re-

pair the alternator.

HINT:

If the battery is fully charged, the indication will sometimes be

less than standard amperage.

LEXUS RX300 (RM785E)

CH–5

CHARGING – ALTERNATOR

ALTERNATOR

CH07D–02

COMPONENTS

Alternator Wire

Plate Washer

Alternator Connector

Pivot Bolt

Adjusting Lock Bolt

Adjusting Bolt

Alternator

Drive Belt

B12256

Alternator Washer

z Front Bearing Bearing Cover

Drive End Frame

Bearing Cover

Pulley z Rear Bearing

Rotor

Rear Seal Plate

Retainer

Terminal Insulator

Brush Holder

Rear End Cover

Front Seal Plate

Coil Assembly

z Non–reusable part

B12257

LEXUS RX300 (RM785E)

CH–6

CHARGING – ALTERNATOR

CH07E–02

Pivot Bolt REMOVAL

1. REMOVE DRIVE BELT

Loosen the pivot bolt, adjusting lock bolt, and adjusting bolt,

and remove the drive belt.

Torque:

Pivot bolt: 56 N·m (570 kgf·cm, 41 ft·lbf)

Lock bolt: 18 N·m (180 kgf·cm, 13 ft·lbf)

Adjusting Adjusting Bolt

Lock Bolt B12258

2. REMOVE ALTERNATOR

(a) Disconnect the alternator connector.

(b) Remove the nut, and disconnect the alternator wire.

(c) Disconnect the wire harness from the clip.

(d) Remove the pivot bolt, plate washer, adjusting lock bolt

and alternator.

B12259

LEXUS RX300 (RM785E)

CH–7

CHARGING – ALTERNATOR

CH0G6–01

DISASSEMBLY

1. REMOVE REAR END COVER

(a) Remove the 3 nuts and end cover.

(b) Remove the terminal insulator.

B12260

2. REMOVE BRUSH HOLDER

(a) Remove the rear seal plate from the brush holder.

(b) Remove the 2 screws and brush holder.

(c) Remove the front seal plate from the coil assembly.

B12261

3. REMOVE PULLEY

(a) Hold SST (A) with a torque wrench, and tighten SST (B)

clockwise to the specified torque.

Turn SST 09820–63010

SST (A) Torque: 39 N·m (400 kgf·cm, 29 ft·lbf)

(b) Check that SST (A) is secured to the rotor shaft.

SST (B)

P10835

(c) Mount SST (C) in a vise.

(d) Insert SST (B) into SST (C), and attach the pulley nut to

SST (C).

SST (B)

Insert

SST (C)

P10834

(e) To loosen the pulley nut, turn SST (A) in the direction

shown in the illustration.

SST (C)

NOTICE:

To prevent damage to the rotor shaft, do not

SST (A) loosen the pulley nut more than one–half of a turn.

(f) Remove the alternator from SST (C).

Turn P10827

LEXUS RX300 (RM785E)

CH–8

CHARGING – ALTERNATOR

(g) Turn SST (B), and remove SST (A and B).

Turn (h) Remove the pulley nut and pulley.

SST (A)

SST (B)

P10836

4. REMOVE COIL ASSEMBLY

(a) Remove the 4 bolts.

B12262

(b) Using SST, remove the coil assembly.

SST

SST 09950–40011 (09951–04020, 09952–04010

09953–04020, 09954–04010, 09955–04071,

09958–04011)

(c) Remove the alternator washer.

5. REMOVE ROTOR FROM DRIVE END FRAME

B12263

LEXUS RX300 (RM785E)

CH–9

CHARGING – ALTERNATOR

CH0G7–01

Ohmmeter

INSPECTION

1. INSPECT ROTOR

(a) Check the rotor for open circuit.

Using an ohmmeter, check that there is continuity be-

tween the slip rings.

Continuity Standard resistance:

2.3 – 2.7 Ω at 20°C (68°F)

If there is no continuity, replace the rotor.

B12264

(b) Check the rotor for ground.

Ohmmeter

Using an ohmmeter, check that there is no continuity be-

tween the slip ring and rotor.

If there is continuity, replace the rotor.

No Continuity

B12265

(c) Check that the slip rings are not rough or scored.

If rough or scored, replace the rotor.

(d) Using vernier calipers, measure the slip ring diameter.

Standard diameter:

14.2 – 14.4 mm (0.559–0.567 in.)

Minimum diameter:

14.0 mm (0.551 in.)

If the diameter is less than minimum, replace the rotor.

B12266

2. INSPECT BRUSHES

Using a vernier caliper, measure the exposed brush length.

Standard exposed length:

10.5 mm (0.413 in.)

Length

Minimum exposed length:

4.5 mm (0.177 in.)

If the exposed length is less than minimum, replace the brushes

and brush holder assembly.

P13535 3. INSPECT BEARING

Check the bearing is not rough or worn.

If necessary, replace the bearing. (See page CH–10)

LEXUS RX300 (RM785E)

CH–10

CHARGING – ALTERNATOR

CH07H–02

REPLACEMENT

1. REPLACE FRONT BEARING

(a) Remove the 4 screws, bearing retainer and bearing.

B12267

(b) Using SST and a socket wrench and press, press out the

Socket Wrench bearing.

SST 09223–00010

SST

B12268

(c) Using SST and a press, press in a new bearing.

SST 09950–60010 (09951–00480)

SST

(d) Install the bearing retainer with the 4 screws.

Torque: 2.6 N·m (27 kgf·cm, 23 in.·lbf)

B12269

2. REPLACE REAR BEARING

(a) Using SST, remove the bearing cover (outside) and bear-

ing.

SST 09820–00021

SST

NOTICE:

Be careful not to damage the fan.

(b) Remove the bearing cover (inside).

B12270

(c) Place the bearing cover (inside) on the rotor.

B12271

LEXUS RX300 (RM785E)

CH–11

CHARGING – ALTERNATOR

(d) Using SST and a press, press in a new bearing.

SST 09820–00030

SST

B12272

(e) Using SST, push in the bearing cover (outside).

SST 09285–76010

SST

B12273

LEXUS RX300 (RM785E)

CH–12

CHARGING – ALTERNATOR

CH0G8–01

REASSEMBLY

1. INSTALL ROTOR TO DRIVE END FRAME

Pulley (a) Place the drive end frame on the pulley.

(b) Install the rotor to the drive end frame.

B12274

2. INSTALL COIL ASSEMBLY

(a) Place the alternator washer on the rotor.

B12275

29 mm (b) Using a 29 mm socket wrench and press, slowly press in

Socket the coil assembly.

Wrench

B12276

(c) Install the coil assembly with the 4 bolts.

Torque:5.8 N·m (59 kgf·cm, 51 in.·lbf)

B12262

3. INSTALL PULLEY

(a) Install the pulley to the rotor shaft by tightening the pulley

nut by hand.

Turn (b) Hold SST (A) with a torque wrench, and tighten SST (B)

SST (A) clockwise to the specified torque.

SST 09820–63010

Torque: 39 N·m (400 kgf·cm, 29 ft·lbf)

SST (B) (c) Check that SST (A) is secured to the pulley shaft.

P10835

LEXUS RX300 (RM785E)

CH–13

CHARGING – ALTERNATOR

(d) Mount SST (C) in a vise.

(e) Insert SST (B) into SST (C), and attach the pulley nut to

SST (C).

SST (A)

SST (C) Insert

P10834

(f) To torque the pulley nut, turn SST (A) in the direction

shown in the illustration.

Torque: 110.5 N·m (1,125 kgf·cm, 81 ft·lbf)

SST (C)

(g) Remove the alternator from SST (C).

SST (A)

Turn

P10829

(h) Turn SST (B), and remove SST (A and B).

Turn

SST (A)

SST (B)

P10836

4. INSTALL BRUSH HOLDER

(a) Place the front seal plate to the coil assembly.

B12277

(b) Place the brush holder on the coil assembly.

Upward

NOTICE:

Be careful of the holder installation direction.

(c) Install the 2 screws.

Torque: 1.8 N·m (18 kgf·cm, 16 in.·lbf)

(d) Place the real seal plate on the brush holder.

B12278

LEXUS RX300 (RM785E)

CH–14

CHARGING – ALTERNATOR

5. INSTALL REAR END COVER

(a) Install the terminal insulator.

(b) Install the end cover with the 3 nuts.

Torque: 4.6 N·m (47 kgf·cm, 41 in.·lbf)

6. CHECK THAT ROTOR ROTATES SMOOTHLY

B12260

LEXUS RX300 (RM785E)

CH–15

CHARGING – ALTERNATOR

CH07J–02

INSTALLATION

Installation is in the reverse order of removal (See page CH–6).

LEXUS RX300 (RM785E)

You might also like

- Boat Maintenance Companions: Electrics & Diesel Companions at SeaFrom EverandBoat Maintenance Companions: Electrics & Diesel Companions at SeaNo ratings yet

- Charging SystemDocument16 pagesCharging SystemCậu TúNo ratings yet

- Check your charging system for proper operationDocument16 pagesCheck your charging system for proper operationAbu AliNo ratings yet

- Check Charging System PerformanceDocument28 pagesCheck Charging System PerformanceHugo VillcaNo ratings yet

- On-Vehicle Inspection: 1Gr-Fe Charging - Charging SystemDocument3 pagesOn-Vehicle Inspection: 1Gr-Fe Charging - Charging SystemRichard Andrianjaka LuckyNo ratings yet

- Charging SystemDocument18 pagesCharging SystemChristian Linares AbreuNo ratings yet

- Charging System: On Vehicle InspectionDocument15 pagesCharging System: On Vehicle InspectionHugo VillcaNo ratings yet

- 1GR FE ChargingDocument15 pages1GR FE ChargingJorge Miguel Couto CabralNo ratings yet

- Charging System: Precautions CH-2 Troubleshooting CH-2 On-Vehicle Inspection CH-2 Alternator CH-6Document18 pagesCharging System: Precautions CH-2 Troubleshooting CH-2 On-Vehicle Inspection CH-2 Alternator CH-6lone_anarchistNo ratings yet

- Charging (5vz-Fe)Document15 pagesCharging (5vz-Fe)Abbode HoraniNo ratings yet

- ksp90 Charching SystemDocument17 pagesksp90 Charching SystemKevin HamiltonNo ratings yet

- Charging System: PrecautionDocument17 pagesCharging System: PrecautionFredNo ratings yet

- Overhaul: 1. Remove Generator Rear End CoverDocument5 pagesOverhaul: 1. Remove Generator Rear End CoverHenry SilvaNo ratings yet

- Overhaul: 1. Remove Magnetic Switch AssyDocument6 pagesOverhaul: 1. Remove Magnetic Switch AssyichamoNo ratings yet

- 2GR FE ChargingDocument25 pages2GR FE Chargingmink4uNo ratings yet

- ChargingDocument17 pagesChargingSJElliNo ratings yet

- Toyota Camry 2006-2011 2AZ-FE ChargingDocument21 pagesToyota Camry 2006-2011 2AZ-FE ChargingMichael MatthewsNo ratings yet

- 1GR FE ChargingDocument15 pages1GR FE ChargingDemosthenes QuintanaNo ratings yet

- Starter Assy (1.3Kw) (1Az-Fe) : OverhaulDocument6 pagesStarter Assy (1.3Kw) (1Az-Fe) : OverhaulHenry SilvaNo ratings yet

- Maintenance Operations: Engine Cold Engine OperationsDocument18 pagesMaintenance Operations: Engine Cold Engine OperationsJorgeAlbuquerqueNo ratings yet

- CH PDFDocument19 pagesCH PDFzeroNo ratings yet

- Ignicion Tacoma96Document5 pagesIgnicion Tacoma96Hugo Armando Garcia LepeNo ratings yet

- Speed Control Diagnosis and TestingDocument1 pageSpeed Control Diagnosis and TestingEduardo MacMasterNo ratings yet

- Ignition System: On-Vehicle InspectionDocument15 pagesIgnition System: On-Vehicle Inspectionchaisak2506No ratings yet

- Battery ChargingDocument80 pagesBattery Chargingpollob rajNo ratings yet

- Ignition Systems - 2JZ-GEDocument18 pagesIgnition Systems - 2JZ-GERicardo AlbertoNo ratings yet

- InspectionDocument2 pagesInspectionRacing GarageNo ratings yet

- Formate No. MNT (E) \ F 02 Maintenance Check ListDocument1 pageFormate No. MNT (E) \ F 02 Maintenance Check ListSumeet TrivediNo ratings yet

- Starter Assy (1.2Kw) (1Az-Fe) : OverhaulDocument8 pagesStarter Assy (1.2Kw) (1Az-Fe) : OverhaulHenry SilvaNo ratings yet

- Overhaul: 1. Remove Generator Rear End CoverDocument5 pagesOverhaul: 1. Remove Generator Rear End CoverHenry SilvaNo ratings yet

- Avensis Intake System PDFDocument19 pagesAvensis Intake System PDFMladen VidovićNo ratings yet

- GDM 5010PTDocument52 pagesGDM 5010PTmarentNo ratings yet

- Charging System: PrecautionDocument17 pagesCharging System: PrecautionlogammicNo ratings yet

- Power Steering PDFDocument93 pagesPower Steering PDFWaldo Fuentes100% (1)

- 2JZ-GTE Ignition System GuideDocument13 pages2JZ-GTE Ignition System GuideAbbode HoraniNo ratings yet

- Starting & ChargingDocument33 pagesStarting & ChargingMusat Catalin-Marian100% (1)

- 19 - Starting Hal 1-12Document12 pages19 - Starting Hal 1-12Fahmi NurinNo ratings yet

- Overhaul Cylinder Block 1AZ-FE EngineDocument17 pagesOverhaul Cylinder Block 1AZ-FE EngineHenry SilvaNo ratings yet

- PL Horns 8G - 1Document4 pagesPL Horns 8G - 1Pelis CloneNo ratings yet

- 121 2AZ-FE Engine Control System - Throttle BodyDocument8 pages121 2AZ-FE Engine Control System - Throttle BodydanielmaycarazoNo ratings yet

- IgnitionDocument29 pagesIgnitionChristian Linares AbreuNo ratings yet

- Spill Control Valve InspectionDocument1 pageSpill Control Valve InspectionArdi AgusmanNo ratings yet

- 2AZ-FE Charging CH1-17Document17 pages2AZ-FE Charging CH1-17AlelukinNo ratings yet

- Removal of AlternatorDocument11 pagesRemoval of AlternatorvixentdNo ratings yet

- Keeway Focus Matrix Electrical System SchemaDocument12 pagesKeeway Focus Matrix Electrical System SchemaugoranNo ratings yet

- Starting System (2Az-Fe) : InspectionDocument40 pagesStarting System (2Az-Fe) : InspectionTung Nguyen100% (1)

- Alternator Inspection GuideDocument4 pagesAlternator Inspection GuideMiguel ruizNo ratings yet

- Horns: Description and OperationDocument6 pagesHorns: Description and OperationLilisbethBasantaNo ratings yet

- Ignition PDFDocument16 pagesIgnition PDFDoDuyBacNo ratings yet

- General Information Configuration and FunctionDocument46 pagesGeneral Information Configuration and FunctionFabian Carrasco NaulaNo ratings yet

- Overhaul: 1. Remove Repair Service Starter KitDocument6 pagesOverhaul: 1. Remove Repair Service Starter KitKolela DjibrilNo ratings yet

- FrenosDocument22 pagesFrenosKevin figueroaNo ratings yet

- Speed Sensor: ComponentsDocument3 pagesSpeed Sensor: ComponentsYdelkadiasmela DominguezmorelNo ratings yet

- Compressor: On - Vehicle InspectionDocument7 pagesCompressor: On - Vehicle InspectionMaximoxtremo Corazónde CampeonNo ratings yet

- 2c 5000electricalDocument16 pages2c 5000electricalJanetCruzRamirezNo ratings yet

- Lights Stays OnDocument3 pagesLights Stays OnJohn VelezNo ratings yet

- Inspection of Torque Converter Clutch and Drive PlateDocument1 pageInspection of Torque Converter Clutch and Drive PlateMayobanex Moya MartinezNo ratings yet

- Propeller ShaftDocument13 pagesPropeller ShaftjasonphxNo ratings yet

- LubricationDocument21 pagesLubricationjasonphxNo ratings yet

- PreparationDocument79 pagesPreparationjasonphxNo ratings yet

- Caution - Reading ManualDocument1 pageCaution - Reading ManualIshmael WoolooNo ratings yet

- BrakeDocument65 pagesBrakejasonphxNo ratings yet

- FEMA Wind Retrofit Guide For Residential BuildingsDocument115 pagesFEMA Wind Retrofit Guide For Residential BuildingsjasonphxNo ratings yet

- SteeringDocument52 pagesSteeringjasonphxNo ratings yet

- Blu-Ray Disc Player: User ManualDocument34 pagesBlu-Ray Disc Player: User ManualjasonphxNo ratings yet

- Sonicare Essence E5300 Cordless Rechargeable Toothbrushh - Owners ManualDocument60 pagesSonicare Essence E5300 Cordless Rechargeable Toothbrushh - Owners ManualjasonphxNo ratings yet

- Maytag Neptune Washer Service Manual MAH6500AWWDocument157 pagesMaytag Neptune Washer Service Manual MAH6500AWWPhilippeleGrande9967% (9)

- Technical Publication Combined UnitsDocument13 pagesTechnical Publication Combined UnitsjasonphxNo ratings yet

- Sylvania 6432GG SDTV SpecificationsDocument1 pageSylvania 6432GG SDTV SpecificationsjasonphxNo ratings yet

- Viewsonic LCD Monitor - Model VX1962WM - User GuideDocument25 pagesViewsonic LCD Monitor - Model VX1962WM - User GuidejasonphxNo ratings yet

- 85 87 Radcom Mar05Document3 pages85 87 Radcom Mar05Billy NoonNo ratings yet

- MC3 Sullair PartsListManual 185 KubotaDocument60 pagesMC3 Sullair PartsListManual 185 Kubotaivan castillonNo ratings yet

- Shimadzu Mobileart Plus Mux 100h Installation Manual PDFDocument152 pagesShimadzu Mobileart Plus Mux 100h Installation Manual PDFbajo05100% (7)

- Tacho Troubleshooting v1.3Document23 pagesTacho Troubleshooting v1.3Wagner GuimarãesNo ratings yet

- Ic-R8600 Eng Basic 3bDocument96 pagesIc-R8600 Eng Basic 3bfilzaNo ratings yet

- EthosD ManualDocument14 pagesEthosD Manualapi-26966403100% (1)

- PROFIBUS Slave Step7 2.1Document30 pagesPROFIBUS Slave Step7 2.1Johana Carolina BetancurNo ratings yet

- Fagor Compact Drives and Motors Quick ReferenceDocument28 pagesFagor Compact Drives and Motors Quick ReferenceJessica RoyNo ratings yet

- UPC1Document24 pagesUPC1Bogicevic DejanNo ratings yet

- MINOLTA EP3015 TroubleshoootingDocument132 pagesMINOLTA EP3015 TroubleshoootingciphardNo ratings yet

- KD105 ManualDocument22 pagesKD105 ManualJoel Leandro Ibarra CoriaNo ratings yet

- 1996 Mazda MPV PDFDocument104 pages1996 Mazda MPV PDFBariki Birding100% (2)

- Operating Instructions For Electromagnetic Flowmeter Model: MIMDocument69 pagesOperating Instructions For Electromagnetic Flowmeter Model: MIMZsolt BodóNo ratings yet

- Wode Installation Guide v.1.0Document14 pagesWode Installation Guide v.1.0Christos HadjijovanniNo ratings yet

- UMG80BS-41 SPMDocument111 pagesUMG80BS-41 SPMDmitriy SemakovNo ratings yet

- ZU TD-500-HT Typical 2013 EN PDFDocument446 pagesZU TD-500-HT Typical 2013 EN PDFamekhzoumiNo ratings yet

- L293D Motor Driver PDFDocument6 pagesL293D Motor Driver PDFPedro Cu Aguirre100% (1)

- Onkyo MD 2321 Owners ManualDocument32 pagesOnkyo MD 2321 Owners ManualCelio Mota RiveraNo ratings yet

- Infusion PumpDocument3 pagesInfusion Pumpnicole isla100% (1)

- ATV312 ProfibusDP CommsManualDocument37 pagesATV312 ProfibusDP CommsManualeirisarriNo ratings yet

- GAM Cubicle: MV Distribution Factory Built Assemblies at Your Service AnglaisDocument30 pagesGAM Cubicle: MV Distribution Factory Built Assemblies at Your Service AnglaisDania DedeNo ratings yet

- 500E2 Service ManualDocument102 pages500E2 Service Manualedwin ortega medina100% (4)

- Manual Módulo Interfaz Cortina de Seguridad Banner 62822Document12 pagesManual Módulo Interfaz Cortina de Seguridad Banner 62822Guillermo GarciaNo ratings yet

- MB2 HardwareManual 2Document43 pagesMB2 HardwareManual 2NamiJen LobatoNo ratings yet

- Apex Mini PlusDocument15 pagesApex Mini PlusRomi Kurniawan PrikitiewNo ratings yet

- Operation Manual-3a - Gie-1109-Om3aDocument74 pagesOperation Manual-3a - Gie-1109-Om3aAwliya Taqwa100% (1)

- Eycon HA029280 5Document262 pagesEycon HA029280 5Hammad MalikNo ratings yet

- MCC PanelDocument86 pagesMCC PanelRavindra TiwariNo ratings yet

- DIY ABS Diagnostics GuideDocument2 pagesDIY ABS Diagnostics GuideErln LimaNo ratings yet

- Emp2 Box Pressure TransmitterDocument8 pagesEmp2 Box Pressure TransmitterAsif HameedNo ratings yet