Professional Documents

Culture Documents

Overhaul: 1. Remove Generator Rear End Cover

Uploaded by

Henry SilvaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Overhaul: 1. Remove Generator Rear End Cover

Uploaded by

Henry SilvaCopyright:

Available Formats

19−9

STARTING & CHARGING − GENERATOR ASSY (2AZ−FSE)

190W0−01

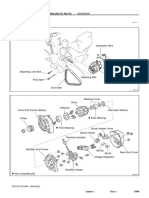

OVERHAUL

1. REMOVE GENERATOR REAR END COVER

(a) Remove the 2 terminal covers by turning them counter-

clockwise.

A80108

(b) Remove the screw, 2 nuts and end cover.

B09748

2. REMOVE REGULATOR SUB−ASSY GENERATOR

W/BRUSH

(a) Remove the 3 screws and regulator.

B09749

3. REMOVE STATOR SUB−ASSY GENERATOR

W/RECTIFIRE

(a) Remove the 4 bolts.

B09750

2AZ−FSE ENGINE REPAIR MANUAL (RM1083E)

19−10

STARTING & CHARGING − GENERATOR ASSY (2AZ−FSE)

(b) Using a screwdriver, pry out the stator.

4. REMOVE BEARING SET GENERATOR

B10446

5. REMOVE PULLEY SET GENERATOR

(a) Clamp the swivel arm in a vise.

NOTICE:

Be careful not to damage the fan.

(b) Using an impact wrench, remove the nut and spring

washer, then detach the pulley.

B10014

6. REMOVE GENERATOR ROTOR ASSY

(a) Using a press, press out the rotor and spacer ring.

B10015

Ohmmeter 7. INSPECT GENERATOR ROTOR ASSY

(a) Check the rotor for open circuit.

Slip Ring (1) Using an ohmmeter, measure the resistance be-

tween the slip rings.

Standard resistance: 1.8 to 2.8 W at 20_C (68_F)

If the resistance is not as specified, replace the rotor assy.

B10452

Ohmmeter

(b) Check the rotor for ground.

(1) Using an ohmmeter, measure the resistance be-

tween the slip ring and rotor core.

Standard: 10 kW or higher

If the resistance is not as specified, replace the rotor assy.

(c) Inspect slip rings.

Rotor (1) Check that the slip rings are not rough or scored.

Core 10 kW or Higher If rough or scored, replace the rotor assy.

B10453

2AZ−FSE ENGINE REPAIR MANUAL (RM1083E)

19−11

STARTING & CHARGING − GENERATOR ASSY (2AZ−FSE)

(d) Inspect the slip rings.

(1) Check that the slip rings are not rough or scored.

If rough or scored, replace the rotor assy.

(2) Using a vernier caliper, measure the slip ring diame-

ter.

Standard diameter: 15.3 to 15.5 mm (0.602 to 0.610 in.)

Minimum diameter: 14.3 mm (0.561 in.)

If the diameter is less than the minimum, replace the rotor assy.

B00896

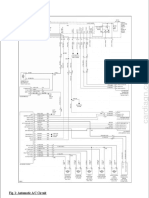

8. INSPECT STATOR SUB−ASSY GENERATOR

Negative (−) Terminal Rectifier Terminal

W/RECTIFIRE

(a) Using an ohmmeter, measure the resistance between the

Ohmmeter generator’s negative (−) terminal and rectifier terminal.

(1) Connect the ohmmeter’s positive (+) probe to the

generator’s negative (−) terminals and the negative

(−) probe to the rectifier terminals. Measure the re-

sistance one by one.

10 kW or Higher

B09843 Standard: 10 kW or higher

(2) Connect the ohmmeter’s positive (+) probe to the

rectifier terminals and the negative (−) probe to the

generator’s negative (−) terminals. Measure the re-

sistance one by one.

Standard: Below 1 W

If the result is not as specified, replace the stator sub−assy gen-

erator w/ rectifier.

(b) Using an ohmmeter, measure the resistance between the

Rectifier Terminal

rectifier terminals.

Standard: Below 1 W

Ohmmeter If the result is not as specified, replace the stator sub−assy gen-

erator w/ rectifier.

Below 1 W

B09844

Length 9. INSPECT BRUSH

(a) Using a vernier caliper, measure the exposed brush

length.

Standard exposed length:

13.2 mm (0.520 in.) in new condition

Minimum exposed length: 6.0 mm (0.236 in.)

If the exposed length is less than the minimum, replace the reg-

ulator sub−assy generator w/ brush.

B09845

2AZ−FSE ENGINE REPAIR MANUAL (RM1083E)

19−12

STARTING & CHARGING − GENERATOR ASSY (2AZ−FSE)

10. INSTALL GENERATOR ROTOR ASSY

(a) Using SST and a press, press in the rotor.

SST SST 09285−76010

NOTICE:

Avoid misalignment during pressing.

B10019

11. INSTALL PULLEY SET GENERATOR

(a) Clamp the rotor in a soft jaw vise.

(b) Install the pulley with the spring washer and nut.

Torque: 65 N×m (663 kgf×cm, 48 ft×lbf)

B10014

12. INSTALL BEARING SET GENERATOR

(a) Insert the fitting ring into the position shown in the illustra-

tion.

(b) Align the key of the fitting ring with the keyway of the sta-

tor.

(c) Install the bearing.

B09847

13. INSTALL STATOR SUB−ASSY GENERATOR

W/RECTIFIRE

(a) Align the key of the drive end frame with the keyway of the

stator generator.

(b) Install the stator with the 4 bolts.

Torque: 3.5 N×m (36 kgf×cm, 31 in.×lbf)

B09750

14. INSTALL REGULATOR SUB−ASSY GENERATOR

W/BRUSH

(a) Attach the brushes and terminals to the rectifier end

frame of the regulator.

B09848

2AZ−FSE ENGINE REPAIR MANUAL (RM1083E)

19−13

STARTING & CHARGING − GENERATOR ASSY (2AZ−FSE)

(b) Install the regulator with the 3 screws.

With Washer

Torque:

2.2 N×m (22 kgf×cm, 19 in.×lbf) for screw without wash-

er

1.2 N×m (12 kgf×cm, 11 in.×lbf) for screw with washer

HINT:

Install the screw with the plate washer to the position shown in

Without

the illustration.

Washer

B10021

Nut A Screw 15. INSTALL GENERATOR REAR END COVER

(a) Install the end cover with the 2 nuts and screw.

Torque:

19.5 N×m (199 kgf×cm, 14 ft×lbf) for nut A

12 N×m (122 kgf×cm, 9 ft×lbf) for nut B

2.4 N×m (24 kgf×cm, 21 in.×lbf) for screw

Nut B

B09748

(b) Install the 2 terminal covers by turning them clockwise.

A80108

2AZ−FSE ENGINE REPAIR MANUAL (RM1083E)

You might also like

- Overhaul: 1. Remove Generator Rear End CoverDocument5 pagesOverhaul: 1. Remove Generator Rear End CoverHenry SilvaNo ratings yet

- Starter Assy (1.2Kw) (1Az-Fe) : OverhaulDocument8 pagesStarter Assy (1.2Kw) (1Az-Fe) : OverhaulHenry SilvaNo ratings yet

- Overhaul: 1. Remove Starter Yoke AssyDocument6 pagesOverhaul: 1. Remove Starter Yoke AssyIslam AttiaNo ratings yet

- Generator Assy (1Az-Fe) : OverhaulDocument5 pagesGenerator Assy (1Az-Fe) : OverhaulHenry SilvaNo ratings yet

- Overhaul: 1. Remove Magnetic Switch AssyDocument6 pagesOverhaul: 1. Remove Magnetic Switch AssyichamoNo ratings yet

- Starter Assy (1.3Kw) (1Az-Fe) : OverhaulDocument6 pagesStarter Assy (1.3Kw) (1Az-Fe) : OverhaulHenry SilvaNo ratings yet

- Overhaul: 1. Remove Repair Service Starter KitDocument6 pagesOverhaul: 1. Remove Repair Service Starter KitIslam AttiaNo ratings yet

- Generator: Removal of Generator (4A-Fe)Document20 pagesGenerator: Removal of Generator (4A-Fe)henysNo ratings yet

- MANUAL BOOK DifferentialDocument14 pagesMANUAL BOOK DifferentialHaris100% (2)

- Drive Belt (1Nz Fe/2Nz Fe) : ReplacementDocument2 pagesDrive Belt (1Nz Fe/2Nz Fe) : ReplacementEse FregeneNo ratings yet

- Matrix 2003 2zz 8Document10 pagesMatrix 2003 2zz 8alan lantiguaNo ratings yet

- StarterDocument16 pagesStarterswap2gzNo ratings yet

- Inspection: OhmmeterDocument4 pagesInspection: OhmmeterMiguel ruizNo ratings yet

- Calibracion Valvulas Toyota 1GRFEDocument9 pagesCalibracion Valvulas Toyota 1GRFEJose Antonio Rivero ReyesNo ratings yet

- Overhaul: 1. Remove Repair Service Starter KitDocument6 pagesOverhaul: 1. Remove Repair Service Starter KitKolela DjibrilNo ratings yet

- Speed Sensor: ComponentsDocument3 pagesSpeed Sensor: ComponentsYdelkadiasmela DominguezmorelNo ratings yet

- FCPL Brake: Adjustment and MaintenanceDocument4 pagesFCPL Brake: Adjustment and MaintenanceВладимирNo ratings yet

- Removal: Automatic Transmission (A750F)Document5 pagesRemoval: Automatic Transmission (A750F)joe nathanNo ratings yet

- Partial Engine Assy (1Nz Fe/2Nz Fe) : OverhaulDocument26 pagesPartial Engine Assy (1Nz Fe/2Nz Fe) : OverhaulNelson Caño Basalo100% (3)

- Overhaul: - Vane Pump AssyDocument7 pagesOverhaul: - Vane Pump AssyRomy MNo ratings yet

- Generator: ComponentsDocument8 pagesGenerator: Componentsjuan riveraNo ratings yet

- ChargingDocument17 pagesChargingjasonphxNo ratings yet

- Knock Sensor (1Gr-Fe) : ReplacementDocument2 pagesKnock Sensor (1Gr-Fe) : ReplacementRodrigo VillagraNo ratings yet

- InspDocument1 pageInspMansur KhanNo ratings yet

- Removal of AlternatorDocument11 pagesRemoval of AlternatorvixentdNo ratings yet

- Compressor: On - Vehicle InspectionDocument7 pagesCompressor: On - Vehicle InspectionMaximoxtremo Corazónde CampeonNo ratings yet

- Sienna Timing Belt ReplacementDocument8 pagesSienna Timing Belt ReplacementGlenn MartinNo ratings yet

- 03 - Valve Clearance - AdjustmentDocument5 pages03 - Valve Clearance - AdjustmentjordantNo ratings yet

- AlternatorDocument19 pagesAlternatorcpgmotorsNo ratings yet

- 2006-2008-Cbf1000-A-11 AlternatorDocument8 pages2006-2008-Cbf1000-A-11 AlternatorMurariu IonutNo ratings yet

- Disassembly: Power Steering Vane Pump (2Jz Ge)Document1 pageDisassembly: Power Steering Vane Pump (2Jz Ge)Moh DeBrNo ratings yet

- Overhaul: 1. Remove Valve LifterDocument17 pagesOverhaul: 1. Remove Valve LifterIslam AttiaNo ratings yet

- InspectionDocument2 pagesInspectionRacing GarageNo ratings yet

- Toyota 2azfe Valve Clearance PDFDocument9 pagesToyota 2azfe Valve Clearance PDFMarcos EmmanuelNo ratings yet

- Platz 02Document7 pagesPlatz 02dawitmesfin9No ratings yet

- 1 AzDocument7 pages1 AzEdU RECTIFICANo ratings yet

- Installation: Hint: After Installation, Fill AFT and Check The Fluid Level (See Page)Document200 pagesInstallation: Hint: After Installation, Fill AFT and Check The Fluid Level (See Page)Julio FuentesNo ratings yet

- Toyota TercelDocument29 pagesToyota TercelAbdon Reyes100% (1)

- Insp Valve Clearance 2.7 3rz PDFDocument5 pagesInsp Valve Clearance 2.7 3rz PDFEdwin Versteeg100% (1)

- 19 - Starting Hal 1-12Document12 pages19 - Starting Hal 1-12Fahmi NurinNo ratings yet

- Starting PDFDocument19 pagesStarting PDFAndrey GladyshevNo ratings yet

- Cylinder Bloc DissasemblyDocument8 pagesCylinder Bloc DissasemblyYannick de WalqueNo ratings yet

- Generator 3Document1 pageGenerator 3Racing GarageNo ratings yet

- 1GR FE ChargingDocument15 pages1GR FE ChargingDemosthenes QuintanaNo ratings yet

- Injection Timing (5L) : InspectionDocument2 pagesInjection Timing (5L) : InspectionaliNo ratings yet

- Toyota 5l Valve ClearanceDocument5 pagesToyota 5l Valve ClearancedennoNo ratings yet

- Toyota 5l Valve ClearanceDocument5 pagesToyota 5l Valve ClearancedennoNo ratings yet

- Calibracion de Valvulas Toyota 1nz YarisDocument11 pagesCalibracion de Valvulas Toyota 1nz Yariscpaolinod100% (3)

- Installation: 1Gr-Fe Engine Mechanical - Drive BeltDocument1 pageInstallation: 1Gr-Fe Engine Mechanical - Drive BeltPedro Javier Castro SanchezNo ratings yet

- TestDocument2 pagesTestsalusfrankNo ratings yet

- Transmission Valve Body Assy (A245E/A246E) : OverhaulDocument2 pagesTransmission Valve Body Assy (A245E/A246E) : OverhaulGearauto Power100% (2)

- Rack and Pinion2Document18 pagesRack and Pinion2Romy MNo ratings yet

- 8-11... Lobo Service ManualDocument41 pages8-11... Lobo Service ManualRusonegro100% (1)

- Camshaft (1Nz Fe/2Nz Fe) : ReplacementDocument8 pagesCamshaft (1Nz Fe/2Nz Fe) : ReplacementMaung KyawNo ratings yet

- 81 Ex440d SMSUPPDocument14 pages81 Ex440d SMSUPPwopontourNo ratings yet

- ដេម៉ារ័រប្រភេទពីញ៉ុងប្លាណេទៃ 1MZ FE ដោះបំបែកនិងត្រួតពិនិត្យDocument9 pagesដេម៉ារ័រប្រភេទពីញ៉ុងប្លាណេទៃ 1MZ FE ដោះបំបែកនិងត្រួតពិនិត្យSopharith YimNo ratings yet

- Charging System: PrecautionDocument17 pagesCharging System: PrecautionlogammicNo ratings yet

- Overhaul: Manual Transmission/TransaxleDocument9 pagesOverhaul: Manual Transmission/TransaxleMax K.No ratings yet

- Overhaul: Manual Transmission/TransaxleDocument10 pagesOverhaul: Manual Transmission/TransaxleMax K.No ratings yet

- 110 Waveform Generator Projects for the Home ConstructorFrom Everand110 Waveform Generator Projects for the Home ConstructorRating: 4 out of 5 stars4/5 (1)

- 2012 RAM - Automatic HVAC CircuitDocument2 pages2012 RAM - Automatic HVAC CircuitHenry SilvaNo ratings yet

- 2012 RAM - Clutch SystemDocument23 pages2012 RAM - Clutch SystemHenry SilvaNo ratings yet

- 2012 RAM - Supplemental Restraints CircuitDocument2 pages2012 RAM - Supplemental Restraints CircuitHenry SilvaNo ratings yet

- Overhaul: 1. Remove Oil Filler Cap Sub-AssyDocument33 pagesOverhaul: 1. Remove Oil Filler Cap Sub-AssyHenry SilvaNo ratings yet

- Engine Mechanical: PreparationDocument3 pagesEngine Mechanical: PreparationHenry SilvaNo ratings yet

- 08 Supplemental Restraint System Air BagDocument5 pages08 Supplemental Restraint System Air BagHenry SilvaNo ratings yet

- 2012 RAM - Tires & WheelsDocument51 pages2012 RAM - Tires & WheelsHenry SilvaNo ratings yet

- Repair Instruction For Engine Repair Manual: PrecautionDocument3 pagesRepair Instruction For Engine Repair Manual: PrecautionHenry SilvaNo ratings yet

- Overhaul: - Oil Pump AssyDocument3 pagesOverhaul: - Oil Pump AssyHenry SilvaNo ratings yet

- Terms For Engine Repair Manual: Abbreviations Used in ManualDocument5 pagesTerms For Engine Repair Manual: Abbreviations Used in ManualHenry SilvaNo ratings yet

- How To Use This Engine Repair Manual: General InformationDocument3 pagesHow To Use This Engine Repair Manual: General InformationHenry SilvaNo ratings yet

- Oil Pump Assy (1Az-Fe) : OverhaulDocument2 pagesOil Pump Assy (1Az-Fe) : OverhaulHenry SilvaNo ratings yet

- Starter Assy (1.3Kw) (1Az-Fe) : OverhaulDocument6 pagesStarter Assy (1.3Kw) (1Az-Fe) : OverhaulHenry SilvaNo ratings yet

- Engine Mechanical: PreparationDocument3 pagesEngine Mechanical: PreparationHenry SilvaNo ratings yet

- Overhaul: 1. Remove Oil Pump Strainer SetDocument3 pagesOverhaul: 1. Remove Oil Pump Strainer SetHenry SilvaNo ratings yet

- Overhaul: 1. Inspect Connecting Rod Thrust ClearanceDocument17 pagesOverhaul: 1. Inspect Connecting Rod Thrust ClearanceHenry SilvaNo ratings yet

- Cylinder Block (1Az-Fe) : OverhaulDocument17 pagesCylinder Block (1Az-Fe) : OverhaulHenry SilvaNo ratings yet

- Glossary of Sae and Toyota TermsDocument3 pagesGlossary of Sae and Toyota TermsHenry SilvaNo ratings yet

- Material Item Specification Fill CapacityDocument14 pagesMaterial Item Specification Fill CapacityHenry SilvaNo ratings yet

- Overhaul: 1. Remove Oil Filler Cap Sub Assy 2. Remove Oil Filler Cap Gasket 3. Remove Ventilation Valve Sub AssyDocument36 pagesOverhaul: 1. Remove Oil Filler Cap Sub Assy 2. Remove Oil Filler Cap Gasket 3. Remove Ventilation Valve Sub AssyHenry SilvaNo ratings yet

- 97 Wiring: General InformationDocument39 pages97 Wiring: General InformationHenry SilvaNo ratings yet

- 1970 Dodge Challenger - Dart - Cooling System PDFDocument12 pages1970 Dodge Challenger - Dart - Cooling System PDFHenry SilvaNo ratings yet

- Clikstar Dispositivo Administrador InsulinaDocument11 pagesClikstar Dispositivo Administrador InsulinaHenry SilvaNo ratings yet

- CHG Altima L32Document30 pagesCHG Altima L32Henry SilvaNo ratings yet

- Dual Clutch SystemDocument13 pagesDual Clutch SystemHenry SilvaNo ratings yet

- TUCSON (LM) 2010 G 2.4 DOHC Clutch System: SpecificationDocument11 pagesTUCSON (LM) 2010 G 2.4 DOHC Clutch System: SpecificationHenry SilvaNo ratings yet

- Preparing - Your - Lab - D-6660 July 2002Document11 pagesPreparing - Your - Lab - D-6660 July 2002Navi MoralesNo ratings yet

- PlatinumGMT Diode Laser - User Manual (Ver.3) (8519683)Document22 pagesPlatinumGMT Diode Laser - User Manual (Ver.3) (8519683)Lacramioara FituNo ratings yet

- KSB Centrifugal OverhungDocument10 pagesKSB Centrifugal Overhungঅজানা রশ্মি Ajana rashmiNo ratings yet

- Samsung Introduction of New 40T v3Document15 pagesSamsung Introduction of New 40T v3costel cracanaNo ratings yet

- TC600EDocument2 pagesTC600ERadekNo ratings yet

- Software PatentsDocument5 pagesSoftware PatentsoguzzerkanNo ratings yet

- Methods of Data CollectionDocument38 pagesMethods of Data CollectionGaurav AtreyaNo ratings yet

- The UK Government Digital ServiceDocument11 pagesThe UK Government Digital Serviceilyas mabroukNo ratings yet

- 3685 Mir 006 PDFDocument1 page3685 Mir 006 PDFashishpearlNo ratings yet

- RRB PO PRELIMS Quants (Day-11) 164983111818Document16 pagesRRB PO PRELIMS Quants (Day-11) 164983111818surya ponnadaNo ratings yet

- Case Study FinanceDocument2 pagesCase Study FinanceAkansha GoyalNo ratings yet

- Convert Sign Language To SpeechDocument29 pagesConvert Sign Language To SpeechBon DokNo ratings yet

- Katalog Części Bobcat 320C From 517811001 To 51789999 PartsDocument345 pagesKatalog Części Bobcat 320C From 517811001 To 51789999 PartsHubert TojaNo ratings yet

- TEMS Pocket 21.3 - Device SpecificationDocument45 pagesTEMS Pocket 21.3 - Device Specificationhanhdk100% (1)

- Module2-Signals and SystemsDocument21 pagesModule2-Signals and SystemsAkul PaiNo ratings yet

- Studio Infinity - Library Case StudyDocument5 pagesStudio Infinity - Library Case StudyGayathriNo ratings yet

- TUV ISO Action List 2020Document5 pagesTUV ISO Action List 2020chittineni0% (1)

- How To Fix Ink Absorber FullDocument1 pageHow To Fix Ink Absorber Fullmicrowstuff71% (7)

- Chapter 3 Refractory Installation in The Cement Rotary KilnDocument86 pagesChapter 3 Refractory Installation in The Cement Rotary KilnMKPashaPasha88% (8)

- WI-VI TechnologyDocument23 pagesWI-VI Technologyshaikali100% (5)

- Wafer 5825&6Document1 pageWafer 5825&6RB STNo ratings yet

- Practical File IPDocument27 pagesPractical File IPtanulakhwal09No ratings yet

- Wargames Illustrated #006Document52 pagesWargames Illustrated #006Анатолий Золотухин100% (1)

- Zeiss AI EbookDocument56 pagesZeiss AI EbookRaylson De SÁ Melo UFCNo ratings yet

- 1J2 S4hana1909 BPD en UsDocument18 pages1J2 S4hana1909 BPD en UsBiji RoyNo ratings yet

- Embedded Systems Unit 2 Part 3-1Document50 pagesEmbedded Systems Unit 2 Part 3-1Donthula LayaNo ratings yet

- JOUR280 Demo 8Document6 pagesJOUR280 Demo 8madridjago aasNo ratings yet

- Manual Telehanddler TH580B / SLH1-UpDocument56 pagesManual Telehanddler TH580B / SLH1-UpRichard Peru100% (6)

- Select USA 2021 VirtualDocument15 pagesSelect USA 2021 VirtualGaurav TripathiNo ratings yet

- PF ProjectDocument16 pagesPF Projectsunnia munsifNo ratings yet