Professional Documents

Culture Documents

Overhaul: 1. Remove Repair Service Starter Kit

Uploaded by

Islam AttiaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Overhaul: 1. Remove Repair Service Starter Kit

Uploaded by

Islam AttiaCopyright:

Available Formats

19−2

STARTING & CHARGING − STARTER ASSY(1.6KW) (1GR−FE)

190L3−01

OVERHAUL

1. REMOVE REPAIR SERVICE STARTER KIT

(a) Remove the nut, and disconnect the lead wire from the re-

pair service starter kit.

A76123

(b) Remove the 2 screws holding the repair service starter kit

to the starter drive housing.

(c) Remove the repair service starter kit.

(d) Remove the return spring and plunger.

A76124

2. REMOVE STARTER YOKE ASSY

(a) Remove the 2 through bolts, and pull out the starter yoke

assy together with the commutator end frame assy.

A76127

3. REMOVE STARTER COMMUTATOR END FRAME ASSY

(a) Remove the commutator end frame assy from the starter yoke assy.

4. REMOVE STARTER ARMATURE PLATE

(a) Remove the starter armature plate from the starter yoke assy.

5. REMOVE STARTER COMMUTATOR END FRAME COVER

(a) Using a screwdriver, remove the cover.

1GR−FE ENGINE REPAIR MANUAL (RM1005E)

19−3

STARTING & CHARGING − STARTER ASSY(1.6KW) (1GR−FE)

6. REMOVE STARTER ARMATURE ASSY

(a) Using snap ring pliers, remove the snap ring and plate

washer.

(b) Remove the starter armature assy from commutator end

frame assy.

A73993

7. REMOVE PLANETARY GEAR

(a) Remove the 3 planetary gears.

A76128

8. REMOVE STARTER CENTER BEARING CLUTCH

SUB−ASSY

(a) Remove the starter center bearing clutch w/ drive lever

set pin from the starter drive housing.

(b) Remove the drive lever set pin from the starter center

bearing clutch.

A73990

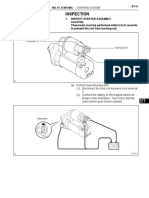

9. INSPECT STARTER ARMATURE ASSY

(a) Check the commutator for open circuit.

(1) Using an ohmmeter, check that there is continuity

between the segments of the commutator.

Continuity If there is no continuity between any segments, replace the ar-

mature.

A73983

(b) Check the commutator for ground.

(1) Using an ohmmeter, check that there is no continu-

ity between the commutator and armature coil core.

If there is continuity, replace the armature.

(c) Check the commutator for dirty and burn on surface.

No Continuity If the surface is dirty or burnt, correct it with sandpaper (No.400)

or a lathe.

A73984

1GR−FE ENGINE REPAIR MANUAL (RM1005E)

19−4

STARTING & CHARGING − STARTER ASSY(1.6KW) (1GR−FE)

(d) Using vernier calipers, measure the commutator length.

Standard length: 3.1 mm (0.122 in.)

Maximum length: 3.8 mm (0.150 in.)

If the length is greater than maximum, replace the armature.

Length

A58584

10. INSPECT STARTER COMMUTATOR END FRAME

ASSY

(a) Using vernier calipers, measure the brush holder length.

Length Standard length: 9.0 mm (0.354 in.)

Maximum length: 4.0 mm (0.158 in.)

If the length is less than minimum, replace the starter commuta-

tor end frame assy.

A76677

(b) Check the brush holder.

No Continuity

(1) Using an ohmmeter, check that there is no continu-

ity between the positive (+) and negative (−) brush

holders.

If the there is continuity repair or replace the starter commutator

end frame assy.

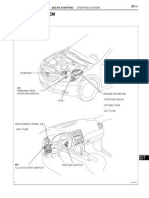

11. INSPECT STARTER CENTER BEARING CLUTCH

SUB−ASSY

A76436 (a) Inspect the gear teeth on the planetary gear, internal gear

and starter clutch for wear or damage.

If the gear is damaged, replace it.

If damaged, replace the gear or clutch assembly. If damaged,

also check the drive plate ring gear for wear or damage.

(b) Check the clutch pinion gear.

(1) Rotate the clutch pinion gear clockwise and check

Free

that it turns freely.

(2) Try to rotate the clutch pinion gear counterclock-

wise and check that it locks.

If necessary, replace the center bearing clutch sub−assy.

Lock

A73987

1GR−FE ENGINE REPAIR MANUAL (RM1005E)

19−5

STARTING & CHARGING − STARTER ASSY(1.6KW) (1GR−FE)

12. INSPECT REPAIR SERVICE STARTER KIT

(a) Check the plunger.

(1) Push in the plunger and check that it returns quickly

to its original position.

If necessary, replace the repair service starter kit.

A58586

(b) Check the pull−in coil for open circuit.

Terminal 50

(1) Using an ohmmeter, check that there is continuity

between terminal 50 and C.

If there is no continuity, replace the repair service starter kit.

Continuity

Terminal C

A76126

Terminal 50

(c) Check whether the hold−in coil has an open circuit.

(1) Using an ohmmeter, check that there is continuity

between terminal 50 and the switch body.

If there is no continuity, replace the repair service starter kit.

Continuity A76129

13. INSTALL STARTER CENTER BEARING CLUTCH

SUB−ASSY

(a) Install the drive lever set pin to the starter center bearing

clutch.

(b) Install the starter center bearing clutch w/ drive lever set

pin to the starter drive housing.

A73990

14. INSTALL PLANETARY GEAR

(a) Apply grease to the planetary gears and pin parts of the

planetary shaft.

(b) Install the 3 planetary gears.

15. INSTALL STARTER ARMATURE ASSY

(a) Apply grease to the plate washer and armature shaft.

(b) Install the armature shaft to the starter commutator end

frame assy.

A76128

1GR−FE ENGINE REPAIR MANUAL (RM1005E)

19−6

STARTING & CHARGING − STARTER ASSY(1.6KW) (1GR−FE)

(c) Using snap ring pliers, install the plate washer and new

snap ring.

A73993

(d) Using vernier calipers, measure the snap ring.

Length Maximum length: 5.0 mm (0.197 in.)

If the length is greater than maximum, replace the new snap

ring.

A58810

16. INSTALL STARTER COMMUTATOR END FRAME COVER

17. INSTALL STARTER ARMATURE PLATE

(a) Insert the starter armature plate to the starter yoke assy.

(b) Align the cutout of the plate with the protrusion inside the

starter yoke, and install the plate.

18. INSTALL STARTER COMMUTATOR END FRAME

ASSY

A73991

(a) Align the starter commutator rubber end frame with the

cutout of starter yoke.

(b) Install starter commutator end frame to starter yoke assy.

A58587

1GR−FE ENGINE REPAIR MANUAL (RM1005E)

19−7

STARTING & CHARGING − STARTER ASSY(1.6KW) (1GR−FE)

19. INSTALL STARTER YOKE ASSY

(a) Align the starter yoke assy with the cutout of starter drive

housing.

A76130

(b) Install the starter yoke assy with the 2 through bolts.

Torque: 6.0 N×m (61 kgf×cm, 53 in.×lbf)

20. INSTALL REPAIR SERVICE STARTER KIT

(a) Apply grease to the plunger and hook.

A76127

(b) Hang the plunger hook of the repair service starter kit to

the drive lever.

(c) Install the plunger and return spring.

A76131

(d) Install the repair service starter kit with the 2 screws.

Torque: 7.5 N×m (76 kgf×cm, 66 in.×lbf)

A76124

(e) Connect the lead wire to the terminal with the nut.

Torque: 10 N×m (102 kgf×cm, 7.4 ft×lbf)

A76123

1GR−FE ENGINE REPAIR MANUAL (RM1005E)

You might also like

- 110 Waveform Generator Projects for the Home ConstructorFrom Everand110 Waveform Generator Projects for the Home ConstructorRating: 4 out of 5 stars4/5 (1)

- Starter Assy (1.3Kw) (1Az-Fe) : OverhaulDocument6 pagesStarter Assy (1.3Kw) (1Az-Fe) : OverhaulHenry SilvaNo ratings yet

- Overhaul: 1. Remove Repair Service Starter KitDocument6 pagesOverhaul: 1. Remove Repair Service Starter KitKolela DjibrilNo ratings yet

- Operational Amplifier Circuits: Analysis and DesignFrom EverandOperational Amplifier Circuits: Analysis and DesignRating: 4.5 out of 5 stars4.5/5 (2)

- Overhaul: 1. Remove Starter Yoke AssyDocument6 pagesOverhaul: 1. Remove Starter Yoke AssyIslam AttiaNo ratings yet

- Starter Assy (1.2Kw) (1Az-Fe) : OverhaulDocument8 pagesStarter Assy (1.2Kw) (1Az-Fe) : OverhaulHenry SilvaNo ratings yet

- Overhaul: 1. Remove Generator Rear End CoverDocument5 pagesOverhaul: 1. Remove Generator Rear End CoverHenry SilvaNo ratings yet

- StarterDocument16 pagesStarterswap2gzNo ratings yet

- Overhaul: 1. Remove Magnetic Switch AssyDocument6 pagesOverhaul: 1. Remove Magnetic Switch AssyichamoNo ratings yet

- Overhaul: 1. Remove Generator Rear End CoverDocument5 pagesOverhaul: 1. Remove Generator Rear End CoverHenry SilvaNo ratings yet

- Generator Assy (1Az-Fe) : OverhaulDocument5 pagesGenerator Assy (1Az-Fe) : OverhaulHenry SilvaNo ratings yet

- 19 - Starting and Charging PDFDocument22 pages19 - Starting and Charging PDFJen-Yung ChangNo ratings yet

- ដេម៉ារ័រប្រភេទពីញ៉ុងប្លាណេទៃ 1MZ FE ដោះបំបែកនិងត្រួតពិនិត្យDocument9 pagesដេម៉ារ័រប្រភេទពីញ៉ុងប្លាណេទៃ 1MZ FE ដោះបំបែកនិងត្រួតពិនិត្យSopharith YimNo ratings yet

- Generator: Removal of Generator (4A-Fe)Document20 pagesGenerator: Removal of Generator (4A-Fe)henysNo ratings yet

- Overhauling a Starter AssemblyDocument6 pagesOverhauling a Starter AssemblydiemnganNo ratings yet

- 1GR FE StartingDocument27 pages1GR FE StartingJorge Miguel Couto CabralNo ratings yet

- AlternatorDocument19 pagesAlternatorcpgmotorsNo ratings yet

- Removal of AlternatorDocument11 pagesRemoval of AlternatorvixentdNo ratings yet

- Automatic Transaxle's DisassemblyDocument32 pagesAutomatic Transaxle's Disassemblymohamed A.abdeltwabNo ratings yet

- Overhaul: - Vane Pump AssyDocument7 pagesOverhaul: - Vane Pump AssyRomy MNo ratings yet

- Matrix 2003 2zz 8Document10 pagesMatrix 2003 2zz 8alan lantiguaNo ratings yet

- InspectionDocument2 pagesInspectionRacing GarageNo ratings yet

- 13 - Starting TOYOTA PDFDocument19 pages13 - Starting TOYOTA PDFAngello Esquerre RojasNo ratings yet

- Manual Transmission Overhaul ProceduresDocument9 pagesManual Transmission Overhaul ProceduresMax K.No ratings yet

- Automatic Transaxle Replacement GuideDocument11 pagesAutomatic Transaxle Replacement GuideluisNo ratings yet

- Overhaul: 1. Remove Transmission Control Shaft Lever RHDocument43 pagesOverhaul: 1. Remove Transmission Control Shaft Lever RHBắc HoàngNo ratings yet

- Sienna Timing Belt ReplacementDocument8 pagesSienna Timing Belt ReplacementGlenn MartinNo ratings yet

- Overhauling a Differential Step-by-StepDocument14 pagesOverhauling a Differential Step-by-StepHaris100% (2)

- Overhaul: 1. Inspect Connecting Rod Thrust ClearanceDocument17 pagesOverhaul: 1. Inspect Connecting Rod Thrust ClearanceHenry SilvaNo ratings yet

- Overhaul: 1. Fix Clutch Drum & Input Shaft AssyDocument22 pagesOverhaul: 1. Fix Clutch Drum & Input Shaft AssyBắc HoàngNo ratings yet

- Starting System (2Az-Fe) : InspectionDocument40 pagesStarting System (2Az-Fe) : InspectionTung Nguyen100% (1)

- Overhaul: 1. Remove Valve LifterDocument17 pagesOverhaul: 1. Remove Valve LifterIslam AttiaNo ratings yet

- Park/Neutral Position Switch Adjustment GuideDocument50 pagesPark/Neutral Position Switch Adjustment GuideminaryNo ratings yet

- 19 - Starting Hal 1-12Document12 pages19 - Starting Hal 1-12Fahmi NurinNo ratings yet

- 2AZ FE StartingDocument16 pages2AZ FE StartingLuks FernandezNo ratings yet

- Park/Neutral Position Switch Assy (Atm) : ReplacementDocument3 pagesPark/Neutral Position Switch Assy (Atm) : ReplacementluisNo ratings yet

- Disassembly: 2Uz-Fe Engine Mechanical - Engine UnitDocument21 pagesDisassembly: 2Uz-Fe Engine Mechanical - Engine UnitMateusz Jaskuła100% (1)

- Overhaul Cylinder Block 1AZ-FE EngineDocument17 pagesOverhaul Cylinder Block 1AZ-FE EngineHenry SilvaNo ratings yet

- Valve Clearance: InspectionDocument5 pagesValve Clearance: InspectionПежов СитроенNo ratings yet

- C250 Manual Transmission Output Shaft Inspection and Repair ProceduresDocument10 pagesC250 Manual Transmission Output Shaft Inspection and Repair ProceduresMax K.No ratings yet

- w040001 PDFDocument31 pagesw040001 PDFresolution8878No ratings yet

- 8-11... Lobo Service ManualDocument41 pages8-11... Lobo Service ManualRusonegro100% (1)

- Alternator Inspection GuideDocument4 pagesAlternator Inspection GuideMiguel ruizNo ratings yet

- Camshaft Removal Guide for 1NZ-FE/2NZ-FE EnginesDocument8 pagesCamshaft Removal Guide for 1NZ-FE/2NZ-FE EnginesMaung KyawNo ratings yet

- Overhaul: 1. Remove Transmission Control Shaft Lever LH (A750F Except 4runner, Gx470)Document43 pagesOverhaul: 1. Remove Transmission Control Shaft Lever LH (A750F Except 4runner, Gx470)joe nathanNo ratings yet

- Overhaul: 1. Remove Oil Pump CoverDocument3 pagesOverhaul: 1. Remove Oil Pump CoverIslam AttiaNo ratings yet

- Partial Engine Assy (1Nz Fe/2Nz Fe) : OverhaulDocument26 pagesPartial Engine Assy (1Nz Fe/2Nz Fe) : OverhaulNelson Caño Basalo100% (3)

- Differential CaseDocument5 pagesDifferential Casejeremih alhegnNo ratings yet

- Motor 1AZ-FE OverhaulDocument29 pagesMotor 1AZ-FE OverhaulfredhNo ratings yet

- Overhaul: 1. Inspect Connecting Rod Thrust ClearanceDocument22 pagesOverhaul: 1. Inspect Connecting Rod Thrust ClearanceIslam AttiaNo ratings yet

- Inspection of Torque Converter Clutch and Drive PlateDocument1 pageInspection of Torque Converter Clutch and Drive PlateMayobanex Moya MartinezNo ratings yet

- Removal: Torx Screw Screw CaseDocument2 pagesRemoval: Torx Screw Screw CasejuanNo ratings yet

- Overhaul: 1. Remove Speedometer Drive (MTM) GearDocument5 pagesOverhaul: 1. Remove Speedometer Drive (MTM) GearMax K.No ratings yet

- 40-09 Park Neutral Position Switch Assy (Atm) AdjustmentDocument6 pages40-09 Park Neutral Position Switch Assy (Atm) AdjustmentCelso BidinotiNo ratings yet

- Floor Shift CableDocument3 pagesFloor Shift CableTilleya MadramootooNo ratings yet

- Partial Engine Assembly2Document34 pagesPartial Engine Assembly2jeremih alhegnNo ratings yet

- Starting PDFDocument19 pagesStarting PDFAndrey GladyshevNo ratings yet

- Removal: (A) (B) (B) LockDocument4 pagesRemoval: (A) (B) (B) Lockjoe nathanNo ratings yet

- Ns/Gs A-598 Manual Transaxle 21 - 5: SERVICE PROCEDURES (Continued)Document3 pagesNs/Gs A-598 Manual Transaxle 21 - 5: SERVICE PROCEDURES (Continued)Luca TrottaNo ratings yet

- XCMG 25Document14 pagesXCMG 25Islam AttiaNo ratings yet

- XCMG Iflex5 Operators ManualDocument44 pagesXCMG Iflex5 Operators ManualIslam AttiaNo ratings yet

- XCMG Iflex5 Operators ManualDocument42 pagesXCMG Iflex5 Operators ManualIslam AttiaNo ratings yet

- XCMG Iflex5 Operators ManualDocument44 pagesXCMG Iflex5 Operators ManualIslam AttiaNo ratings yet

- XCMG Iflex5 Operators ManualDocument42 pagesXCMG Iflex5 Operators ManualIslam AttiaNo ratings yet

- Technical SpecificationsDocument4 pagesTechnical SpecificationsIslam AttiaNo ratings yet

- XCMG 25Document7 pagesXCMG 25Islam AttiaNo ratings yet

- XCMG Iflex5 Operators ManualDocument69 pagesXCMG Iflex5 Operators ManualIslam AttiaNo ratings yet

- XCMG 25Document7 pagesXCMG 25Islam AttiaNo ratings yet

- Operating & Maintenance Manual: XE210C Hydraulic ExcavatorDocument154 pagesOperating & Maintenance Manual: XE210C Hydraulic Excavatornajafali100% (1)

- SpecificationsDocument5 pagesSpecificationsIslam AttiaNo ratings yet

- XCMG XC6-3006K - XC6Document11 pagesXCMG XC6-3006K - XC6Islam AttiaNo ratings yet

- XCMG XC6Document4 pagesXCMG XC6Islam AttiaNo ratings yet

- XCMG Forklifts Technical ManualsDocument16 pagesXCMG Forklifts Technical ManualsIslam AttiaNo ratings yet

- XCMG QUY55 Crawler Crane Operator's ManualDocument88 pagesXCMG QUY55 Crawler Crane Operator's ManualIslam AttiaNo ratings yet

- XCMG RT70E Load ChartDocument24 pagesXCMG RT70E Load ChartIslam AttiaNo ratings yet

- XCMG Catalogue 2017Document14 pagesXCMG Catalogue 2017Islam AttiaNo ratings yet

- XCMG SQ10SK3Q Operation and Maintenance ManualDocument36 pagesXCMG SQ10SK3Q Operation and Maintenance ManualIslam Attia0% (1)

- Operating & Maintenance Manual: XE210C Hydraulic ExcavatorDocument154 pagesOperating & Maintenance Manual: XE210C Hydraulic Excavatornajafali100% (1)

- V222TI Installation Instructions ManualDocument91 pagesV222TI Installation Instructions ManualLisandroNo ratings yet

- Doosan HP450 Operator Manual PDFDocument108 pagesDoosan HP450 Operator Manual PDFLuis Panti EkNo ratings yet

- Standard Fuel Consumption (Model)Document11 pagesStandard Fuel Consumption (Model)Sreekanth Sattiraju87% (45)

- S 5-Troubleshooting-Diagnostic Codes PresentDocument54 pagesS 5-Troubleshooting-Diagnostic Codes PresentSkrzynie BiegówNo ratings yet

- Doosan Daewoo D1146Document147 pagesDoosan Daewoo D1146FranciscoOliveira100% (2)

- XCMG QUY150 Load ChartDocument8 pagesXCMG QUY150 Load ChartIslam AttiaNo ratings yet

- XCMG QY-12 Electrical Wiringing SchematicDocument6 pagesXCMG QY-12 Electrical Wiringing SchematicIslam AttiaNo ratings yet

- DE12 Diesel Engine Shop ManualDocument165 pagesDE12 Diesel Engine Shop ManualkevUwUr93% (15)

- XCMG Iflex5 Operators ManualDocument42 pagesXCMG Iflex5 Operators ManualIslam AttiaNo ratings yet

- XCMG ZL50GN G-Series Wheel Loader - Outline DimensionDocument6 pagesXCMG ZL50GN G-Series Wheel Loader - Outline DimensionIslam AttiaNo ratings yet

- XCMG Forklifts Technical ManualsDocument16 pagesXCMG Forklifts Technical ManualsIslam AttiaNo ratings yet

- P13303EN Opticruise tcm40-358169 PDFDocument6 pagesP13303EN Opticruise tcm40-358169 PDFWin Min TunNo ratings yet

- FD50 100Document86 pagesFD50 100Vüsal 1No ratings yet

- ACMA Member ListDocument162 pagesACMA Member ListGp Mishra81% (16)

- TASKalfa 3501i 4501i 5501i PL UK Rev4 PDFDocument78 pagesTASKalfa 3501i 4501i 5501i PL UK Rev4 PDFlupin30000100% (1)

- The Double ClutchDocument60 pagesThe Double Clutchnicolae_popescu_18100% (1)

- Dynamic simulation of an innovative permanently engaged mechanism for starting systemsDocument8 pagesDynamic simulation of an innovative permanently engaged mechanism for starting systemsmichelotti72No ratings yet

- Atsg Transmission 4f27e DL Technical ServiceDocument10 pagesAtsg Transmission 4f27e DL Technical Servicedavid100% (46)

- King Sheet Pile - ICE PaperDocument6 pagesKing Sheet Pile - ICE Papergaurave999No ratings yet

- AR25.20-S-0070S Bleed Clutch Operating System 28.4.15: AS00.00-Z-0010-01ADocument2 pagesAR25.20-S-0070S Bleed Clutch Operating System 28.4.15: AS00.00-Z-0010-01AChristian Askøe VollmersNo ratings yet

- CL PDFDocument12 pagesCL PDFJesusNo ratings yet

- Subaru Impreza 2002Document3,366 pagesSubaru Impreza 2002Tamás Nagy67% (3)

- B1550HSTDDocument312 pagesB1550HSTDalexNo ratings yet

- David Brown Cropmaster VAK1 Series Operating and Maintenance InstructionsDocument51 pagesDavid Brown Cropmaster VAK1 Series Operating and Maintenance Instructionstusa tuzesqui100% (1)

- D8K Track Type Tractor Specs PDFDocument6 pagesD8K Track Type Tractor Specs PDFDavid Ramirez100% (2)

- ED Assignment 1Document2 pagesED Assignment 1sushant.sahayee20No ratings yet

- Auto Trans Overhaul Rav4Document109 pagesAuto Trans Overhaul Rav4Eliut BenavidesNo ratings yet

- AllisonDocument507 pagesAllisonrashid83% (6)

- Worx125 Service Manual2Document165 pagesWorx125 Service Manual2doctee100% (1)

- 24 5DDDDDocument2 pages24 5DDDDsubham jaiswalNo ratings yet

- Honda CVTDocument6 pagesHonda CVTAbo FatmaNo ratings yet

- DOM Some Problems 1Document21 pagesDOM Some Problems 1NagarajuRbNo ratings yet

- Manitowoc 111 80 Product GuideDocument24 pagesManitowoc 111 80 Product GuideZian HennNo ratings yet

- Manuale Officina Beta 400Document134 pagesManuale Officina Beta 400DomenicoNo ratings yet

- Cotta SI2E Speed Increaser Dec 2020Document2 pagesCotta SI2E Speed Increaser Dec 2020umeshNo ratings yet

- Snowmobile Two Stroke 2005 Service ManualDocument300 pagesSnowmobile Two Stroke 2005 Service ManualАртёмNo ratings yet

- Hummer H2 2004 Cooling System Mechanical/electricalDocument140 pagesHummer H2 2004 Cooling System Mechanical/electricalHendrik CastensNo ratings yet

- Offroad Training Guide 2020Document32 pagesOffroad Training Guide 2020moniqueNo ratings yet

- E4nb71 - 300ZXDocument99 pagesE4nb71 - 300ZXbricasco100% (1)

- Chapter 5 - Friction Devices - Theory of Machines - Part 1Document17 pagesChapter 5 - Friction Devices - Theory of Machines - Part 1Sandip GhoshNo ratings yet

- Electromagnetic Clutch System Full Seminar Report 4537Document30 pagesElectromagnetic Clutch System Full Seminar Report 4537Dani RiccNo ratings yet