Professional Documents

Culture Documents

Overhaul: 1. Remove Valve Lifter

Uploaded by

Islam AttiaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Overhaul: 1. Remove Valve Lifter

Uploaded by

Islam AttiaCopyright:

Available Formats

14−55

ENGINE MECHANICAL − CYLINDER HEAD ASSY (1GR−FE)

1415I−01

OVERHAUL

1. REMOVE VALVE LIFTER

HINT:

Arrange the valve lifter in the correct order.

A75601

2. REMOVE VALVE

SST HINT:

Arrange the valves, inner compression springs, valve spring re-

tainers and valve spring retainer rocks in the correct order.

(a) Place the cylinder head on the wooden block.

(b) Using SST, compress the inner compression spring and

remove the 2 valve spring retainer rocks.

SST 09202−70020 (09202−00010)

Wooden Block

A75602 (c) Remove the valve, inner compression spring and valve

spring and valve spring retainer.

3. REMOVE VALVE SPRING SEAT

(a) Using compressed air and a magnetic finger, remove the

valve spring seat by blowing air.

A75603

4. REMOVE VALVE STEM OIL O SEAL OR RING

(a) Using a needle−nose pliers, remove the valve stem oil

seal.

A75604

1GR−FE ENGINE REPAIR MANUAL (RM1005E)

14−56

ENGINE MECHANICAL − CYLINDER HEAD ASSY (1GR−FE)

5. CLEAN CYLINDER HEAD SUB−ASSY

(a) Using a gasket scraper, remove all th gasket material from

the cylinder block contact surface.

NOTICE:

Be careful not to scratch the cylinder block contact sur-

face.

A75605

(b) Using a wire brush, remove all the carbon from the com-

bustion chambers.

NOTICE:

Be careful not to scratch the combustion chambers.

A75606

(c) Using a valve guide bushing brush and solvent, clean all

the valve guide bushes.

A75607

(d) Using a soft brush and solvent, thoroughly clean the cylin-

der head.

A75608

1GR−FE ENGINE REPAIR MANUAL (RM1005E)

14−57

ENGINE MECHANICAL − CYLINDER HEAD ASSY (1GR−FE)

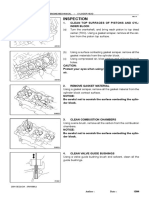

6. INSPECT CYLINDER HEAD SUB−ASSY

(a) Inspect for flatness.

(1) Using a precision straight edge and feeler gauge,

measure the surfaces contacting the cylinder block

and manifolds for warpage.

Maximum warpage: 0.10 mm (0.0039 in.)

If warpage is greater than maximum, replace the cylinder head.

Cylinder Block Side:

Intake Manifold Side:

Exhaust Manifold Side:

A75609

(b) Inspect for cranks.

(1) Using a dye penetrant, check the combustion

chamber, intake ports, exhaust ports and cylinder

block surface for cracks.

If cracked, replace the cylinder head.

A75610

7. CLEAN VALVE

(a) Using a gasket scraper, chip off any carbon from the valve

head.

(b) Using a wire brush, thoroughly clean the valve.

EM0580

1GR−FE ENGINE REPAIR MANUAL (RM1005E)

14−58

ENGINE MECHANICAL − CYLINDER HEAD ASSY (1GR−FE)

8. INSPECT VALVE

(a) Inspect for valve stem diameter.

(1) Using a micrometer, measure the diameter of the

valve stem.

Valve stem diameter:

Intake 5.470 − 5.485 mm (0.2154 − 0.2159 in.)

Exhaust 5.465 − 5.480 mm (0.2152 − 0.2158 in.)

A32770

(b) Inspect for valve face angle.

(1) Grind the valve enough to remove pits and carbon.

(2) Check that the valve is ground to the correct valve

face angle.

Valve face angle: 44.5_

44.5_

A75611

(c) Inspect for valve head margin thickness.

(1) Using a vernier calipers, check the valve head mar-

gin thickness.

Standard margin thickness: 1.0 mm (0.039 in.)

Minimum margin thickness: 0.5 mm (0.020 in.)

Margin If the margin thickness is less than the minimum, replace the

Thickness valve.

EM0181

(d) Inspect for overall length.

(1) Using a vernier calipers, check the overall length.

Standard overall length:

Intake 106.95 mm (4.2106 in.)

Overall

Exhaust 105.80 mm (4.1654 in.)

Length

Minimum overall length:

Intake 106.40 mm (4.1890 in.)

Exhaust 105.30 mm (4.1457 in.)

EM2534

If the overall length is less than minimum, replace the valve.

(e) Inspect for valve stem tip.

(1) Check the surface of the valve stem tip for wear.

NOTICE:

Do not grind off more than minimum length.

If the valve stem tip is worn, resurface the tip with a grinder or

replace the valve.

EM0255

1GR−FE ENGINE REPAIR MANUAL (RM1005E)

14−59

ENGINE MECHANICAL − CYLINDER HEAD ASSY (1GR−FE)

9. CLEAN VALVE SEAT

(a) Using a 45_ carbide cutter, resurface the valve seats.

(b) Remove only enough metal to clean the valve seats.

A75612

10. INSPECT VALVE SEAT

(a) Apply a light coat of prussian blue (or white lead) to the

valve face.

(b) Lightly press the valve against the valve seat.

NOTICE:

Width

Do not rotate the valve.

(c) Check the valve face and seat according to the following

procedure.

P12729 (1) If blue appears 360_ around the face, the valve is

concentric.

If not, replace the valve.

(2) If blue appears 360_ around the valve seat, the

guide and face are concentric.

If not, resurface the valve seat.

(3) Check that the seat contact is in the middle of the

valve face with these width.

Standard width: 1.0 − 1.4 mm (0.039 − 0.055 in.)

11. REPAIR VALVE SEAT

NOTICE:

45_ Take off a cutter gradually to makes smooth intake valve

30_ seat.

(a) If the seating is too high on the valve face, use 30_ and

45_ cutters to correct the seat.

1.0 − 1.4 mm

A62787

Intake Side: (b) Intake side:

If the seating is too low on the valve face, use 60_ and 45_

60_

cutters to correct the seat.

45_

1.0 − 1.4 mm

A75613

1GR−FE ENGINE REPAIR MANUAL (RM1005E)

14−60

ENGINE MECHANICAL − CYLINDER HEAD ASSY (1GR−FE)

Exhaust Side: (c) Exhaust side:

If the seating is too low on the valve face, use 75_ and 45_

75_ cutters to correct the seat.

45_

1.0 − 1.4 mm

A62788

(d) Hand−lap the valve and valve seat with an abrasive com-

pound.

(e) After hand−lapping, clean the valve and valve seat.

A75614

12. INSPECT INNER COMPRESSION SPRING

Deviation (a) Inspect for squareness.

(1) Using a steel square, measure the squareness of

the inner compression spring.

Maximum deviation: 2.0 mm (0.079 in.)

If the deviation is greater than maximum, replace the inner com-

pression spring.

EM0988

(b) Inspect for free length.

(1) Using a vernier calipers, measure the free length of

the inner compression spring.

Free length: 47.80 mm (1.8819 in.)

If the free length is not as specified, replace the inner compres-

sion spring.

EM0801

(c) Inspect for tension.

(1) Using a spring tester, measure the tension of the in-

ner compression spring at the specified installed

length.

Installed tension:

186.2 − 205.8 N (19.0 − 21.0 kgf, 41.9 − 46.3 lbf) at 33.3

mm (1.311 in.)

If the installed tension is not specified, replace the inner com-

EM0281 pression spring.

1GR−FE ENGINE REPAIR MANUAL (RM1005E)

14−61

ENGINE MECHANICAL − CYLINDER HEAD ASSY (1GR−FE)

13. INSPECT VALVE GUIDE BUSH OIL CLEARANCE

(a) Using a caliper gauge, measure the inside diameter of the

valve guide bush.

Inside diameter:

5.51 − 5.53 mm (0.2169 − 0.2177 in.)

(b) Subtract the valve stem diameter measurement (Step 8)

from the valve guide bush inside diameter measurement.

Standard oil clearance:

A75615 Intake 0.025 − 0.060 mm (0.0010 − 0.0024 in.)

Exhaust 0.030 − 0.065 mm (0.0012 − 0.0026 in.)

Maximum oil clearance:

Intake 0.08 mm (0.0031 in.)

Exhaust 0.10 mm (0.0039 in..)

If the oil clearance is greater than maximum, replace the valve

and valve guide bush.

14. REMOVE VALVE GUIDE BUSH

(a) Gradually heat the cylinder head to 80 − 100_C (176 −

212_F).

A75616

(b) Place the cylinder head on the wooden block.

SST (c) Using SST, tap out the valve guide bush.

SST 09201−10000, 09201−01055, 09950−70010

(09951−07100)

Wooden Block

A75617

1GR−FE ENGINE REPAIR MANUAL (RM1005E)

14−62

ENGINE MECHANICAL − CYLINDER HEAD ASSY (1GR−FE)

15. INSTALL VALVE GUIDE BUSH

(a) Using a caliper gauge, measure the bush bore diameter

of the cylinder head.

Diameter Bush bore diameter:

10.295 − 10.315 mm (0.4053 − 0.4061 in.)

If the bush bore diameter of the cylinder head is greater than

10.315 mm (0.4061 in.), machine the bush bore to the dimen-

sion of 10.345 − 10.365 mm (0.4073 − 0.4081 in.).

A75618 Valve guide bush diameter

STD 10.333 − 10.344 mm (0.4068 − 0.4072 in.)

O/S 0.05 10.383 − 10.394 mm (0.4088 − 0.4092 in.)

(b) Gradually heat the cylinder head to 80 − 100_C (176 −

212_F).

A75616

(c) Place the cylinder head on the wooden block.

SST

Protrusion (d) Using SST, tap in a new valve guide bush to the specified

Height protrusion height.

SST 09201−10000, 09201−01055, 09950−70010

(09951−07100)

Protrusion height: 9.3 − 9.7 mm (0.366 − 0.382 in.)

Wooden Block

A75619

(e) Using a sharp 5.5 mm reamer, ream the valve guide bush

to obtain the standard specified clearance between the

valve guide bush and valve stem.

Standard oil clearance:

Intake 0.025 − 0.060 mm (0.0010 − 0.0024 in.)

Exhaust 0.030 − 0.065 mm (0.0012 − 0.0026 in.)

A75620

1GR−FE ENGINE REPAIR MANUAL (RM1005E)

14−63

ENGINE MECHANICAL − CYLINDER HEAD ASSY (1GR−FE)

16. INSPECT VALVE LIFTER

(a) Using a micrometer measure the valve lifter diameter.

Valve lifter diameter:

30.966 − 30.976 mm (1.2191 − 1.2195 in.)

P16860

17. INSPECT VALVE LIFTER OIL CLEARANCE

(a) Using a caliper gauge, measure the lifter bore diameter

Diameter of the cylinder head.

Lifter bore diameter:

31.009 − 31.025 mm (1.2208 − 1.2215 in.)

(b) Subtract the valve lifter diameter measurement (Step 16)

from the lifter bore diameter measurement.

Standard oil clearance:

A75621 0.033 − 0.059 mm (0.0013 − 0.0023 in.)

Maximum oil clearance: 0.08 mm (0.0031 in.)

If the oil clearance is greater than maximum, replace the valve

lifter.

If necessary, replace the cylinder head.

18. INSPECT CAMSHAFT OIL CLEARANCE

Plastigage (a) Clean the camshaft bearing caps, camshaft bearings and

camshaft journals.

(b) Install the camshaft bearing. (See page 14−4)

(c) Place the camshaft on the cylinder head.

(d) Lay a strip of Plastigage across each of the camshaft jour-

nals.

(e) Install the camshaft bearing caps. (See page 14−4)

A75622 NOTICE:

Do not turn the camshafts.

(f) Remove the camshaft bearing caps. (See page 14−4)

1GR−FE ENGINE REPAIR MANUAL (RM1005E)

14−64

ENGINE MECHANICAL − CYLINDER HEAD ASSY (1GR−FE)

(g) Measure the Plastigage at its widest point.

Standard oil clearance (Cylinder head RH):

No. 1

0.008 − 0.038 mm (0.0003 − 0.0015 in.)

(Intake)

No. 1

0.040 − 0.079 mm (0.0016 − 0.0031 in.)

(Exhaust)

Others 0.025 − 0.062 mm (0.0010 − 0.0024 in.)

Standard oil clearance (Cylinder head LH):

A75623

No. 1 0.040 − 0.079 mm (0.0016 − 0.0031 in.)

Others 0.025 − 0.062 mm (0.0010 − 0.0024 in.)

Maximum oil clearance (Cylinder head RH):

No. 1

0.07 mm (0.0028 in.)

(Intake)

Others 0.10 mm (0.0039 in.)

Maximum oil clearance (Cylinder head LH):

0.10 mm (0.0039 in.)

If the oil clearance is greater than maximum, replace the cam-

shaft bearings and/or camshaft.

If necessary, replace the camshaft bearing caps and cylinder

head as a set.

Reference:

Cylinder head journal

40.009 − 40.017 mm (1.5752 − 1.5755 in.)

bore diameter

Camshaft bearing

center wall thickness 2.004 − 2.008 mm (0.0789 − 0.0791 in.)

(Mark ”2”)

Camshaft journal di-

35.971 − 35.985 mm (1.4165 − 1.4167 in.)

ameter

(h) Remove the Plastigage completely.

(i) Remove the camshafts.

(j) Remove the camshaft bearing.

19. INSPECT CAMSHAFT THRUST CLEARANCE

(a) Install the camshafts. (See page 14−4)

(b) Using a dial indicator, measure the thrust clearance while

moving the camshaft back and forth.

Standard thrust clearance:

0.04 − 0.09 mm (0.016 − 0.035 in.)

Maximum thrust clearance: 0.11 mm (0.0043 in.)

If the thrust clearance is greater than maximum, replace the

A75624 camshafts.

If necessary, replace the camshaft bearing caps and cylinder

head as a set.

1GR−FE ENGINE REPAIR MANUAL (RM1005E)

14−65

ENGINE MECHANICAL − CYLINDER HEAD ASSY (1GR−FE)

20. INSTALL RING PIN

(a) Using a plastic−faced hammer, tap in the new ring pins to

the specified protrusion height.

Specified protrusion height:

2.7 − 3.3 mm (0.106 − 0.130 in.)

Cylinder Head RH Side: Cylinder Head LH Side:

11 mm

Protrusion

8 mm Height

Engine Engine

Front Front

A75625

1GR−FE ENGINE REPAIR MANUAL (RM1005E)

14−66

ENGINE MECHANICAL − CYLINDER HEAD ASSY (1GR−FE)

21. INSTALL STRAIGHT PIN

(a) Using a plastic−faced hammer, tap in the new straight

pins to the specified protrusion height.

Specified protrusion height:

A 17.5 − 19.5 mm (0.689 − 0.768 in.)

B 7.5 − 8.5 mm (0.295 − 0.335 in.)

C 7.0 − 9.0 mm (0.276 − 0.354 in.)

Cylinder Head RH Side:

Upper Side:

Front Side:

B

Intake Manifold Side:

Cylinder Head LH Side: C

Upper Side:

Front Side:

B

Intake Manifold Side:

8 mm

5 mm

Protrusion

34 mm Protrusion

Height 13.8 mm

Height

C

B and C

A

A75627

1GR−FE ENGINE REPAIR MANUAL (RM1005E)

14−67

ENGINE MECHANICAL − CYLINDER HEAD ASSY (1GR−FE)

22. INSTALL STUD BOLT

(a) Using the torx socket wrench E5 and E7, install the stud

bolts.

Torque:

4.0 N×m (41 kgf×cm, 35 in.×lbf) for stud bolt A

9.0 N×m (92 kgf×cm, 80 in.×lbf) for stud bolt B

Cylinder Head RH Side:

Upper Side:

Rear Side:

Exhaust Manifold Side:

Cylinder Head LH Side:

B

Upper Side:

Rear Side:

A

A

18 mm

Exhaust Manifold Side:

12 mm

37.5 mm

33.3 mm

9 mm 13 mm

B A B

A75629

1GR−FE ENGINE REPAIR MANUAL (RM1005E)

14−68

ENGINE MECHANICAL − CYLINDER HEAD ASSY (1GR−FE)

23. INSTALL UNION

(a) Apply adhesive to 2 or 3 threads of the bolt end.

Adhesive:

Part No. 08833 − 00070, THREE BOND 1324 or equiva-

lent

(b) Using a deep socket wrench 12, install the unions.

Torque: 15 N×m (150 kgf×cm, 11 ft×lbf)

Adhesive

A75631

Cylinder Head RH (Front) Side: Cylinder Head LH (Intake Manifold) Side:

A B

67 mm

9 mm 9 mm

30 mm

A B A75632

1GR−FE ENGINE REPAIR MANUAL (RM1005E)

14−69

ENGINE MECHANICAL − CYLINDER HEAD ASSY (1GR−FE)

24. INSTALL TIGHT PLUG

(a) Apply adhesive around tight plug.

Adhesive Adhesive:

Part No. 08833 − 00070, THREE BOND 1324 or equiva-

lent

(b) Using SST, tap in the tight plugs to the specified depth.

SST 09950−60010 (09951−00250), 09950−70010

(09951−07150)

A58129 Specified depth: 1.5 mm (0.059 in.)

Cylinder Head RH (Rear) Side: Cylinder Head LH (Rear) Side:

SST

Depth

A75633

1GR−FE ENGINE REPAIR MANUAL (RM1005E)

14−70

ENGINE MECHANICAL − CYLINDER HEAD ASSY (1GR−FE)

25. INSTALL W/ HEAD STRAIGHT SCREW PLUG

(a) Using a straight hexagon wrench 14, install a new gasket

and straight screw plug.

Torque: 80 N×m (816 kgf×cm, 59 ft×lbf)

Cylinder Head RH Side: Cylinder Head LH Side:

Upper Side: Upper Side:

Front Side: Front Side:

A75634

26. INSTALL VALVE STEM OIL O SEAL OR RING

Light Brown Gray

HINT:

The intake valve stem oil seal is light brown and the exhaust

valve stem oil seal is gray.

(a) Apply a light coat of engine oil to the valve guide bush.

Intake Side: Exhaust Side:

A76162

(b) Using SST, push in a new valve stem oil seal.

SST

SST 09201−41020

A75639

1GR−FE ENGINE REPAIR MANUAL (RM1005E)

14−71

ENGINE MECHANICAL − CYLINDER HEAD ASSY (1GR−FE)

27. INSTALL VALVE SPRING SEAT

A75638

28. INSTALL VALVE

(a) Apply the engine oil to the valve as shown in the illustra-

35 mm tion.

(1.378 in.)

A75640

(b) Place the cylinder head on the wooden block.

SST (c) Install the valve, inner compression spring and valve

spring retainer.

(d) Using SST, compress the inner compression spring and

place the 2 valve spring retainer rocks around the valve

stem.

SST 09202−70020 (09202−00010)

Wooden Block

A75602

(e) Using a pin punch 5, lightly tap the valve stem tip to en-

sure a proper fit.

NOTICE:

Be careful not to damage the valve stem tip.

A75641

29. INSTALL VALVE LIFTER

(a) Apply the engine oil to the valve stem end and valve lifter,

and install its.

(b) Check that the valve lifter rotates smoothly by hand.

A75601

1GR−FE ENGINE REPAIR MANUAL (RM1005E)

You might also like

- Plymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceFrom EverandPlymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceNo ratings yet

- Overhaul: 1. Remove Valve LifterDocument13 pagesOverhaul: 1. Remove Valve LifterMark Anthony FletcherNo ratings yet

- Cyl Head InstallDocument8 pagesCyl Head InstallYannick de WalqueNo ratings yet

- 14 - Cylinder Head - InspectionDocument9 pages14 - Cylinder Head - InspectionNazmul HassanNo ratings yet

- Overhaul: 1. Inspect Connecting Rod Thrust ClearanceDocument22 pagesOverhaul: 1. Inspect Connecting Rod Thrust ClearanceIslam AttiaNo ratings yet

- Disassembly: 2Uz-Fe Engine Mechanical - Engine UnitDocument21 pagesDisassembly: 2Uz-Fe Engine Mechanical - Engine UnitMateusz Jaskuła100% (1)

- Valve Clearance: InspectionDocument5 pagesValve Clearance: InspectionПежов СитроенNo ratings yet

- w040001 PDFDocument31 pagesw040001 PDFresolution8878No ratings yet

- 1 AzDocument7 pages1 AzEdU RECTIFICANo ratings yet

- Valve Clearance PDFDocument10 pagesValve Clearance PDFspammed Scribd userNo ratings yet

- Overhaul: 1. Remove Oil Filler Cap Sub-AssyDocument33 pagesOverhaul: 1. Remove Oil Filler Cap Sub-AssyHenry SilvaNo ratings yet

- Partial Engine Assy (1Nz Fe/2Nz Fe) : OverhaulDocument26 pagesPartial Engine Assy (1Nz Fe/2Nz Fe) : OverhaulNelson Caño Basalo100% (3)

- Overhaul: 1. Fix Clutch Drum & Input Shaft AssyDocument22 pagesOverhaul: 1. Fix Clutch Drum & Input Shaft AssyBắc HoàngNo ratings yet

- Adjust Valve Clearance on 2002 ECHO RM884UDocument6 pagesAdjust Valve Clearance on 2002 ECHO RM884UBoncu BoncuNo ratings yet

- Matrix 2003 2zz 8Document10 pagesMatrix 2003 2zz 8alan lantiguaNo ratings yet

- Overhaul Partial Engine Assembly 2AZ-FSEDocument36 pagesOverhaul Partial Engine Assembly 2AZ-FSEHenry SilvaNo ratings yet

- Overhaul: - Vane Pump AssyDocument7 pagesOverhaul: - Vane Pump AssyRomy MNo ratings yet

- Sienna Timing Belt ReplacementDocument8 pagesSienna Timing Belt ReplacementGlenn MartinNo ratings yet

- Overhaul: Partial Engine Assy (1Gr Fe)Document50 pagesOverhaul: Partial Engine Assy (1Gr Fe)Islam AttiaNo ratings yet

- Motor 1AZ-FE OverhaulDocument29 pagesMotor 1AZ-FE OverhaulfredhNo ratings yet

- Overhaul: 1. Inspect Connecting Rod Thrust ClearanceDocument16 pagesOverhaul: 1. Inspect Connecting Rod Thrust ClearanceAntonio TorresNo ratings yet

- Valve Clearance: AdjustmentDocument10 pagesValve Clearance: AdjustmentDannyDDannyD100% (1)

- Camshaft Removal Guide for 1NZ-FE/2NZ-FE EnginesDocument8 pagesCamshaft Removal Guide for 1NZ-FE/2NZ-FE EnginesMaung KyawNo ratings yet

- Camshaft GearDocument10 pagesCamshaft GearJuan Antonio Ochoa PadronNo ratings yet

- Removal: 2Tr-Fe Engine Mechanical - CamshaftDocument12 pagesRemoval: 2Tr-Fe Engine Mechanical - CamshaftNorberto Calcina100% (1)

- 03 - Valve Clearance - AdjustmentDocument5 pages03 - Valve Clearance - AdjustmentjordantNo ratings yet

- Disassembly: Power Steering Vane Pump (2Jz Ge)Document1 pageDisassembly: Power Steering Vane Pump (2Jz Ge)Moh DeBrNo ratings yet

- Platz 02Document7 pagesPlatz 02dawitmesfin9No ratings yet

- Overhaul: 1. Inspect Connecting Rod Thrust ClearanceDocument17 pagesOverhaul: 1. Inspect Connecting Rod Thrust ClearanceHenry SilvaNo ratings yet

- Camshaft (Hilux/1Kd-Ftv, 2Kd-Ftv (Tasa Made For Argentina) ) : ReplacementDocument5 pagesCamshaft (Hilux/1Kd-Ftv, 2Kd-Ftv (Tasa Made For Argentina) ) : ReplacementJefry LehgansNo ratings yet

- Partial Engine Assembly2Document34 pagesPartial Engine Assembly2jeremih alhegnNo ratings yet

- Manual de Repararacion Yaris 1NZFEDocument18 pagesManual de Repararacion Yaris 1NZFEVictorNo ratings yet

- Toyota LC HZJ78 02 CL ClutchDocument4 pagesToyota LC HZJ78 02 CL Clutchyannis.spinnerNo ratings yet

- Overhaul Cylinder Block 1AZ-FE EngineDocument17 pagesOverhaul Cylinder Block 1AZ-FE EngineHenry SilvaNo ratings yet

- Removal: CH-7 SR-24Document3 pagesRemoval: CH-7 SR-24Boncu BoncuNo ratings yet

- Valve Clearance (1Hd Fte) : InspectionDocument2 pagesValve Clearance (1Hd Fte) : InspectionArief SoehartoNo ratings yet

- Clutch Por SacarDocument4 pagesClutch Por SacarVides AyalaNo ratings yet

- On-Vehicle Repair: Valve Body Removal of Valve BodyDocument10 pagesOn-Vehicle Repair: Valve Body Removal of Valve BodyMayobanex Moya MartinezNo ratings yet

- Insp Valve Clearance 2.7 3rz PDFDocument5 pagesInsp Valve Clearance 2.7 3rz PDFEdwin Versteeg100% (1)

- Engine Mechanical PDFDocument193 pagesEngine Mechanical PDFDean BNo ratings yet

- Inspection: - Cylinder BlockDocument6 pagesInspection: - Cylinder Blockdawitmesfin9No ratings yet

- Install cylinder block componentsDocument7 pagesInstall cylinder block componentsYannick de WalqueNo ratings yet

- Calibracion de Valvulas Toyota 1nz YarisDocument11 pagesCalibracion de Valvulas Toyota 1nz Yariscpaolinod100% (3)

- Oil Pump Assy (1Az-Fe) : OverhaulDocument2 pagesOil Pump Assy (1Az-Fe) : OverhaulHenry SilvaNo ratings yet

- Manual 245 U140F 060Document6 pagesManual 245 U140F 060Nacho Arroyo100% (2)

- 5vz-Fe Timing Belt InstallationDocument6 pages5vz-Fe Timing Belt InstallationJorge RisquezNo ratings yet

- On-Vehicle Repair Valve Body Removal of Valve Body: Automatic TransmissionDocument6 pagesOn-Vehicle Repair Valve Body Removal of Valve Body: Automatic TransmissionMayobanex Moya MartinezNo ratings yet

- Set Timing Engine - Mechanical - 5s-Fe-2Document2 pagesSet Timing Engine - Mechanical - 5s-Fe-2Nato DlAngelesNo ratings yet

- Engine Cylinder Block Disassembly GuideDocument8 pagesEngine Cylinder Block Disassembly GuideYannick de WalqueNo ratings yet

- Timing Belt (Hilux/1Kd-Ftv, 2Kd-Ftv (Tasa Made For Argentina) )Document5 pagesTiming Belt (Hilux/1Kd-Ftv, 2Kd-Ftv (Tasa Made For Argentina) )Ben GreenNo ratings yet

- Overhaul: 1. Remove Transmission Control Shaft Lever RHDocument43 pagesOverhaul: 1. Remove Transmission Control Shaft Lever RHBắc HoàngNo ratings yet

- Httplexus - Solar3.eurmrm684em em 0026 PDFDocument5 pagesHttplexus - Solar3.eurmrm684em em 0026 PDFWiz KingNo ratings yet

- Toyota 4efe - Correa de Distribucion PDFDocument11 pagesToyota 4efe - Correa de Distribucion PDFRonald Gareca RuedaNo ratings yet

- Toyota 5l Valve ClearanceDocument5 pagesToyota 5l Valve ClearancedennoNo ratings yet

- Toyota 5l Valve ClearanceDocument5 pagesToyota 5l Valve ClearancedennoNo ratings yet

- Calibracion Valvulas Toyota 1GRFEDocument9 pagesCalibracion Valvulas Toyota 1GRFEJose Antonio Rivero ReyesNo ratings yet

- Overhaul: 1. Remove Starter Yoke AssyDocument6 pagesOverhaul: 1. Remove Starter Yoke AssyIslam AttiaNo ratings yet

- Remove FU-22 2GR-FE Fuel PumpDocument3 pagesRemove FU-22 2GR-FE Fuel PumpRen KiyoshiiNo ratings yet

- Calibracion de Valvulas Toyota 6V Hi Lux 1GRDocument19 pagesCalibracion de Valvulas Toyota 6V Hi Lux 1GRcpaolinodNo ratings yet

- Torque Converter Clutch Case: Automatic TransmissionDocument4 pagesTorque Converter Clutch Case: Automatic TransmissionAnton FortovNo ratings yet

- XCMG Iflex5 Operators ManualDocument44 pagesXCMG Iflex5 Operators ManualIslam AttiaNo ratings yet

- XCMG Iflex5 Operators ManualDocument42 pagesXCMG Iflex5 Operators ManualIslam AttiaNo ratings yet

- XCMG 25Document14 pagesXCMG 25Islam AttiaNo ratings yet

- XCMG Iflex5 Operators ManualDocument42 pagesXCMG Iflex5 Operators ManualIslam AttiaNo ratings yet

- XCMG Iflex5 Operators ManualDocument44 pagesXCMG Iflex5 Operators ManualIslam AttiaNo ratings yet

- XCMG 25Document7 pagesXCMG 25Islam AttiaNo ratings yet

- XCMG Iflex5 Operators ManualDocument69 pagesXCMG Iflex5 Operators ManualIslam AttiaNo ratings yet

- SpecificationsDocument5 pagesSpecificationsIslam AttiaNo ratings yet

- XCMG RT70E Load ChartDocument24 pagesXCMG RT70E Load ChartIslam AttiaNo ratings yet

- XCMG XC6Document4 pagesXCMG XC6Islam AttiaNo ratings yet

- XCMG QUY55 Crawler Crane Operator's ManualDocument88 pagesXCMG QUY55 Crawler Crane Operator's ManualIslam AttiaNo ratings yet

- XCMG Forklifts Technical ManualsDocument16 pagesXCMG Forklifts Technical ManualsIslam AttiaNo ratings yet

- XCMG 25Document7 pagesXCMG 25Islam AttiaNo ratings yet

- Technical SpecificationsDocument4 pagesTechnical SpecificationsIslam AttiaNo ratings yet

- Standard Fuel Consumption (Model)Document11 pagesStandard Fuel Consumption (Model)Sreekanth Sattiraju87% (45)

- XCMG Catalogue 2017Document14 pagesXCMG Catalogue 2017Islam AttiaNo ratings yet

- XCMG XC6-3006K - XC6Document11 pagesXCMG XC6-3006K - XC6Islam AttiaNo ratings yet

- Operating & Maintenance Manual: XE210C Hydraulic ExcavatorDocument154 pagesOperating & Maintenance Manual: XE210C Hydraulic Excavatornajafali100% (1)

- V222TI Installation Instructions ManualDocument91 pagesV222TI Installation Instructions ManualLisandroNo ratings yet

- Operating & Maintenance Manual: XE210C Hydraulic ExcavatorDocument154 pagesOperating & Maintenance Manual: XE210C Hydraulic Excavatornajafali100% (1)

- Doosan HP450 Operator Manual PDFDocument108 pagesDoosan HP450 Operator Manual PDFLuis Panti EkNo ratings yet

- DE12 Diesel Engine Shop ManualDocument165 pagesDE12 Diesel Engine Shop ManualkevUwUr93% (15)

- S 5-Troubleshooting-Diagnostic Codes PresentDocument54 pagesS 5-Troubleshooting-Diagnostic Codes PresentSkrzynie BiegówNo ratings yet

- XCMG SQ10SK3Q Operation and Maintenance ManualDocument36 pagesXCMG SQ10SK3Q Operation and Maintenance ManualIslam Attia0% (1)

- XCMG QY-12 Electrical Wiringing SchematicDocument6 pagesXCMG QY-12 Electrical Wiringing SchematicIslam AttiaNo ratings yet

- XCMG QUY150 Load ChartDocument8 pagesXCMG QUY150 Load ChartIslam AttiaNo ratings yet

- Doosan Daewoo D1146Document147 pagesDoosan Daewoo D1146FranciscoOliveira100% (2)

- XCMG Iflex5 Operators ManualDocument42 pagesXCMG Iflex5 Operators ManualIslam AttiaNo ratings yet

- XCMG ZL50GN G-Series Wheel Loader - Outline DimensionDocument6 pagesXCMG ZL50GN G-Series Wheel Loader - Outline DimensionIslam AttiaNo ratings yet

- XCMG Forklifts Technical ManualsDocument16 pagesXCMG Forklifts Technical ManualsIslam AttiaNo ratings yet

- JB-Det Overhaul ManualDocument64 pagesJB-Det Overhaul ManualMohdYasirNo ratings yet

- Fastener Tightening SpecificationsDocument6 pagesFastener Tightening Specificationsyeferson mora guerreroNo ratings yet

- Chery A-Series Service ManualDocument564 pagesChery A-Series Service ManualHarlinton descalzi100% (4)

- 3.5-3.9-4.2 Litre V8 EnginesDocument82 pages3.5-3.9-4.2 Litre V8 EnginesGustavo PagniNo ratings yet

- Chery SQR7080 Service Manual 372 Engine Timing BeltDocument44 pagesChery SQR7080 Service Manual 372 Engine Timing BeltFernando Ortiz100% (1)

- Remove Install ValvesDocument3 pagesRemove Install ValvesRendy MechanicNo ratings yet

- Renault F8QT ManualDocument74 pagesRenault F8QT ManualJose Luis Medina100% (1)

- 5-Cylinder Direct Petrol Injection Engine 2.5LDocument237 pages5-Cylinder Direct Petrol Injection Engine 2.5Lberenice togaNo ratings yet

- AfterSales Training - Air Cooled Engine RepairDocument72 pagesAfterSales Training - Air Cooled Engine RepairPaul Williams100% (2)

- GSX1400 Manual Section 3 EngineDocument78 pagesGSX1400 Manual Section 3 EngineDeaferrantNo ratings yet

- Service Manual 157QMJDocument60 pagesService Manual 157QMJGeert Verfaillie67% (3)

- Air Compressor: Model J08C-TP With 1 CylinderDocument21 pagesAir Compressor: Model J08C-TP With 1 Cylindernguyen phuong nhaNo ratings yet

- MB308 1Document11 pagesMB308 1Amanz MKNo ratings yet

- Kawasaki KLX110 & KLX110L Service Repair Manual - Chapter 4 - Engine Top EndDocument41 pagesKawasaki KLX110 & KLX110L Service Repair Manual - Chapter 4 - Engine Top EndbarackkNo ratings yet

- 2.0L ENGINE Chevy Tracker 1999Document52 pages2.0L ENGINE Chevy Tracker 1999andres german romeroNo ratings yet

- 07 2984BDocument22 pages07 2984BCHARLES HUMBERTO0% (1)

- Preparation Materials Preparation Materials Engine Engine Mechanical CoolingDocument142 pagesPreparation Materials Preparation Materials Engine Engine Mechanical CoolinghaelstoneNo ratings yet

- Yamaha XS650 XS 650 Service Repair ManualDocument213 pagesYamaha XS650 XS 650 Service Repair Manualandy miller100% (4)

- Cylinder Head Assembly Reassembly (4JK1)Document13 pagesCylinder Head Assembly Reassembly (4JK1)TALLER DE MECATRONICANo ratings yet

- 02-Engine Mechanical SystemDocument116 pages02-Engine Mechanical Systemsalvador341No ratings yet

- Engine Component Inspection GuideDocument248 pagesEngine Component Inspection GuideLolok Tiviyanto100% (3)

- Audi Q3 RS - CTS CZGDocument285 pagesAudi Q3 RS - CTS CZGRoland HendriksNo ratings yet

- AVEO 2007-2010/wave - 07-10/engine Mechanical - 1.5L/Repair Instructions - Off VehicleDocument39 pagesAVEO 2007-2010/wave - 07-10/engine Mechanical - 1.5L/Repair Instructions - Off VehicleArley Hernandez100% (1)

- Data-Tech 2012-13 Hyundai Tucson Instalacion de Culata 2.0L-2.4L LIBRODocument74 pagesData-Tech 2012-13 Hyundai Tucson Instalacion de Culata 2.0L-2.4L LIBRORubenNo ratings yet

- V1-Complete List and Quotation For Rig Spare Parts GEM1 0910-28009Document3 pagesV1-Complete List and Quotation For Rig Spare Parts GEM1 0910-28009AmirNo ratings yet

- E 911 73 Katalog PDFDocument484 pagesE 911 73 Katalog PDFexigencetradingNo ratings yet

- Overhaul Guide for B3 EngineDocument44 pagesOverhaul Guide for B3 EnginesatthatNo ratings yet

- 4.2L Engine PDFDocument28 pages4.2L Engine PDFIvanov Hernandez Freire67% (3)

- Cylinder Head ValvesDocument6 pagesCylinder Head ValvesjoaobargasNo ratings yet

- Perkins Diesel Engine 2006-12t1Document87 pagesPerkins Diesel Engine 2006-12t1Armando OrtaNo ratings yet