Professional Documents

Culture Documents

Install cylinder block components

Uploaded by

Yannick de WalqueOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Install cylinder block components

Uploaded by

Yannick de WalqueCopyright:

Available Formats

EM−76

ENGINE MECHANICAL − CYLINDER BLOCK

EM1RY−01

REASSEMBLY

HINT:

S Thoroughly clean all parts to be assembled.

S Before installing the parts, apply fresh engine oil to all slid-

ing and rotating surfaces.

S Replace all gaskets, O−rings and oil seals with new parts.

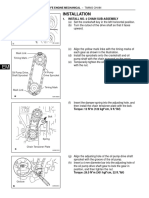

1. ASSEMBLE PISTON AND CONNECTING ROD

(a) Install a new snap ring on one side of the piston pin hole.

(b) Gradually heat the piston to 60˚C (140˚F).

(c) Coat the piston pin and piston hole of the piston with en-

gine oil.

A09505

Front Mark (d) Align the front marks of the piston and connecting rod,

(Arrow) and push in the piston pin with your thumb.

(e) Install a new snap ring on the other side of the piston pin

hole.

2. INSTALL PISTON RINGS

(a) Install the coil by hand.

Front Mark

(Protrusion)

A09506

(b) Using a piston ring expander, install the oil ring.

HINT:

Coil Joint Face the end gap of the oil ring in the opposite direction coil

joint.

Oil Ring End EM0242

(c) Using a piston ring expander, install the No.2 and No.1

Code Mark piston rings with the code mark facing upward.

No. 1 Code mark:

No. 1 1T

No. 2 2T

No. 2 NOTICE:

Make the expansion of the piston ring as small as neces-

Code Mark sary.

A09458

1CD−FTV ENGINE SUP (RM856E)

EM−77

ENGINE MECHANICAL − CYLINDER BLOCK

Front D No. 1 (d) Position the piston rings so that the ring ends are as

Mark Compression shown.

(Arrow) Ring

D Oil Ring

D No. 2

Compression

Ring

D Coil A09507

3. INSTALL CONNECTING ROD BEARINGS

(a) Align the bearing claw with the groove of the connecting

rod or connecting cap.

(b) Install the bearings in the connecting rod and connecting

rod cap.

A09508

4. INSTALL CYLINDER BLOCK OIL ORIFICE

Using a 6 mm hexagon wrench, install the oil orifice.

Torque: 9 N·m (90 kgf·cm, 78 in.·lbf)

6 mm Hexagon

Wrench

A09473

5. INSTALL OIL NOZZLES

Install the oil nozzle with the bolt. Install the 4 oil nozzles.

Torque: 7.4 N·m (75 kgf·cm, 65 in.·lbf)

A09503

6. INSTALL MAIN BEARINGS

HINT:

Upper bearings have an oil groove and oil holes; lower bearings

do not.

(a) Align the bearing claw with the claw groove of the cylinder

block, and push in the 5 upper bearings.

A09509

1CD−FTV ENGINE SUP (RM856E)

EM−78

ENGINE MECHANICAL − CYLINDER BLOCK

(b) Align the bearing claw with the claw groove of the main

bearing cap, and push in the 5 lower bearings.

A09513

7. INSTALL UPPER THRUST WASHERS

Install the 2 thrust washers under the No. 3 journal position of

the cylinder block with the oil grooves facing outward.

8. PLACE CRANKSHAFT ON CYLINDER BLOCK

Groove A09510

9. I NSTALL M AI N BEARI NG CAPS AND LO W ER

THRUST WASHERS

(a) Install the 2 thrust washers on the No. 3 bearing cap with

the oil grooves facing outward.

Groove

A09512

(b) Install the 5 main bearing caps in their proper locations.

HINT:

Each bearing cap has a number and a front mark.

A16011

(c) Apply a light coat of engine oil on the threads and under

the heads of the main bearing cap bolts.

(d) Install and uniformly tighten the 10 bolts of the main bear-

ing cap in several passes.

Torque: 115 N·m (1,150 kgf·cm, 85 ft·lbf)

(e) Check that the crankshaft turns smoothly.

10. CHECK CRANKSHAFT THRUST CLEARANCE

(See page EM−59)

A09497

1CD−FTV ENGINE SUP (RM856E)

EM−79

ENGINE MECHANICAL − CYLINDER BLOCK

Front Mark 11. I NSTALL PI STO N AND CO NNECTI NG RO D AS-

(Arrow) SEMBLES

Push Using a piston ring compressor, push the correct numbered pis-

ton and connecting rod assemblies into each cylinder with the

Front

front mark of the piston facing forward.

A09511

Front Mark 12. PLACE CONNECTING ROD CAP ON CONNECTING

(Protrusion) ROD

(a) Match the numbered connecting rod cap with the con-

necting rod.

(b) Install the connecting rod cap with the front mark facing

forward.

13. INSTALL CONNECTING ROD CAP BOLTS

HINT:

A09514 S The cap bolts are tightened in 2 progressive steps (steps

(b) and (d)).

S If any of the connecting rod cap bolts is broken or de-

formed, replace it.

(a) Apply a light coat of engine oil on the threads and under

the heads of the of the connecting rod cap bolts.

(b) Install and alternately tighten the 2 cap bolts in several

passes.

Torque: 30 N·m (300 kgf·cm, 22 ft·lbf)

If any of the cap bolts does not meet the torque specification,

replace the connecting rod cap bolts.

A09493

(c) Mark the front of the cap bolt with the paint.

90˚ 90˚ (d) Relight the cap bolts 90˚ as shown.

(e) Check that the painted mark is now at a 90˚ angle to the

Front front.

Painted Mark (f) Check that the crankshaft turns smoothly.

14. CHECK CONNECTING ROD THRUST CLEARANCE

(See page EM−59)

A09490

1CD−FTV ENGINE SUP (RM856E)

EM−80

ENGINE MECHANICAL − CYLINDER BLOCK

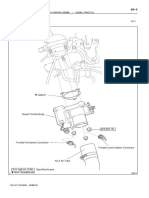

15. INSTALL STUD BOLT OF REAR OIL SEAL RETAINER

Adhesive HINT:

When using a new rear oil seal retainer, stud bolt must be

installed.

Apply adhesive to the threads of the stud bolt and install it.

Adhesive: Part No. 08833−00070, THREE BOND 1324

or equivalent

16. INSTALL REAR OIL SEAL RETAINER

A09445 (a) Remove any old packing (FIPG) material and be careful

not to drop any oil on the contact surfaces of the oil seal

retainer and cylinder block.

S Thoroughly clean all components to remove all the

loose material.

S Using a non−residue solvent, clean both sealing

surfaces.

(b) Apply seal packing to the oil seal retainer as shown in the

illustration.

Seal Width

Seal packing: Part No. 08826−00080 or equivalent

2 − 3 mm S Install a nozzle that has been cut to a 2 − 3 mm (0.08

− 0.12 in.) opening.

S Parts must be assembled within 15 minutes of ap-

plication. Otherwise the material must be removed

and reapplied.

A09476 S Immediately remove nozzle from the tube and rein-

stall cap.

(c) Install the oil seal retainer with the 6 bolts. Uniformly tight-

en the bolt in several passes.

Torque: 7.4 N·m (75 kgf·cm, 65 in.·lbf)

(d) Install the oil pan insulator with the bolt.

Torque: 7.5 N·m (76 kgf·cm, 66 in.·lbf)

17. INSTALL OIL PUMP (See page LU−14)

18. INSTALL OIL STRAINER, NO. 2 OIL PAN AND OIL LEV-

EL SENSOR (See page LU−14)

19. INSTALL OIL JET PRESSURE VALVE

Using an 8 mm hexagon wrench, install a new gasket and the

pressure valve.

Torque: 30 N·m (310 kgf·cm, 22 ft·lbf)

8 mm 20. INSTALL NO. 1 FUEL PIPE

Hexagon Install the fuel pipe with the 3 bolts.

Wrench Torque:

8.8 N·m (90 kgf·cm, 78 in.·lbf) for 12 mm head

A09519 20.5 N·m (210 kgf·cm, 15 ft·lbf) for 14 mm head

1CD−FTV ENGINE SUP (RM856E)

EM−81

ENGINE MECHANICAL − CYLINDER BLOCK

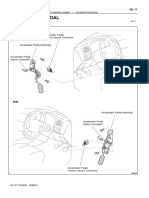

21. INSTALL OIL PRESSURE SWITCH

(See page LU−1)

22. INSTALL NO. 1 OIL COOLER PIPE

Install 2 new gaskets and the oil cooler pipe with the union bolt.

Torque: 56.4 N·m (575 kgf·cm, 42 ft·lbf)

23. INSTALL ENGINE COOLANT DRAIN UNION

Seal Packing

(a) Apply seal packing to 2 or 3 threads.

Seal packing: Part No. 08826−00100 or equivalent

P12477

(b) Install the drain union.

Torque: 28.5 N·m (290 kgf·cm, 21 ft·lbf)

HINT:

Upper After applying the specified torque, if the drain pipe of the drain

Front union is not at the position shown in the illustration, rotate the

drain union further to clockwise and make the drain pipe face

downward.

60˚ 24. INSTALL OIL COOLER (See page LU−21)

A09522

25. INSTALL OIL FILTER BRACKET

Install the oil filter bracket and gasket with the bolt and 2 nuts.

Torque: 34 N·m (347 kgf·cm, 25 ft·lbf)

A15985

26. INSTALL DRIVE BELT TENSIONER

Install the drive belt tensioner with the bolt and 2 nuts.

Torque: 87 N·m (887 kgf·cm, 64 ft·lbf)

27. INSTALL ALTERNATOR BRACKET

Install the alternator bracket with the 2 bolts.

Torque: 31.4 N·m (320 kgf·cm, 23 ft·lbf)

28. INSTALL ALTERNATOR

29. INSTALL THERMOSTAT AND WATER INLET

B14662 (See page CO−11)

30. INSTALL WATER PUMP (See page CO−7)

1CD−FTV ENGINE SUP (RM856E)

EM−82

ENGINE MECHANICAL − CYLINDER BLOCK

31. INSTALL SUPPLY PUMP (See Pub. No. RM697E, on

page FU−18)

32. INSTALL CYLINDER HEAD (See page EM−47)

33. INSTALL TIMING BELT AND PULLEYS

(See page EM−18)

34. DISCONNECT ENGINE FROM ENGINE STAND

35. INSTALL REAR END PLATE

36. INSTALL FLYWHEEL

(a) Apply adhesive to 2 or 3 threads of the bolt end.

Adhesive Adhesive: Part No. 08833−00070, THREE BOND 1324

or equivalent

A09444

(b) Install and uniformly tighten the 8 bolts in several passes

5 and in the sequence shown.

Torque: 88.2 N·m (900 kgf·cm, 65 ft·lbf)

1

6 7

3 4

8 6

2

A09446

1CD−FTV ENGINE SUP (RM856E)

You might also like

- Plymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceFrom EverandPlymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceNo ratings yet

- Reassembly: 1. Assemble Piston and Connecting RodDocument7 pagesReassembly: 1. Assemble Piston and Connecting Roddawitmesfin9No ratings yet

- Balance Shaft, CamryDocument13 pagesBalance Shaft, CamryLeonardNo ratings yet

- Reassembly: 1. Assemble Piston and Connecting RodDocument7 pagesReassembly: 1. Assemble Piston and Connecting Roddolphi_742078No ratings yet

- Procedimiento de Instalacion de La Culata Toyota 3sz-Ve PDFDocument12 pagesProcedimiento de Instalacion de La Culata Toyota 3sz-Ve PDFirvan hardiansyahNo ratings yet

- Chery - SQR477F 1.5L 16V Sohc L4Document4 pagesChery - SQR477F 1.5L 16V Sohc L4ferran_alfonso0% (2)

- Sincronizacion de Motor Toyota 2az-Fe (1)Document12 pagesSincronizacion de Motor Toyota 2az-Fe (1)Williams NavasNo ratings yet

- Sincronizacion de Motor Toyota 2az-FeDocument12 pagesSincronizacion de Motor Toyota 2az-FeWilliams NavasNo ratings yet

- Armado de Cabeza HiluxDocument5 pagesArmado de Cabeza HiluxOscar CAPSSANo ratings yet

- Removal: 2Tr-Fe Engine Mechanical - CamshaftDocument12 pagesRemoval: 2Tr-Fe Engine Mechanical - CamshaftNorberto Calcina100% (1)

- 2zz-Cylinder Head - InstallationDocument5 pages2zz-Cylinder Head - InstallationGullwing Motor Service100% (1)

- Ï Partial Engine Assy (1Cd ïFTV) (From September, 2003)Document3 pagesÏ Partial Engine Assy (1Cd ïFTV) (From September, 2003)victorjoseteixeiraNo ratings yet

- Replacement: 2Az-Fe Engine Mechanical - Engine UnitDocument5 pagesReplacement: 2Az-Fe Engine Mechanical - Engine UnitUmar ShamsudinNo ratings yet

- Httplexus - Solar3.eurmrm684em em 0026 PDFDocument5 pagesHttplexus - Solar3.eurmrm684em em 0026 PDFWiz KingNo ratings yet

- Drive Pinion Shaft: Automatic TransmissionDocument7 pagesDrive Pinion Shaft: Automatic TransmissionAnton FortovNo ratings yet

- INSTDocument13 pagesINSTJuan Antonio Ochoa PadronNo ratings yet

- 2zr Fe Engine Mechanical Cylinder Head Gasket Installation 2009 Matrix PDFDocument7 pages2zr Fe Engine Mechanical Cylinder Head Gasket Installation 2009 Matrix PDFruben carranza100% (1)

- Replacement: Cylinder BlockDocument3 pagesReplacement: Cylinder BlockMoh DeBrNo ratings yet

- On-Vehicle Repair: Valve Body Removal of Valve BodyDocument10 pagesOn-Vehicle Repair: Valve Body Removal of Valve BodyMayobanex Moya MartinezNo ratings yet

- Oilpump4afe PDFDocument7 pagesOilpump4afe PDFhanzhio elNo ratings yet

- 1996 Toyota TERCEL 1.5L Engine Cylinder Head InstallationDocument10 pages1996 Toyota TERCEL 1.5L Engine Cylinder Head InstallationF. RamirezNo ratings yet

- Calibracion de Valvulas Toyota 1nz YarisDocument11 pagesCalibracion de Valvulas Toyota 1nz Yariscpaolinod100% (3)

- Overhaul: 1. Remove Valve LifterDocument17 pagesOverhaul: 1. Remove Valve LifterIslam AttiaNo ratings yet

- Overhaul: 1. Inspect Connecting Rod Thrust ClearanceDocument16 pagesOverhaul: 1. Inspect Connecting Rod Thrust ClearanceAntonio TorresNo ratings yet

- Overhaul: Partial Engine Assy (1Gr Fe)Document50 pagesOverhaul: Partial Engine Assy (1Gr Fe)Islam AttiaNo ratings yet

- Cylinder Bloc ReplacementDocument2 pagesCylinder Bloc ReplacementYannick de WalqueNo ratings yet

- Engine Unit Reassembly-1Document33 pagesEngine Unit Reassembly-1Mr KayNo ratings yet

- 10 - Timing Chain - Installation PDFDocument11 pages10 - Timing Chain - Installation PDFbakriramzi100% (2)

- Overhaul: 1. Inspect Connecting Rod Thrust ClearanceDocument22 pagesOverhaul: 1. Inspect Connecting Rod Thrust ClearanceIslam AttiaNo ratings yet

- On-Vehicle Repair Valve Body Removal of Valve Body: Automatic TransmissionDocument6 pagesOn-Vehicle Repair Valve Body Removal of Valve Body: Automatic TransmissionMayobanex Moya MartinezNo ratings yet

- Cylinder Head Gasket - Installation (01 - 2010 - ) (Cylinder Head Assembly) - ALLDATA Repair Toyota Camry 2.5LtsDocument17 pagesCylinder Head Gasket - Installation (01 - 2010 - ) (Cylinder Head Assembly) - ALLDATA Repair Toyota Camry 2.5LtsFran SanchezNo ratings yet

- 5vz-Fe Timing Belt InstallationDocument6 pages5vz-Fe Timing Belt InstallationJorge RisquezNo ratings yet

- CHERY - Tiggo5 - T21 - SR48F 2.0 16V - Cabeçote - Torque de ApertoDocument1 pageCHERY - Tiggo5 - T21 - SR48F 2.0 16V - Cabeçote - Torque de ApertoWiterMarcosNo ratings yet

- Camshaft (Hilux/1Kd-Ftv, 2Kd-Ftv (Tasa Made For Argentina) ) : ReplacementDocument5 pagesCamshaft (Hilux/1Kd-Ftv, 2Kd-Ftv (Tasa Made For Argentina) ) : ReplacementJefry LehgansNo ratings yet

- Platz 02Document7 pagesPlatz 02dawitmesfin9No ratings yet

- Disassembly: 2Uz-Fe Engine Mechanical - Engine UnitDocument21 pagesDisassembly: 2Uz-Fe Engine Mechanical - Engine UnitMateusz Jaskuła100% (1)

- Reassembly: Press SST Bearing Oil Seal Front Housing Vinyl TapeDocument2 pagesReassembly: Press SST Bearing Oil Seal Front Housing Vinyl TapeMoh DeBrNo ratings yet

- Partial Engine Assy (1Nz Fe/2Nz Fe) : OverhaulDocument26 pagesPartial Engine Assy (1Nz Fe/2Nz Fe) : OverhaulNelson Caño Basalo100% (3)

- Oil Pump Overhaul StepsDocument3 pagesOil Pump Overhaul StepsHenry SilvaNo ratings yet

- 1 AzDocument7 pages1 AzEdU RECTIFICANo ratings yet

- Camshaft Removal Guide for 1NZ-FE/2NZ-FE EnginesDocument8 pagesCamshaft Removal Guide for 1NZ-FE/2NZ-FE EnginesMaung KyawNo ratings yet

- Assembling C32Document24 pagesAssembling C32Muhammad Ramadhan100% (2)

- Inst Cylinder HeadDocument8 pagesInst Cylinder Headmanuel1357100% (1)

- Armado de Block Vvti DualDocument11 pagesArmado de Block Vvti DualNelsonNo ratings yet

- 200 CC6Document14 pages200 CC6Edward KaranjaNo ratings yet

- TIS - Scion 2006 Xa RepairDocument5 pagesTIS - Scion 2006 Xa RepairJuan Antonio Ochoa PadronNo ratings yet

- Motor ProboxDocument12 pagesMotor ProboxrufuruNo ratings yet

- Nissan Almera n16 2001 Electronic Repair Manual 140Document1 pageNissan Almera n16 2001 Electronic Repair Manual 140netifig352No ratings yet

- Oil Pump Assy (1Az-Fe) : OverhaulDocument2 pagesOil Pump Assy (1Az-Fe) : OverhaulHenry SilvaNo ratings yet

- Key Points about Assembling or Disassembling WP6 Diesel Engines 培训资料 Training Material 国际配套服务部 徐衍国Document27 pagesKey Points about Assembling or Disassembling WP6 Diesel Engines 培训资料 Training Material 国际配套服务部 徐衍国Manutenção Base AnápolisNo ratings yet

- Informacion Motor KomatsuDocument8 pagesInformacion Motor KomatsuKike HernandezNo ratings yet

- Manual de Repararacion Yaris 1NZFEDocument18 pagesManual de Repararacion Yaris 1NZFEVictorNo ratings yet

- 01 4G64S4M & 4G69S4N Engine-2Document38 pages01 4G64S4M & 4G69S4N Engine-2vitor santosNo ratings yet

- 10 - Timing Chain - InstallationDocument7 pages10 - Timing Chain - Installation08088338No ratings yet

- 1gr Fe - Cadena de DistribucionDocument5 pages1gr Fe - Cadena de DistribucionMartin KoopmannNo ratings yet

- Replacement: - Oil Pump AssyDocument1 pageReplacement: - Oil Pump AssyJoel Majeed StroudeNo ratings yet

- Cutout: Downloaded From Manuals Search EngineDocument10 pagesCutout: Downloaded From Manuals Search EngineDavid QuispeNo ratings yet

- Boletim Tecnico - JF016 - Re0f10dDocument9 pagesBoletim Tecnico - JF016 - Re0f10dautomaticosbrasilNo ratings yet

- Valve Clearance: AdjustmentDocument10 pagesValve Clearance: AdjustmentDannyDDannyD100% (1)

- Timing Chain Oil SealDocument2 pagesTiming Chain Oil SealEduardo Segundo Gonzalez MuñozNo ratings yet

- 1VD FTV Engine SpecsDocument4 pages1VD FTV Engine SpecsYannick de Walque0% (1)

- Cylinder Bloc InspectionDocument7 pagesCylinder Bloc InspectionYannick de WalqueNo ratings yet

- Cla Valve ComponentsDocument1 pageCla Valve ComponentsYannick de WalqueNo ratings yet

- Cylinder Block: ComponentsDocument3 pagesCylinder Block: ComponentsYannick de WalqueNo ratings yet

- Cylinder Bloc ReplacementDocument2 pagesCylinder Bloc ReplacementYannick de WalqueNo ratings yet

- Diesel Throttle: ComponentsDocument1 pageDiesel Throttle: ComponentsYannick de WalqueNo ratings yet

- Cyl Head InstallDocument8 pagesCyl Head InstallYannick de WalqueNo ratings yet

- Catalytic Converter For Oxidation (Cco) System: On Vehicle InspectionDocument1 pageCatalytic Converter For Oxidation (Cco) System: On Vehicle InspectionYannick de WalqueNo ratings yet

- Transfert Inspection LC200Document1 pageTransfert Inspection LC200Yannick de WalqueNo ratings yet

- Air Flow Meter InspectionDocument1 pageAir Flow Meter InspectionYannick de WalqueNo ratings yet

- Click here to prepare for 4WD system inspectionDocument32 pagesClick here to prepare for 4WD system inspectionYannick de WalqueNo ratings yet

- Camshaft Postion Sensor InspectDocument1 pageCamshaft Postion Sensor InspectYannick de WalqueNo ratings yet

- Engine Cylinder Block Disassembly GuideDocument8 pagesEngine Cylinder Block Disassembly GuideYannick de WalqueNo ratings yet

- Crankshaft Position Sensor InspectionDocument1 pageCrankshaft Position Sensor InspectionYannick de WalqueNo ratings yet

- Hydraulic brake booster disassembly guideDocument10 pagesHydraulic brake booster disassembly guideYannick de WalqueNo ratings yet

- Accelerator Pedal ComponentDocument1 pageAccelerator Pedal ComponentYannick de WalqueNo ratings yet

- Hydraulic Brake Booster Installation LC 200Document17 pagesHydraulic Brake Booster Installation LC 200Yannick de WalqueNo ratings yet

- Highlander Terminal EcmDocument3 pagesHighlander Terminal EcmYannick de WalqueNo ratings yet

- Fail Safe Chart: If Any of The Following Codes Are Recorded, The ECM Enters Fail Safe ModeDocument2 pagesFail Safe Chart: If Any of The Following Codes Are Recorded, The ECM Enters Fail Safe ModeYannick de WalqueNo ratings yet

- Hydraulic Brake Booster Reassembly LC200Document11 pagesHydraulic Brake Booster Reassembly LC200Yannick de WalqueNo ratings yet

- Highlander PRBLM Symptoms TableDocument1 pageHighlander PRBLM Symptoms TableYannick de WalqueNo ratings yet

- Diagnostic Trouble Code Chart: DiagnosticsDocument10 pagesDiagnostic Trouble Code Chart: DiagnosticsYannick de WalqueNo ratings yet

- CIRCUIT DIAGRAMDocument40 pagesCIRCUIT DIAGRAMYannick de WalqueNo ratings yet

- Ewd LCR 200Document190 pagesEwd LCR 200Yannick de Walque100% (1)

- LCR 200 Wiring Routing and Connector PDFDocument397 pagesLCR 200 Wiring Routing and Connector PDFYannick de WalqueNo ratings yet

- Cruise Control (1VD-FTV W/o DPF) (Before Jan. 2013 Production), ECT and A/T Indicator (1VD-FTV W/o DPF) (Before Jan. 2013 Production), Engine Control (1VD-FTV W/o DPF) (Before Jan. 2013 Production)Document28 pagesCruise Control (1VD-FTV W/o DPF) (Before Jan. 2013 Production), ECT and A/T Indicator (1VD-FTV W/o DPF) (Before Jan. 2013 Production), Engine Control (1VD-FTV W/o DPF) (Before Jan. 2013 Production)Yannick de WalqueNo ratings yet

- Data List/Active TestDocument6 pagesData List/Active TestYannick de WalqueNo ratings yet

- 2018 Gle Owner ManualDocument398 pages2018 Gle Owner ManualYannick de WalqueNo ratings yet

- Audi Q7Document277 pagesAudi Q7Yannick de WalqueNo ratings yet

- Catalogue BRIO Ultrasonic Cleaning EquipmentDocument35 pagesCatalogue BRIO Ultrasonic Cleaning Equipmentغزوان عماد الدين الحسينيNo ratings yet

- Exp MN Sm090 en r0 SealsDocument60 pagesExp MN Sm090 en r0 SealsbaliNo ratings yet

- Manual Book KBB R4-2 0237Document52 pagesManual Book KBB R4-2 0237andikanugroho1100% (1)

- Hydraulic Pum Gear Forklift - p01Document1 pageHydraulic Pum Gear Forklift - p01sơn forkliftNo ratings yet

- Overhauling For Maag Gear Box (CPU Version) of Tube MillDocument60 pagesOverhauling For Maag Gear Box (CPU Version) of Tube MillMahmoud Mohammad100% (6)

- Mitsubishi TD02/03 & TF035 Turbo Repair GuideDocument28 pagesMitsubishi TD02/03 & TF035 Turbo Repair GuideRiahi RezegNo ratings yet

- CFD Simulation of Multi Phase Twin Screw PumpDocument56 pagesCFD Simulation of Multi Phase Twin Screw PumpSoumendu Banik100% (1)

- Six Months Industrial Training Report at International Tractors Limited HoshiarpurDocument8 pagesSix Months Industrial Training Report at International Tractors Limited HoshiarpurOmprakashSainiNo ratings yet

- LLU Roller Rail Guides Catalogue - 16404 (EN)Document64 pagesLLU Roller Rail Guides Catalogue - 16404 (EN)vijay agreNo ratings yet

- Bebin Mech TechnicianDocument3 pagesBebin Mech TechnicianDIJUNo ratings yet

- Positive Displacement Pump PDFDocument345 pagesPositive Displacement Pump PDFTapas Chaudhuri100% (3)

- MTN User ManualDocument26 pagesMTN User ManualScarlat AlvesNo ratings yet

- Manual de Mantenimiento JWS400Document42 pagesManual de Mantenimiento JWS400gfwtNo ratings yet

- Master Tools Machinery & Equipment: ExclusiveDocument9 pagesMaster Tools Machinery & Equipment: ExclusiveDavid ApplemanNo ratings yet

- Centrifugal pump data sheet under 40 charactersDocument1 pageCentrifugal pump data sheet under 40 charactersSiddiqui Muhammad AshfaqueNo ratings yet

- Megacpk: Standardised Chemical PumpDocument26 pagesMegacpk: Standardised Chemical PumpMelyssa Motta da SilvaNo ratings yet

- 31 29 00 32Document24 pages31 29 00 32Femita RodríguezNo ratings yet

- 13 SlidingcontactbearingsDocument43 pages13 SlidingcontactbearingsMohammad AamirNo ratings yet

- SKF Rolling Bearings Catalogue PDFDocument1,363 pagesSKF Rolling Bearings Catalogue PDFlaura100% (5)

- 544-04 - Engine ConstructionDocument52 pages544-04 - Engine ConstructionHENIGUEDRINo ratings yet

- Catalog Gearbox AUMADocument24 pagesCatalog Gearbox AUMATrieNo ratings yet

- Boxford 8 Inch Shaper PDFDocument21 pagesBoxford 8 Inch Shaper PDFOlavo PastoreNo ratings yet

- Tube MillDocument364 pagesTube MillSHIVAJI CHOUDHURY100% (1)

- TMMR F SeriesDocument4 pagesTMMR F SeriesAnonymous H3I29yjNo ratings yet

- Double Shaft Paddle Mixers: Powder Dry MixingDocument5 pagesDouble Shaft Paddle Mixers: Powder Dry MixingEmmanuel Ferry BorreNo ratings yet

- Aprilia Atlantic Arrecife 200Document224 pagesAprilia Atlantic Arrecife 200chemizpsNo ratings yet

- Parts Manual: SERIAL NUMBER: P232D - XXXX - 9661 CNF (Tier 2)Document186 pagesParts Manual: SERIAL NUMBER: P232D - XXXX - 9661 CNF (Tier 2)Leonardo VilarinhoNo ratings yet

- Rotary Drilling BrochureDocument28 pagesRotary Drilling BrochureMohan Preeth100% (2)

- Hibon NX Serisi Blover Katalogu - IngilizceDocument8 pagesHibon NX Serisi Blover Katalogu - IngilizceDocu CenterNo ratings yet