Professional Documents

Culture Documents

Cyl Head Install

Uploaded by

Yannick de WalqueOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Cyl Head Install

Uploaded by

Yannick de WalqueCopyright:

Available Formats

EM−35

ENGINE MECHANICAL − CYLINDER HEAD

EM13E−03

INSPECTION

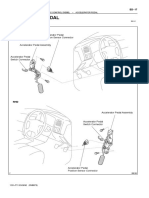

1. CLEAN TO P SURFACES O F PI STO NS AND CYL-

INDER BLOCK

(a) Turn the crankshaft, and bring each piston to top dead

center (TDC). Using a gasket scraper, remove all the car-

bon from the top surface of the piston.

A09675

(b) Using a gasket scraper, remove all the gasket material

from the top surface of the cylinder block.

NOTICE:

Be careful not to scratch the cylinder head contact surface.

(c) Using compressed air, blow carbon and oil from the bolt

holes.

CAUTION:

Protect your eyes when using high−pressure compressed

A09531 air.

2. INSPECT TOP SURFACE OF CYLINDER BLOCK FOR

FLATNESS (See page EM−67)

3. CLEAN CYLINDER HEAD

(a) Using a gasket scraper, remove all the gasket material

from the contact surface of the cylinder block.

NOTICE:

Be careful not to scratch the cylinder block contact sur-

face.

A09532

(b) Using a valve guide bushing brush and solvent, clean all

the guide bushings.

A09538

1CD−FTV ENGINE SUP (RM856E)

EM−36

ENGINE MECHANICAL − CYLINDER HEAD

(c) Using a soft brush and solvent, thoroughly clean the cylin-

der head.

A09535

4. INSPECT CYLINDER HEAD

(a) Inspect for flatness.

Using a precision straight edge and feeler gauge, mea-

sure the surfaces contacting the cylinder block and the

manifolds for warpage.

Maximum warpage:

Cylinder Block Side 0.08 mm (0.0031 in.) for cylinder block side

0.20 mm (0.0079 in.) for manifold side

If warpage is greater than maximum, replace the cylinder head.

Intake Manifold Side

Exhaust Manifold Side

A09556

(b) Inspect for cracks.

Using a dye penetrant, check the intake ports, exhaust

ports and cylinder block contact surface for cracks.

If cracked, replace the cylinder head.

A09534

5. CLEAN VALVES

(a) Using a gasket scraper, chip off any carbon from the valve

head.

(b) Using a wire brush, thoroughly clean the valve.

EM0580

1CD−FTV ENGINE SUP (RM856E)

EM−37

ENGINE MECHANICAL − CYLINDER HEAD

6. INSPECT VALVE STEMS AND GUIDE BUSHINGS

(a) Using a caliper gauge, measure the inside diameter of the

guide bushing.

Bushing inside diameter:

6.010 − 6.030 mm (0.2366 − 0.2374 in.)

A09539

(b) Using a micrometer, measure the diameter of the valve

stem.

Valve stem diameter:

Intake 5.970 − 5.985 mm (0.1957 − 0.1963 in.)

Exhaust 5.960 − 5.975 mm (0.2346 − 0.2352 in.)

(c) Subtract the valve stem diameter measurement from the

guide bushing inside diameter measurement.

Standard oil clearance:

Z00052

Intake 0.025 − 0.060 mm (0.0010 − 0.0024 in.)

Exhaust 0.035 − 0.070 mm (0.0014 − 0.0028 in.)

Maximum oil clearance:

Intake 0.08 mm (0.0031 in.)

Exhaust 0.10 mm (0.0039 in.)

If the clearance is greater than maximum, replace the valve and

guide bushing. (See page EM−43)

7. INSPECT AND GRIND VALVES

(a) Grind the valve enough to remove pits and carbon.

(b) Check that the valve is ground to the correct valve face

angle.

Valve face angle: 44.5˚

44.5˚

Z00054

(c) Check the valve head margin thickness.

Standard margin thickness: 0.9 mm (0.035 in.)

Minimum margin thickness: 0.6 mm (0.024 in.)

If the margin thickness is less than minimum, replace the valve.

Margin Thickness

EM0181

1CD−FTV ENGINE SUP (RM856E)

EM−38

ENGINE MECHANICAL − CYLINDER HEAD

(d) Check the valve overall length.

Standard overall length:

Intake 102.53 mm (4.0366 in.)

Exhaust 101.97 mm (4.0146 in.)

Overall Length

Minimum overall length:

Intake 102.10 mm (4.0197 in.)

Exhaust 101.55 mm (3.99801in.)

EM2534 If the overall length is less than minimum, replace the valve.

(e) Check the surface of the valve stem tip for wear.

If the valve stem tip is worn, resurface the tip with a grinder or

replace the valve.

NOTICE:

Do not grind off more than the minimum length.

EM0255

8. INSPECT AND CLEAN VALVE SEATS

45˚ Carbide

Cutter (a) Using a 45˚ carbide cutter, resurface the valve seats.

Remove only enough metal to clean the seats.

A08405

(b) Check the valve seating position.

Apply a light coat of prussian blue (or white lead) to the

valve face. Lightly press the valve against the seat. Do not

rotate valve.

(c) Check the valve face and seat for the following:

Width S If blue appears 360˚ around the face, the valve is

concentric. If not, replace the valve.

S If blue appears 360˚ around the valve seat, the

A08407 guide and face are concentric. If not, resurface the

seat.

S Check that the seat contact is in the middle of the

valve face with the following width:

Intake 1.2 − 1.6 mm (0.047 − 0.063 in.)

Exhaust 1.6 − 2.0 mm (0.063 − 0.079 in.)

1CD−FTV ENGINE SUP (RM856E)

EM−39

ENGINE MECHANICAL − CYLINDER HEAD

If not, correct the valve seats as follows:

(1) If the seating is too high on the valve face, use 25˚

25˚ and 45˚ cutters to correct the seat.

45˚

Contacting Width

Z03988

Intake 70˚ (2) Intake:

Exhaust 65˚ If the seating is too low on the valve face, use 70˚

45˚ and 45˚ cutters to correct the seat.

(3) Exhaust:

If the seating is too low on the valve face, use 65˚

and 45˚ cutters to correct the seat.

Contacting Width

Z02853

(d) Hand−lap the valve and valve seat with an abrasive com-

pound.

(e) After hand−lapping, clean the valve and valve seat.

A09537

Deviation 9. INSPECT VALVE SPRINGS

(a) Using a steel square, measure the deviation of the valve

spring.

Maximum deviation: 2.0 mm (0.079 in.)

If the deviation is greater than maximum, replace the valve

spring.

A08410

(b) Using a vernier caliper, measure the free length of the

valve spring.

Free length: 40.45 mm (1.5925 in.)

If the free length is not as specified, replace the valve spring.

A08411

1CD−FTV ENGINE SUP (RM856E)

EM−40

ENGINE MECHANICAL − CYLINDER HEAD

(c) Using a spring tester, measure the tension of the valve

spring at the specified installed length.

Installed tension:

177 − 195 N (18.0 − 19.9 kgf, 39.7 − 44.1 lbf)

at 31.1 mm (1.224 in.)

If the installed tension is not as specified, replace the valve

spring.

EM0281

10. INSPECT CAMSHAFTS

(a) Inspect the circle runout.

(1) Place the camshaft on V−blocks.

(2) Using a dial indicator, measure the circle runout at

the center journal.

Maximum circle runout: 0.06 mm (0.0024 in.)

If the circle runout is greater than maximum, replace the cam-

shaft.

A09550

(b) Using a micrometer, measure the cam lobe height.

Standard cam lobe height:

Intake 46.57 − 46.67 mm (1.8335 − 1.8374 in.)

Exhaust 47.52 − 47.62 mm (1.8709 − 1.8748 in.)

Minimum cam lobe height:

Intake 46.10 mm (1.8150 in.)

Exhaust 47.05 mm (1.8524 in.)

A09551 If the cam lobe height is less than minimum, replace the cam-

shaft.

(c) Using a micrometer, measure the journal diameter.

Journal diameter:

26.969 − 26.985 mm (1.0618 − 1.0624 in.)

If the journal diameter is not as specified, check the oil clear-

ance.

A09552

(d) Inspect the journal oil clearance.

Plastigage (1) Clean the bearing caps and camshaft carrier.

(2) Check that bearings for flaking and scoring.

If the bearings are damaged, replace the bearing caps, cam-

shaft carrier and cylinder head as a set.

(3) Place the camshaft carrier and camshafts on the

cylinder head.

(4) Lay a strip of Plastigage across each of the cam-

A09546 shaft journals.

1CD−FTV ENGINE SUP (RM856E)

EM−41

ENGINE MECHANICAL − CYLINDER HEAD

(5) Install the bearing caps. (See page EM−47)

NOTICE:

Do not turn the camshaft.

(6) Remove the bearing caps.

A09557

(7) Measure the Plastigage at its widest point.

Standard oil clearance:

0.025 − 0.062 mm (0.0010 − 0.0024 in.)

Maximum oil clearance: 0.08 mm (0.0031 in.)

If the oil clearance is greater than maximum, replace the cam-

shaft. If necessary, replace the bearing caps, camshaft carrier

and cylinder head as a set.

(8) Completely remove the Plastigage.

A09547

(e) Inspect the camshaft thrust clearance.

(1) Install the camshaft. (See page EM−47)

(2) Using a dial indicator, measure the thrust clearance

while moving the camshaft back and forth.

Standard thrust clearance:

0.035 − 0.110 mm (0.0014 − 0.0043 in.)

If the thrust clearance is not as specified, replace the camshaft.

If necessary, replace the bearing caps, camshaft carrier and

A09545 cylinder head as a set.

(f) Inspect the camshaft gear backlash.

(1) Install the camshafts. (See page EM−47)

(2) Using a dial indicator, measure the backlash.

Standard backlash:

0.014 − 0.070 mm (0.0006 − 0.0028 in.)

Maximum backlash: 0.17 mm (0.0067 in.)

If the backlash is greater then maximum, replace the cam-

shafts.

A09548

11. INSPECT VALVE LIFTERS AND LIFTER BORES

(a) Using a caliper gauge, measure the lifter bore diameter

of the cylinder head.

Lifter bore diameter:

28.010 − 28.031 mm (1.1028 − 1.1036 in.)

A09544

1CD−FTV ENGINE SUP (RM856E)

EM−42

ENGINE MECHANICAL − CYLINDER HEAD

(b) Using a micrometer, measure the lifter diameter.

Lifter diameter:

27.975 − 27.985 mm (1.1014 − 1.1018 in.)

(c) Subtract the lifter diameter measurement from the lifter

bore diameter measurement.

Standard oil clearance:

0.025 − 0.056 mm (0.0010 − 0.0022 in.)

Maximum oil clearance: 0.08 mm (0.0031 in.)

EM2196 If the oil clearance is greater than maximum, replace the lifter.

If necessary, replace the cylinder head.

Intake 12. INSPECT MANIFOLDS

Using a precision straight edge and feeler gauge, measure the

surface contacting the cylinder head for warpage.

Maximum warpage:

Intake 0.1 mm (0.0039 in.)

Exhaust

Exhaust 0.4 mm (0.0157 in.)

If warpage is greater than maximum, replace the manifold.

A09562

13. INSPECT CYLINDER HEAD BOLTS

Using vernier calipers, measure the tension portion diameter of

the bolt.

Standard outside diameter:

10.75 − 11.00 mm (0.4232 − 0.4331 in.)

Minimum outside diameter: 10.40 mm (0.4094 in.)

If the diameter is less than minimum, replace the bolt.

Measuring Point

16 mm (0.63 in.) A09555

1CD−FTV ENGINE SUP (RM856E)

You might also like

- Plymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceFrom EverandPlymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceNo ratings yet

- 14 - Cylinder Head - InspectionDocument9 pages14 - Cylinder Head - InspectionNazmul HassanNo ratings yet

- Camshaft GearDocument10 pagesCamshaft GearJuan Antonio Ochoa PadronNo ratings yet

- Cylinder Bloc InspectionDocument7 pagesCylinder Bloc InspectionYannick de WalqueNo ratings yet

- Inspection: - Cylinder BlockDocument6 pagesInspection: - Cylinder Blockdawitmesfin9No ratings yet

- Overhaul: 1. Remove Valve LifterDocument17 pagesOverhaul: 1. Remove Valve LifterIslam AttiaNo ratings yet

- Inspection: 1. Clean Cylinder BlockDocument7 pagesInspection: 1. Clean Cylinder Blockdolphi_742078No ratings yet

- Overhaul: - Vane Pump AssyDocument7 pagesOverhaul: - Vane Pump AssyRomy MNo ratings yet

- Valve Clearance: InspectionDocument5 pagesValve Clearance: InspectionПежов СитроенNo ratings yet

- Overhaul: 1. Inspect Connecting Rod Thrust ClearanceDocument16 pagesOverhaul: 1. Inspect Connecting Rod Thrust ClearanceAntonio TorresNo ratings yet

- Overhaul: 1. Remove Valve LifterDocument13 pagesOverhaul: 1. Remove Valve LifterMark Anthony FletcherNo ratings yet

- Overhaul: 1. Inspect Connecting Rod Thrust ClearanceDocument22 pagesOverhaul: 1. Inspect Connecting Rod Thrust ClearanceIslam AttiaNo ratings yet

- MSA5T0122A27579Document8 pagesMSA5T0122A27579miguelNo ratings yet

- Inspecting and Checking an Engine Cylinder BlockDocument6 pagesInspecting and Checking an Engine Cylinder BlockmhNo ratings yet

- Calibracion 1C EnglishDocument5 pagesCalibracion 1C EnglishJuan BrunoNo ratings yet

- Valve Clearance: AdjustmentDocument10 pagesValve Clearance: AdjustmentDannyDDannyD100% (1)

- Clutch Por SacarDocument4 pagesClutch Por SacarVides AyalaNo ratings yet

- Toyota 5l Valve ClearanceDocument5 pagesToyota 5l Valve ClearancedennoNo ratings yet

- Toyota 5l Valve ClearanceDocument5 pagesToyota 5l Valve ClearancedennoNo ratings yet

- Platz 02Document7 pagesPlatz 02dawitmesfin9No ratings yet

- Matrix 2003 2zz 8Document10 pagesMatrix 2003 2zz 8alan lantiguaNo ratings yet

- 03 - Valve Clearance - AdjustmentDocument5 pages03 - Valve Clearance - AdjustmentjordantNo ratings yet

- w040001 PDFDocument31 pagesw040001 PDFresolution8878No ratings yet

- 1 AzDocument7 pages1 AzEdU RECTIFICANo ratings yet

- Manual de Repararacion Yaris 1NZFEDocument18 pagesManual de Repararacion Yaris 1NZFEVictorNo ratings yet

- Replacement: Cylinder BlockDocument3 pagesReplacement: Cylinder BlockMoh DeBrNo ratings yet

- Overhaul Cylinder Block 1AZ-FE EngineDocument17 pagesOverhaul Cylinder Block 1AZ-FE EngineHenry SilvaNo ratings yet

- Overhaul: 1. Inspect Connecting Rod Thrust ClearanceDocument17 pagesOverhaul: 1. Inspect Connecting Rod Thrust ClearanceHenry SilvaNo ratings yet

- Armado de Cabeza HiluxDocument5 pagesArmado de Cabeza HiluxOscar CAPSSANo ratings yet

- Inspection: - Input ShaftDocument2 pagesInspection: - Input ShaftsalusfrankNo ratings yet

- Disassembly: 2Uz-Fe Engine Mechanical - Engine UnitDocument21 pagesDisassembly: 2Uz-Fe Engine Mechanical - Engine UnitMateusz Jaskuła100% (1)

- Removal: 2Tr-Fe Engine Mechanical - CamshaftDocument12 pagesRemoval: 2Tr-Fe Engine Mechanical - CamshaftNorberto Calcina100% (1)

- Oil Pump Assy (1Az-Fe) : OverhaulDocument2 pagesOil Pump Assy (1Az-Fe) : OverhaulHenry SilvaNo ratings yet

- Adjust Valve Clearance on 2002 ECHO RM884UDocument6 pagesAdjust Valve Clearance on 2002 ECHO RM884UBoncu BoncuNo ratings yet

- Nissan Almera n16 2001 Electronic Repair Manual 114Document1 pageNissan Almera n16 2001 Electronic Repair Manual 114netifig352No ratings yet

- 1HD-T 2Document37 pages1HD-T 2HERMAWAN100% (2)

- Engine Cylinder Block Disassembly GuideDocument8 pagesEngine Cylinder Block Disassembly GuideYannick de WalqueNo ratings yet

- Adjust Valve Clearance 2AZ-FE EngineDocument9 pagesAdjust Valve Clearance 2AZ-FE EngineMarcos EmmanuelNo ratings yet

- Overhaul Front Brake of 2004 Toyota CorollaDocument5 pagesOverhaul Front Brake of 2004 Toyota Corollajeremih alhegnNo ratings yet

- Manual Transmission Overhaul ProceduresDocument9 pagesManual Transmission Overhaul ProceduresMax K.No ratings yet

- LC Winch ManualDocument20 pagesLC Winch ManualDNo ratings yet

- Partial Engine Assembly2Document34 pagesPartial Engine Assembly2jeremih alhegnNo ratings yet

- 01 4G64S4M & 4G69S4N Engine-2Document38 pages01 4G64S4M & 4G69S4N Engine-2vitor santosNo ratings yet

- On-Vehicle Repair Valve Body Removal of Valve Body: Automatic TransmissionDocument6 pagesOn-Vehicle Repair Valve Body Removal of Valve Body: Automatic TransmissionMayobanex Moya MartinezNo ratings yet

- Toyota 4efe - Correa de Distribucion PDFDocument11 pagesToyota 4efe - Correa de Distribucion PDFRonald Gareca RuedaNo ratings yet

- Installation of Cylinder Head: Downloaded From Manuals Search EngineDocument6 pagesInstallation of Cylinder Head: Downloaded From Manuals Search EngineDavid QuispeNo ratings yet

- Overhaul: 1. Remove Oil Pump CoverDocument3 pagesOverhaul: 1. Remove Oil Pump CoverIslam AttiaNo ratings yet

- Reassembly: 1. Assemble Piston and Connecting RodDocument7 pagesReassembly: 1. Assemble Piston and Connecting Roddawitmesfin9No ratings yet

- Insp Valve Clearance 2.7 3rz PDFDocument5 pagesInsp Valve Clearance 2.7 3rz PDFEdwin Versteeg100% (1)

- Partial Engine Assy (1Nz Fe/2Nz Fe) : OverhaulDocument26 pagesPartial Engine Assy (1Nz Fe/2Nz Fe) : OverhaulNelson Caño Basalo100% (3)

- Automatic Transmission High and Reverse Clutch GuideDocument6 pagesAutomatic Transmission High and Reverse Clutch GuideAnton FortovNo ratings yet

- Replacement: 2Az-Fe Engine Mechanical - Engine UnitDocument5 pagesReplacement: 2Az-Fe Engine Mechanical - Engine UnitUmar ShamsudinNo ratings yet

- On-Vehicle Repair: Valve Body Removal of Valve BodyDocument10 pagesOn-Vehicle Repair: Valve Body Removal of Valve BodyMayobanex Moya MartinezNo ratings yet

- Overhaul: Partial Engine Assy (1Gr Fe)Document50 pagesOverhaul: Partial Engine Assy (1Gr Fe)Islam AttiaNo ratings yet

- Install cylinder block componentsDocument7 pagesInstall cylinder block componentsYannick de WalqueNo ratings yet

- CYLINDER HEAD COMPONENTS AND REMOVAL GUIDEDocument35 pagesCYLINDER HEAD COMPONENTS AND REMOVAL GUIDEAlex Hernandez100% (2)

- 1gr Fe - Cadena de DistribucionDocument5 pages1gr Fe - Cadena de DistribucionMartin KoopmannNo ratings yet

- Automatic Transaxle's DisassemblyDocument32 pagesAutomatic Transaxle's Disassemblymohamed A.abdeltwabNo ratings yet

- Reassembly: 1. Assemble Piston and Connecting RodDocument7 pagesReassembly: 1. Assemble Piston and Connecting Roddolphi_742078No ratings yet

- Procedimiento de Instalacion de La Culata Toyota 3sz-Ve PDFDocument12 pagesProcedimiento de Instalacion de La Culata Toyota 3sz-Ve PDFirvan hardiansyahNo ratings yet

- Cla Valve ComponentsDocument1 pageCla Valve ComponentsYannick de WalqueNo ratings yet

- Cylinder Block: ComponentsDocument3 pagesCylinder Block: ComponentsYannick de WalqueNo ratings yet

- Install cylinder block componentsDocument7 pagesInstall cylinder block componentsYannick de WalqueNo ratings yet

- 1VD FTV Engine SpecsDocument4 pages1VD FTV Engine SpecsYannick de Walque0% (1)

- Cylinder Bloc ReplacementDocument2 pagesCylinder Bloc ReplacementYannick de WalqueNo ratings yet

- Crankshaft Position Sensor InspectionDocument1 pageCrankshaft Position Sensor InspectionYannick de WalqueNo ratings yet

- Diesel Throttle: ComponentsDocument1 pageDiesel Throttle: ComponentsYannick de WalqueNo ratings yet

- Engine Cylinder Block Disassembly GuideDocument8 pagesEngine Cylinder Block Disassembly GuideYannick de WalqueNo ratings yet

- Hydraulic Brake Booster Installation LC 200Document17 pagesHydraulic Brake Booster Installation LC 200Yannick de WalqueNo ratings yet

- Catalytic Converter For Oxidation (Cco) System: On Vehicle InspectionDocument1 pageCatalytic Converter For Oxidation (Cco) System: On Vehicle InspectionYannick de WalqueNo ratings yet

- Accelerator Pedal ComponentDocument1 pageAccelerator Pedal ComponentYannick de WalqueNo ratings yet

- Air Flow Meter InspectionDocument1 pageAir Flow Meter InspectionYannick de WalqueNo ratings yet

- Camshaft Postion Sensor InspectDocument1 pageCamshaft Postion Sensor InspectYannick de WalqueNo ratings yet

- Click here to prepare for 4WD system inspectionDocument32 pagesClick here to prepare for 4WD system inspectionYannick de WalqueNo ratings yet

- Transfert Inspection LC200Document1 pageTransfert Inspection LC200Yannick de WalqueNo ratings yet

- Hydraulic Brake Booster Reassembly LC200Document11 pagesHydraulic Brake Booster Reassembly LC200Yannick de WalqueNo ratings yet

- LCR 200 Wiring Routing and Connector PDFDocument397 pagesLCR 200 Wiring Routing and Connector PDFYannick de WalqueNo ratings yet

- Hydraulic brake booster disassembly guideDocument10 pagesHydraulic brake booster disassembly guideYannick de WalqueNo ratings yet

- Fail Safe Chart: If Any of The Following Codes Are Recorded, The ECM Enters Fail Safe ModeDocument2 pagesFail Safe Chart: If Any of The Following Codes Are Recorded, The ECM Enters Fail Safe ModeYannick de WalqueNo ratings yet

- Highlander PRBLM Symptoms TableDocument1 pageHighlander PRBLM Symptoms TableYannick de WalqueNo ratings yet

- Highlander Terminal EcmDocument3 pagesHighlander Terminal EcmYannick de WalqueNo ratings yet

- CIRCUIT DIAGRAMDocument40 pagesCIRCUIT DIAGRAMYannick de WalqueNo ratings yet

- Data List/Active TestDocument6 pagesData List/Active TestYannick de WalqueNo ratings yet

- Ewd LCR 200Document190 pagesEwd LCR 200Yannick de Walque100% (1)

- Diagnostic Trouble Code Chart: DiagnosticsDocument10 pagesDiagnostic Trouble Code Chart: DiagnosticsYannick de WalqueNo ratings yet

- Cruise Control (1VD-FTV W/o DPF) (Before Jan. 2013 Production), ECT and A/T Indicator (1VD-FTV W/o DPF) (Before Jan. 2013 Production), Engine Control (1VD-FTV W/o DPF) (Before Jan. 2013 Production)Document28 pagesCruise Control (1VD-FTV W/o DPF) (Before Jan. 2013 Production), ECT and A/T Indicator (1VD-FTV W/o DPF) (Before Jan. 2013 Production), Engine Control (1VD-FTV W/o DPF) (Before Jan. 2013 Production)Yannick de WalqueNo ratings yet

- 2018 Gle Owner ManualDocument398 pages2018 Gle Owner ManualYannick de WalqueNo ratings yet

- Audi Q7Document277 pagesAudi Q7Yannick de WalqueNo ratings yet

- Software MetricsDocument253 pagesSoftware MetricsAditya ChourasiyaNo ratings yet

- Mousavi, Aliha, Imani - 2020 - On The Use of Edge Cracked Short Bend Beam Specimen For PMMA Fracture Toughness Testing Under Mixed-ModeDocument1 pageMousavi, Aliha, Imani - 2020 - On The Use of Edge Cracked Short Bend Beam Specimen For PMMA Fracture Toughness Testing Under Mixed-ModeMorteza AtaeiNo ratings yet

- Indigo Assessment - Cynthia Nieto VargasDocument14 pagesIndigo Assessment - Cynthia Nieto Vargasapi-506651646No ratings yet

- 03-2ezii (Ex-Lx-Dx) Codde 3 QRH1 V1Document352 pages03-2ezii (Ex-Lx-Dx) Codde 3 QRH1 V1sadh94No ratings yet

- Sublimation of CaffeineDocument3 pagesSublimation of CaffeineNabil ShaikhNo ratings yet

- Sustainable Transport Development in Nepal: Challenges and StrategiesDocument18 pagesSustainable Transport Development in Nepal: Challenges and StrategiesRamesh PokharelNo ratings yet

- SAE StandardDocument28 pagesSAE Standardwei foo83% (6)

- Detailed Lesson Plan in Science IVDocument12 pagesDetailed Lesson Plan in Science IVAgnes DumlaoNo ratings yet

- pd1185 Fire CodeDocument3 pagespd1185 Fire CodeCamille MangaranNo ratings yet

- Life 365 V 2 Users ManualDocument67 pagesLife 365 V 2 Users ManualAmanda VegaNo ratings yet

- Hdpe Alathon H5520 EquistarDocument2 pagesHdpe Alathon H5520 EquistarEric Mahonri PereidaNo ratings yet

- BOnd Strength ASTM-F904-98Document1 pageBOnd Strength ASTM-F904-98akash.biradarNo ratings yet

- System ConfigurationDocument13 pagesSystem ConfigurationEdlyn Estopa BuenoNo ratings yet

- JIMCO Filter Catalog with Products and SpecificationsDocument8 pagesJIMCO Filter Catalog with Products and SpecificationsDedy CjNo ratings yet

- GSM Channels LogicalDocument8 pagesGSM Channels LogicalbeetelnutsNo ratings yet

- Computer Aided Design Course Code: 3341904Document7 pagesComputer Aided Design Course Code: 3341904Dhaval UpadhyayNo ratings yet

- Çimsa Eco White TDS (EN)Document1 pageÇimsa Eco White TDS (EN)Babu NysemereNo ratings yet

- 92v Parts List ViperDocument194 pages92v Parts List Viperreltih18No ratings yet

- Fsls 11.10 Adminguide EngDocument67 pagesFsls 11.10 Adminguide Engsurender78No ratings yet

- Plastic Sub Pumps Catalog 60Hz - USDocument44 pagesPlastic Sub Pumps Catalog 60Hz - UScarlosNo ratings yet

- Wae 22462 AuDocument8 pagesWae 22462 AuDaniel ManoleNo ratings yet

- Dunlop Cement Based Adhesives - SDS10024Document4 pagesDunlop Cement Based Adhesives - SDS10024Dominic LeeNo ratings yet

- USBN Bahasa Inggris 2021Document6 pagesUSBN Bahasa Inggris 2021Indah timorentiNo ratings yet

- Genetic AlgorithmDocument46 pagesGenetic AlgorithmJerryNo ratings yet

- Phaser3300MFP Firmware Upgrade Instructions CWISDocument2 pagesPhaser3300MFP Firmware Upgrade Instructions CWISAlgenis De Leon RamirezNo ratings yet

- Thermit Australia Product Catalogue 2012Document20 pagesThermit Australia Product Catalogue 2012Rey Luis TehNo ratings yet

- Billing No. 4 Accomplishement ReportDocument1 pageBilling No. 4 Accomplishement ReportGOB ConstructionNo ratings yet

- Xlpe - Ls243Nta: - 1 Technical Data Sheet Crosslinkable Polyethylene CompoundDocument3 pagesXlpe - Ls243Nta: - 1 Technical Data Sheet Crosslinkable Polyethylene CompoundLe MinhNo ratings yet

- Tetra Cardboard Packer 70 - CopyDocument808 pagesTetra Cardboard Packer 70 - CopyOmar AlneasNo ratings yet

- PM IS - 12818 June2021Document10 pagesPM IS - 12818 June2021Mahendra AhirwarNo ratings yet