Professional Documents

Culture Documents

Formate No. MNT (E) \ F 02 Maintenance Check List

Uploaded by

Sumeet Trivedi0 ratings0% found this document useful (0 votes)

19 views1 pageOriginal Title

Maintenance Checklist Fore Ot Crane 142708

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

19 views1 pageFormate No. MNT (E) \ F 02 Maintenance Check List

Uploaded by

Sumeet TrivediCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 1

FORMATE. NO.

: MNT (E) \ F 02

QUALITY MANAGEMENT SYSTEM

REV. NO. : 08

MAINTENANCE CHECK LIST REV. DATE : 01.04.2019

DEPARTMENT : ELECTRICAL PAGE : 01 OF 01

Section :STEEL MELTING SHOP

LOCATION : SMS

Equipment : EOT Cranes

Expected

S.No. Specific Instruction time (Min)

1 Take "work permit" from concerned departments. 10

S.No. Operative ( Power Supply ON and equipment in running condition ) Check points

1 Clean the all panels, resistance box,motors,brake and brake panel ,Both JB, Control and lighting Transformer by Dry compressed air 90

2 Visually check any burning of connection inside the Panels,JB's,Resistance boxes. 30

3 Visually check the healthiness of current collectors. 30

4 Visually check the healthiness of Cable jockey movement and trailing cables sag. 30

5 Visually check the operation of Brake mechanism and record the voltage,current and gaps between armature & core. 30

6 Visually observe the power contactors and observe for any chattering sound. 30

7 Check the UB lighting healthiness. 10

8 Check the healthiness of end limit switches,rotary geared limit switches and counter weight limit switches. 30

9 Check the motors for any abnormality i.e. vibration,temperature,sound and record the running current fo Stator and rotor. 45

10 Check the healthiness of Master controllers,Bell,cabin fan & exhaust fan. 60

S.No. Non-Operative ( Power supply in OFF condition ) Check points

1 Addition to the above following points to be checked. 300

2 Check the motors as per Slip Ring Induction motor checklist. 110

3 Check the Panels as per Feeders in MCC checklist. 100

4 Check the healthiness of control and lighting transformers. 20

5 Check the tightness of links & connecting bolts of resistance box. 30

6 Check the healthiness of power terminations at resistance box. 30

7 Check for the equal resistance in the all the three phases of rotor circuit at resistance box. 20

8 Check the presence of all the resistance box cover & the water protection top cover. 30

9 Check the timers for its healthiness and time setting. 20

10 Check the Dash pot over load relay oil level. If required, top up the same up to required level.Also check for any 30

11 Check the condition & operation of brake assembly & brake shoes, if essential, inform Mech. and get it corrected 30

12 Check the oil level in thruster.If required, top up the same up to required level. 30

13 Check the roller of cable trolly of trailling cable. if required. replace it. 30

14 Check the Current collector terminal tightness and wear & tear of its shoe.If required ,replace it. 30

15 Check the mounting of the panels on the crane to ensure that they are secure properly & do not shake when crane 30

16 Take the trail of MH,AH,CT,LT motion and Magnet of the Crane. Also ensure all the electrical interlocks 30

PREPARED BY : AGM (Electrical) APPROVED BY : HOD (E/A)

You might also like

- Maintenance Manual Electrical Part 2Document60 pagesMaintenance Manual Electrical Part 2madhuNo ratings yet

- Job Description Remarks: Single Phase Preventer and Y/ Timer) Decoloursation, BurnsDocument2 pagesJob Description Remarks: Single Phase Preventer and Y/ Timer) Decoloursation, Burnssanjeev267No ratings yet

- Fire Water Motor Engine PMDocument5 pagesFire Water Motor Engine PMShamsuddin SoomroNo ratings yet

- Northern Power Generation Maintenance ChecksDocument7 pagesNorthern Power Generation Maintenance ChecksNoor Ahmad WahgoNo ratings yet

- Check Sheet For (Misc.)Document10 pagesCheck Sheet For (Misc.)Noor Ahmad WahgoNo ratings yet

- Check Sheet For (M&G Section)Document7 pagesCheck Sheet For (M&G Section)Noor Ahmad WahgoNo ratings yet

- HV Substation Testing Maintenance Practise IEM Seminar 18th November 202...Document51 pagesHV Substation Testing Maintenance Practise IEM Seminar 18th November 202...Pujayantha KumarNo ratings yet

- Maintenance Schedule Kiln Shut Down AUG 19Document17 pagesMaintenance Schedule Kiln Shut Down AUG 19swarupkumarnayakNo ratings yet

- A/b/c/d/e/f - PassDocument6 pagesA/b/c/d/e/f - PassVikrant DeshmukhNo ratings yet

- Preventive Maintenance of 6.6/11KV Circuit Breaker: ProtocolDocument3 pagesPreventive Maintenance of 6.6/11KV Circuit Breaker: ProtocolVikrant DeshmukhNo ratings yet

- Transformer Test Report SampleDocument10 pagesTransformer Test Report Samplej74926778No ratings yet

- B1 Engine: To IndexDocument32 pagesB1 Engine: To IndexKwun Hok ChongNo ratings yet

- ChargingDocument17 pagesChargingjasonphxNo ratings yet

- KemppiDocument43 pagesKemppiIon SudituNo ratings yet

- Eot Ibl Crane Yearly ChecksheetDocument3 pagesEot Ibl Crane Yearly ChecksheetAmit ThakurNo ratings yet

- ATV 2008-015 OUTLANDER 400 EFI (Lights, Gauge and Accessories) - Shop Manual - 04FXemAAG - SM51Y08S10 - enDocument33 pagesATV 2008-015 OUTLANDER 400 EFI (Lights, Gauge and Accessories) - Shop Manual - 04FXemAAG - SM51Y08S10 - enfeNo ratings yet

- Wap-7 PLW / Izn / NerDocument49 pagesWap-7 PLW / Izn / NerShrish ShankhdharNo ratings yet

- MX GT90Document51 pagesMX GT90Gaby FigueroaNo ratings yet

- EN-RAC-04 - Power Substation MaintenanceDocument30 pagesEN-RAC-04 - Power Substation Maintenancemd_khudNo ratings yet

- Amod - Amod-511 - Manual ElectricidadDocument73 pagesAmod - Amod-511 - Manual ElectricidadKevin Flores OllaguezNo ratings yet

- MCC and Panels Maintenance ProcedureDocument15 pagesMCC and Panels Maintenance ProcedureEldhose PaulNo ratings yet

- BE (Body Electrical System)Document37 pagesBE (Body Electrical System)RomusNo ratings yet

- General Information: Checks & RepairsDocument24 pagesGeneral Information: Checks & RepairsChristian BedoyaNo ratings yet

- SMP-E-010 - Power TransformersDocument2 pagesSMP-E-010 - Power TransformersNaeem HussainNo ratings yet

- Gek 91718Document14 pagesGek 91718mauricio suarezNo ratings yet

- Maintenance Manual for Magnetic Float Level SwitchDocument3 pagesMaintenance Manual for Magnetic Float Level SwitchJovizal AristianNo ratings yet

- Stearns Electronic Brake Release Indicator (Proving Switch) ArmatureActuated Brake Series Product SheetDocument2 pagesStearns Electronic Brake Release Indicator (Proving Switch) ArmatureActuated Brake Series Product Sheetashar khanNo ratings yet

- HVAC Preventive Maintenance Checklists-12Document61 pagesHVAC Preventive Maintenance Checklists-12JawadNo ratings yet

- Charging SystemDocument16 pagesCharging SystemCậu TúNo ratings yet

- Technical Service Manual For KempomatDocument53 pagesTechnical Service Manual For KempomatAugustoferreira Ferreira100% (1)

- AC Loco Refresher-SCR-1Document126 pagesAC Loco Refresher-SCR-1SATYANARAYANA BODDULANo ratings yet

- Gs Generator TroubleshootingDocument38 pagesGs Generator Troubleshootingகோவி கோபால் ஆர்ட்ஸ்No ratings yet

- PDFDocument89 pagesPDFAbel GaunaNo ratings yet

- Stadyne GovornorDocument4 pagesStadyne GovornorM. ShaatNo ratings yet

- Check your charging system for proper operationDocument16 pagesCheck your charging system for proper operationAbu AliNo ratings yet

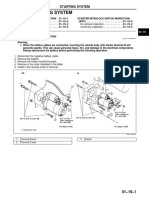

- Starting SystemDocument2 pagesStarting SystemSebastian SirventNo ratings yet

- CL-NG-6460-002-029 Checklist For Metal Clad Switchgear Rev00Document4 pagesCL-NG-6460-002-029 Checklist For Metal Clad Switchgear Rev00WajahatNo ratings yet

- Standard Check List: NTPC TelanganaDocument4 pagesStandard Check List: NTPC TelanganaVikrant DeshmukhNo ratings yet

- Transformers 22Document32 pagesTransformers 22aiswaryaNo ratings yet

- Daihatsu Sirion Model m300 Series Service Manual No9890 EngineDocument32 pagesDaihatsu Sirion Model m300 Series Service Manual No9890 EngineJakub TarasinNo ratings yet

- PM Text As Per Bcel-002Document4 pagesPM Text As Per Bcel-002Jay Rameshbhai ParikhNo ratings yet

- Daihatsu Type K3 Engine Service Manual No.9737 No.9332 No. 9237 Starting System PDFDocument23 pagesDaihatsu Type K3 Engine Service Manual No.9737 No.9332 No. 9237 Starting System PDFMozes SimataaNo ratings yet

- Construction Check Sheet Power & Auxilliary Transformer E-012ADocument2 pagesConstruction Check Sheet Power & Auxilliary Transformer E-012AhrimklimNo ratings yet

- GR00000800 00e PDFDocument16 pagesGR00000800 00e PDFToponari MedveNo ratings yet

- SAMSUNGVR22EOCHASSISLW22N23NLCDTVSMDocument64 pagesSAMSUNGVR22EOCHASSISLW22N23NLCDTVSMvideosonNo ratings yet

- Federal Electric - Short Catalogue 2016 PDFDocument28 pagesFederal Electric - Short Catalogue 2016 PDFzohaib khalidNo ratings yet

- CL-NG-6460-002-025 Checklist For CVT Rev00Document3 pagesCL-NG-6460-002-025 Checklist For CVT Rev00WajahatNo ratings yet

- TDC - YER.1.00000 Updated (TDS-3)Document4 pagesTDC - YER.1.00000 Updated (TDS-3)Mohamed AnwarNo ratings yet

- Samsung Syncmaster 570b cn15ms TFT PDFDocument38 pagesSamsung Syncmaster 570b cn15ms TFT PDFYes YesyesNo ratings yet

- Ps8306 LV MCCB MaintenanceDocument5 pagesPs8306 LV MCCB MaintenancePhuc PhamNo ratings yet

- 3300 - 440v Transformer Maintenance ProcedureDocument4 pages3300 - 440v Transformer Maintenance ProcedureGunadevan ChandrasekaranNo ratings yet

- Ps8305 LV Acb MaintenanceDocument5 pagesPs8305 LV Acb MaintenancePhuc PhamNo ratings yet

- For Transformer Ohmmeter DC Winding Resistance Test Set MTO210 Catalog Number MTO210Document74 pagesFor Transformer Ohmmeter DC Winding Resistance Test Set MTO210 Catalog Number MTO210PET MADAKKATHARANo ratings yet

- 842Document11 pages842cleberNo ratings yet

- Trouble Code Diagnosis: Tcu Diagnostic System OverviewDocument10 pagesTrouble Code Diagnosis: Tcu Diagnostic System Overviewkeiner cassianiNo ratings yet

- TCU Diagnostic Trouble Code GuideDocument10 pagesTCU Diagnostic Trouble Code Guidekeiner cassianiNo ratings yet

- Trouble Code Diagnosis: Tcu Diagnostic System OverviewDocument10 pagesTrouble Code Diagnosis: Tcu Diagnostic System Overviewkeiner cassianiNo ratings yet

- Samsung Lcd-tv-lw15m23cp Ve15eo Chassis (ET)Document52 pagesSamsung Lcd-tv-lw15m23cp Ve15eo Chassis (ET)videoson100% (1)

- CFD Trading Guide: Essential Info for BeginnersDocument19 pagesCFD Trading Guide: Essential Info for BeginnersSumeet TrivediNo ratings yet

- BLT Servo Drive and Motor Manual and DrawingDocument144 pagesBLT Servo Drive and Motor Manual and DrawingSumeet TrivediNo ratings yet

- LPG Safety Data Sheet Highlights HazardsDocument10 pagesLPG Safety Data Sheet Highlights HazardsShaikhRizwanNo ratings yet

- 1 SDH 000460 R 0102Document52 pages1 SDH 000460 R 0102erikNo ratings yet

- Paint Thinner MSDSDocument6 pagesPaint Thinner MSDSwidyNo ratings yet

- Must Know Before You Start Trading ForexDocument11 pagesMust Know Before You Start Trading ForexAkın GündoğduNo ratings yet

- RTU-710H Wireless I/O Module With On-Off and Analog I/O: Claudiastr. 5 51149 Köln-Porz GermanyDocument81 pagesRTU-710H Wireless I/O Module With On-Off and Analog I/O: Claudiastr. 5 51149 Köln-Porz GermanySumeet TrivediNo ratings yet

- Configuring The FlexTimer For Position and Speed Measurement With An EncoderDocument10 pagesConfiguring The FlexTimer For Position and Speed Measurement With An EncoderSumeet TrivediNo ratings yet

- GALVI Shoe Brakes BrochureDocument53 pagesGALVI Shoe Brakes BrochureCANH NGUYENNo ratings yet

- Simatic st80 STPC Chap02 English 2015Document90 pagesSimatic st80 STPC Chap02 English 2015Sumeet TrivediNo ratings yet

- MOLmanualPY1 01Document128 pagesMOLmanualPY1 01Sumeet Trivedi100% (1)

- Temp Scanner RTDDocument21 pagesTemp Scanner RTDSumeet TrivediNo ratings yet

- SIEP-C710617 - 05 GA700 Technical ManualDocument940 pagesSIEP-C710617 - 05 GA700 Technical ManualSawon100% (1)

- Power Cable XLPEDocument6 pagesPower Cable XLPEsudhir5441No ratings yet

- Catalog Complete - Rotex Fluid Control System PDFDocument444 pagesCatalog Complete - Rotex Fluid Control System PDFSumeet TrivediNo ratings yet

- Uport 1100 Series User'S Manual: Fifth Edition, May 2009Document49 pagesUport 1100 Series User'S Manual: Fifth Edition, May 2009Sumeet TrivediNo ratings yet

- Standard Motor CatalogDocument140 pagesStandard Motor CatalogStrato VariusNo ratings yet

- Sabar Group: Three Phase Cooling Tower MotorsDocument2 pagesSabar Group: Three Phase Cooling Tower MotorsHrithik Sai TummalaNo ratings yet

- Manual Relevador DigitripDocument84 pagesManual Relevador DigitripJulian Canseco zarateNo ratings yet

- C Power Acb Catalogue PDFDocument35 pagesC Power Acb Catalogue PDFsabeer100% (1)

- RET 630 Differential ProtectionDocument33 pagesRET 630 Differential ProtectionNarvin Raj ChandraNo ratings yet

- Casio Fx-570-991es Plus enDocument46 pagesCasio Fx-570-991es Plus enstiga2010100% (1)

- ESP Operation and Maintenance GuideDocument42 pagesESP Operation and Maintenance GuideWahyu ßagus TriwiyonoNo ratings yet

- ABB TransformerDocument17 pagesABB Transformer15472No ratings yet

- Logo System Manual en-US en-USDocument344 pagesLogo System Manual en-US en-USglanchezNo ratings yet

- Applying Fast Recovery Diodes - 5SYA 2064Document12 pagesApplying Fast Recovery Diodes - 5SYA 2064Sumeet TrivediNo ratings yet

- DM5230/DM5240 Energy Meter Troubleshooting GuideDocument2 pagesDM5230/DM5240 Energy Meter Troubleshooting GuideSumeet TrivediNo ratings yet

- Process ControlDocument144 pagesProcess Control14071988100% (1)

- DC1000 Manual enDocument27 pagesDC1000 Manual enLeonardo QuintanaNo ratings yet

- Dynagen 2014 SpecSheets ES52 PDFDocument2 pagesDynagen 2014 SpecSheets ES52 PDFBrianHaze100% (1)

- Questions On LCR CircuitDocument2 pagesQuestions On LCR CircuitKRISHNA PARIHARNo ratings yet

- Doosan DX140LC, DX180LC Electrical Wiring DiagramsDocument129 pagesDoosan DX140LC, DX180LC Electrical Wiring DiagramsEngAbdelrahman Khames100% (3)

- S8 SyllabusDocument208 pagesS8 Syllabusshyam krishnan sNo ratings yet

- 52di Esm-2Document109 pages52di Esm-2Vance IbzNo ratings yet

- MC4 Te Conectivity Ficha TecnicaDocument2 pagesMC4 Te Conectivity Ficha TecnicaLuis Guzmán100% (1)

- 2019 - Dual Power Source Switching Control To Li-Ion Battery Charger For Medical Power System ApplicationsDocument4 pages2019 - Dual Power Source Switching Control To Li-Ion Battery Charger For Medical Power System ApplicationsFuzzer11No ratings yet

- Project Report On Power Transformer RepairDocument8 pagesProject Report On Power Transformer RepairEIRI Board of Consultants and Publishers100% (1)

- Vashi ElectricalsDocument4 pagesVashi ElectricalssantuNo ratings yet

- Line Differential Protection IED RED670Document51 pagesLine Differential Protection IED RED670mentongNo ratings yet

- 1SDA066472R1 Moe e xt2 xt4 220 250v Ac DC X Rem ContDocument2 pages1SDA066472R1 Moe e xt2 xt4 220 250v Ac DC X Rem ContHaluk TmlNo ratings yet

- Electronic Devices Floyd 7th Edition Solution ManualDocument171 pagesElectronic Devices Floyd 7th Edition Solution Manualعبدالرحمن المحماديNo ratings yet

- Basic panel-mounted fault annunciator configurationDocument16 pagesBasic panel-mounted fault annunciator configurationraulNo ratings yet

- Kea 081 AnlDocument17 pagesKea 081 Anlamin shirkhaniNo ratings yet

- Dhalkebar Substation Field Visit PDFDocument10 pagesDhalkebar Substation Field Visit PDFGaurav RegmiNo ratings yet

- Two Transistor Model and Turn On MethodsDocument19 pagesTwo Transistor Model and Turn On MethodsSahale Shera Lutse 18BEE0376No ratings yet

- P7M18009 HRB4824600 Rev.08 PREMSET Operation GuideDocument65 pagesP7M18009 HRB4824600 Rev.08 PREMSET Operation Guidexteel100% (1)

- Determine optimal PV panel orientationDocument35 pagesDetermine optimal PV panel orientationnoudjuhNo ratings yet

- WAMS in Indian Context-PaperDocument6 pagesWAMS in Indian Context-PaperShashwat KothariNo ratings yet

- Catalogue 8djh36 enDocument44 pagesCatalogue 8djh36 enJoanna BaileyNo ratings yet

- Um1r483500e3 Rev B 48v 3500w Rectifier 2022Document26 pagesUm1r483500e3 Rev B 48v 3500w Rectifier 2022Yu MaNo ratings yet

- EPEVER Datasheet UPowerDocument5 pagesEPEVER Datasheet UPowerAlisson OliveiraNo ratings yet

- Catalog Tehnic UFH Unitati Comanda Cu Fir C35-33 Si TermostateDocument30 pagesCatalog Tehnic UFH Unitati Comanda Cu Fir C35-33 Si TermostateUPOTERMNo ratings yet

- Bateria Litio KWH Tab V 10909234 AssemblysheetDocument34 pagesBateria Litio KWH Tab V 10909234 Assemblysheetkantero106No ratings yet

- Process-Dependent Power Supply Systems for Automobile PlantsDocument6 pagesProcess-Dependent Power Supply Systems for Automobile PlantsMuhammad HarisNo ratings yet

- SMART GRID UNIT III SMART METERSDocument32 pagesSMART GRID UNIT III SMART METERSAmmu PuniNo ratings yet

- HFA08TB60: Ultrafast, Soft Recovery Diode HexfredDocument6 pagesHFA08TB60: Ultrafast, Soft Recovery Diode HexfredQuickerManNo ratings yet

- Module 5 - BJT BiasingDocument13 pagesModule 5 - BJT BiasingKenNo ratings yet

- Trainer Kit For Pressure MeasurementDocument1 pageTrainer Kit For Pressure MeasurementAdvanceElectronicesNo ratings yet

- Cie Earth Tester.187133635Document3 pagesCie Earth Tester.187133635velan84No ratings yet