Professional Documents

Culture Documents

Applying Fast Recovery Diodes - 5SYA 2064

Uploaded by

Sumeet TrivediOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Applying Fast Recovery Diodes - 5SYA 2064

Uploaded by

Sumeet TrivediCopyright:

Available Formats

Application Note 5SYA 2064-01

Applying fast recovery diodes

ABB Switzerland Ltd, Semiconductors

has a long history of producing high

power fast recovery diodes for applica-

tions such as Voltage Source Converters

(VSC), Current Source Converters (CSC)

and DC choppers. The diodes are

typically used in combination with IGCTs

and GTOs as freewheeling diodes,

snubber diodes and clamp diodes.

Power and productivity

for a better world™

Contents

Page

1 Introduction 3

2 Fast recovery diode product range from ABB 3

2.1 GTO diodes 3

2.1.1 GTO freewheeling diodes 3

2.2 IGCT diodes 3

3 Data sheet users guide 3

3.1 IGCT-Diode data sheet 4

4 Design recommendations 9

4.1 Determine the right diode for standard application conditions 9

4.2 Determine the right diode for customized application conditions 9

4.3 Diode switching and important parameters to consider 10

4.3.1 Diode turn-on 10

4.3.2 Diode turn-off 11

4.3.3 Surge current rating 11

5 References 11

2 Applying fast recovery diodes I Application Note 5SYA 2064-01

1 Introduction ABB’s snubber diode product range is presented in Table 2.

When designing with fast recovery diodes, there are certain issues

to be considered, the most important of these are addressed in 2.2 IGCT diodes

this application note. The design of IGCT diodes is optimized for switching against

highest dv/dt. This is typically the case in applications with IGCTs

2 Fast recovery diode product range from ABB where the semiconductors don’t have any dv/dt snubber but

2.1 GTO diodes rather a so called clamp circuit. The clamp circuit (Fig. 13) limits

2.1.1 GTO freewheeling diodes the commutation voltage but doesn’t limit the dv/dt of IGCTs and

This type of diode is mainly designed for use in anti-parallel to a diodes during turn-off. To handle the speed of the switching, an

GTO. A GTO needs a snubber that limits dv/dt and di/dt. These inductive snubber is used to reduce di/dt.

diodes are therefore designed to work under conditions with a ABB’s IGCT diode product range is presented in Table 3.

turn-off di/dt of some hundred amps per microsecond in combi-

nation with a dv/dt in a range of some hundred volts per micro- 3 Data sheet users guide

second. Additional important attributes are high cosmic radiation Section 3.1 is a detailed guide to the proper understanding of an

withstand ratings when blocking and low electrical losses in IGCT-Diode data sheet. Parameters and ratings are defined while

on-state and during switching. following the sequence in which parameters appear in the data

sheet. For explanation purposes, data and diagrams associated

ABB’s GTO freewheeling diode product range is presented in with the IGCT diode 5SDF 10H4503 have been used. However,

Table 1. this guide is applicable to all IGCT diodes. For actual data of

5SDF 10H4503 please refer to the Datasheet in the ABB internet

2.1.2 Snubber diodes website.

Snubber diodes are optimized for the use in GTO snubber Data sheets of GTO freewheeling diodes and snubber diodes are

circuits. These diodes are designed for switching with high di/dt similarly specified and are therefore to read similarly.

against high dv/dt. Electrical losses and cosmic radiation

withstand rating are not as important as with freewheeling diodes.

Parameter VRRM VDC IF(AV)M IFSM V(T0) rF IRM Qrr TVJM Rth(j-c) Rth(c-h) Fm Housing

Tc = 1 ms 10 ms

TVJM di/dt=300 «Type»

85 °C TVJM TVJM

A/us ø x h

V V A kA kA V m A µC °C K/kW K/kW kN [mm]

5SDF 05D2505 2500 1500 420 27 8.5 1.7 0.62 470 840 125 40 8 11 “D” 60 x 26

5SDF 11F2501 2500 1500 950 65 21 1.2 0.38 550 1200 125 20 5 22 “F” 75 x 26

5SDF 07F4501 4500 2800 650 44 16 1.4 1.00 600 1900 125 20 5 22 “F” 75 x 26

5SDF 13H4501 4500 2800 1200 60 25 1.3 0.48 800 3000 125 12 3 40 “H” 95 x 26

5SDF 10H6004 6000 3800 1100 44 18 1.5 0.60 1000 6000 125 12 3 40 “H” 95 x 26

Table 1: GTO freewheeling diode product range

Parameter VRRM VDC IF(AV)M IFSM V(T0) rF IRM Qrr TVJM Rth(j-c) Rth(c-h) Fm Housing

Tc = 1 ms 10 ms

TVJM di/dt=100 «Type»

85 °C TVJM TVJM

A/us ø x h

V V A kA kA V m A µC °C K/kW K/kW kN [mm]

5SDF 05D2501 2500 1100 490 27 8.5 1.4 0.5 250 900 125 40 8 11 “D” 60 x 26

5SDF 03D4501 4500 2400 320 12 5.0 2.0 1.5 200 1000 125 40 8 11 “D” 60 x 26

5SDF 07H4501 4500 2400 900 40 16.0 1.8 0.9 260 1700 125 12 3 40 “H” 95 x 26

5SDF 02D6002 6000 3000 250 11.4 3.6 2.5 2.5 260 2000 125 40 8 11 “D” 60 x 26

Table 2: GTO snubber diode product range

Parameter VRRM VDC IF(AV)M IFSM V(T0) rF IRM di/dt TVJM Rth(j-c) Rth(c-h) Fm Housing

Tc = 1 ms 10 ms

TVJM

max. «Type»

70 °C TVJM TVJM ø x h

V V A kA kA V m A A/us °C K/kW K/kW kN [mm]

5SDF 03D4502 4500 2800 275 10 5 2.15 2.80 355 300 115 40 8 16 “D” 60 x 26

5SDF 05F4502 4500 2800 435 32 16 2.42 2.10 610 430 115 17 5 20 “F” 75 x 26

5SDF 10H4502 4500 2800 810 40 24 2.42 1.10 1150 650 115 12 3 44 “H” 95 x 26

5SDF 10H4503 4500 2800 1100 47 20 1.75 0.88 1520 600 125 12 3 40 “H” 95 x 26

5SDF 10H4520 4500 2800 1440 56 25 1.75 0.88 1600 600 140 10 3 40 “H” 95 x 26

5SDF 16L4503 4500 2800 1650 47 26 1.90 0.79 1200 600 125 6.5 3 40 “L” 120 x 26

5SDF 02D6004 5500 3300 175 8 3 3.35 7.20 300 220 115 40 8 16 “D” 60 x 26

5SDF 04F6004 5500 3300 380 22 10 2.70 2.80 600 340 115 22 5 20 “F” 75 x 26

5SDF 08H6005 5500 3300 585 40 18 4.50 1.30 900 440 115 12 3 44 “H” 95 x 26

Table 3: IGCT diode product range

3 Applying fast recovery diodes I Application Note 5SYA 2064-01

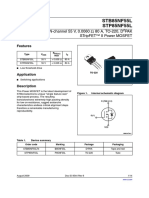

3.1 IGCT-Diode data sheet Characteristic values

Parameter Symbol Conditions min typ max Unit

Weight m 0.83 kg

Housing thickness H 26.0 26.4 mm

Surface creepage D s 33

mm

distance

Air strike distance D a 20

mm

Fm: The mounting force is the recommended force to be applied

• Patented free-floating technology for optimal device performance. Too low a mounting force will

• Industry standard housing increase the thermal impedance thus leading to higher junction

• Cosmic radiation withstand rating temperature excursions resulting in a lower operating lifetime for

• Low on-state and switching losses the diode. Too high a clamping force may crack the wafer during

• Optimized for snubberless operation load cycling. It is important to apply a homogeneous force over

the whole contact area. Otherwise, electrical and reliability perfor-

The key features give the basic voltage and current ratings of mance are reduced. For details please consult the ABB applica-

the diode. These ratings are repeated later in the data sheet tion note 5SYA2036 «Recommendations regarding mechanical

where the conditions at which the value is valid are shown. clamping of Press Pack High Power Semiconductors».

Each of them is explained at the appropriate place in this section. a: Maximum permissible acceleration in any direction at the given

The parameter values are followed by a short description of the conditions. The value for a clamped device is only valid within the

main features of the diode. given mounting force limits.

m: Weight of the device.

Blocking H: Height of the device when clamped at the given force.

1)

Maximum rated values Ds: The surface creepage distance is the shortest path along the

Parameter Symbol Conditions Value Unit housing between anode and cathode.

Repetitive peak reverse voltage VRRM f = Hz, tp = 10ms 4500 V Da: The air strike distance is defined as the shortest direct path

Tvj = 125 °C between anode and cathode.

Permanent DC voltage for VDC-link Ambient cosmic 2800 V

100 FIT failure rate radiation at sea level in On-state

1)

open air. (100% Duty) Maximum rated values

Permanent DC voltage for VDC-link Ambient cosmic 3200 V Parameter Symbol Conditions min typ max Unit

100 FIT failure rate radiation at sea level in Max. average on-state IF(AV)M Half sine wave, 1100 A

open air. (5% Duty) current TC = 70 °C

Max. RMS on-state IF(RMS) 1740 A

Characteristic values current

3

Parameter Symbol Conditions min typ max Unit Max. peak non repeti- IFSM tp = 10 ms, 20x10 A

Repetitive peak IRRM VR = VRRM, 50 mA tive surge current Tvj = 125 °C

reverse current Tvj = 125 °C VR = 0 V

2 6 2

Limiting load integral l t 2x10 A s

3

VRRM: Maximum voltage that the device can block repetitively. Max. peak non repeti- IFSM tp = 30 ms, 12x10 A

Above this level the device may be damaged or become tive current Tvj = 125 °C

destroyed. This parameter is measured with 10 millisecond (ms) VR = 0 V

2 6 2

half-sine pulses with a repetition frequency of 50 hertz (Hz). The Limiting load integral l t 2.16x10 A s

limit for maximum single-pulse voltage (VRSM) is normally not

stated in the ABB datasheets since it is equal to VRRM. Characteristic values

VDC-link: These numbers define the maximum DC-link voltage of a Parameter Symbol Conditions min typ max Unit

voltage source inverter or a chopper application to achieve maxi- On-state voltage VF IF = 2500 A, 3.1 3.8 V

mum 100 FIT (Failure in Time, 1 FIT corresponds to 1 failure in 109 Tvj = 125 °C

component hours) under the defined conditions. For more details Threshold voltage V(T0) Tvj = 125 °C 1.75 V

please read the ABB application note 5SYA2061 «Cosmic ray on Slope resistance rT IF = 500...2500 A 0.88 m

FRD». Switching against higher voltage than the maximum stated

VDC-link is not recommended since it can lead to abrupt cut-off of IF(AV)M and IF(RMS): are the maximum allowable average and RMS

the reverse recovery current of the diode, so called snap-off. device currents defined for 180 ° sine wave pulses of 50 percent

IRRM: The maximum leakage current at the given conditions. duty cycle at the specified case temperature. The definitions are

arbitrary but standard thus allowing device comparisons.

IFSM and I2t: The maximum peak forward surge current and

Mechanical data the integral of the square of the current over one period are

1)

Maximum rated values defined for 10 ms and 30 ms wide, half sine-wave current

Parameter Symbol Conditions min typ max Unit pulses without reapplied voltage. Above these values, the device

Mounting force F m 36 40 46 kN may fail (short-circuit). These parameters are required for protec-

2

Acceleration a Device unclamped 50 m/s tion co-ordination. For currents that clearly differ from half sine

2

Acceleration a Device clamped 200 m/s wave shape the above stated numbers and the curves in Fig. 4

4 Applying fast recovery diodes I Application Note 5SYA 2064-01

and Fig. 5 are not applicable. For evaluation of such cases please A) VF = 2.6V @ IF = 3300A -> Err-2 = 9.5 Ws @ the stated conditions

contact ABB’s Application Support. Additional information is B) VF = 4.25V @ IF = 3300A -> Err-1 = 6.0 Ws @ the stated conditions

provided in section 4.3.3.

VF: The forward voltage drop of the diode at the given conditions. To adapt the datasheet conditions to the application conditions,

The threshold voltage V(T0) and the slope resistance rT allow a di/dt and IFM can be linear interpolated between the curves

linear representation of the diode forward voltage drop and are in Fig 6 and Fig 7. Small differences in the range of 15 percent

used for simple calculations of conduction losses in the current in VDC-link can be linear extrapolated. For loss calculations with

range stated under «conditions». parameters that greatly differ from the stated datasheet condi-

tions please contact ABB’s Application Support.

Turn-on

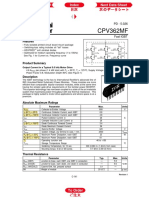

Characteristic values Thermal

1)

Parameter Symbol Conditions min typ max Unit Maximum rated values

Peak forward recovery VFRM dlF/dt=600A/µs, 80 V Parameter Symbol Conditions min typ max Unit

voltage Tvj = 125 °C Operating junction Tvj 0 125 °C

dlF/dt=3000A/µs, 250 V temperature range

Tvj = 125 °C Storage temperature Tstg -40 125 °C

range

VFRM: The dynamic peak forward voltage drop of the diode during

turn-on. VFRM and dIF/dt are defined in Fig 12. A more detailed Characteristic values

description is written in section 4.3.1. Parameter Symbol Conditions min typ max Unit

Thermal resistance Rth(j-c) Double-side 12 K/kW

Turn-off junction to case cooled

1)

Maximum rated values Fm = 36...46 kN

Parameter Symbol Conditions min typ max Unit Rth(j-c)A Anode-side 24 K/kW

Max. decay rate of di/dtcrit IF = 4000 A 600 A/µs cooled

on-state current VDC-Link = 2800 V Fm = 36...46 kN

-dlF/dt = 600 A/µs Rth(j-c)C Cathode-side 24 K/kW

LCL = 300 nH cooled

CCL-Link = 10µF Fm = 36...46 kN

RCL-Link = 65 Thermal resistance Rth(c-h) Double-side 3 K/kW

Tvj = 125 °C case to heatsink cooled

DCL = 5SDF 10H4503 Fm = 36...46 kN

Thermal resistance Rth(c-h) Single-side 6 K/kW

Characteristic values case to heatsink cooled

Parameter Symbol Conditions min typ max Unit Fm = 36...46 kN

Reverse recovery IRM IF = 3300 A 1520 A

current VDC-Link = 2800 V Analytical function for transient thermal impedance:

Reverse recovery Qrr -dlF/dt = 600 A/µs 5250 µC

charge LCL = 300 nH

Turn-off energy Err CCL = 10µF 9.5 J

RCL = 65

Tvj = 125 °C

DCL = 5SDF 10H4503

di/dtcrit: Maximum turn-off di/dt that the device can handle at the

stated conditions. Above this level the device may be destroyed.

Especially higher values in LCL or VDC-Link drastically reduce turn-off

capability.

IRM: Maximum reverse recovery current at the stated conditions.

Dependencies of di/dt and forward current IF are shown in Fig. 9.

Qrr: Maximum reverse recovery charge at the stated conditions.

Dependencies of di/dt and forward current IF are shown in Fig. 8.

Err: Maximum turn-off energy at the stated conditions. The Err

value is highly depending on the on-state voltage of the individual

diode. This should be considered when doing loss simulations.

Since VF typically shows a scatter in the range of some

100 millivolts (mV) we recommend doing diode total-loss calcula-

tions at application conditions with the extreme combinations

Err-1_@ VF-max and Err-2_@ VF-min. This corresponds to either a

Fig. 1: Transient thermal impedance junction-to-case

diode with high on-state or a diode with low on-state. Please see

Fig 10. In this particular case we recommend to simulate diode

losses with a device

5 Applying fast recovery diodes I Application Note 5SYA 2064-01

Tvj: The operating junction temperature range gives the limits The model (Fig. 2) gives a mathematical expression for the maxi-

within which the silicon of the diode should be used. If the limits mum on-state voltage at Tvj = 25 °C for the given current interval

are exceeded, the ratings for the device are no longer valid and which is much greater than the interval given for the simple linear

there is a risk of catastrophic failure. model given by V(T0) and rT.

Tstg: The temperature interval within which the diode must be On-state voltage drop of the diode as a function of the on-state

stored to ensure that it will be operational at a later use. Tstg-min current at the given temperatures for normal operation current

and Tstg-max are the extreme temperatures and are not levels.

recommended for long time storage. For long time storage please

refer to Specification 5SZK 9104 «Specification of environmental

class for pressure contact Diodes, PCTs and GTOs – STORAGE»

The thermal resistance junction to case, Rth(j-c), and the thermal

resistance case to heat sink, Rth(c-h), are measures of how well

the power losses can be transferred to the cooling system. The

values are given both for double-sided cooling, where the device

is clamped between two heat sinks, and single-sided cooling,

where the device is clamped to only one heat sink. The values are

valid for a homogeneously applied clamping force over the whole

contact area of the diode. The temperature rise of the «virtual

junction» (the silicon wafer inside the diode) in relation to the heat

sink is calculated using Equation 1. Rth(j-c) and Rth(c-h) should be as

low as possible since the temperature of the silicon determines

the current capability of the diode. Furthermore the temperature

excursion of the silicon wafer determines the load-cycling

capability and thus the life expectancy of the diode.

Eqn 1

where TJH is the temperature difference between the silicon

wafer and the heat sink.

Fig. 3: Max. on-state voltage characteristics

The transient thermal impedance emulates the rise of junction

temperature versus time when a constant power is dissipated in The model (Fig. 3) gives a mathematical expression for the maxi-

the junction. This function can either be specified as a curve or mum on-state voltage at Tvj = 25 °C for the given current interval

as an analytic function with the superposition of four exponential which is much greater than the interval given for the simple linear

terms. The analytic expression is particularly useful for computer model given by V(T0) and rT.

calculations. On-state voltage drop of the diode as a function of the on-state

current at the given temperatures for the extended current levels

up to the magnitude of IFSM. The curves are calculated with

above mathematical expressions.

Fig. 4: Surge on-state current vs. pulse length. Half-sine wave

Surge current limit and surge current integral for half-sine pulses

Fig. 2: Max. on-state voltage characteristics

of different pulse widths with no reapplied voltage (Fig. 4). The

curves are given for a starting temperature of Tvj-max.

6 Applying fast recovery diodes I Application Note 5SYA 2064-01

Fig. 7: Upper scatter range of turn-off energy per pulse vs. reverse current rise rate

Fig. 5: Surge on-state current vs. number of pulses, half-sine wave, 10 ms, 50Hz

Surge current limit with no reapplied voltage as a function of the Maximum turn-off energy at the given conditions as a function of

number of applied 10 ms half-sine pulses with a repetition rate of the rate of decline of current before the commutation (Fig. 7). See

50 Hz for a starting temperature of Tvj-max (Fig. 5). figure 12 for definitions.

Maximum reverse recovery charge at the given conditions as a

function of the rate of decline of current before the commutation.

Fig. 6: Upper scatter range of turn-off energy per pulse vs. turn-off current

See figure 12 for definitions.

Fig. 8: Upper scatter range of repetitive reverse recovery charge vs. reverse current rise

Maximum turn-off energy at the given conditions as a function of

rate.

the on-state current IF before the commutation. See figure 12 for

definitions (Fig. 6). Maximum reverse recovery current at the given conditions as a

function of the rate of decline of current before the commutation

(Fig. 8). See figure 12 for definitions.

7 Applying fast recovery diodes I Application Note 5SYA 2064-01

Fig. 9: Upper scatter range of reverse recovery current vs. reverse current rise rate

Fig. 11: Diode Safe Operating Area

Safe operating area at the given conditions (Fig. 11). See figure

Maximum reverse recovery current at the given conditions as a

12 for definitions. Use of the diode outside these operation condi-

function of the rate of decline of current before the commutation

tions could lead to catastrophic failures and should therefore be

(Fig. 9). See figure 12 for definitions.

avoided.

VF(t), IF (t)

dIF/dt -dIF/dt

VFR

IF (t) IF (t)

Qrr

VF (t) VF (t)

tfr t

tfr (typ) 10 µs

VR (t)

IRM

Fig. 12: General current and voltage waveforms

Electrical circuit used when determining the turn-on and turn-

off data sheet ratings. CCL, DCL, RS and LCL represent the clamp

circuit to limit switching over-voltages. LCL is a stray inductance

and restricts the switching capability of the circuit. It should be

designed as small as possible in an application.

Fig. 10: Max. turn-off energy per pulse vs. on-state voltage. The turn-off parameters Err and Qrr are only specified on the DUT

Maximum turn-off switching energy depending on the on-state of position as a freewheeling diode. The reason is that on clamp

the diode at the given conditions (Fig. 10). The curve represents position (DCL) turn-off losses are typically not the limiting criteria.

the upper scatter range of Err of the production distribution.

Fig. 13: Test circuit

8 Applying fast recovery diodes I Application Note 5SYA 2064-01

GTO applications:

GTO Type Recommended Recommended

freewheeling snubber

diodes diodes

5SGA 15F2502 5SDF 05D2505 5SDF 05D2501

5SDF 11F2501

5SGA 20H2501 5SDF 05D2505 5SDF 05D2501

5SDF 11F2501

5SGA 25H2501 5SDF 05D2505 5SDF 05D2501

5SDF 11F2501

5SGA 30J2501 5SDF 11F2501 5SDF 05D2501

5SGA 06D4502 5SDF 03D4501 5SDF 03D4501

5SGA 20H4502 5SDF 03D4501 5SDF 03D4501

5SDF 07F4501

5SGA 30J4502 5SDF 07F4501 5SDF 03D4501

5SDF 13H4501

5SGA 40L4501 5SDF 13H4501 5SDF 03D4501

5SDF 07H4501

5SGF 30J4502 5SDF 07F4501 5SDF 03D4501

5SDF 13H4501 5SDF 07H4501

Fig. 14: Outline drawing, all dimensions are in millimeters and represent nominal values

5SGF 40L4502 5SDF 13H4501 5SDF 03D4501

unless stated otherwise

5SDF 07H4501

Table 4: Recommended diodes for GTO applications

Related documents:

Doc. Nr. Titel

IGCT applications

5SYA 2036 Recommendations regarding mechanical clamping of Press

Pack High Power Semiconductors GTO Type Recommended Recommended Recommended

5SYA 2061 Failure rates of fast recovery diodes due to cosmic rays

freewheeling clamp NPC

5SZK 9104 Specification of environmental class for pressure contact diodes, diodes diodes diodes**

PCTs and GTO, STORAGE. Available on request, please 5SHX 08F4510 Integrated 5SDF 03D4502 5SDF 03D4502

contact ABB’s Application Support. 5SHX 14H4510 Integrated 5SDF 03D4502 5SDF 03D4502

5SZK 9105 Specification of environmental class for pressure contact diodes, 5SDF 05F4502 5SDF 05F4502

PCTs and GTO, TRANSPORTATION. Available on request,

5SDF 10H4503

please contact ABB’s Application Support. 5SHX 26L4510 Integrated 5SDF 03D4502 5SDF 05F4502

Please refer to http://www.abb.com/semiconductors for current versions. 5SDF 05F4502 5SDF 10H4503

5SDF 10H4520

A list of applicable documents is included at the end of the data

5SHX 06F6010 Integrated 5SDF 02D6004 5SDF 02D6004

sheet.

5SDF 04F6004

5SHX 10H6010 Integrated 5SDF 02D6004 5SDF 04F6004

4 Design recommendations

5SDF 04F6004 5SDF 08H6005

4.1 Determine the right diode for standard application

5SHX 19L6010 Integrated 5SDF 02D6004 5SDF 04F6004

conditions

5SDF 08H6005 5SDF 08H6005

If the application conditions are close to the specified conditions

5SHY 35L4510 5SDF 10H4503 5SDF 05F4502 5SDF 10H4503

in the datasheets of the used GTO or IGCT ABB recommends the

5SHY 35L4511 5SDF 10H4520 5SDF 10H4503 5SDF 10H4520

use of the following diodes. If several diodes are recommended

5SHY 35L4512 5SDF 16L4503 5SDF 10H4520 5SDF 16L4503

by ABB, the decision should be made according to the needs of

5SHY 55L4500

the application: Table 5: Recommended diodes for IGCT applications

• High expected losses in the diode -> use the larger diode

• GTO/GCT and diodes in one combined -> use the diode with ** Note: NPC diodes stand for Neutral Point Clamp diodes. These diodes are

mechanical clamp system adequate mounting force typically used in 3-level inverters. The conditions to which these diodes are

• Application conditions very close to the -> use the larger diode subjected are typically similar to the conditions of a freewheeling diode used in

GTO/IGCT SOA limits an IGCT inverter.

4.2 Determine the right diode for customized application

conditions

If the application conditions differ from the specified conditions in

the datasheet, the following parameters must be defined:

a) Diode type?

Freewheeling diode, dv/dt at turn-off < 700V/µs GTO freew-

heeling diode

9 Applying fast recovery diodes I Application Note 5SYA 2064-01

Freewheeling diode, dv/dt at turn-off > 700V/µs IGCT diode Measurements have shown that the VFRM vs. di/dt characteristic is

slightly digressive. VFRM values at 125 °C are about double those

Snubber diode in a GTO-application, no dc-blocking operation at 25 °C. This behavior can be explained by reduced charge

GTO snubber diode carrier mobility at elevated temperatures.

Clamp diode in an IGCT-application IGCT diode Comparing VFRM values between diodes of different thickness, it is

obvious that dynamic forward voltage increases exponentially with

b) Voltage class? device thickness. This is explicable by the difficulty in achieving

Diodes with higher blocking voltage typically show steady-state carrier concentration in a thick device within a few

- Higher forward recovery during turn-on μs. Fig. 16 shows typical VFRM values relating to the active wafer

- Increased ruggedness and softness while turning off area of ABB diodes. The red and orange curves belong to 6 kV

- Higher on-state and switching losses IGCT diodes and 5.5 kV IGCT diodes at Tvj = 125 °C, 80 °C and

- Much lower cosmic radiation FIT rate at compared voltage. 25 °C while the blue colored curve is applicable for 4.5 kV diodes

Please consider application notes 5SYA2051 «Voltage ratings at Tvj = 125 °C. To estimate typical VFRM values of ABB diodes

of high power semiconductors» and 5SYA2061 «Cosmic ray on at a specific diF/dt the «di/dt per wafer area» of Fig. 16 has to be

FRD» multiplied by the active wafer area of the diode. The active area of

the different diodes correspond to the housing type which is listed

c) Diode-diameter? in tables 1-3 where

Diodes with larger diameter show

- Lower forward recovery during turn-on D - housing corresponds to an active area of 24.3 cm2

- Increased ruggedness F - housing corresponds to an active area of 33.8 cm2

- Lower on-state losses H - housing corresponds to an active area of 46.3 cm2

- Proportional to the silicon area higher cosmic radiation FIT rate L - housing corresponds to an active area of 65.2 cm2

at compared voltage

- Lower thermal impedance

- The need for higher clamping force. From a mechanical point

of view it is often preferable to clamp IGCT (GTO) und its related

diodes in one single clamp system. If devices in one mechanical

clamp have unequal pole-piece diameter, force spreaders have

to be used. Please consider application note 5SYA2036

«Recommendations regarding mechanical clamping of Press

Pack High Power Semiconductors».

4.3 Diode switching and important parameters to consider

4.3.1 Diode turn-on

During turn-on of a diode the two parameters turn-on energy (Eon)

and peak forward recovery voltage (VFRM) are important to review

regarding the specific needs of the application.

Fig. 16: Peak forward recovery voltage as a function of di/dt per wafer area

To estimate turn-on losses of a diode equation 2 can be taken to

calculate the order of magnitude of Eon.

Eon_typ 1/6 * VFRM * diF/dt * tfr2 [Ws] Eqn 2

Where Eon_typ are the estimated typical turn-on losses, diF/dt is the

applied turn-on di/dt, VFRM is the peak forward recovery voltage at

diF/dt and tfr is the time constant of VFRM. Tfr depends on different

parameter but can be chosen as 5 µs for this raw calculation.

Example 1:

Fig. 15: Peak forward recovery voltage as a function of time

5SDF 10H4503, 4.5 kV IGCT diode in L-housing on freewheeling

position, diF/dt = 600 A/µs, Tvj = 125 °C

Fig. 15 shows the initial forward voltage overshoot VFRM, when a

diode turns on with a high di/dt. VFRM is the peak voltage, and tfr di/dt per wafer area = 600 A/µs / 46.3 cm2 = 13 A/(µs*cm2)

characterizes the decay of the overshoot. The voltage overshoot VFRM 40 V

originates from the fact that conductivity of the diode is initially Eon_typ 1/6 * 40 V * 600 A/µs * 5µs2 = 0.1 Ws

reduced, because the number of free charge carriers available is

much lower than in the steady-state. The device needs time to

build up the required electron and hole concentration, within the Example 2:

bulk of the silicon. 5SDF 02D6004, 6 kV IGCT diode in D-housing on clamp position,

10 Applying fast recovery diodes I Application Note 5SYA 2064-01

diF/dt = 2500 A/µs, Tvj = 125 °C so small as to not contribute much to turn-off losses,

despite reverse voltage being already high at this time. The

di/dt per wafer area = 2000 A/µs / 24.3 cm2 = 82 A/µs*cm2 application specific VR(t) is one of the main reasons that different

VFRM 350 V diode designs are recommended for application conditions such

Eon_ty 1/6 * 350 V * 2000 A/µs * 5µs2 = 2.9 Ws as GTO-snubber diode, GTO-freewheeling diode or IGCT free-

wheeling- NPC- and clamp-diode. It is not recommended to use

diodes above the maximum values specified in the data sheets.

It is obvious that turn-on losses of a diode on a freewheeling posi- Especially the use of diodes in IGCT applications without dv/dt

tion are in most cases negligible since the diode typically has a limitation is very sensitive regarding VDC-Link and LCL.

large diameter and the diF/dt is in the range below 1000 A/µs.

On a clamp position or on a snubber position the turn-on losses 4.3.3 Surge current rating

can become relevant. diF/dt is equal to the turn-off di/dt of the IFSM is the maximum allowed, non-repetitive and pulse-width

Switch (GTO or IGCT) and can be much higher than on a free- dependent peak value of a half-sinusoidal surge current, applied

wheeling position. Typical diF/dt that can be expected are in the at an instant when the diode is operating at its maximum junc-

range of the turn-off current of the switch per 1µs. E.g. turn-off of tion temperature Tvjm. Although, in practice, the case temperature

3000 A leads to a diF/dt in the range of 3000 A/µs. prior to a surge is always below Tvjm, both the junction and the

housing are heated to Tvjm when the surge current limit is es-

As a further effect VFRM of diodes on a GTO-snubber position tablished. This worst-case test condition provides an additional

or on an IGCT freewheeling- or clamp-position increases the margin to the real stress in an application.

dynamic commutation voltage of the Switch (GTO, IGCT with its During a surge, the junction heats up to a temperature well above

freewheeling diode). This so called spike voltage VDSP is speci- its rated maximum value. Therefore, the diode is no longer able

fied in the GTO and IGCT datasheets under «general current and to block rated voltage, so the IFSM values are valid only for VR = 0

voltage waveforms». High values of this spike voltage reduce V after the surge, i.e. without reapplied voltage. Although a single

the switching capability of the switch. Because of this a larger surge does not cause any irreversible damage to the silicon wafer,

snubber diode or IGCT diode increases the turn-off capability of it should not be allowed to occur too frequently.

the switch and vice versa. In terms of turn-off capability of the I2t is an abbreviation and stands for IF2 dt. This value is derived

switch it is also recommended not to use too high voltage diodes. from the IFSM value discussed above, according to equation 3:

Typically snubber, clamp and freewheeling diodes are of the same

voltage class as the related GTO or IGCT. It only makes sense to Eqn 3

choose diodes of a higher voltage class if ruggedness in terms of

turn-off switching of the diode itself is critical. (for half-sinusoidal waveforms) [A2s]

4.3.2 Diode turn-off To protect the diode, the I2t of a semiconductor fuse must be

Fig 17 shows the turn off of an IGCT diode on a freewheeling lower than the maximum I2t of the diode. The caveat for IFSM

position. The forward current, IF, is switched off with a certain applies similarly to I2t.

diF/dt (determined by the driving voltage and the di/dt limiting

inductance), and continues to flow in the reverse direction until The shape of IFSM of applications depends on the protection

the pn junction is able to block reverse voltage. At this time, the concept and the electrical circuit and is therefore individual. The

reverse recovery current has reached its peak value IRM. The sinusoidal waveforms described in the datasheets typically don’t

subsequent decay of the current and rise in reverse voltage are appear in applications with fast switching diodes. IFSM is a stan-

mainly determined by the diode itself and the applied voltage as dardised value that enables comparison of datasheets of different

a function of time. The applied voltage shape depends on the devices and even of different manufacturers. When IFSM is ex-

circuit of the application pected to be close to the diode capability, ABB is able to simulate

the stress that occurs under application conditions.

VF(t), I F

As input data for the simulation i(t), starting values of Tcase and

-dI F/dt Tjunction and the mounting force Fm are needed. I(t) should be

available in a numerical form such as ASCII or Excel.

IF (t

5 References

1) IEC 60747 «Semiconductor Devices»

2) 5SYA2036 «Recommendations regarding mechanical clamping

Qr of Press Pack High Power Semiconductors»

VF 3) 5SYA2051 «Voltage ratings of high power semiconductors»

t 4) 5SYA2061 «Failure rates of fast recovery diodes due to

cosmic rays»

VR 5) 5SZK9104 «Specification of environmental class for pressure

IR

contact diodes, PCTs and GTO, STORAGE»

6) 5SZK9105 «Specification of environmental class for pressure

Fig. 17: Turn-off of an IGCT freewheeling diode

contact diodes, PCTs and GTO, TRANSPORTATION»

It is the goal of the diode design engineer to ensure that the tail

current decays in a «soft» manner, meaning without ringing or The application notes, Reference 2 - 4, are available at www.abb.

overshoot provoking «snap», and that tail current and tail time are com/semiconductors

11 Applying fast recovery diodes I Application Note 5SYA 2064-01

The environmental specifications 5 – 6 are available on request; ABB Switzerland Ltd

please contact ABB’s Application Support Semiconductors

Fabrikstrasse 3

6 Revision history CH-5600 Lenzburg

Version Change Authors Switzerland

Tel: +41 58 586 14 19

01 Thomas Setz Fax: +41 58 586 13 06

E-Mail: abbsem@ch.abb.com

www.abb.com/semiconductors

02.09.2013

Note

We reserve the right to make technical changes

or to modify the contents of this document

Application note 5SYA 2064-01

without prior notice.

We reserve all rights in this document and the

information contained therein. Any reproduction

or utilisation of this document or parts thereof for

commercial purposes without our prior written

consent is forbidden.

Any liability for use of our products contrary to the

instructions in this document is excluded.

Power and productivity

for a better world™

You might also like

- IGCT TrainingDocument57 pagesIGCT TrainingVivek KumarNo ratings yet

- Applying IGBT and Diode Dies - 5SYA 2059-04Document12 pagesApplying IGBT and Diode Dies - 5SYA 2059-04FarnazNo ratings yet

- ABB HighPowerSemiconductorsProductCatalogue2013 PDFDocument36 pagesABB HighPowerSemiconductorsProductCatalogue2013 PDFPopovici PaulNo ratings yet

- RD 2015-05-001-V01 Evaluation Board For M909 ModulesDocument24 pagesRD 2015-05-001-V01 Evaluation Board For M909 ModulesasokanenNo ratings yet

- CPV 363 MFDocument9 pagesCPV 363 MFSergio MuriloNo ratings yet

- 5SYA2053-04 Applying IGBTsDocument40 pages5SYA2053-04 Applying IGBTsFahmi MohamedNo ratings yet

- STP310N10F7Document13 pagesSTP310N10F7Lu HoaNo ratings yet

- Ta7280p, Ta7281pDocument15 pagesTa7280p, Ta7281pivirgilNo ratings yet

- ABB Semiconductors. High-Power Semiconductors. Product Catalog. 2015Document72 pagesABB Semiconductors. High-Power Semiconductors. Product Catalog. 2015navaron64No ratings yet

- Svcet: EE6503 - Power ElectronicsDocument11 pagesSvcet: EE6503 - Power ElectronicsSatyanarayana GurramNo ratings yet

- Isolated DC-DC ConverterDocument4 pagesIsolated DC-DC ConverterUge AjjaNo ratings yet

- QB NewDocument13 pagesQB NewNarasimman DonNo ratings yet

- Ee6503 - Power Electronics: 2 Marks and 16 Marks-Question Bank Unit 1 - Introduction Two MarksDocument30 pagesEe6503 - Power Electronics: 2 Marks and 16 Marks-Question Bank Unit 1 - Introduction Two Marksdishore312No ratings yet

- Igbt or IgctDocument6 pagesIgbt or IgctJulian De MarcosNo ratings yet

- DD-7 Service Notes PDFDocument24 pagesDD-7 Service Notes PDFjamesNo ratings yet

- STB95N3LLH6, STD95N3LLH6 STP95N3LLH6, Stu95n3llh6Document18 pagesSTB95N3LLH6, STD95N3LLH6 STP95N3LLH6, Stu95n3llh6Pedro GarciaNo ratings yet

- Guide to Discrete IGBTsDocument16 pagesGuide to Discrete IGBTsPablo AllosiaNo ratings yet

- We en Web in Ar Sic Mosfet 1638931895460Document29 pagesWe en Web in Ar Sic Mosfet 1638931895460Алексей ЯмаNo ratings yet

- IGBT's Application Note EngDocument38 pagesIGBT's Application Note Engospidera100% (1)

- Stn3Nf06L: N-Channel 60 V, 0.07 Ω Typ., 4 A Stripfet™ Ii Power Mosfet In A Sot-223 PackageDocument12 pagesStn3Nf06L: N-Channel 60 V, 0.07 Ω Typ., 4 A Stripfet™ Ii Power Mosfet In A Sot-223 Packageramesh sahukhalNo ratings yet

- IR21571 Ballast Control IC Design Kit GuideDocument16 pagesIR21571 Ballast Control IC Design Kit Guide1cvbnmNo ratings yet

- STGF 10 NC 60 KDDocument30 pagesSTGF 10 NC 60 KDFonos ServisNo ratings yet

- IPD60R360P7 InfineonDocument14 pagesIPD60R360P7 InfineonJimmy Varela TraderNo ratings yet

- Uln 2803 CDocument22 pagesUln 2803 CJesin KimNo ratings yet

- Making Inverter Welder - IRFDocument18 pagesMaking Inverter Welder - IRFShaun Dwyer Van Heerden0% (1)

- 3 A Low Drop Positive Voltage Regulator: Adjustable and FixedDocument27 pages3 A Low Drop Positive Voltage Regulator: Adjustable and FixedTT DVNo ratings yet

- 4NF20L STMicroelectronics PDFDocument12 pages4NF20L STMicroelectronics PDFTiago eletrônicaNo ratings yet

- MP3388Document12 pagesMP3388mirandowebsNo ratings yet

- Infineon-IPA60R360P7-DataSheet-v02_03-ENDocument14 pagesInfineon-IPA60R360P7-DataSheet-v02_03-ENcostelcnNo ratings yet

- Stl16N65M2: N-Channel 650 V, 0.325 Typ., 7.5 A Mdmesh M2 Power Mosfet in A Powerflat™ 5X6 HV PackageDocument16 pagesStl16N65M2: N-Channel 650 V, 0.325 Typ., 7.5 A Mdmesh M2 Power Mosfet in A Powerflat™ 5X6 HV PackageJihan ElectronicNo ratings yet

- Std5N52U Stf5N52U: N-Channel 525 V, 1.28, 4.4 A, Dpak, To-220Fp Ultrafastmesh™ Power MosfetDocument15 pagesStd5N52U Stf5N52U: N-Channel 525 V, 1.28, 4.4 A, Dpak, To-220Fp Ultrafastmesh™ Power Mosfetmeri_horvatNo ratings yet

- Surge Protector and Filter Specifications: Technical DataDocument16 pagesSurge Protector and Filter Specifications: Technical DataJuan Esteban Benjumea BenjumeaNo ratings yet

- Mosfet FDPS 2p102aDocument6 pagesMosfet FDPS 2p102aAssiseletroNo ratings yet

- LG - 32lb9rta Me Eay41970901 PDFDocument139 pagesLG - 32lb9rta Me Eay41970901 PDFLuděk CsibaNo ratings yet

- Max 16841 Ev KitDocument16 pagesMax 16841 Ev KitjorojoroNo ratings yet

- Performance EMI Filter: Single-Phase FiltersDocument4 pagesPerformance EMI Filter: Single-Phase FiltersbobmarllyNo ratings yet

- Infineon IPW65R018CFD7 DataSheet v02 00 EN-2498174Document15 pagesInfineon IPW65R018CFD7 DataSheet v02 00 EN-2498174RAMESH JUNJUNo ratings yet

- 3 Hints For Application: 3.1 Dimensioning and Selection of Mosfet, Igbt and Skiippack ModulesDocument7 pages3 Hints For Application: 3.1 Dimensioning and Selection of Mosfet, Igbt and Skiippack ModulesDan DanubiusNo ratings yet

- MUL-PRC004-E4_08012007 RAUPDocument58 pagesMUL-PRC004-E4_08012007 RAUPsena Desahakeerthi patabandigeNo ratings yet

- 5SYA2053 03ApplyingIGBTsDocument37 pages5SYA2053 03ApplyingIGBTsAnonymous 1AAjd0No ratings yet

- Infineon IPD65R1K4C6 DataSheet v02 01 enDocument15 pagesInfineon IPD65R1K4C6 DataSheet v02 01 encarol2No ratings yet

- STB85NF55L STP85NF55L: N-Channel 55 V, 0.0060, 80 A, TO-220, D PAK Stripfet™ Ii Power MosfetDocument14 pagesSTB85NF55L STP85NF55L: N-Channel 55 V, 0.0060, 80 A, TO-220, D PAK Stripfet™ Ii Power Mosfetmobil benerNo ratings yet

- Transil™: Complies With The Following StandardsDocument11 pagesTransil™: Complies With The Following Standardsyafix34669No ratings yet

- Harmony Time - RE8TA21BUTQDocument9 pagesHarmony Time - RE8TA21BUTQAli AbdelFattahNo ratings yet

- Schrack Power PCB Relay U/UB (V23148) : General Purpose Relays PCB RelaysDocument3 pagesSchrack Power PCB Relay U/UB (V23148) : General Purpose Relays PCB Relaysremus popescuNo ratings yet

- IRD1-T2: Transformer Differential Protection RelayDocument24 pagesIRD1-T2: Transformer Differential Protection RelayTaufiqtadNo ratings yet

- Design Guide: TLP5214A Smart Gate Driver Coupler Inverter ApplicationsDocument27 pagesDesign Guide: TLP5214A Smart Gate Driver Coupler Inverter ApplicationsMuleNo ratings yet

- MBR2045CT MBRB2045CT MBR2045CT-1: Schottky Rectifier 20 AmpDocument9 pagesMBR2045CT MBRB2045CT MBR2045CT-1: Schottky Rectifier 20 AmpMiloud ChouguiNo ratings yet

- DatasheetDocument8 pagesDatasheetVACHAN KUMAR 17BEE1151No ratings yet

- stgf19nc60kdDocument26 pagesstgf19nc60kdCesar JakobyNo ratings yet

- Augmented Spark Gap Igniter For Propellants: Descr Mouser Part NumberDocument3 pagesAugmented Spark Gap Igniter For Propellants: Descr Mouser Part NumberFrançois LeroyNo ratings yet

- AOZ1948AIDocument13 pagesAOZ1948AIfox7878No ratings yet

- Hufa76413dk8 768757Document14 pagesHufa76413dk8 768757Movison AustinNo ratings yet

- Structure of Fast Power Diodes 49-53 - SemikronDocument7 pagesStructure of Fast Power Diodes 49-53 - SemikronPelotaDeTrapoNo ratings yet

- lsd815 65 XX PFDocument9 pageslsd815 65 XX PFDavid MoodyNo ratings yet

- TDA7072 DatasheetDocument11 pagesTDA7072 Datasheetsergio_741No ratings yet

- Design and Implementation of A 5 kVA InverterDocument22 pagesDesign and Implementation of A 5 kVA InverterscribsunilNo ratings yet

- Diode, Transistor & Fet Circuits Manual: Newnes Circuits Manual SeriesFrom EverandDiode, Transistor & Fet Circuits Manual: Newnes Circuits Manual SeriesRating: 4.5 out of 5 stars4.5/5 (7)

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- Physics and Technology of Crystalline Oxide Semiconductor CAAC-IGZO: Application to LSIFrom EverandPhysics and Technology of Crystalline Oxide Semiconductor CAAC-IGZO: Application to LSINo ratings yet

- Paint Thinner MSDSDocument6 pagesPaint Thinner MSDSwidyNo ratings yet

- CFD Trading Guide: Essential Info for BeginnersDocument19 pagesCFD Trading Guide: Essential Info for BeginnersSumeet TrivediNo ratings yet

- Must Know Before You Start Trading ForexDocument11 pagesMust Know Before You Start Trading ForexAkın GündoğduNo ratings yet

- RTU-710H Wireless I/O Module With On-Off and Analog I/O: Claudiastr. 5 51149 Köln-Porz GermanyDocument81 pagesRTU-710H Wireless I/O Module With On-Off and Analog I/O: Claudiastr. 5 51149 Köln-Porz GermanySumeet TrivediNo ratings yet

- Configuring The FlexTimer For Position and Speed Measurement With An EncoderDocument10 pagesConfiguring The FlexTimer For Position and Speed Measurement With An EncoderSumeet TrivediNo ratings yet

- Formate No. MNT (E) \ F 02 Maintenance Check ListDocument1 pageFormate No. MNT (E) \ F 02 Maintenance Check ListSumeet TrivediNo ratings yet

- 1 SDH 000460 R 0102Document52 pages1 SDH 000460 R 0102erikNo ratings yet

- BLT Servo Drive and Motor Manual and DrawingDocument144 pagesBLT Servo Drive and Motor Manual and DrawingSumeet TrivediNo ratings yet

- LPG Safety Data Sheet Highlights HazardsDocument10 pagesLPG Safety Data Sheet Highlights HazardsShaikhRizwanNo ratings yet

- RET 630 Differential ProtectionDocument33 pagesRET 630 Differential ProtectionNarvin Raj ChandraNo ratings yet

- MOLmanualPY1 01Document128 pagesMOLmanualPY1 01Sumeet Trivedi100% (1)

- GALVI Shoe Brakes BrochureDocument53 pagesGALVI Shoe Brakes BrochureCANH NGUYENNo ratings yet

- SIEP-C710617 - 05 GA700 Technical ManualDocument940 pagesSIEP-C710617 - 05 GA700 Technical ManualSawon100% (1)

- Simatic st80 STPC Chap02 English 2015Document90 pagesSimatic st80 STPC Chap02 English 2015Sumeet TrivediNo ratings yet

- Power Cable XLPEDocument6 pagesPower Cable XLPEsudhir5441No ratings yet

- Catalog Complete - Rotex Fluid Control System PDFDocument444 pagesCatalog Complete - Rotex Fluid Control System PDFSumeet TrivediNo ratings yet

- Uport 1100 Series User'S Manual: Fifth Edition, May 2009Document49 pagesUport 1100 Series User'S Manual: Fifth Edition, May 2009Sumeet TrivediNo ratings yet

- DM5230/DM5240 Energy Meter Troubleshooting GuideDocument2 pagesDM5230/DM5240 Energy Meter Troubleshooting GuideSumeet TrivediNo ratings yet

- Temp Scanner RTDDocument21 pagesTemp Scanner RTDSumeet TrivediNo ratings yet

- Standard Motor CatalogDocument140 pagesStandard Motor CatalogStrato VariusNo ratings yet

- Casio Fx-570-991es Plus enDocument46 pagesCasio Fx-570-991es Plus enstiga2010100% (1)

- C Power Acb Catalogue PDFDocument35 pagesC Power Acb Catalogue PDFsabeer100% (1)

- Process ControlDocument144 pagesProcess Control14071988100% (1)

- Sabar Group: Three Phase Cooling Tower MotorsDocument2 pagesSabar Group: Three Phase Cooling Tower MotorsHrithik Sai TummalaNo ratings yet

- Manual Relevador DigitripDocument84 pagesManual Relevador DigitripJulian Canseco zarateNo ratings yet

- ESP Operation and Maintenance GuideDocument42 pagesESP Operation and Maintenance GuideWahyu ßagus TriwiyonoNo ratings yet

- ABB TransformerDocument17 pagesABB Transformer15472No ratings yet

- DC1000 Manual enDocument27 pagesDC1000 Manual enLeonardo QuintanaNo ratings yet

- Logo System Manual en-US en-USDocument344 pagesLogo System Manual en-US en-USglanchezNo ratings yet

- PrimeTime AdvancedOCV WPDocument9 pagesPrimeTime AdvancedOCV WPPraful GaikwadNo ratings yet

- ECE 320 Chapter 4: DC MotorsDocument7 pagesECE 320 Chapter 4: DC MotorsHüseyin Murat PolaterNo ratings yet

- Tuning fuzzy PID controllers using techniques from conventional PID controlDocument22 pagesTuning fuzzy PID controllers using techniques from conventional PID controlJessica VélezNo ratings yet

- VAMP 260: Power Monitoring UnitDocument162 pagesVAMP 260: Power Monitoring UnitAli HassanNo ratings yet

- Specification Sheet - Kohler Gas GeneratorDocument4 pagesSpecification Sheet - Kohler Gas GeneratorDayo Idowu0% (1)

- FCU-6000 System ManualDocument68 pagesFCU-6000 System Manualadavit73No ratings yet

- Silicon Power Transistor: Data SheetDocument6 pagesSilicon Power Transistor: Data SheetCarlos Iran Benítez MedinaNo ratings yet

- TM 11 2635AQmeter617 CUDocument57 pagesTM 11 2635AQmeter617 CUbobNo ratings yet

- Error Code 590-9Document6 pagesError Code 590-9Rajan Mullappilly80% (5)

- Rohde Cms 50Document20 pagesRohde Cms 50ASTNo ratings yet

- Intel 80186Document175 pagesIntel 80186Róbert MargitNo ratings yet

- Vacuum Breaker Merk Siemens 3AH2 PDFDocument40 pagesVacuum Breaker Merk Siemens 3AH2 PDFZhaqir HusseinNo ratings yet

- RRU3832 Description: Huawei Technologies Co., LTDDocument15 pagesRRU3832 Description: Huawei Technologies Co., LTDJhordan Felipe100% (1)

- SV-82 Instruction Manual Revision GuideDocument27 pagesSV-82 Instruction Manual Revision GuideAmjad Hossen100% (1)

- Modular Analog Audio Mixer - PAPERDocument11 pagesModular Analog Audio Mixer - PAPERFabio MonteiroNo ratings yet

- Crfs-Sran Label SetDocument6 pagesCrfs-Sran Label SetNirdosh ChhasatiyaNo ratings yet

- 1981 Corvette Ac SystemDocument34 pages1981 Corvette Ac SystemJoseph SnyderNo ratings yet

- Pressure Measurement: Performance Characteristics Ambient ConditionsDocument6 pagesPressure Measurement: Performance Characteristics Ambient ConditionsAl GCNo ratings yet

- Atmel At89sxx IspDocument6 pagesAtmel At89sxx IspkametocoNo ratings yet

- Lecture 8: Digital Modulation II: Chapter 5 - Modulation Techniques For Mobile RadioDocument63 pagesLecture 8: Digital Modulation II: Chapter 5 - Modulation Techniques For Mobile RadiobonfireeNo ratings yet

- Audio, Video and Media Module: Transducers, EQ and FiltersDocument16 pagesAudio, Video and Media Module: Transducers, EQ and FiltersIsmail MusharafNo ratings yet

- Q.Peak Duo Xl-G11.3: Enduring High PerformanceDocument2 pagesQ.Peak Duo Xl-G11.3: Enduring High Performancezheljoy datuinNo ratings yet

- Password Based Door Lock SystemDocument25 pagesPassword Based Door Lock SystemChaudhary PavitraNo ratings yet

- Iec 60664 1 2007 en FR PDFDocument19 pagesIec 60664 1 2007 en FR PDFphong vi0% (1)

- Valhalla Shimmer NotesDocument8 pagesValhalla Shimmer NotesNatanael ManriqueNo ratings yet

- CH 4-MCM-WSDocument8 pagesCH 4-MCM-WSmmkishore067No ratings yet

- Ad Converters TeoriDocument21 pagesAd Converters Teorioferamal9562No ratings yet

- Ringmaster installation, operation and maintenance guideDocument92 pagesRingmaster installation, operation and maintenance guideosmpot100% (1)

- SF Gas Insulated Ring Main Unit RMUDocument24 pagesSF Gas Insulated Ring Main Unit RMUr_mukuyuNo ratings yet

- Description and Operation: Unison Industries Component Maintenance Manual Ignition LeadsDocument2 pagesDescription and Operation: Unison Industries Component Maintenance Manual Ignition Leadsmaty englerNo ratings yet