Professional Documents

Culture Documents

Air Condition Switch Cabinet Room 10555586 en

Uploaded by

Ordoñez Navarro Yanny XavierOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Air Condition Switch Cabinet Room 10555586 en

Uploaded by

Ordoñez Navarro Yanny XavierCopyright:

Available Formats

WWW.AIRCONTECH.

COM

OPERATING MANUAL

Liebherr AC810

Article no.: Freigegeben

The product Liebherr AC810 is referred to in the following by the

terms E-house air conditioning unit or air conditioning unit. © 2015 Aircontech GmbH

AIRCONTECH GmbH

Albert Schädler Strasse 7

AT- 6800 Feldkirch, Austria

Tel +43 5522 84184-0

Fax +43 5522 84184-14

office@aircontech.eu

www.aircontech.eu

3

Table of contents:

General information ........................................................................................................................ 5

1.1 Information about this manual ................................................................................ 5

1.2 Applicable documents ............................................................................................ 5

1.3 General view .......................................................................................................... 5

1.4 Symbol explanation ................................................................................................ 6

1.4.1 Safety instructions .............................................................................................. 6

1.4.2 Special safety instructions .................................................................................. 6

1.4.3 Tips and recommendations ................................................................................ 6

1.5 Liability limitation .................................................................................................... 7

1.6 Copyright ............................................................................................................... 7

1.7 Customer service ................................................................................................... 7

Safety ............................................................................................................................................... 8

2.1 Product safety ........................................................................................................ 8

2.2 Intended use .......................................................................................................... 8

2.3 Essential dangers .................................................................................................. 9

2.3.1 Hazards caused by electrical energy .................................................................. 9

2.3.2 Danger due to fire .............................................................................................. 9

2.3.3 Enviromental condition danger ........................................................................... 9

2.3.4 Danger due to contents under pressure ............................................................10

2.4 Personnel requirements ........................................................................................10

2.4.1 Qualifications ....................................................................................................10

2.5 Installed safety equipment ....................................................................................11

2.6 Environmental protection ......................................................................................11

2.7 Signage ................................................................................................................11

Technical data ............................................................................................................................... 12

3.1 Dimensions and weight .........................................................................................12

3.2 General information ..............................................................................................12

3.3 Connection values ................................................................................................12

3.4 Operating conditions .............................................................................................12

3.5 Type plate .............................................................................................................13

3.6 Scope of delivery ..................................................................................................13

Structure and function ................................................................................................................. 14

4.1 Brief description ....................................................................................................14

4.2 Functional principle ...............................................................................................14

4.3 Operating elements - explanation of the function keys ..........................................15

4.4 Display - explanation of the display .......................................................................15

Transport ....................................................................................................................................... 16

5.1 Safety instructions for transport.............................................................................16

5.2 Fastening points....................................................................................................16

5.3 Packaging .............................................................................................................17

5.3.1 Symbols on the packaging ................................................................................17

5.4 Storage .................................................................................................................17

5.4.1 Storage of packaged pieces ..............................................................................17

Installation ..................................................................................................................................... 18

6.1 Safety instructions for installation ..........................................................................18

6.2 Establish potential equalisation .............................................................................18

6.3 Mechanical installation ..........................................................................................19

6.3.1 Installation .........................................................................................................19

6.4 Interfaces/Connections .........................................................................................20

6.5 Connection of the air conditioning unit ..................................................................20

Start-up .......................................................................................................................................... 21

Bedienungsanleitung Liebherr AC810

4

7.1 First-time start-up ..................................................................................................21

7.2 Acceptance/release ..............................................................................................21

Operation ....................................................................................................................................... 22

8.1 Safety instructions for operation ............................................................................22

8.2 Operating modes ..................................................................................................22

8.3 Settings via the control unit ...................................................................................23

Maintenance .................................................................................................................................. 24

9.1 Maintenance schedule ..........................................................................................24

9.2 Spare parts ...........................................................................................................25

9.3 Service fluids and auxiliary agents ........................................................................26

9.4 Measures following successful maintenance.........................................................26

Maintenance/faults...................................................................................................................... 27

10.1 Safety instructions for correcting faults ..................................................................27

10.2 Immediate measures prior to troubleshooting .......................................................27

10.3 Fault messages.....................................................................................................27

10.4 Faults ....................................................................................................................28

10.5 Troubleshooting ....................................................................................................28

10.5.1 In case of fault, the following points must be checked in advance: ................28

10.6 Start-up after troubleshooting ................................................................................28

Dismantling and disposal .......................................................................................................... 29

11.1 Safety instructions for dismantling and disposal ....................................................29

11.2 Dismantling ...........................................................................................................29

11.3 Disposal ................................................................................................................29

Appendix ...................................................................................................................................... 30

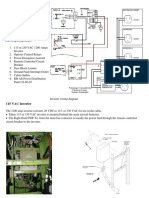

12.1 Liebherr AC810 circuit diagram .............................................................................30

12.2 R407c refrigerant safety data sheet ......................................................................30

12.3 Decontamination Declaration ................................................................................30

12.4 Declaration of Incorporation ..................................................................................30

12.5 Replacement Parts Catalogue ..............................................................................30

12.6 Product data sheets ..............................................................................................30

Bedienungsanleitung Liebherr AC810

General information 5

General information

1.1 Information about this manual

This operating manual includes the most important

instructions for operating the air conditioning unit safely

and efficiently. These safety warnings must be taken into

account at all times when working with the air conditioning

unit.

In the event of contradictory statements between the

different languages, the German version always takes

precedence.

The operating instructions must be kept permanently

available at the cabin air conditioning unit.

In addition to the operating instructions, the generally

applicable accident prevention and environmental

protection regulations, including any local ordinances, must

be posted and observed.

NOTE!

Operating manuals are provided once in German and

English as standard.

Provision of the operating manual in the official language of

the respective country in which the air conditioning unit is

operated is the responsibility of the operator.

1.2 Applicable documents

In addition to this manual, you have also received the following

documents. The instructions and notes included must be observe at all

times.

Spare parts list

Electrical circuit diagram

NOTE!

Product sheets for installed components may be requested

directly from the manufacturer. Manufacturers are listed in

the replacement parts catalogue.

1.3 General view

Liebherr AC810

Bedienungsanleitung Liebherr AC810

General information 6

1.4 Symbol explanation

1.4.1 Safety instructions Safety instructions in this manual are marked by symbols. The safety

instructions are introduced by signal words that express the degree of

the danger involved.

DANGER!

The combination of symbol and signal word indicates

immediate dangerous situations that could cause death if

they are not avoided.

WARNING!

The combination of symbol and signal word indicates

possible dangerous situations that could cause death or

severe injuries if they are not avoided.

CAUTION!

The combination of symbol and signal word indicates

possible dangerous situations that could cause slight or

light injuries if they are not avoided.

NOTE!

The combination of symbol and description indicates

possible dangerous situations that could cause property

and environmental damage if they are not avoided.

1.4.2 Special safety The following symbols are used in the safety instructions to indicate

instructions special dangers

ELECTRICAL DANGER!

The combination of symbol and signal word indicates

immediate dangerous situations due to electrical current. If

a labelled notice is not observed, severe or fatal injuries

could result.

FIRE HAZARD!

The combination of symbol and signal word indicates

dangers in connection with flammable materials. If a

labelled notice is not observed, fires and significant injuries

may result.

1.4.3 Tips and TIP

recommendations

This symbol emphasises useful tips and recommendations

and information for efficient and faultless operation.

Bedienungsanleitung Liebherr AC810

General information 7

1.5 Liability limitation

Our "general terms of sales and delivery conditions" apply. These are

available at www.aircontech.eu in the currently valid version as a

download.

Warranty and liability claims for damage to persons and property are

excluded where they can be traced back to one or several causes

mentioned below:

a) Improper use of the air conditioning unit

b) Operation of the air conditioning unit with defective safety

equipment or incorrectly fitted or non-operational safety and

protection equipment

c) Non-observation or incorrect execution of the instructions in the

operating manual with respect to transport, storage, installation,

initial operation, operation, and maintenance of the air conditioning

unit

d) Independent changes to the air conditioning unit

e) Insufficient monitoring of the air conditioning unit parts which are

subject to wear or servicing

f) Use of non-approved replacement parts

g) Cases of catastrophes caused by the action of foreign bodies and

force majeure.

1.6 Copyright

The contents of this document are copyrighted. Their use is permitted

within the scope of use of the product. Use that goes beyond this us

not permitted without written approval from the manufacturer

1.7 Customer service

Address AIRCONTECH GmbH

Albert Schädler Strasse 7

AT- 6800 Feldkirch, Austria

Telephone +43 5522 84184-0

Telefax +43 5522 84184-14

E-mail office@aircontech.eu

Internet www.aircontech.eu

Bedienungsanleitung Liebherr AC810

Safety 8

Safety

To reduce risks to personnel as well as property damage and

dangerous situations, the safety instructions listed here and in other

sections must be followed.

2.1 Product safety

The basic condition for safe handling and faultless operation of this air

conditioning unit is knowledge of the fundamental safety instructions

and locally applicable regulations and rules for accident prevention.

The air conditioning unit has been built according to the latest state of

the art in engineering and the recognised safety-related rules.

Nonetheless, use may cause hazards for life and limb of the user or of

third parties and may result in impairments of the air conditioning unit or

other property.

Failures which may affect safety have to be remedied immediately.

These safety instructions must be observed by all persons who work on

and with the air conditioning unit.

All safety and hazard information on the "air conditioning unit" must be

kept in legible condition and must be replaced, if and when required.

2.2 Intended use

This product is an incomplete machine designed for connection in a

cabin/room and is intended for permanent placement in the

cabin/room.

The air conditioning unit is designed to cool the cabin/room.

Proper use requires observation of the following points at least:

Observance of all instructions provided in the operating

instructions.

Observation of inspection and servicing work.

Aircontech GmbH accepts no liability for any resulting damage.

WARNING!

Danger in case of incorrect use!

Applications other than those specified are considered

improper and are not permitted.

Dangers may result in case of incorrect use. The air

conditioning unit is delivered ready for use and must not be

filled with refrigerant.

The life cycle of the air conditioning unit may only be

achieved via correct use as described in these instructions.

Bedienungsanleitung Liebherr AC810

Safety 9

2.3 Essential dangers

The residual risks resulting from the unit are described in the following

section.

To reduce risks to people and property damage and dangerous

situations, the safety instructions listed here and in additional sections

must be followed.

2.3.1 Hazards caused by electrical energy

Electrical current Mortal danger due to electrical current!

Immediate mortal danger due to electrical shock if contact

is made with current-conducting parts.

Work on electrical components may only be carried out by

qualified electricians.

In case of damage to the insulation of current-conducting

parts, switch off immediately and initiate repairs.

Prior to starting work on active parts, ensure that they are

free of current.

1. Activation

2. Secure against reactivation

3. Freedom from current ensured

4. Earth and short circuiting

5. Cover/barricade energised

neighbouring parts

Never bypass or deactivate fuses. When replacing fuses,

maintain the correct current rating specifications.

Keep moisture away from current-conducting parts.

The electrical equipment and wiring of the air conditioning

unit must be checked regularly. Controllers and control

elements in the air conditioning unit must be checked after

all repair, upkeep, and maintenance work for functionality.

The electrical interfaces to other components or machines

must always be kept sealed.

Access is limited to authorised personnel only by use of

keys or special tools.

2.3.2 Danger due to fire

Flammable filling medium FIRE HAZARD!

The safety-relevant instructions for fire prevention when

handling refrigerants must be followed according to the

specifications of the respective safety data sheet.

Keep suitable extinguishing agents ready

In case of fire, stop work immediately. Leave the danger

area until all clear and sound the alarm.

2.3.3 Enviromental condition danger

Insufficient oxygen DANGER!

This air conditioning unit works in circulating operation.

This means that no fresh air is fed into the interior space.

When working for extended periods, a fresh air supply must

be provided in the switch cabinet area.

Bedienungsanleitung Liebherr AC810

Safety 10

2.3.4 Danger due to contents under pressure

WARNING!

Hoses and lines under pressure may move out of control in

case of incorrect handling or stored media may be

released, which could cause severe injuries.

Prior to beginning work on these components

- Discharge all pressure and discharge residual

energy

- Ensure that the medium cannot escape

unintentionally.

- Defective components that are under pressure

must be replaced immediately by sufficiently

qualified personnel.

2.4 Personnel requirements

2.4.1 Qualifications

Only trained and instructed staff may operate the air

conditioning unit.

The responsibilities of the personnel with regard to

operation, repair and servicing must be clearly defined.

These requirements must be observed during the entire

handling of the air conditioning unit.

Personnel still in training may only work on the air

conditioning unit under the supervision of experienced

colleagues.

Activities Persons with Technical

expertise

technical Electricians

(cooling

training technology)

Attachment X

Startup X X

Operation X

Trouble shooting X X

Trouble

shooting: X

mechanical

Trouble

shooting: X

Refrigeration circuit

Trouble

shooting: X

electrical

Servicing and

X

repair

Maintenance X X

Decommissioning,

X X

storage

Visual inspections X

Bedienungsanleitung Liebherr AC810

Safety 11

2.5 Installed safety equipment

Safety equipment Mortal danger due to electrical current!

Electrical safety equipment such as fault current circuit

breakers and automatic breakers for line protection must be

implemented and inspected prior to start-up.

Prior to opening the air conditioning unit, it must be free of

electrical potential.

Safety equipment (control elements) may only be

removed/replaced under the following circumstances:

- Once the unit has been brought to a complete stop

- Securing against restarting

- the air conditioning unit has been separated from the

power mains

Measures must be taken in advance to prevent

environmental damage caused by escaping refrigerant or

oil.

Safety equipment must be fitted correctly by the operator

and checked regularly for functionality.

2.6 Environmental protection

Note

Measures must be taken in advance to prevent

environmental damage caused by escaping refrigerant or

oil.

Components filled with refrigerant or oil must be checked

regularly by the operator for functionality and sealing.

2.7 Signage

No direct water jet

Attach potential equalisation here

Attachment point for hoisting the load

Bedienungsanleitung Liebherr AC810

Technical data 12

Technical data

3.1 Dimensions and weight

Air conditioning unit height 698 mm

Air conditioning unit width 603 mm

Air conditioning unit depth 1404 mm

Air conditioning unit total weight 85 kg

3.2 General information

Filling medium Refrigerant R407c / 2250 gr

Filling quantity 2250 grams

Maximum operating 29 bar

pressure

Power output Maximum cooling power 8.1 kW at (60 Hz)

Maximum fan power 850 m ³/6 stages

Noise emission (stand-alone operation) 71 dB(A)

Housing Powder-coated RAL 7047 - sea-water resistant

3.3 Connection values

Control voltage 24 (24 – 29) VDC

Operating voltage 400 (360 – 440) (50 Hz) VAC

400 (396 – 484) (60 Hz) VAC

Fuse protection Fan 25 A

Fan 25 A

Power supply 3-phase 16 A

Power Air conditioning unit 3.5 kW

consumption

Line cross-section 2.5 mm²

Protection class Terminal box IP65

Interfaces Power supply connection See electrical diagram

socket for type designation

Control voltage See electrical diagram

connection socket for type designation

3.4 Operating conditions

Operating temperature range -20 °C to 50 °C?

Storage/transport temperature range -40°C to 60°C?

Use in explosive atmospheres or underground No

Bedienungsanleitung Liebherr AC810

13

3.5 Type plate

Type plates are located at the designated position,

1. Manufacturer

2. Device type - serial number

3. Year of manufacture

4. Working material/filling weight

5. User note

3.6 Scope of delivery

Description Quantit Detail

y

Liebherr AC810 1 see intended use

Assembly kit 1 Assembly kit consisting

of clamp-type tool holder

and screws

Handbook including replacement 1 Provided electronically

parts catalogue by the operator. Updates

and administration by

Air conditioning unit circuit 1

the operator

diagram

Refrigerant safety data sheet 1

Bedienungsanleitung Liebherr AC810

Structure and function 14

Structure and function

4.1 Brief description

The air conditioning unit is used to cool the cabin/room.

The control acts on the component in such a way that the requested

temperatures are produced in the cabin / room - inside. It receives

information from the temperature sensor and the pressure switch. It

consists of a basic unit: the control panel which is located in the

operating panel. The regulating unit in the control panel contains the

main CPU and a keypad for programming the functions of the air-

conditioning unit as well as a display for parameters, operating status

and temperature

4.2 Functional principle

The air is extracted from the cabin through the filter into the air

conditioning unit, cooled, and fed back into the cabin through the blower

nozzles (circulating operation).

Bedienungsanleitung Liebherr AC810

15

4.3 Operating elements - explanation of the function keys

Circulating air button

Increase the fan stage

Decrease the fan stage

Decrease temperature

Increase temperature

Air-conditioning button

cooling (AC) / ventilation

(ECON)

4.4 Display - explanation of the display

Display in "cooling" mode Display of the fan capacity Display in "ventilation" mode

Display "OFF"

when the unit

has been

switched off

Reference to display Display of the temperature set Display in case of activated

of the exterior circulating air

temperature

Display when "outside" frost

limit undercut

Bedienungsanleitung Liebherr AC810

Transport, packaging, and storage 16

Transport

5.1 Safety instructions for transport

Suspended loads WARNING!

Mortal danger due to suspended loads!

Loads may swing out and fall during hoisting processes.

This may cause severe injuries and even death.

Never move under the swinging area of suspended

loads.

Only moved loads with supervision.

Only use permitted lifting equipment and lashing

equipment with sufficient supporting capacity

Do not attach ropes and belts at sharp edges, do not

knot them or twist them.

Set down the load whenever you leave the workplace.

Incorrect transport NOTE!

Property damage due to incorrect transport!

Incorrect transport can cause transported pieces to fall or

tip over. This may result in significant property damage.

When unloading transported pieces upon delivery and

during company-internal transport, proceed carefully and

observe the symbols and instructions on the packaging

Only use the intended connection points

Only remove packaging shortly prior to assembly

Transport Forklift, crane, and lifting equipment must be designed for the

weight and transportation

The transported piece must be fastened securely on the palette.

The operator of the forklift or crane must be authorised to drive

warehouse transportation equipment with a driver's seat/driver's

stand or cranes according to locally applicable regulations.

Ensure that the lifting fork is positioned under the pallet and not

underneath the air conditioning unit itself during lifting.

For information on the type, dimensions and sizes of the fastening

material as well as on the placement of the anchorages, please

refer to the assembly manual.

The product is delivered on a 140 cm x 60 cm pallet.

The air conditioning unit is wrapped in foil and diverse small parts are

included in a box.

The transport packaging including the air conditioning unit inside it is

strapped firmly onto the palette.

5.2 Fastening points

Screw ring screws (not included in

the delivery) completely into the

four fastening points to lift the

load.

Recommendation:

2x ring screw DIN 580 M12

Bedienungsanleitung Liebherr AC810

Installation 17

5.3 Packaging

The individual packed pieces have been packed according to the

expected transport conditions.

The packaging should protect the individual components until assembly

against transport damage, corrosion, and other types of damage.

Do not destroy the packaging and only remove it shortly prior to

assembly.

The product is delivered on a 140 cm x 60 cm pallet.

The air conditioning unit is wrapped in foil and diverse small parts are

included in a box.

The transport packaging including the air conditioning unit inside it is

strapped firmly onto the palette.

5.3.1 Symbols on the packaging

The following symbols may be present on the packaging.

Top The arrow tips of the symbol indicate the top side of the

packaged piece. They must always point up, otherwise the

contents could be damaged.

Fragile This indicates packaged pieces that are fragile or sensitive.

Treat these packaged pieces carefully, do not let them fall,

and no not allow them to be impacted.

Protect against water Protect the packaged pieces against water and keep them

dry.

Centre of gravity This indicates the centre of gravity of the packaged pieces.

Observe the location of the centre of gravity during lifting

and transportation.

5.4 Storage

5.4.1 Storage of Store the packaged pieces in the following conditions.

packaged pieces

Store in the original packaging.

Do not store outdoors or allow unauthorised access

Store in a dry and dust-free place

Do not expose to aggressive media

Protect against direct sunshine

Only place on firmly supporting ground

Avoid mechanical vibrations.

Storage temperature: - 40° to 55°C

In case of storage for over one calendar year, contact the

manufacturer prior to installation and start-up.

Bedienungsanleitung Liebherr AC810

Installation 18

Installation

6.1 Safety instructions for installation

Secure against DANGER!

reactivation Mortal danger due to unauthorised reactivation!

Unauthorised reactivation of the energy supply during

installation results in danger of severe injuries up to death

of persons in the danger area.

Prior to starting the work, switch off all energy sources

and secure them against reactivation.

Incorrect installation WARNING!

Danger of injury due to incorrect installation!

Incorrect installation could lead to severe injuries and

serious property damage.

Prior to starting the work, ensure sufficient freedom of

movement for installation

Handle open, sharp components carefully

Ensure tidiness and cleanliness at the installation

location

Mount components properly. Adhere to prescribed screw

tightening torques

Secure components against falling down or tipping over

Installation of the NOTE!

incomplete machine Only carry out installation after checking the provisions

of the machinery directive.

The product is intended exclusively for incorporation within

a machine or incomplete machine and therefore does not

correspond with all requirements of the machinery directive.

6.2 Establish potential equalisation

WARNING!

Danger due to incendiary sparks and contact voltage!

Incorrect installation could lead to severe injuries and

serious property damage.

Connect the machine properly to the local potential

equalisation rail and check the functionality of the

potential equalisation.

Connect all housing parts of the components and connect to the local

potential equalisation in order to prevent errors connected with the fault

current protection switch, incendiary sparks, and contact voltage.

Check the protective system following connection for functionality.

Bedienungsanleitung Liebherr AC810

Installation 19

6.3 Mechanical installation

Installation and Installation and connection of the incomplete machine (air conditioning

connection unit) is intended to be carried out by the operator and is subject to

proprietary and locally applicable technical and safety-relevant

specifications.

Inspections, assembly plans, and technical equipment to be used are

specified by the operator.

Incorrect assembly WARNING!

Danger of injury due to incorrect installation!

Incorrect installation could lead to severe injuries and

serious property damage.

Prior to starting the work, ensure sufficient freedom of

movement for installation

Handle open, sharp components carefully

Mount components properly. Adhere to prescribed screw

tightening torques

Secure components against falling or tipping over

6.3.1 Installation

The installation is planned by Liebherr GmbH and is subject to the

complete specifications of Liebherr GmbH

All technical and safety-related instructions have to be observed

during attachment.

For data on the type, size and thickness of the fastening material

as well as on the placement of the anchorage, please refer to the

existing drawings and instructions of Liebherr GmbH.

All cables have to be fitted to the outside wall of the cabin/room by

means of bulkhead screw connections. All cables must be laid on

the inside of the cabin/room in accordance with the rules.

Bedienungsanleitung Liebherr AC810

Installation 20

6.4 Interfaces/Connections

Power supply See the electrical See the spare parts

diagram for type list for article

designation numbers

Control voltage See the electrical See the spare parts

diagram for type list for article

designation numbers

6.5 Connection of the air conditioning unit

The connection is planned by Liebherr GmbH and is subject to the

complete specifications of Liebherr GmbH.

All technical and safety-related instructions have to be observed

during installation.

For information on the type, size and thickness of the connecting

material, please refer to the existing circuit drawings and

instructions of Liebherr GmbH.

All cables have to be fitted to the outside wall of the cabin/room by

means of bulkhead screw connections. All cables must be laid on

the inside of the cabin/room in accordance with the rules.

Bedienungsanleitung Liebherr AC810

Start-up 21

Start-up

7.1 First-time start-up

Inspection prior to first- Over the course of first-time start-up, ensure that all of the necessary

time start-up requirements are met so that the air conditioning unit is able to function

correctly.

Incorrect placement CAUTION!

position Technical damage due to incorrect placement position!

Switching on after reclined transport is prohibited.

To prevent technical damage, the air conditioning unit must

be moved to the correct placement position for operation

and a waiting time of at least one hour must be observed.

Checking requirements The climate unit has been installed and aligned according to the

assembly manual.

The possible transport safeguards have been removed

The potential equalisation has been established correctly and

connected to the potential equalisation rail.

The air conditioning unit has been connected professionally to the

voltage supply connections.

A written work authorisation or acceptance log is available

General functionality Visual inspection for damage prior to starting.

checks Remove foreign bodies or condenser dirt from the air intake and air

outlet of the condenser as required.

Check the interior filter. (in air diffuser plate)

Check DC control voltage (24 – 29 V)

Check the AC power supply direction of rotation! (right-hand

rotation)

Check the rotation of the evaporator fan. The air flow at the outlet

nozzles (air diffuser plate) may be set to six levels.

Check booth condenser fans after the compressor starts up. (air

flow from the air conditioning unit in the surrounding area).

No fault signal from the air conditioning unit present.

7.2 Acceptance/release

The acceptance and release of the air conditioning unit is completed by

the operator according to his applicable specifications.

Bedienungsanleitung Liebherr AC810

Operation 22

Operation

8.1 Safety instructions for operation

Incorrect operation DANGER!

Danger of injury due to incorrect operation!

Incorrect operation could lead to severe injuries and serious

property damage.

Complete all operating steps according to the

specifications and instructions of this manual.

Never deactivate or bypass safety equipment during

operation.

External activation NOTE!

controls The air conditioning unit does not feature its own

activation controls!

The operator of the air conditioning unit shall provide the

activation controls of the air conditioning unit with regard to

the complete system.

Status signals with regard to possible operating conditions

or faults are executed via the interfaces (connection plug-

ins).

8.2 Operating modes

Adherence to the following points is required for perfect function.

Ideally, the air conditioning unit should be started at low outside

temperatures.

Manual mode The air conditioning unit is planned for manual operation.

Automatic mode The air conditioning unit is planned for automatic operation.

Mode Function Activation Note

SWITCHING ON Power supply to internal controls and individual Supply

components

SWITCHING No power supply to internal controls and individual

OFF components

COOLING The desired room temperature is reached Selecting the

The target and actual values of the desired room control unit

temperature are achieved via external activation

controls.

VENTILATION Fan for air circulation in the cabin via 6-stage power

controls.

Bedienungsanleitung Liebherr AC810

23

8.3 Settings via the control unit

Mode Function Activation

Temperature - The requested room temperature is set by pressing "Decrease

setpoint temperature the "Decrease temperature" and "Increase temperature" and

temperature" buttons. "Increase

temperature".

Fan setting - Use of The requested fan stage is set by pressing the Pressing the "A/C"

the fan in the central "Decrease temperature" and "Increase temperature" button for 5 sec

control room buttons. (recommended)

The selected fan stage is indicated on the upper or

edge of the display in the form of a bar. Switching the unit

To switch from manual mode to automatic mode: on/off

Selecting operating When switched off manually, the "ECON" symbol Pressing the "A/C"

mode - cooling or appears on the display to indicate that a ventilation- button switches the

ventilation only mode is running. air-conditioning

compressor on and off

manually. This also

generally occurs

automatically through

a comparison of the

interior and exterior

temperature.

Circulating air control This function is not included in the AC810 since it is Pressing the

exclusively a circulating air conditioner. circulating air button

toggles between

circulating air and

fresh air.

When circulating air is

selected, the

Circulating Air symbol

appears on the lower

right of the display.

Display of the outside Indicated by the thermometer symbol at bottom left of Pressing and holding

temperature the display. The display automatically switches back the Circulation button

to the selected room temperature afterwards. for 4 seconds displays

the exterior

temperature for 5

seconds.

Snowflake symbol The snowflake symbol appears on the display to

warn against low outside temperatures (danger of

frost). Automatic

Bedienungsanleitung Liebherr AC810

Maintenance 24

Maintenance

Maintenance work is required for optimal and fault-free operation.

The air conditioning unit is essentially designed to be low-

maintenance and to have a long service life. The service life

depends crucially on the use conditions and maintenance

work carried out.

If components of the air conditioning unit are sent to

Aircontech GmbH for maintenance and repair purposes, then

a completed decontamination declaration must be received

by Aircontech GmbH beforehand. Without this form,

acceptance of the components will be declined.

A copy template of the decontamination declaration is

provided in the appendix of this manual.

9.1 Maintenance schedule

Interval Maintenance work Personnel

daily Inspection according to operator's specifications

weekly Ventilation and aeration and filter Operator

inspection/cleaning/and replacement as required service/maintenance

personnel

monthly Check screw connections for tight fit Operator

service/maintenance

Check condensate and rainwater and clean as

personnel

required

annually Check system sealing. Check for leaks. Technical personnel

(refrigeration technician)

Check electrical connections for mechanical stress Electrician

and stable seating

Check the earth/potential equalisation for stable Qualified electrician (in part

seating and functionality. with additional explosion

protection qualification)

1000 operation Replacing the circulating air filter Operator

hours Check the function of the fan at all 6 stages service/maintenance

personnel

4000 operation The cover of the system must be opened and the Technical personnel

hours heat exchanger cleaned with compressed air from (refrigeration technician)

the inside towards the outside

Bedienungsanleitung Liebherr AC810

25

9.2 Spare parts

WARNING!

Danger of injury in case incorrect spare parts!

Use of incorrect or defective spare parts could result in

damage to personnel and could cause damage, malfunction,

or total failure.

Only spare parts from the manufacturer or spare parts

approved by the manufacturer may be used.

Parts of the air conditioning unit that are not in perfect

condition must be replaced with identical parts immediately

to exclude potential danger!

Guarantee void

Use of spare parts that are not approved shall void the

manufacturer's guarantee.

Purchase replacement parts from contractual distributors or

the manufacturer

Bedienungsanleitung Liebherr AC810

Maintenance 26

9.3 Service fluids and auxiliary agents

Cleaning agents The use of cleaners and a moist cloth is limited to cleaning the housing

of the climate unit.

Gently blowing off with compressed air is recommended for cleaning

the inside of the air conditioning unit.

WARNING!

Risk of injury due to use of compressed air!

Hoses and lines under pressure may move out of control in

case of incorrect handling or medium under high pressure

may be released, which could cause severe injuries.

Solvents DANGER!

Fire hazard due to use of solvents!

Use of solvents (e.g. for cleaning purposes) can lead to

independent ignition of solvent vapours on hot surfaces.

DANGER!

Electrical danger due to use of water jets for cleaning!

The use of a water jet to clean the air conditioning unit is

forbidden.

9.4 Measures following successful maintenance

After completion of maintenance work and prior to activation of the

machine, carry out the following steps.

Check stable seating of all previously loosened connections

Check that all previously removed protective equipment and

coverings are installed again correctly.

Ensure that all tools, materials, and other equipment have been

removed from the work area

Clean the work area and remove any possibly leaked materials

such as fluids or similar.

Ensure that all machine safety equipment functions free of

problems.

Bedienungsanleitung Liebherr AC810

Maintenance/faults 27

Maintenance/faults

In case of multiple occurring faults, shorten the maintenance interval

according of the actual load.

In case of faults that cannot be corrected by the following instructions,

contact the manufacturer.

10.1 Safety instructions for correcting faults

DANGER!

Mortal danger due to unauthorised reactivation!

Unauthorised reactivation of the energy supply during error

correction and fault correction could result severe injuries

up to death of persons in the danger area.

Incorrect fault correction WARNING!

Danger of injury due to incorrect fault correction!

Incorrectly carried out troubleshooting could cause severe

injury and serious property damage.

Structural changes WARNING!

Do not attach, modify, or convert anything on the air

conditioning unit without approval of the manufacturer. This

also applies for welding of load-bearing parts and any other

modifications to the delivered condition.

All reconfiguration measures must be approved in writing by

the manufacturer

Faults in the refrigerant NOTE!

circulation Troubleshooting of the air conditioning unit is limited to the

electrical equipment.

In case of faults in the area of refrigerant-conducting parts,

the defective components must be sent to the

manufacturer.

10.2 Immediate measures prior to troubleshooting

In the fan area, heavily soiled fans should be dismantled and

cleaned or replaced.

In case of severe soiling which cannot be removed, replace the

individual parts.

Check all stages of the fan (evaporator fan)

Check both fans of the condenser for correct running

10.3 Fault messages

The air conditioning unit has 4 signal outputs to transfer a fault

message to the control unit.

This manual describes the signal outputs, but not the fault message

displayed on the operating unit.

Bedienungsanleitung Liebherr AC810

Maintenance/faults 28

10.4 Faults

Display format Meaning of output signal

E1 Interruption - sensor for outside temperature

E2 Short circuit - sensor for outside temperature

E3 Interruption - sensor for inside temperature

E4 Short circuit - sensor for inside temperature

A/C flashing Temperature sensor fault of the evaporator

10.5 Troubleshooting

The operator may only troubleshoot the unit's electrical equipment. To simplify trouble

shooting, test devices (orange flap) have been fitted at the relays. In the area of the

coolant-guiding parts, it is necessary to remove the unit and to send it to the

manufacturer.

10.5.1 In case of fault, the following points must be checked in advance:

The air-conditioning unit must be cleaned (using compressed air) in the air intake and

outlet areas in accordance with the degree of soiling. In the fan area, heavily soiled

fans should be dismantled. During dismantling, the unit must be secured against being

switched on. (Disconnect the system from mains power)

In case of severe soiling which cannot be removed, the individual parts have to be

replaced.

The subsequent start-up should be conducted in the same manner as a first-time

start-up.

Power supply of the unit

Switch the unit on by using the control

Check all six fan stages

Set the unit to A/C on the display

Set the temperature to LO

10.6 Start-up after troubleshooting

After remedying a fault, complete the following steps.

Reset emergency stop devices

Acknowledge the fault at the controls

Ensure that no persons are present in the danger area

Start up again according to the start-up instructions.

Bedienungsanleitung Liebherr AC810

Dismantling and disposal 29

Dismantling and disposal

After the useful life of the air conditioning unit is reached, it must be

dismantled and disposed of in an environmentally friendly manner.

11.1 Safety instructions for dismantling and disposal

Incorrect dismantling WARNING!

Danger of injury due to incorrect dismantling!

Stored residual energy, sharp components, pointed tips and

corners on or in the air conditioning unit, or the required

tools may cause injuries.

Prior to starting the work, ensure sufficient space.

Handle open, sharp components carefully.

Ensure tidiness and cleanliness at the workplace!

Components and tools laying loosely on each other or

around are sources of danger.

Dismantle components properly. Take the weight of

components which may be very heavy into account.

Secure the components against falling or tipping over

Contact the manufacturer if anything is unclear.

11.2 Dismantling

After the useful life of the air conditioning unit is reached, it must be

dismantled and disposed of in an environmentally friendly manner.

Switch off the unit completely and secure it against reactivation.

Disconnect the complete energy and media supply from the air

conditioning unit, discharge residual energy.

Remove operating equipment and auxiliary materials and residual

processing materials and dispose in an environmentally friendly

manner.

Next, clean modules and components professionally and dismantle

according to locally applicable labour protection and environmental

protection regulations.

11.3 Disposal

Provided no return or disposal agreement has been made, dismantled

components or complete units must be provided to recycling

operations.

Disposal of the air conditioning unit components, operating equipment,

and auxiliary materials is subject to local legal regulations.

Only deliver the parts to be disposed of to authorised specialists

NOTE!

Danger to the environment due to incorrect disposal!

Dispose of components contaminated with environmentally

hazardous media according to the specifications in the

safety data sheet.

In case of doubt, request information regarding

environmentally friendly disposal from local agencies or

specialist companies.

Bedienungsanleitung Liebherr AC810

30

Appendix

12.1 Liebherr AC810 circuit diagram

12.2 R407c refrigerant safety data sheet

12.3 Decontamination Declaration

12.4 Declaration of Incorporation

12.5 Replacement Parts Catalogue

12.6 Product data sheets

Bedienungsanleitung Liebherr AC810

You might also like

- PIC Microcontroller Projects in C: Basic to AdvancedFrom EverandPIC Microcontroller Projects in C: Basic to AdvancedRating: 5 out of 5 stars5/5 (10)

- Practical Process Control for Engineers and TechniciansFrom EverandPractical Process Control for Engineers and TechniciansRating: 5 out of 5 stars5/5 (3)

- 1MRK511310-UEN - en Application Manual Bay Control REC670 2.0 IECDocument548 pages1MRK511310-UEN - en Application Manual Bay Control REC670 2.0 IECPhuongThao NguyenNo ratings yet

- Relion 670 Series Rel670Document270 pagesRelion 670 Series Rel670MukeshNo ratings yet

- Trucks Overall Vehicle - On-Board Electrical System, Bus System On-Board Electrical Systems, System Networking, Instruments Run Trainer DocumentDocument218 pagesTrucks Overall Vehicle - On-Board Electrical System, Bus System On-Board Electrical Systems, System Networking, Instruments Run Trainer DocumentsalloumNo ratings yet

- Application ManualDocument918 pagesApplication ManualRus ClaudiuNo ratings yet

- Proportional Directional Valves With Field Bus Interface, With and Without Integrated Axis Controller (IAC-P and IFB-P)Document140 pagesProportional Directional Valves With Field Bus Interface, With and Without Integrated Axis Controller (IAC-P and IFB-P)Rakhee SinhaNo ratings yet

- Ret670 PDFDocument318 pagesRet670 PDFmirage1977No ratings yet

- 1MRK504169-UEN C en Application Manual Transformer Protection RET650 Version 2.2Document334 pages1MRK504169-UEN C en Application Manual Transformer Protection RET650 Version 2.2srinivasan balakrishnanNo ratings yet

- 1MRK511310-UUS A en Application Manual Bay Control REC670 2.0 ANSIDocument570 pages1MRK511310-UUS A en Application Manual Bay Control REC670 2.0 ANSIGilcimar DiasNo ratings yet

- 1MRK506340-UUS - en Commissioning Manual Line Distance Protection REL670 2.0 ANSIDocument292 pages1MRK506340-UUS - en Commissioning Manual Line Distance Protection REL670 2.0 ANSIbalasniperNo ratings yet

- 3BSE041880-600 en System 800xa Control 6.0 AC 800M Getting StartedDocument136 pages3BSE041880-600 en System 800xa Control 6.0 AC 800M Getting StartedgicntNo ratings yet

- Alcatellucent Oxo Connect SeriesDocument216 pagesAlcatellucent Oxo Connect SeriesAsnake TegenawNo ratings yet

- 1MRK506111-UEN en Application Manual REL 521 2.3 PDFDocument610 pages1MRK506111-UEN en Application Manual REL 521 2.3 PDFsenthil kumarNo ratings yet

- 1MRK511305-UEN - en Communication Protocol Manual LON 670 Series 2.0 IECDocument74 pages1MRK511305-UEN - en Communication Protocol Manual LON 670 Series 2.0 IECVenkat KrishnanNo ratings yet

- 3BSE041880-511 en System 800xa Control 5.1 AC 800M Getting StartedDocument136 pages3BSE041880-511 en System 800xa Control 5.1 AC 800M Getting StartedTNo ratings yet

- Operation and Maintenance Manual: Inclined Platform LiftDocument39 pagesOperation and Maintenance Manual: Inclined Platform Liftraymon janszenNo ratings yet

- ACGM0142V50ENDDocument177 pagesACGM0142V50ENDDuy TrungNo ratings yet

- ER900 LenDocument84 pagesER900 Lenvincenzo grecoNo ratings yet

- IEM User ManualDocument80 pagesIEM User ManualSas Volta Sr.No ratings yet

- Wilo Submersible PumpDocument56 pagesWilo Submersible Pumpmohamed eidNo ratings yet

- Ot2.6 Am Otclientadmin 8AL90638USAH 1 enDocument199 pagesOt2.6 Am Otclientadmin 8AL90638USAH 1 enJoe GbanugNo ratings yet

- 502034-UEN - TM G650I 1p1Document604 pages502034-UEN - TM G650I 1p1Hai PhamNo ratings yet

- Operating Instructions: D-Lab.1 FamilyDocument524 pagesOperating Instructions: D-Lab.1 FamilyKodak CristalNo ratings yet

- Generator Protection REG670 2.1 ANSI: Commissioning ManualDocument292 pagesGenerator Protection REG670 2.1 ANSI: Commissioning ManualDiego dos Santos AmaralNo ratings yet

- VortexDocument136 pagesVortexLuis Felipe Turriate AlvaradoNo ratings yet

- Service Manual Frize - GBDocument56 pagesService Manual Frize - GBpol8331No ratings yet

- Red650 2.1 PDFDocument806 pagesRed650 2.1 PDFPanu Mark IINo ratings yet

- Digital Voltage Regulator: Installation and MaintenanceDocument20 pagesDigital Voltage Regulator: Installation and MaintenanceAteeqNo ratings yet

- f44 How To Use Leica tp1020 Automatic Tissue ProcessorDocument96 pagesf44 How To Use Leica tp1020 Automatic Tissue ProcessorAnjani AuliaNo ratings yet

- AC800MDocument230 pagesAC800MedwinmenaNo ratings yet

- REL551 Operators ManualDocument86 pagesREL551 Operators Manualelo_elo_elo_eloNo ratings yet

- Manuale Indicatore Di Processo Minebea Intec X3 - PR5410Document340 pagesManuale Indicatore Di Processo Minebea Intec X3 - PR5410Miguel cejasNo ratings yet

- Manual Técnico PENTRA 60 (2020 - 08 - 20 02 - 50 - 44 UTC)Document260 pagesManual Técnico PENTRA 60 (2020 - 08 - 20 02 - 50 - 44 UTC)Arnoldo FelixNo ratings yet

- 1MRK505388-UEN C en Application Manual Busbar Protection REB650 Version 2.2Document272 pages1MRK505388-UEN C en Application Manual Busbar Protection REB650 Version 2.2srinivasan balakrishnanNo ratings yet

- C48C Product ManualDocument55 pagesC48C Product ManualDomingo Martínez LópezNo ratings yet

- AlphaESS - Storion-T50100 Battery Installation Manual - V2Document45 pagesAlphaESS - Storion-T50100 Battery Installation Manual - V2kapsethdceNo ratings yet

- 1MRK506109-UEN en Application Manual REL 511 2.3 PDFDocument602 pages1MRK506109-UEN en Application Manual REL 511 2.3 PDFAulino CuambeNo ratings yet

- FP OPC Server: User's ManualDocument96 pagesFP OPC Server: User's ManualPetio MineffNo ratings yet

- Man pr5230 Inst en 949905052300-Rel3.50Document300 pagesMan pr5230 Inst en 949905052300-Rel3.50EdwardHuamanArmauliaNo ratings yet

- 818 IC Pump: ManualDocument56 pages818 IC Pump: ManualKhalid Zghear100% (1)

- Advant Controller 410Document502 pagesAdvant Controller 410cristhian.eduardo99No ratings yet

- Ashcroft Ate 2 ManualDocument86 pagesAshcroft Ate 2 ManualKevin IllescasNo ratings yet

- Technical Service Manual For OCE 7XXXDocument384 pagesTechnical Service Manual For OCE 7XXXWaleedNo ratings yet

- 4 Static Characteristics Rev 6 090325Document136 pages4 Static Characteristics Rev 6 090325shajilNo ratings yet

- Nihon-Kohden TEC-5521E Defibrillator - Service ManualDocument112 pagesNihon-Kohden TEC-5521E Defibrillator - Service ManualCarlos R. SanchezNo ratings yet

- Abb REF 615 PDFDocument184 pagesAbb REF 615 PDFulyjohnignacioNo ratings yet

- Doc3110 March 2015 B - Eagle User Manual enDocument60 pagesDoc3110 March 2015 B - Eagle User Manual enAli AhmadNo ratings yet

- Maquet Equipment Servicemanual en en GlobalDocument40 pagesMaquet Equipment Servicemanual en en Globaltaioba2010No ratings yet

- 3503 Operators ManualDocument280 pages3503 Operators ManualFernando Aurelio de CastroNo ratings yet

- Manual de Aplicacion REF630Document128 pagesManual de Aplicacion REF630inxs_the_bestNo ratings yet

- Irb 660 180 3.15Document54 pagesIrb 660 180 3.15laurentiuflorentin2019No ratings yet

- ANALIZADOR EDAN H50 User Manual PDFDocument80 pagesANALIZADOR EDAN H50 User Manual PDFLuis Alberto Montesinos Guillen100% (1)

- Power Electronic Units (Contrac) LME620-AI, PME120-AI (Integrated) EAN823, EBN853, EBN861 (Field-Mounting)Document46 pagesPower Electronic Units (Contrac) LME620-AI, PME120-AI (Integrated) EAN823, EBN853, EBN861 (Field-Mounting)febri kurniaNo ratings yet

- ABB Busbar Protection REB670 2.0 ANSIDocument498 pagesABB Busbar Protection REB670 2.0 ANSIksg9731No ratings yet

- 3BSE027630-510 en S800 I O DTM 5.3Document184 pages3BSE027630-510 en S800 I O DTM 5.3ilke HANNo ratings yet

- AC 800M Controller HardwareDocument308 pagesAC 800M Controller HardwareToni BaenkNo ratings yet

- 113003.en v5.1.x 2019 Fabian Hfo Ifu PDFDocument178 pages113003.en v5.1.x 2019 Fabian Hfo Ifu PDFLeevan BauNo ratings yet

- Weg Automation cfw-11 Users Manual PDFDocument91 pagesWeg Automation cfw-11 Users Manual PDFCARLOS100% (1)

- Banco de Baterias - HZB 2V Bloc AGMDocument12 pagesBanco de Baterias - HZB 2V Bloc AGMtheloniussherekNo ratings yet

- D D D D D D D D D: Description/ordering InformationDocument13 pagesD D D D D D D D D: Description/ordering InformationAdilson ToledoNo ratings yet

- Cs 6 P 235 PXDocument2 pagesCs 6 P 235 PXonurkaya1No ratings yet

- Cat. Vickers - Válvulas KBCG3Document12 pagesCat. Vickers - Válvulas KBCG3Elcio AzevedoNo ratings yet

- 75-42rD Impulse Manual Mar2003 PDFDocument23 pages75-42rD Impulse Manual Mar2003 PDFLeandro MussoNo ratings yet

- LEARJET 45 AC Electrical SystemDocument4 pagesLEARJET 45 AC Electrical SystemRAFAEL MANZANILLANo ratings yet

- F70MC光纤陀螺仪 英文 改Document4 pagesF70MC光纤陀螺仪 英文 改Liu AllieNo ratings yet

- RENR88270001Document4 pagesRENR88270001Guido Emanuel SteinbachNo ratings yet

- Wind Up Torch Hand Cranked, Dynamo, LED AmendDocument9 pagesWind Up Torch Hand Cranked, Dynamo, LED AmendMarius DanilaNo ratings yet

- EbookDocument2 pagesEbookAG Gumelar MuktiNo ratings yet

- Fonte PWS-801Document20 pagesFonte PWS-801LuizNo ratings yet

- 컨베어속도조절 가변저항 - VR-RV24YN+20S (B103) PDFDocument7 pages컨베어속도조절 가변저항 - VR-RV24YN+20S (B103) PDF박상길No ratings yet

- Schneider Distribution Transformer1Document44 pagesSchneider Distribution Transformer1STEVE58100% (3)

- EXPERIMENT NO 3 (Comparator)Document2 pagesEXPERIMENT NO 3 (Comparator)Jaideep Singh100% (2)

- Rockford Fosgate 1100a2Document2 pagesRockford Fosgate 1100a2floyd21No ratings yet

- 2538 - ABB - AppNotes - 2.0 - 1HC0138866 EN AADocument10 pages2538 - ABB - AppNotes - 2.0 - 1HC0138866 EN AAMuhammad LuqmanNo ratings yet

- Substrate Integrated Waveguide Microwave Encyclopedia Microwaves101Document5 pagesSubstrate Integrated Waveguide Microwave Encyclopedia Microwaves101Dr-Pritam Singh BakariyaNo ratings yet

- En Acs880 Q971 Atex Ag G A4Document52 pagesEn Acs880 Q971 Atex Ag G A4Romildo FernandesNo ratings yet

- MiCOM P433P435 TechnicalManual2Document212 pagesMiCOM P433P435 TechnicalManual2Eng-Abdallh GremanNo ratings yet

- Communications PDFDocument12 pagesCommunications PDFChester Kyles ColitaNo ratings yet

- Tutorial 7 - Synchronous MachinesDocument4 pagesTutorial 7 - Synchronous MachinesMohdFirdaus100% (1)

- C03 - HVSG 11Document20 pagesC03 - HVSG 11princensikan23No ratings yet

- Electrostats-INSP YTDocument29 pagesElectrostats-INSP YTAryan GuptaNo ratings yet

- Gas Insulated SubstationDocument21 pagesGas Insulated SubstationMeghana BRNo ratings yet

- Part 34 Electrical Scope of Works (Qtel)Document18 pagesPart 34 Electrical Scope of Works (Qtel)rajaraja12150% (1)

- Troubleshooting 1Document15 pagesTroubleshooting 1ANURAG SHARMA100% (1)

- EE081-Lighting Engineering-Pr-Inst PDFDocument62 pagesEE081-Lighting Engineering-Pr-Inst PDFSameera KodikaraNo ratings yet

- Snap Trac Proportional Solenoid Driver: N123-001 SeriesDocument4 pagesSnap Trac Proportional Solenoid Driver: N123-001 SeriesArmannovNo ratings yet

- Introduction To Semiconductor DevicesDocument1 pageIntroduction To Semiconductor Devicesgalih suryo gumilangNo ratings yet

- Servicemanual GSI 38Document96 pagesServicemanual GSI 38khanasf2001_85989873No ratings yet