Professional Documents

Culture Documents

A Mindset To Continuous Improvement

A Mindset To Continuous Improvement

Uploaded by

Mustafa Ghaleiw0 ratings0% found this document useful (0 votes)

2 views1 pageOriginal Title

A Mindset to Continuous Improvement

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

2 views1 pageA Mindset To Continuous Improvement

A Mindset To Continuous Improvement

Uploaded by

Mustafa GhaleiwCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 1

O R G A N I Z AT I O N P RO F I L E

TAKE MEDLINE INDUSTRIES

SIX EMPLOY EES 12,000+

YEARS IN SIX SIGMA 1.5

A Mindset to Continuous Improvement

Each issue, Six Sigma Forum Magazine (SSFM) asks ment by the organization to change. For projects,

six questions about an organization’s Six Sigma program. we adopt a more structured data-driven approach

such as DMAIC.

SSFM: What are some lessons you and your team

learned from Six Sigma implementation? THUSU: What has been the biggest challenge to Six Sigma

Leadership support, a well-structured deployment and how did you overcome it? Our biggest challenge

plan, project selection, training and sustaining gains has been with the effective use of our finite resources

are fundamental elements to a successful implemen- coupled with the timely identification and selection

tion of a lean Six Sigma (LSS) program. of the right improvement opportuni-

A key lesson for us has been in assigning ties to deliver bottom-line results to our

the right resources to the right project, organization. To overcome this chal-

and providing the team with the neces- lenge, we use a Medline Accountability

sary time to execute and complete a proj- Program to create a culture of align-

ect. In addition, providing the appropri- ment, focus and integrity that helps

ate training and guidance is a critical to operationalize our annual strategic

component required for our homegrown plan. Our baseline calendar consists of

change agents to succeed. periodic checkpoints to monitor prog-

ress and, if necessary, course correct to

Manav Thusu, Black

How do you know when a project isn’t Belt, process improve- ensure we achieve our key goals.

working? Typically, projects start with ment engineer, Medline

great anticipation, excitement and What are your favorite Six Sigma

energy. It is imperative that define, mea- resources? The organizations that

sure, analye, improve and control (DMAIC) tollgate Medline finds most helpful are ASQ, the American

reviews occur in a timely and thorough manner at Society for Engineering Management, and the

each phase of the process. The define tollgate is a Institute of Industrial and Systems Engineers. We also

critical assessment step to prevent a poorly scoped find that iSixSigma, Lean Enterprise Institute and

project from continuing through the rest of the Gemba Academy are helpful quality resources. Don’t

phases. Furthermore, maintaining a sustainable, forget to join LinkedIn lean and Six Sigma members

lasting impact is equally critical, and mentors must groups to connect online with quality profession-

consistently engage and encourage active participa- als around the world and talk about current trends

tion from project sponsors. in the field. When it comes to technology, Minitab,

SigmaXL and EngineRoom are our favorites.

What has been your most creative use of Six Sigma

at your organization? We have adopted a three-fold When should you not apply Six Sigma? LSS is a cul-

blended approach for continuous improvement ini- tural mindset that enhances and compliments an

tiatives, each supported by an incentive program to organization’s commitment to continual improve-

keep our team members engaged and motivated. ment. Many organizations fall prey to deploying a Six

Simple Kaizen: When the solution is known, revers- Sigma initiative prematurely. The initial focus should

ible, and data exists to support the change. Kaizen be to optimize operations by applying the basic build-

Blitz: When the scope is narrow and the solution is ing blocks of lean. Recognize that Six Sigma is fact-

seemingly simple; we perform a root cause analy- based with an obsessive focus on reliable data and

sis to validate and perform a blitz. Projects: When one should refrain from applying the DMAIC method

the root cause is undefined, the solution is more when the root cause is known, the solution is evident

obscure, and there is a pressing need and commit- or no means exist to quantify a problem.

24 I MAY 2016 I WWW.ASQ.ORG

You might also like

- Lean Six Sigma: A Practical Guide for Getting Started with Lean Six Sigma along with How It Can Be Integrated with Agile and ScrumFrom EverandLean Six Sigma: A Practical Guide for Getting Started with Lean Six Sigma along with How It Can Be Integrated with Agile and ScrumRating: 4.5 out of 5 stars4.5/5 (30)

- Lean Six Sigma: The Ultimate Practical Guide. Discover The Six Sigma Methodology, Improve Quality and Speed and Learn How to Improve Your BusinessFrom EverandLean Six Sigma: The Ultimate Practical Guide. Discover The Six Sigma Methodology, Improve Quality and Speed and Learn How to Improve Your BusinessNo ratings yet

- Finland and NokiaDocument3 pagesFinland and NokiaSebastian-Gabriel NegruNo ratings yet

- Hormegeddon - Bill BonnerDocument306 pagesHormegeddon - Bill BonnerHumberto Martins100% (4)

- Six Sigma..Document3 pagesSix Sigma..MuralibhatNo ratings yet

- Total Quality Through Six Sigma: Leadership Commitment: Top Management Not Only Initiates Six SigmaDocument3 pagesTotal Quality Through Six Sigma: Leadership Commitment: Top Management Not Only Initiates Six SigmaKhurram KhanNo ratings yet

- Chap07 Conclusions and Future ScopeDocument3 pagesChap07 Conclusions and Future ScopeNavneet Mishra100% (1)

- Application of Six-Sigma in Educational Quality Management: Javad MehrabiDocument5 pagesApplication of Six-Sigma in Educational Quality Management: Javad MehrabiJuan Camilo Valderrama BalageraNo ratings yet

- Lean Six Sigma Master ThesisDocument7 pagesLean Six Sigma Master Thesiskerrylewiswashington100% (2)

- 6sigma of HRMDocument14 pages6sigma of HRMtnizar_003No ratings yet

- SixSigma Friend or FoeDocument4 pagesSixSigma Friend or Foeapi-3822924No ratings yet

- Lean Six Sigma Green Belt 1Document45 pagesLean Six Sigma Green Belt 1Eric BolinNo ratings yet

- Six SigmaDocument4 pagesSix SigmaLaksh SinghalNo ratings yet

- Chapter 2Document7 pagesChapter 2Meher TulipNo ratings yet

- Lean Six Sigma White BeltDocument14 pagesLean Six Sigma White BeltCovaci MihailNo ratings yet

- Six Sigma 6Document5 pagesSix Sigma 6pploredanaNo ratings yet

- Bringing Lean Systems Thinking To Six SigmaDocument4 pagesBringing Lean Systems Thinking To Six Sigmasreekanthm00001No ratings yet

- Research Paper On Lean Six SigmaDocument7 pagesResearch Paper On Lean Six Sigmafvf237cz100% (1)

- Lessons Learned in 6sigma ImplementationDocument4 pagesLessons Learned in 6sigma ImplementationAmin ChhipaNo ratings yet

- Application of Six Sigma in HospitalsDocument22 pagesApplication of Six Sigma in HospitalsJagadeep Gandhi GangavarapuNo ratings yet

- Benchmark Six Sigma Consulting BrochureDocument4 pagesBenchmark Six Sigma Consulting BrochureMrinmoy An AmbidextrousNo ratings yet

- Thesis On Lean Six SigmaDocument5 pagesThesis On Lean Six SigmaBuyALiteratureReviewPaperSingapore100% (2)

- Bs and HR Six Sigma PracticesDocument38 pagesBs and HR Six Sigma PracticesSwati SoodNo ratings yet

- Six Sigma - Friend or Foe?Document4 pagesSix Sigma - Friend or Foe?souravp2k5No ratings yet

- sixsigma&DOE PDFDocument2 pagessixsigma&DOE PDFbudiyono9No ratings yet

- Lean Six Sigma PHD ThesisDocument4 pagesLean Six Sigma PHD Thesissandrawilleyelpaso100% (2)

- Six SigmaDocument25 pagesSix SigmaSubash DhakalNo ratings yet

- Six Sigma - I Made Prahlada Gusti WarmadewaDocument4 pagesSix Sigma - I Made Prahlada Gusti WarmadewaDedeprahladaNo ratings yet

- Six Sigma DefinedDocument6 pagesSix Sigma DefinedRaman ShanmugaNo ratings yet

- Module 1.0 Define Phase - 1.1 The Basics of Six Sigma (51-60)Document12 pagesModule 1.0 Define Phase - 1.1 The Basics of Six Sigma (51-60)igorsfrNo ratings yet

- Six SigmaDocument11 pagesSix SigmaJaishimmaNo ratings yet

- BM 117 Unit 6 Six Sigma StudentDocument8 pagesBM 117 Unit 6 Six Sigma StudentFefeth TanNo ratings yet

- The History of Six Sigma: Black BeltsDocument4 pagesThe History of Six Sigma: Black BeltsRecep GüleçNo ratings yet

- Frequently Asked Questions About Six SigmaDocument3 pagesFrequently Asked Questions About Six SigmapcthienNo ratings yet

- Six Sigma DictionaryDocument3 pagesSix Sigma Dictionarylara.fernandez.f4461No ratings yet

- Six Sigma at Many Organizations Simply Means A Measure of Quality That Strives For Near PerfectionDocument5 pagesSix Sigma at Many Organizations Simply Means A Measure of Quality That Strives For Near Perfectionali_raza661No ratings yet

- Snee 2010Document22 pagesSnee 2010pchumiNo ratings yet

- What Is Kaizen?: The Role of Human Resources (HR) in Six SigmaDocument4 pagesWhat Is Kaizen?: The Role of Human Resources (HR) in Six SigmaReshma ManjunathNo ratings yet

- Chapter 2 Six Sigma History and Application (OK)Document14 pagesChapter 2 Six Sigma History and Application (OK)Islam Abdou AbbasNo ratings yet

- The Role of Human Resources (HR) in Six Sigma: Related ArticlesDocument6 pagesThe Role of Human Resources (HR) in Six Sigma: Related ArticlesbasantkshetriNo ratings yet

- Lean Six Sigma Project - A Beginner's Guide: - NilakantasrinivasanDocument8 pagesLean Six Sigma Project - A Beginner's Guide: - NilakantasrinivasanRHTi BDNo ratings yet

- Lean Six Sigma Project - A Beginner's Guide: - NilakantasrinivasanDocument8 pagesLean Six Sigma Project - A Beginner's Guide: - NilakantasrinivasanZeeshan AliNo ratings yet

- Using The Five W'S and One H Approach To Six SigmaDocument6 pagesUsing The Five W'S and One H Approach To Six SigmaMadan JoshiNo ratings yet

- Asq What Is Six SigmaDocument6 pagesAsq What Is Six SigmaCloud RedfieldNo ratings yet

- Six Sigma Q&A Guide PDFDocument21 pagesSix Sigma Q&A Guide PDFPramendra7No ratings yet

- Six Sigma Implementation by Indian Manufacturing Smes - An Empirical StudyDocument22 pagesSix Sigma Implementation by Indian Manufacturing Smes - An Empirical StudyRanti IrmarianiNo ratings yet

- Lean 6s White PaperDocument9 pagesLean 6s White PapermikcraNo ratings yet

- 10 Essentials For A Successful Lean Six Sigma JourneyDocument4 pages10 Essentials For A Successful Lean Six Sigma JourneyDarren TanNo ratings yet

- Group Case StudyDocument3 pagesGroup Case StudyAjouwad Khandoker ÆdibNo ratings yet

- Key Ingredients For A Successful Six Sigma ProgramDocument10 pagesKey Ingredients For A Successful Six Sigma Programchamith2010No ratings yet

- Assignment: Submitted To: Submitted By: Anita Mam Mahek DhawanDocument7 pagesAssignment: Submitted To: Submitted By: Anita Mam Mahek DhawanAisha BarbieNo ratings yet

- Main AssignmentDocument12 pagesMain Assignmentsvijay87sNo ratings yet

- A. Explain The Critical Success Factors For Six Sigma With ExamplesDocument4 pagesA. Explain The Critical Success Factors For Six Sigma With ExamplesAyyanrajNo ratings yet

- Six - Sigma Lecture LectureDocument55 pagesSix - Sigma Lecture LectureDr-Mohammed FaridNo ratings yet

- Synopsis - An Analysis of Six Sigma Implementation Process at TCSDocument18 pagesSynopsis - An Analysis of Six Sigma Implementation Process at TCSChanpreet Singh GroverNo ratings yet

- Is This A Six Sigma, Lean, or Kaizen Project?: Terence T. BurtonDocument2 pagesIs This A Six Sigma, Lean, or Kaizen Project?: Terence T. BurtonCarlos Moreira da SilvaNo ratings yet

- Bring Quality Near Perfection With Six Sigma: Inspiring Business ConfidenceDocument4 pagesBring Quality Near Perfection With Six Sigma: Inspiring Business ConfidenceSharat ChandraNo ratings yet

- KW SixSigmaDocument3 pagesKW SixSigmaMoe NagaNo ratings yet

- Lean Philosophy: Lean Six Sigma ● Lean Startup ● Lean Enterprise ● Lean Analytics ● 5s Methodologies. Process & Techniques for Building a Lean Enterprise to a Lean Business.From EverandLean Philosophy: Lean Six Sigma ● Lean Startup ● Lean Enterprise ● Lean Analytics ● 5s Methodologies. Process & Techniques for Building a Lean Enterprise to a Lean Business.No ratings yet

- Lean ● Kaizen ● Kanban: Six Sigma ● Startup ● Enterprise ● Analytics ● 5s Methodologies. Exploits Kaizen System for Perpetual Improvement. Exploits Kanban System for Optimize Workflow.From EverandLean ● Kaizen ● Kanban: Six Sigma ● Startup ● Enterprise ● Analytics ● 5s Methodologies. Exploits Kaizen System for Perpetual Improvement. Exploits Kanban System for Optimize Workflow.No ratings yet

- The 5 Day Lean Six Sigma Green Belt: A Practical Approach to Understanding and Utilizing Lean Six SigmaFrom EverandThe 5 Day Lean Six Sigma Green Belt: A Practical Approach to Understanding and Utilizing Lean Six SigmaRating: 5 out of 5 stars5/5 (1)

- Analytical Problem SolvingDocument7 pagesAnalytical Problem SolvingadamNo ratings yet

- A Better WayDocument5 pagesA Better WayadamNo ratings yet

- To Change Is To Change TwiceDocument3 pagesTo Change Is To Change TwiceadamNo ratings yet

- Get Around The BoxDocument2 pagesGet Around The BoxadamNo ratings yet

- Two Crucial ErrorsDocument3 pagesTwo Crucial ErrorsadamNo ratings yet

- Back To SchoolDocument2 pagesBack To SchooladamNo ratings yet

- Behind The Interviewing CurtainDocument2 pagesBehind The Interviewing CurtainadamNo ratings yet

- CEB Build A Culture of QualityDocument16 pagesCEB Build A Culture of QualityadamNo ratings yet

- Swift PursuitDocument5 pagesSwift PursuitadamNo ratings yet

- App B Monitoring Measurement ChecklistDocument2 pagesApp B Monitoring Measurement ChecklistadamNo ratings yet

- How To Demostrate Risk Based Thinking To AuditorsDocument2 pagesHow To Demostrate Risk Based Thinking To AuditorsadamNo ratings yet

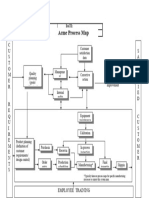

- App-A - Acme-Process-Map-1Document1 pageApp-A - Acme-Process-Map-1adamNo ratings yet

- App A Product Design Development Process ModelDocument1 pageApp A Product Design Development Process ModeladamNo ratings yet

- Psychological Impact of MetricsDocument4 pagesPsychological Impact of MetricsadamNo ratings yet

- Cafe DavaoDocument2 pagesCafe DavaoGeeryl TayoneNo ratings yet

- The Completed Testament Age and The Ideal Kingdom - Sun Myung MoonDocument766 pagesThe Completed Testament Age and The Ideal Kingdom - Sun Myung MoonAnonymous zzVTntK2xNo ratings yet

- The Book of LifeDocument3 pagesThe Book of LifefranklinNo ratings yet

- Chapter 4Document41 pagesChapter 4MubeenNo ratings yet

- 2024 Tuition Fees Terms and Conditions For Australian Fee Paying StudentsDocument20 pages2024 Tuition Fees Terms and Conditions For Australian Fee Paying StudentsBoyNo ratings yet

- Judgement DayDocument10 pagesJudgement DayPaul SavvyNo ratings yet

- People vs. Bisda (Full Case)Document31 pagesPeople vs. Bisda (Full Case)Karen Feyt MallariNo ratings yet

- BBC Learning English 6 Minute English Private FosteringDocument4 pagesBBC Learning English 6 Minute English Private FosteringAsefeh KianiNo ratings yet

- BAPARD Video Conference Equipment Financial Proposal PDFDocument3 pagesBAPARD Video Conference Equipment Financial Proposal PDFAungsinghla MarmaNo ratings yet

- Face Recognition Attendance System ThesisDocument7 pagesFace Recognition Attendance System Thesisidmwergld100% (2)

- The Harbinger, The Inverted Tree, and Prophetic SpeculationDocument8 pagesThe Harbinger, The Inverted Tree, and Prophetic SpeculationJeremy James50% (2)

- Research MethodologyDocument2 pagesResearch MethodologyLouie OmpadNo ratings yet

- The Interior CastleDocument15 pagesThe Interior CastlejjpulikenNo ratings yet

- Final Report On Internship at 3t Oil & GasDocument32 pagesFinal Report On Internship at 3t Oil & Gasmba betaNo ratings yet

- World Folktales An Anthology of Multicultural Folk LiteratureDocument164 pagesWorld Folktales An Anthology of Multicultural Folk LiteratureAnonymous zNyWGQWXk1100% (4)

- Maximus To Gloucester, Letter 27 (Withheld) ExplicationDocument3 pagesMaximus To Gloucester, Letter 27 (Withheld) ExplicationJoshua JeromeNo ratings yet

- A Study On Buddhist Circuits in BiharDocument46 pagesA Study On Buddhist Circuits in BiharAshish BansoreNo ratings yet

- Budget For Field TripDocument3 pagesBudget For Field TripNana Tweneboah0% (1)

- العقوبات الواردة في قانون المرور الكويتي دراسة مقارنة مع بعض الدول العربية والأجنبيةDocument21 pagesالعقوبات الواردة في قانون المرور الكويتي دراسة مقارنة مع بعض الدول العربية والأجنبيةSamar MNo ratings yet

- Certified List of Candidates: Philippines PhilippinesDocument8 pagesCertified List of Candidates: Philippines Philippinesmaria laboNo ratings yet

- 04 - Culture Industry - Enlightenment As Mass Deception PDFDocument11 pages04 - Culture Industry - Enlightenment As Mass Deception PDFMikaela JeanNo ratings yet

- 会计报表中英文对照Document8 pages会计报表中英文对照Kelsey GaoNo ratings yet

- Barnett MotionDocument18 pagesBarnett MotionLaw&CrimeNo ratings yet

- 1 Sect ProformaDocument1 page1 Sect ProformaKerry WeiNo ratings yet

- A Metrical Romance Is A Kind of Poetry Dealing With The Emotions or Phase of Life and The Story Is Told in A SimpleDocument2 pagesA Metrical Romance Is A Kind of Poetry Dealing With The Emotions or Phase of Life and The Story Is Told in A SimpleYanna Bumolo100% (5)

- Lecture CH 2 Sec 110Document46 pagesLecture CH 2 Sec 110Gary BaxleyNo ratings yet

- Activity Meet My Family - T1 - 1Document4 pagesActivity Meet My Family - T1 - 1JARLEY JOHANA BENITEZ ARENAS100% (1)

- Malala YousafzaiDocument6 pagesMalala YousafzaidmgNo ratings yet