Professional Documents

Culture Documents

Pages from 0021-ND Rev 9 Guidelines For Approval of Towing Vessels

Uploaded by

chinnaCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Pages from 0021-ND Rev 9 Guidelines For Approval of Towing Vessels

Uploaded by

chinnaCopyright:

Available Formats

GUIDELINES FOR THE APPROVAL OF TOWING VESSELS

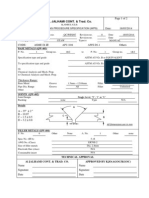

APPENDIX B – BOLLARD PULL TESTS

B.1 GENERAL

B.1.1 The following guidance notes apply to the bollard pull test of any towing vessel which GL Noble Denton

is requested to approve or attend.

B.1.2 The safe working load of the test equipment, fittings and any connection points ashore shall be at least

10% in excess of the designed maximum continuous static bollard pull of the vessel.

B.2 LOCATION

B.2.1 The water depth at the test location shall be at least 20 metres within a radius of 100 metres of the

vessel.

B.2.2 If a water depth of 20 metres cannot be obtained at the test location, then a minimum water depth

which is equal to twice the maximum draught of the vessel may be accepted. The owner of the vessel

must be advised that the reduced water depth may adversely affect the test results.

B.2.3 The test location shall be clear of navigational hazards and underwater obstructions within a radius of

300 metres of the vessel.

B.2.4 The current shall be less than 0.5 metres/second from any direction.

B.2.5 The wind speed shall be less than 5 metres/second from any direction.

B.2.6 The condition of the sea at the test location shall be calm, without swell or waves.

B.3 VESSEL

B.3.1 The draught and trim of the vessel shall be as near as possible to the draught and trim under normal

operating conditions.

B.3.2 The propellers and fuel used during the tests shall be the same as the propellers and fuel used under

normal operating conditions.

B.3.3 All auxiliary equipment such as pumps, generators and other equipment which are driven from the

main engine(s) or propeller shaft(s) during normal operation of the vessel shall be connected during

the test.

B.4 TEST

B.4.1 The distance between the stern of the vessel and the shore shall be at least 300 metres.

B.4.2 If it is not possible to maintain a distance of 300 metres between the stern of the vessel and the shore,

then a minimum distance which is equal to twice the waterline length of the vessel may be accepted.

The owner of the vessel must be advised that the reduced distance between the vessel’s stern and the

shore may adversely affect the test results.

B.4.3 Adequate communications shall be established between the vessel and instrument recording station.

B.4.4 The Continuous Bollard Pull (CBP) test shall be carried out at the manufacturer’s recommended

maximum continuous rating of the main engines (100% MCR), for a period of 10 minutes (see IMO

requirements in Ref [3]) with the vessel on a steady heading.

B.4.5 Whenever possible a maximum (MBP) test shall be carried out at the manufacturer’s maximum rating

of the main engines (typically 110% MCR), for a period of 5 minutes.

B.4.6 When requested, continuous bollard pull may also be verified at different RPM and/or propeller pitch

settings or with fewer propellers or engines in use.

B.4.7 The load cell used for measuring the bollard pull shall have an accuracy of 2% for the average

temperature observed during the test and shall have been calibrated not more than twelve (12) months 9

prior to the test date. The calibration certificate shall be available for inspection on site.

0021/ND REV 9 Page 29 of 33

GUIDELINES FOR THE APPROVAL OF TOWING VESSELS

B.4.8 An autographic recording instrument giving a continuous read-out of the bollard pull shall be connected

to the load cell.

B.4.9 If no continuous record of the test is printed, then the bollard pull shall be the mean of consecutive

readings recorded at 20 second intervals over the test period.

B.5 BOLLARD PULL TESTS ACCEPTANCE

B.5.1 Bollard pull test certificates issued by Classification Societies are acceptable, or by another recognised

body provided that acceptable procedures for the tests are produced.

0021/ND REV 9 Page 30 of 33

You might also like

- Bollard Pull Testing DG ShippingDocument2 pagesBollard Pull Testing DG ShippingJ VermaNo ratings yet

- LrbollpullDocument5 pagesLrbollpullzufi110No ratings yet

- Bollard Pull CodeDocument12 pagesBollard Pull CodeLiladhar Ganesh DhobleNo ratings yet

- Hydrostatic Testing Specification for PipelinesDocument12 pagesHydrostatic Testing Specification for PipelinesMoaatazz NouisriNo ratings yet

- BOLLARD PULL TRIAL CODE FOR TUGS WITH STEERPROP PROPULSORSDocument12 pagesBOLLARD PULL TRIAL CODE FOR TUGS WITH STEERPROP PROPULSORSKimcuong LeNo ratings yet

- Appendix A - Testing Procedure: Bollard PullDocument2 pagesAppendix A - Testing Procedure: Bollard PullAhmed SaadNo ratings yet

- Bollard Pull Trials Best PracticesDocument13 pagesBollard Pull Trials Best PracticesPrakharNo ratings yet

- Report on Ballast Water Management SurveyDocument9 pagesReport on Ballast Water Management SurveyJagjit SinghNo ratings yet

- BMA Bulletin 73 Periodic Bottom Inspection of Passenger ShipsDocument11 pagesBMA Bulletin 73 Periodic Bottom Inspection of Passenger ShipspRADEEP sNo ratings yet

- Information Bulletin No. 150: Inspection and Testing of Automatic Sprinkler SystemsDocument13 pagesInformation Bulletin No. 150: Inspection and Testing of Automatic Sprinkler SystemsNikos LevogiannisNo ratings yet

- Ex BHydrot 24'' 5KmDocument9 pagesEx BHydrot 24'' 5KmJabel Oil Services Technical DPTNo ratings yet

- MS Notice 01 of 2016 - UWILDDocument4 pagesMS Notice 01 of 2016 - UWILDankcr003No ratings yet

- ABS Guidelines For Static Bollard Pull Test ProcedureDocument2 pagesABS Guidelines For Static Bollard Pull Test ProcedureSaid ElsalahgyNo ratings yet

- (Vol C), 2015 Guidance For Inclining Test, 2015 - 2Document18 pages(Vol C), 2015 Guidance For Inclining Test, 2015 - 2Alde MUNo ratings yet

- LB and RB Disengaging Gears and Similar ArrangementsDocument8 pagesLB and RB Disengaging Gears and Similar ArrangementsNAZIM ŞAHAN ERKALNo ratings yet

- 7.3.2.2 Fillet Welds: 7-6 Api S 650Document1 page7.3.2.2 Fillet Welds: 7-6 Api S 650Leonardo Ramirez GuzmanNo ratings yet

- Guidelines for In-Water Surveys of Passenger Ship HullsDocument6 pagesGuidelines for In-Water Surveys of Passenger Ship HullsIgnacio SantanaNo ratings yet

- Installation of Ballast Water Management SystemsDocument7 pagesInstallation of Ballast Water Management Systemslukky prasetyoNo ratings yet

- Generic Equivalent Solution: 2014/02 Use of Simplified Stability Criteria Decked and Open Vessels 7.5M Length Carrying Passengers To SeaDocument2 pagesGeneric Equivalent Solution: 2014/02 Use of Simplified Stability Criteria Decked and Open Vessels 7.5M Length Carrying Passengers To SeataddeoNo ratings yet

- Guidelines For TowingDocument0 pagesGuidelines For TowinghutsonianpNo ratings yet

- Ballast Water Management Surveyor GuidelinesDocument10 pagesBallast Water Management Surveyor GuidelinesNagy A.M. ElnadyNo ratings yet

- Hydrostatic Testing Requirements in API 650Document3 pagesHydrostatic Testing Requirements in API 650Karwan100% (6)

- Test Method For Earthwork Compaction Control by Nuclear GaugeDocument29 pagesTest Method For Earthwork Compaction Control by Nuclear GaugeLennieCartujanoLuceñoNo ratings yet

- Ballast Water Sampling Guide LineDocument15 pagesBallast Water Sampling Guide LinePix FineNo ratings yet

- Survival Craft and Rescue Boat Equipment and Fittings Sea AnchorDocument4 pagesSurvival Craft and Rescue Boat Equipment and Fittings Sea AnchorAmit PandeyNo ratings yet

- API 510 VesselsDocument11 pagesAPI 510 Vesselsmoonstar_dmeNo ratings yet

- MSAE014-QC-PRE-035-Quality Procedure For Hydrostatic TestingDocument12 pagesMSAE014-QC-PRE-035-Quality Procedure For Hydrostatic Testingqamar qateebNo ratings yet

- P 54 Holiday Testing Procedure R1Document43 pagesP 54 Holiday Testing Procedure R1rahul reyashNo ratings yet

- IWS Survey RequirementsDocument2 pagesIWS Survey Requirementsalive2flirt100% (3)

- Drydocking Coast Guard 8634 - STDDocument62 pagesDrydocking Coast Guard 8634 - STDzeek77No ratings yet

- BP Survey Vessel Technical SpecificationDocument10 pagesBP Survey Vessel Technical SpecificationKurniawan PriambodoNo ratings yet

- REferat GMDSS - EPIRBDocument6 pagesREferat GMDSS - EPIRBAntonio FlorinNo ratings yet

- Non Destructive Test On Journal Bearing & Thrust Bearing Pads of KWU Design Steam Turbine During Maintenance InspectionDocument6 pagesNon Destructive Test On Journal Bearing & Thrust Bearing Pads of KWU Design Steam Turbine During Maintenance InspectionRaj Sharma Raj100% (1)

- APV Test RequirementsDocument3 pagesAPV Test RequirementsRuslan ZakirovNo ratings yet

- EFUSION O&M ManualDocument8 pagesEFUSION O&M ManualYutt WattNo ratings yet

- LIFEBOATSDocument40 pagesLIFEBOATSNAZIM ŞAHAN ERKALNo ratings yet

- Hydrostatic Testing: 1 GeneralDocument9 pagesHydrostatic Testing: 1 GeneralPaolita Auza BalderramaNo ratings yet

- QCS 2010 Section 4 Part 11 Alternative Methods For Testing PilesDocument4 pagesQCS 2010 Section 4 Part 11 Alternative Methods For Testing Pilesbryanpastor106No ratings yet

- Instructions To SurveyorsDocument7 pagesInstructions To SurveyorsAndreas IoannouNo ratings yet

- Surface Well Testing - 2020408Document6 pagesSurface Well Testing - 2020408PrashantYadavNo ratings yet

- API 653 NotesDocument10 pagesAPI 653 Notesamine bouizarNo ratings yet

- VBT Procedure Rkl-Pro-06-ThocDocument7 pagesVBT Procedure Rkl-Pro-06-ThocEmmad JriNo ratings yet

- SUFFOLK Pipeline HydrotestDocument24 pagesSUFFOLK Pipeline HydrotestChristopher OjoNo ratings yet

- Ur M74rev1Document7 pagesUr M74rev1Ruben Freile GonzalezNo ratings yet

- Iqwq Ce1091 Vphyt D7 9005 - 0Document5 pagesIqwq Ce1091 Vphyt D7 9005 - 0Bello Friday JacksonNo ratings yet

- Bma Information Bulletin No. 29 Emergency Escape Breathing Devices (Eebd)Document3 pagesBma Information Bulletin No. 29 Emergency Escape Breathing Devices (Eebd)MatthewNo ratings yet

- Tests OnboardDocument6 pagesTests OnboardHari RamNo ratings yet

- Hydrostatic Test Procedure Storage TankDocument15 pagesHydrostatic Test Procedure Storage TankYuwantoniAl75% (4)

- 1744 - UT PROCEDURE (For Final) PDFDocument27 pages1744 - UT PROCEDURE (For Final) PDFpvdang8453100% (1)

- VSPM-09, Surveys, RulesDocument4 pagesVSPM-09, Surveys, RulessahilpawarNo ratings yet

- 510 PC Oct04 Qar-Mid Closed PSJDocument12 pages510 PC Oct04 Qar-Mid Closed PSJCss SfaxienNo ratings yet

- High-Speed Craft: Guide For Building and ClassingDocument5 pagesHigh-Speed Craft: Guide For Building and ClassingAlessandra ChavesNo ratings yet

- Cranes - Function TestDocument7 pagesCranes - Function TestJose CastroNo ratings yet

- Piping Hydro Test ProcedureDocument2 pagesPiping Hydro Test ProcedureSUNNY BOSSNo ratings yet

- Ur P3rev5Document6 pagesUr P3rev5Eren HürcanNo ratings yet

- Ductwork Leakage Testing: A Practical Guide ToDocument17 pagesDuctwork Leakage Testing: A Practical Guide ToGoyal SanjaiNo ratings yet

- Well Control for Completions and InterventionsFrom EverandWell Control for Completions and InterventionsRating: 4 out of 5 stars4/5 (10)

- 737 Performance Reference Handbook - EASA EditionFrom Everand737 Performance Reference Handbook - EASA EditionRating: 4.5 out of 5 stars4.5/5 (3)

- International Regulations for Preventing Collisions at SeaFrom EverandInternational Regulations for Preventing Collisions at SeaNo ratings yet

- Well Integrity for Workovers and RecompletionsFrom EverandWell Integrity for Workovers and RecompletionsRating: 5 out of 5 stars5/5 (3)

- Session 2 - Evolution of LSM From WSM and Introduction To IS-456Document3 pagesSession 2 - Evolution of LSM From WSM and Introduction To IS-456Dhananjay DesaleNo ratings yet

- Turbine Clearance ControlDocument135 pagesTurbine Clearance ControlAnu Partha100% (1)

- Komatsu WB93R-2 engine repair manual sectionsDocument439 pagesKomatsu WB93R-2 engine repair manual sectionsBoyko Vasilev86% (7)

- IA-7 V3 ManualDocument15 pagesIA-7 V3 Manualaleksa64No ratings yet

- Ficha Tecnica Ciac Hi Wall 60 HZ R-22Document1 pageFicha Tecnica Ciac Hi Wall 60 HZ R-22Eduardo GarcíaNo ratings yet

- WSDOT McDowell Final WirelessCommDocument83 pagesWSDOT McDowell Final WirelessCommoldjanusNo ratings yet

- Chapter 7 Software Development StrategiesDocument41 pagesChapter 7 Software Development StrategiesBurime GrajqevciNo ratings yet

- Lavadora LAVAMAT 72950 M3 LAVAMAT 74950 M3Document80 pagesLavadora LAVAMAT 72950 M3 LAVAMAT 74950 M3MarcosNo ratings yet

- Digital Assignment-1 critical path and function point analysisDocument6 pagesDigital Assignment-1 critical path and function point analysisGOVARDHANNo ratings yet

- Solidworks SimulationDocument30 pagesSolidworks SimulationDavid Raj100% (1)

- IIIE Student Project Reports Covering Quality, Lean, Automation & MoreDocument17 pagesIIIE Student Project Reports Covering Quality, Lean, Automation & MoreSwarup mishraNo ratings yet

- Pool Fittings LeafletDocument20 pagesPool Fittings LeafletmohammudaphNo ratings yet

- PTE 526 Natural Gas Engineering: BY Engr. J. O. OwolabiDocument124 pagesPTE 526 Natural Gas Engineering: BY Engr. J. O. Owolabiokeke ekeneNo ratings yet

- Novatel OEM7 Commands Logs ManualDocument1,090 pagesNovatel OEM7 Commands Logs ManualraceralphNo ratings yet

- EE 499, Lecture 03 Frequency ReuseDocument6 pagesEE 499, Lecture 03 Frequency ReuselakshmiNo ratings yet

- Frank GehryDocument12 pagesFrank Gehrya to z CHANNELNo ratings yet

- Description and Operation: Unison Industries Component Maintenance Manual Ignition LeadsDocument2 pagesDescription and Operation: Unison Industries Component Maintenance Manual Ignition Leadsmaty englerNo ratings yet

- MONLEON, REI JULIAN KYLE T. - Module 3 - Assignment 3 - MT NPBST 11 A1Document5 pagesMONLEON, REI JULIAN KYLE T. - Module 3 - Assignment 3 - MT NPBST 11 A1Christian Felix GuevarraNo ratings yet

- UT For Duplex Stainless Steel WeldsDocument5 pagesUT For Duplex Stainless Steel WeldsvsnaiduqcNo ratings yet

- Panasonic Broadcast AG-DVX100A Mechanical Parts ListDocument17 pagesPanasonic Broadcast AG-DVX100A Mechanical Parts ListmxtachoNo ratings yet

- Huong Dan Su DungDocument846 pagesHuong Dan Su DungThien NguyenngocNo ratings yet

- Student Information Maintenance System ProjectDocument4 pagesStudent Information Maintenance System ProjectHarshpreet Singh0% (1)

- Bombe 4Document154 pagesBombe 4Adith K PNo ratings yet

- WPS GTAW pipe welding procedureDocument2 pagesWPS GTAW pipe welding procedureRichard PeriyanayagamNo ratings yet

- Predicting Bottomhole Assembly Performance: J.S. Williamson, A. LubinskiDocument13 pagesPredicting Bottomhole Assembly Performance: J.S. Williamson, A. Lubinskifaishal hafizhNo ratings yet

- Millercatalog Digital FinalDocument103 pagesMillercatalog Digital FinalBoris VukasinovicNo ratings yet

- Analysis and Design of Multi-Storied Building (Main Project) Sita GowriDocument114 pagesAnalysis and Design of Multi-Storied Building (Main Project) Sita Gowridskumar49100% (5)

- Huawei - OSN-3500-2500-1500-Hardware-Description-ManualDocument50 pagesHuawei - OSN-3500-2500-1500-Hardware-Description-ManualHường LêNo ratings yet

- Jss & JSG GuideDocument186 pagesJss & JSG GuideKishore PatilNo ratings yet

- En Iso 13919-1 - 1996Document9 pagesEn Iso 13919-1 - 1996MNo ratings yet