Professional Documents

Culture Documents

Machine Design Term Work

Uploaded by

Chirag PatilCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Machine Design Term Work

Uploaded by

Chirag PatilCopyright:

Available Formats

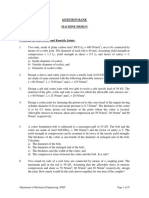

Term Work Questions

Machine Design 1 SEM-VI

The following design exercises also include computer aided drawing of designed

components on A3 size sheets.

1. Design and draw a cotter joint to support a load varying from 30 kN in compression to 30

kN in tension. The material used is carbon steel for which the following allowable stresses

may be used. The load is applied statically. Tensile stress = compressive stress = 50 MPa ;

shear stress = 35 MPa and crushing stress = 90 MPa.

2. Design a knuckle joint to transmit 150 kN. The design stresses may be taken as

75 MPa in tension, 60 MPa in shear and 150 MPa in compression.

3. A rigid coupling is used to transmit 20 kW power at 720 rpm. There are four bolts and the

pitch circle diameter of the bolts is 125 mm. The bolts are made of steel 45C8 (Syt = 380

N/mm2) and the factor of safety is 3. Determine the diameter of the bolts. Assume that the

bolts are finger tight in reamed and ground holes.

4. A semi-elliptic leaf spring used for automobile suspension consists of three extra full-

length leaves and 15 graduated-length leaves, including the master leaf. The centre-to-

centre distance between two eyes of the spring is 1 m. The maximum force that can act on

the spring is 75 kN. For each leaf, the ratio of width to thickness is 9:1. The modulus of

elasticity of the leaf material is 207 000 N/mm2. The leaves are pre-stressed in such a way

that when the force is maximum, the stresses induced in all leaves are same and equal to

450 N/mm2. Determine (i) the width and thickness of the leaves (ii) the initial nip; and (iii)

the initial pre-load required to close the gap C between extra full-length leaves and

graduated-length leaves.

5. Design a screw jack for supporting the machine parts during their repair and maintenance

on the shop fl oor. It should be a general-purpose jack with a load carrying capacity of 100

kN and a maximum lifting height of 0.5 m. The jack is to be manually operated.

You might also like

- DME Question Bank - 3171917Document4 pagesDME Question Bank - 3171917fgyjnsv786No ratings yet

- MD Tut PDFDocument6 pagesMD Tut PDFNelsan PatelNo ratings yet

- Advanced Opensees Algorithms, Volume 1: Probability Analysis Of High Pier Cable-Stayed Bridge Under Multiple-Support Excitations, And LiquefactionFrom EverandAdvanced Opensees Algorithms, Volume 1: Probability Analysis Of High Pier Cable-Stayed Bridge Under Multiple-Support Excitations, And LiquefactionNo ratings yet

- ME6503-Design of Machine Elements PDFDocument15 pagesME6503-Design of Machine Elements PDFkarthikNo ratings yet

- Snist Dom Previous PaperDocument9 pagesSnist Dom Previous PaperKapil Siddhant DevulapalliNo ratings yet

- QuestionsDocument11 pagesQuestionsSundara MoorthyNo ratings yet

- EMD - Practical - 2022-23Document5 pagesEMD - Practical - 2022-23Animesh GhoshNo ratings yet

- End Semester SY Question Paper MDD May 2021Document3 pagesEnd Semester SY Question Paper MDD May 2021FelishiaNo ratings yet

- DMM - I Question Bank For StudentsDocument11 pagesDMM - I Question Bank For StudentsDushyanthkumar DasariNo ratings yet

- DMM - I Question Bank For StudentsDocument11 pagesDMM - I Question Bank For StudentsDushyanthkumar DasariNo ratings yet

- Design of Machine Elements PC-ME 503 Assignment QuestionsDocument5 pagesDesign of Machine Elements PC-ME 503 Assignment Questions039 Md Faizan AhmedNo ratings yet

- Me8593 Iq R17Document4 pagesMe8593 Iq R17Vaideesh LJNo ratings yet

- Question Bank Machine Design A: Numerical Problems: Problems On Pin, Cotter and Knuckle JointsDocument25 pagesQuestion Bank Machine Design A: Numerical Problems: Problems On Pin, Cotter and Knuckle Jointsamol pogakeNo ratings yet

- 08 r05310305 Design of Machine Members IDocument9 pages08 r05310305 Design of Machine Members IKrupanandareddyYarragudiNo ratings yet

- Dme Home Assignment 2019-20Document4 pagesDme Home Assignment 2019-20VenkateshNo ratings yet

- Macine Element I Worksheet for Final ExamDocument4 pagesMacine Element I Worksheet for Final Examdagimawgchew777No ratings yet

- Machine Design & Industrial Drafting SUBJECT CODE:-2141907 Tutorial - 01Document10 pagesMachine Design & Industrial Drafting SUBJECT CODE:-2141907 Tutorial - 01The AIRS CreationsNo ratings yet

- R7310305 Design of Machine Members - IDocument1 pageR7310305 Design of Machine Members - IsivabharathamurthyNo ratings yet

- Design of Machine ElementsDocument10 pagesDesign of Machine ElementsMahalingam NanjappanNo ratings yet

- Design of machine elements exam questions and solutionsDocument3 pagesDesign of machine elements exam questions and solutionsvikaskumar1986No ratings yet

- dmm1 PDFDocument9 pagesdmm1 PDFmohan_rapaka6095No ratings yet

- DME Assignment 1Document2 pagesDME Assignment 1sumikannuNo ratings yet

- Dme Model 2Document6 pagesDme Model 2YashwanthI-StyleKuttiNo ratings yet

- Anna University ME2303 Design of Machine Elements Exam QuestionsDocument3 pagesAnna University ME2303 Design of Machine Elements Exam QuestionssathurvedhaNo ratings yet

- 12me52 MQP-1Document3 pages12me52 MQP-1SumitKumarNo ratings yet

- Machine Members Design AssignmentDocument13 pagesMachine Members Design AssignmentHafiz Mahar28No ratings yet

- 9A14503 Principles of Machine DesignDocument8 pages9A14503 Principles of Machine DesignsivabharathamurthyNo ratings yet

- Machine Elements Design QuestionsDocument5 pagesMachine Elements Design QuestionsbalameckNo ratings yet

- B.Tech Exam Design of Machine Members QuestionsDocument8 pagesB.Tech Exam Design of Machine Members Questionsprk74No ratings yet

- Cat 2 Ear 306Document4 pagesCat 2 Ear 306Mercy MerryNo ratings yet

- UNIT-1: Department of Mechanical EngineeringDocument14 pagesUNIT-1: Department of Mechanical EngineeringManivannan JeevaNo ratings yet

- Kings: Department of Mechanical EngineeringDocument14 pagesKings: Department of Mechanical EngineeringAdam AhmadNo ratings yet

- 3-1 DMM1 (Nov 2009 Regular)Document9 pages3-1 DMM1 (Nov 2009 Regular)micmechNo ratings yet

- Me2303 - Design of Machine ElementsDocument14 pagesMe2303 - Design of Machine ElementsGowtham RajNo ratings yet

- Mechanical Engineering Design QuestionsDocument4 pagesMechanical Engineering Design QuestionsSoham MisalNo ratings yet

- DME Question BankDocument4 pagesDME Question BankILAYAPERUMAL KNo ratings yet

- Machine Elements Question BankDocument3 pagesMachine Elements Question BanksonawanepmsNo ratings yet

- Me 2303 Imp QnsDocument3 pagesMe 2303 Imp QnsAJAY63No ratings yet

- Assignment 02 - Machine DesignDocument2 pagesAssignment 02 - Machine DesignRatan Sadanandan O MNo ratings yet

- DME Chapter Three: or (Summer 15)Document7 pagesDME Chapter Three: or (Summer 15)honeyfunnyNo ratings yet

- MODEL QUESTION PAPER Mechanical VibrationsDocument3 pagesMODEL QUESTION PAPER Mechanical VibrationsDarani PriyaNo ratings yet

- QB Unit-1,2Document5 pagesQB Unit-1,2Agranshu BhardwajNo ratings yet

- Me1302 Dme 2Document4 pagesMe1302 Dme 2sumikannu100% (1)

- Dme Assignment 2Document21 pagesDme Assignment 2helloapple1211No ratings yet

- Me1302 DmeDocument4 pagesMe1302 DmesumikannuNo ratings yet

- ME 1302 - MACHINE DESIGN (5th Mech)Document7 pagesME 1302 - MACHINE DESIGN (5th Mech)Madhu MithaNo ratings yet

- G For The Material Is 82 GN/m2. If The I-Section Is Replaced by A T-Section Made of TheDocument6 pagesG For The Material Is 82 GN/m2. If The I-Section Is Replaced by A T-Section Made of Theክበር ተመስጌንNo ratings yet

- DMM 1 Assignment Questions FinalDocument2 pagesDMM 1 Assignment Questions FinalSrimanthula SrikanthNo ratings yet

- R09 B.Tech III Year I Semester Machine Elements ExamDocument1 pageR09 B.Tech III Year I Semester Machine Elements Examprasaad08No ratings yet

- ME6503-Design of Machine ElementsDocument15 pagesME6503-Design of Machine ElementsBas RamuNo ratings yet

- Unit - 1Document8 pagesUnit - 1Dhileepan KumarasamyNo ratings yet

- Gujarat Technological UniversityDocument2 pagesGujarat Technological UniversityHerat HirparaNo ratings yet

- MDDocument5 pagesMDYogesh DanekarNo ratings yet

- Dme Lab Sheets Ii Iii IvDocument4 pagesDme Lab Sheets Ii Iii IvA58Vikas UbovejaNo ratings yet

- Assignment No. 3 &4 B.Tech Mechanical Engineering Third YearDocument4 pagesAssignment No. 3 &4 B.Tech Mechanical Engineering Third Yearharish_kumar201301No ratings yet

- Dme Quest Ut-2Document9 pagesDme Quest Ut-2aadhithyarajasekaranNo ratings yet

- Machine Elements Design ProblemsDocument3 pagesMachine Elements Design ProblemsHanan ShayiboNo ratings yet

- ChatGPT Money Machine 2024 - The Ultimate Chatbot Cheat Sheet to Go From Clueless Noob to Prompt Prodigy Fast! Complete AI Beginner’s Course to Catch the GPT Gold Rush Before It Leaves You BehindFrom EverandChatGPT Money Machine 2024 - The Ultimate Chatbot Cheat Sheet to Go From Clueless Noob to Prompt Prodigy Fast! Complete AI Beginner’s Course to Catch the GPT Gold Rush Before It Leaves You BehindNo ratings yet

- In the Age of AI: How AI and Emerging Technologies Are Disrupting Industries, Lives, and the Future of WorkFrom EverandIn the Age of AI: How AI and Emerging Technologies Are Disrupting Industries, Lives, and the Future of WorkRating: 5 out of 5 stars5/5 (1)

- Comprehensive Guide to Robotic Process Automation (RPA): Tips, Recommendations, and Strategies for SuccessFrom EverandComprehensive Guide to Robotic Process Automation (RPA): Tips, Recommendations, and Strategies for SuccessNo ratings yet

- Mastering Drones - A Beginner's Guide To Start Making Money With DronesFrom EverandMastering Drones - A Beginner's Guide To Start Making Money With DronesRating: 2.5 out of 5 stars2.5/5 (3)

- Atlas of AI: Power, Politics, and the Planetary Costs of Artificial IntelligenceFrom EverandAtlas of AI: Power, Politics, and the Planetary Costs of Artificial IntelligenceRating: 5 out of 5 stars5/5 (9)

- Artificial You: AI and the Future of Your MindFrom EverandArtificial You: AI and the Future of Your MindRating: 4 out of 5 stars4/5 (3)

- Collection of Raspberry Pi ProjectsFrom EverandCollection of Raspberry Pi ProjectsRating: 5 out of 5 stars5/5 (1)

- Artificial Intelligence Revolution: How AI Will Change our Society, Economy, and CultureFrom EverandArtificial Intelligence Revolution: How AI Will Change our Society, Economy, and CultureRating: 4.5 out of 5 stars4.5/5 (2)

- Arduino: The complete guide to Arduino for beginners, including projects, tips, tricks, and programming!From EverandArduino: The complete guide to Arduino for beginners, including projects, tips, tricks, and programming!Rating: 4 out of 5 stars4/5 (3)

- Create Profitable Side Hustles with Artificial IntelligenceFrom EverandCreate Profitable Side Hustles with Artificial IntelligenceNo ratings yet

- What to Expect When You're Expecting Robots: The Future of Human-Robot CollaborationFrom EverandWhat to Expect When You're Expecting Robots: The Future of Human-Robot CollaborationRating: 4.5 out of 5 stars4.5/5 (2)

- Dark Aeon: Transhumanism and the War Against HumanityFrom EverandDark Aeon: Transhumanism and the War Against HumanityRating: 5 out of 5 stars5/5 (1)

- Artificial Intelligence: The Complete Beginner’s Guide to the Future of A.I.From EverandArtificial Intelligence: The Complete Beginner’s Guide to the Future of A.I.Rating: 4 out of 5 stars4/5 (5)

- PLC Programming & Implementation: An Introduction to PLC Programming Methods and ApplicationsFrom EverandPLC Programming & Implementation: An Introduction to PLC Programming Methods and ApplicationsNo ratings yet

- Robotics: Designing the Mechanisms for Automated MachineryFrom EverandRobotics: Designing the Mechanisms for Automated MachineryRating: 4.5 out of 5 stars4.5/5 (8)

- Visions Of Technology: A Century Of Vital Debate About Machines Systems AFrom EverandVisions Of Technology: A Century Of Vital Debate About Machines Systems ARating: 4 out of 5 stars4/5 (9)

- Design and Operation of Human Locomotion SystemsFrom EverandDesign and Operation of Human Locomotion SystemsMarco CecarelliNo ratings yet

- Artificial Intelligence: From Medieval Robots to Neural NetworksFrom EverandArtificial Intelligence: From Medieval Robots to Neural NetworksRating: 4 out of 5 stars4/5 (3)

- Projects With Microcontrollers And PICCFrom EverandProjects With Microcontrollers And PICCRating: 5 out of 5 stars5/5 (1)

- Modeling, Dynamics, and Control of Electrified VehiclesFrom EverandModeling, Dynamics, and Control of Electrified VehiclesRating: 5 out of 5 stars5/5 (1)