Professional Documents

Culture Documents

ZDC25 PT-21 M

Uploaded by

TRANSSHELFCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

ZDC25 PT-21 M

Uploaded by

TRANSSHELFCopyright:

Available Formats

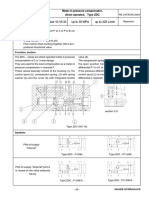

RE 29 224/02.

03

Replaces: 06.99

Meter-in pressure compensator,

direct operated

Type ZDC…

Nominal sizes 10 to 32

Series 2X

Maximum operating pressure 350 bar

Maximum flow 520 L/min

Type ZDC 16..-2X/…

Overview of contents

Contents Page

Features 1

Ordering details 2

Symbols 2

Function, section 3

Technical data 3

Characteristic curves 4 and 5

Unit dimensions 6 and 7 Type ZDC 25..-2X/…

Pilot oil supply 8 and 9

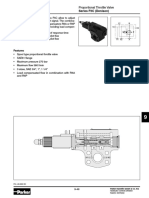

Features

– Sandwich plate design

– Load compensation in port P → A or P → B via a

built-in shuttle valve

– 2-way version „P“

– 3-way version „PT“ (NS 10 - 25)

– Flow control when working together with a

proportional directional valve

– Porting pattern to DIN 24 340 form A

Type ZDC 32..-2X/…

© 2003

by Bosch Rexroth AG, Industrial Hydraulics, D-97813 Lohr am Main

All rights reserved. No part of this document may be reproduced or stored, processed, duplicated or circulated using

electronic systems, in any form or by means, without the prior written authorisation of Bosch Rexroth AG. In the event

of contravention of the above provisions, the contravening party is obliged to pay compensation.

ZDC… 1/10 RE 29 224/02.03

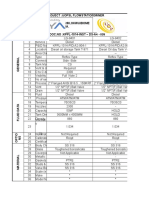

Ordering details

ZDC –2X *

Nominal size

NS 10 = 10 Further details in clear text

NS 16 = 16 M= NBR seals

NS 25 = 25 V= FKM seals

NS 32 (only version P) = 32 (other seals on request)

2-way version (pressure reduction function) =P Attention!

3-way version (pressure limitation function) = PT The compatibility of the seals and pressure

Series 20 to 29 = 2X fluid has to be taken into account!

(20 to 29: unchanged installation and connection dimensions) No code = Without special protection

Pilot oil supply “internal” = No code J= Seawater resistant

Pilot oil supply “external” =X

Pilot oil supply external, port X is closed on the = XL

valve side (only NS 10)

Preferred types and standard components are

highlighted in the EPS price list (RDE 00 165).

Symbols ( 1 = valve side, 2 = plate side)

2-way version „P“ 3-way version „PT“

1 1

Pilot oil supply

„internal“

PX A 2 B Y T P X A 2 B Y T

Type ZDC..P-2X/… Type ZDC..PT-2X/…

1 1

Pilot oil supply

„external“

PX A 2 B Y T P X A 2 B Y T

Type ZDC..P-2X/X… Type ZDC..PT-2X/X…

1 1

Pilot oil supply „external“,

port X is closed on the valve

side (only NS 10)

PX A 2 B Y T P X A 2 B Y T

Type ZDC 10 P-2X/XL… Type ZDC 10 PT-2X/XL…

RE 29 224/02.03 2/10 ZDC…

Function, section

X1 T1 A1 P1 B1 Y1

The ZDC... valves are direct operated meter-in pressure compensators

of 2 or 3-way design.

A A

They are used for the load compensation as a meter-in pressure

compensator in channel P.

These valves basically consist of the housing (1), the control spool

(2), compression spring (3) with spring washer (4) and the cover (5)

with integrated shuttle valve (6).

The compression spring (3) holds the control spool (2) in the open

position from P2 to P1, when the pressure differential P1 → A1 or

P1 → B1 is less than 10 bar. X2 T2 A2 P2 B2 Y2

If the pressure differential exceeds 10 bar, then the control spool (2)

is moved to the left until the pressure differential is restored.

5 3 4 2 1

Section A – A

B

6

Technical data (for applications outside these parameters, please consult us!)

Nominal size NS 10 16 25 32

Flow L/min up to 85 up to 150 up to 325 up to 520

Weight kg 3.0 3.5 8.9 64.7

Installation optional

Operating pressure Ports A, B, P bar up to 350

Port T bar up to 250

Port X bar 30 to 100

Port Y bar up to 150,

up to 30 bar in conjunction with a pilot operated proportional

directional valve

Pressure fluid Mineral oil (HL, HLP) to DIN 51 5241),

Fast bio-degradable pressure fluid to VDMA 24 568 (also see

RE 90 221), HETG (rape seed oil)1), HEPG (polyglycols)2), HEES

(synthetic ester)2),

other pressure fluids on request

1) suitable for NBR and FKM sesals

2) only suitable for FKM seals

Degree of contamination Max. permissible degree of A filter with a minimum

contamination of the pressure retention rate of

fluid is to NAS 1638 βx ≥ 75 is recommended

class 7 x = 10

Pressure fluid temperature range °C – 20 to + 70

Viscosity range mm2/s 15 to 380

ZDC… 3/10 RE 29 224/02.03

Characteristic curves (measured at ν = 41 mm2/s and ϑ = 50 °C)

Flow control P to A, P to B 1 Flow control P to A, P to B

80 4 50

NS 10 NS 10

70

5

Pressure differential pmin in bar →

2 40

60

(pmin = ppump – pload)

50 Flow control

30

3 range

Flow in L/min →

40 6

20

30

20 Throttle range

10

10

0 20 40 60 80 100 0 20 60 80

40

Command value in % → Flow in L/min →

1 With valve type 4 WRZ 10…85… 4 With valve type 4 WRZ 10…64…

2 With valve type 4 WRZ 10…50… 5 With valve type 4 WRZ 10…32…

3 With valve type 4 WRZ 10…25… 6 With valve type 4 WRZ 10…16…

175 50

NS 16 2

Pressure differential pmin in bar →

NS 16

150

1 40

(pmin = ppump – pload)

125

30

100

Flow in L/min →

Flow control

range

75

20

50

10

25

Throttle range

0 20 40 60 80 100 0 25 50 75 100 125 150 175

Command value in % → Flow in L/min →

1 With valve type 4 WRZ 16…100…

2 With valve type 4 WRZ 16…150…

RE 29 224/02.03 4/10 ZDC…

Characteristic curves (measured at ν = 41 mm2/s and ϑ = 50 °C)

350 50

NS 25 2

NS 25

300

1

Pressure differential pmin in bar →

40

250

(pmin = ppump – pload)

30

200

Flow control

Flow in L/min →

range

150

20

100

10

50

Throttle range

0 20 40 60 80 100 0 50 100 150 200 250 300 350

Command value in % → Flow in L/min →

1 With valve type 4 WRZ 25…270…

2 With valve type 4 WRZ 25…325…

700 50

NS 32 NS 32

2

600

Pressure differential pmin in bar →

40

1

500

(pmin = ppump – pload)

30

400

Flow in L/min →

Flow control

300

range

20

200

10

100

Throttle range

0 20 40 60 80 100 0 100 200 300 400 500 600 700

Command value in % → Flow in L/min →

1 With valve type 4 WRZ 32…360…

2 With valve type 4 WRZ 32…520…

ZDC… 5/10 RE 29 224/02.03

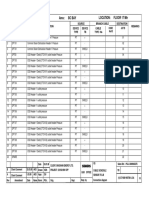

Unit dimensions (in mm)

NS 10

70

25

4 1 1 Name plate

4 x Ø 6,6

11,8

5 71 54 4 R-ring1)

5 Valve fixing screws 1)

P1 1) see table below

X1 Y1

25,5

A1 B1

46

70

Required surface finish of

T1 mating piece

0,01/100mm

3,5 R max 4

148

NS 16

60

25

4 1

166

3

Ø3

76,6 1 2

10,5

4 x Ø 11 34,1 2 x Ø 6,6

1,6

Required surface finish of

X1 mating piece

T1 P1

69,9

71,5

0,01/100mm

91

A1 B1 Y1 R max 4

3

52 18,3 5

50

101,6

1 Name plate

2 Locating pin

Valve fixing screws must be ordered separately!

3 Locating pin hole

4 R-ring NS 10 NS 16 NS 25 NS 32

Ports A2, B2, P2, T2 13.0 x 1.6 x 2.0 22.53 x 2.3 x 2.62 27.8 x 2.6 x 3.0 42.5 x 3.0 x 3.0

Ports X2, Y2 11.18 x 1.6 x 1.78 10.0 x 2.0 x 2.0 19.0 x 3.0 x 3.0 19.0 x 3.0 x 3.0

5 Valve fixing screws S.H.C.S. with internal hexagon DIN 912-10.9

– For bolting together with a pilot operated 4 off M6 x 115 4 off M10 x 120 6 off M12 x 140 6 off M20 x 280

proportional directional valve type WRZ... MA = 15.5 Nm MA = 75 Nm MA = 130 Nm MA = 620 Nm

– 2 off M6 x 120 – –

– MA = 15.5 Nm – –

– For bolting together with a direct operated 4 off M6 x 120

proportional directional valve type WRE... MA = 15.5 Nm

RE 29 224/02.03 6/10 ZDC…

Unit dimensions (in mm)

NS 25

83

44

4 1

4

210 Ø6

94,5 2 1 Name plate

12,5

53,2 2 Locating pin

3 Locating pin hole

Y1 4 R-ring1)

Valve fixing screws1)

4,8

5

T1 P1 1) see table below on page 6

92,1

117

3 X1 A1 B1 Required surface finish of

mating piece

0,01/100mm

60 29,4 6 x Ø 14 R max 4

77

5

130,2

NS 32

70

165

100

6 x Ø 22 Ø6

5 1 4 3 2

1 Name plate

X1 2 Locating pin

B1 A1 3 Locating pin hole

158,8

200

4 R-ring1)

䊐125

P1 T1

95

5 Valve fixing screws1)

20,5

Y1 1)

75

see table below on page 6

41,3 24,5 Required surface finish of

mating piece

76,2

82,5 0,01/100mm

114,3

R max 4

147,6

190,5

260

370

440

ZDC… 7/10 RE 29 224/02.03

Pilot oil supply

Attention!

The pilot operated directional valve, in conjunction with a meter-in

compensator, must be the version with „external pilot oil supply“.

With external pilot oil supply the connection in port P is closed. The With internal pilot oil supply the connection to port P is open. The

pilot oil is suppled by a separate control circuit. pilot oil is taken before the throttling point of the pressure

compensator. (Port X is closed in the sub-plate)

a 0 b a 0 b

a b a b

PX A B Y T P X A B Y T

1 1

Type 4 WRZ…

PX A 2 B Y T PX A 2 B Y T

Type ZDC..P-2X/X… Type ZDC..P-2X/…

NS 10

X1 T1 A1 P1 B1 Y1

internal X2 P2

X2 T2 A2 P2 B2 Y2 external X2 P2

RE 29 224/02.03 8/10 ZDC…

Pilot oil supply

NS 16 Section B – B

T P X

B B P

internal X

P

A B Y

external X

NS 25 Section C – C

T P C Y P X

internal

P X

C

X A B external

NS 32 Section D – D

D P X

B1

X

A1 internal

D P X

P1 T1

external

ZDC… 9/10 RE 29 224/02.03

Notes

Bosch Rexroth AG Bosch Rexroth Limited The data specified above only serves to describe

Industrial Hydraulics the product. No statements concerning a certain

D-97813 Lohr am Main Cromwell Road, St Neots, condition or suitability for a certain application

Zum Eisengießer 1 • D-97816 Lohr am Main Cambs, PE19 2ES can be derived from our information.

Telefon 0 93 52 / 18-0 Tel: 0 14 80/22 32 56 The details stated do not release you from the

Telefax 0 93 52 / 18-23 58 • Telex 6 89 418-0 Fax: 0 14 80/21 90 52 responsibility for carrying out your own

eMail documentation@boschrexroth.de eMail: info@boschrexroth.co.uk assessment and verification. It must be

Internet www.boschrexroth.de remembered that our products are subject to a

natural process of wear and ageing.

RE 29 224/02.03 10/10 ZDC…

Notes

Bosch Rexroth AG Bosch Rexroth Limited The data specified above only serves to describe

Industrial Hydraulics the product. No statements concerning a certain

D-97813 Lohr am Main Cromwell Road, St Neots, condition or suitability for a certain application

Zum Eisengießer 1 • D-97816 Lohr am Main Cambs, PE19 2ES can be derived from our information.

Telefon 0 93 52 / 18-0 Tel: 0 14 80/22 32 56 The details stated do not release you from the

Telefax 0 93 52 / 18-23 58 • Telex 6 89 418-0 Fax: 0 14 80/21 90 52 responsibility for carrying out your own

eMail documentation@boschrexroth.de eMail: info@boschrexroth.co.uk assessment and verification. It must be

Internet www.boschrexroth.de remembered that our products are subject to a

natural process of wear and ageing.

ZDC… 11/10 RE 29 224/02.03

Notes

Bosch Rexroth AG Bosch Rexroth Limited The data specified above only serves to describe

Industrial Hydraulics the product. No statements concerning a certain

D-97813 Lohr am Main Cromwell Road, St Neots, condition or suitability for a certain application

Zum Eisengießer 1 • D-97816 Lohr am Main Cambs, PE19 2ES can be derived from our information.

Telefon 0 93 52 / 18-0 Tel: 0 14 80/22 32 56 The details stated do not release you from the

Telefax 0 93 52 / 18-23 58 • Telex 6 89 418-0 Fax: 0 14 80/21 90 52 responsibility for carrying out your own

eMail documentation@boschrexroth.de eMail: info@boschrexroth.co.uk assessment and verification. It must be

Internet www.boschrexroth.de remembered that our products are subject to a

natural process of wear and ageing.

RE 29 224/02.03 12/10 ZDC…

You might also like

- Re 29224 - 2024-01Document20 pagesRe 29224 - 2024-01Alcides Huacho OsorioNo ratings yet

- ZDR10 Re26585Document8 pagesZDR10 Re26585Tayfun GunalNo ratings yet

- ZDC-16, 25, 32 Meter-In Pressure Compensator, Direct OperatedDocument7 pagesZDC-16, 25, 32 Meter-In Pressure Compensator, Direct Operatednemi90No ratings yet

- Pressure Function - Type L-LCDocument64 pagesPressure Function - Type L-LCDaniel Sandoval FernándezNo ratings yet

- Pressure Reducing-Relief Valves Hydraulics-Rexroth Series ZDRDocument12 pagesPressure Reducing-Relief Valves Hydraulics-Rexroth Series ZDRJORGE ALBERTO PEREZ RAMIREZNo ratings yet

- Re28164 2011-05Document8 pagesRe28164 2011-05Daniel GómezNo ratings yet

- Contractor: Project:Uopsl Flowstation Owner Block:Opl 280, Okwuibome Field, Nigeria. Title:Data Sheet For Level Gauge (Reflex Type)Document4 pagesContractor: Project:Uopsl Flowstation Owner Block:Opl 280, Okwuibome Field, Nigeria. Title:Data Sheet For Level Gauge (Reflex Type)BABILIN VNo ratings yet

- Re29215 2005-09Document20 pagesRe29215 2005-09juan camilo gutierrezNo ratings yet

- ZDB - Re25751 - 2005-10Document8 pagesZDB - Re25751 - 2005-10Tayfun GunalNo ratings yet

- L6234 3 Fazlı Motor SürücüDocument10 pagesL6234 3 Fazlı Motor SürücüEngin UzunNo ratings yet

- Pressure Relief Valve, Pilot Operated, With Pulling FunctionDocument12 pagesPressure Relief Valve, Pilot Operated, With Pulling FunctionMohamed HusseinNo ratings yet

- Inlet Modules Model Code: ExampleDocument1 pageInlet Modules Model Code: ExamplemhasansharifiNo ratings yet

- Proportional 2-Way Flow Control Cartridge M22 X 1,5: Direct Operated Q 25 L/min Q 25 L/min P 350 BarDocument4 pagesProportional 2-Way Flow Control Cartridge M22 X 1,5: Direct Operated Q 25 L/min Q 25 L/min P 350 Barbiomed2083No ratings yet

- Van Rexroth DBDS 6Document16 pagesVan Rexroth DBDS 6Phong DuongNo ratings yet

- Anderson GreenwodDocument6 pagesAnderson Greenwoding.henrypcruzNo ratings yet

- K52 Master ChartDocument1 pageK52 Master ChartSinggih KurniawanNo ratings yet

- Reducteurs DRRP Bosch Rexroth Hydraulique BDocument4 pagesReducteurs DRRP Bosch Rexroth Hydraulique BNguyễn Minh NhấtNo ratings yet

- Re26411 2010-08Document24 pagesRe26411 2010-08wag008No ratings yet

- Solenoid Operated Poppet Valve Cartridge M18 X 1,5: Direct Operated 2/2-And 3/2-Way Q 40 L/min P 350 BarDocument4 pagesSolenoid Operated Poppet Valve Cartridge M18 X 1,5: Direct Operated 2/2-And 3/2-Way Q 40 L/min P 350 Bardani sanNo ratings yet

- Proportional Flow Control Valve, Without Position Control: List of Contents FeaturesDocument16 pagesProportional Flow Control Valve, Without Position Control: List of Contents FeaturesAsifNo ratings yet

- Service Manual Pioneer CDJ 2000-2 (RRV4163) (2010)Document28 pagesService Manual Pioneer CDJ 2000-2 (RRV4163) (2010)GiancaNo ratings yet

- Pressure Safety Valve-Preliminary Sizing: Input DataDocument6 pagesPressure Safety Valve-Preliminary Sizing: Input DataPIDNo ratings yet

- Re 29184-Xe 2021-02Document12 pagesRe 29184-Xe 2021-02emreali1No ratings yet

- Check Valve Hydraulically Pilot Operated PDFDocument8 pagesCheck Valve Hydraulically Pilot Operated PDFnemi90No ratings yet

- Re27518 PDFDocument6 pagesRe27518 PDFAdrianaNo ratings yet

- Proportional Pressure Reducing Valve, Pilot Operated Types DRE and ZDREDocument10 pagesProportional Pressure Reducing Valve, Pilot Operated Types DRE and ZDREPatrick ByronNo ratings yet

- Shimadzu UD-150L X-Ray - Installation GuideDocument35 pagesShimadzu UD-150L X-Ray - Installation GuideLuis Fernando Garcia S100% (1)

- 4/2-Way Spool Valves With Solenoid Operation Type KKDER1Document8 pages4/2-Way Spool Valves With Solenoid Operation Type KKDER1nemi90No ratings yet

- Proportional Pressure Reducing Valve, Pilot-Operated: RE 29282, Edition: 2019-02, Bosch Rexroth AGDocument16 pagesProportional Pressure Reducing Valve, Pilot-Operated: RE 29282, Edition: 2019-02, Bosch Rexroth AGRonald Rayme VenturaNo ratings yet

- Reactor HOJA DE DATOSDocument4 pagesReactor HOJA DE DATOSRodrigo GraciaNo ratings yet

- Pressure Safety Valve-Preliminary Sizing: Input DataDocument5 pagesPressure Safety Valve-Preliminary Sizing: Input DataTun Naing WinNo ratings yet

- Proportional Flow Control Valve, With Inductive Position TransducerDocument16 pagesProportional Flow Control Valve, With Inductive Position TransducerАлександр БулдыгинNo ratings yet

- JB Grouping 2Document18 pagesJB Grouping 2mukesh_kht1No ratings yet

- 3/2-Way Spool Valves With Solenoid Operation Type KKDER1Document8 pages3/2-Way Spool Valves With Solenoid Operation Type KKDER1nemi90No ratings yet

- TPS5125Document21 pagesTPS5125Shaun Dwyer Van HeerdenNo ratings yet

- Water and Winch Pilot Prportional ValveDocument8 pagesWater and Winch Pilot Prportional ValvePankaj RamoleNo ratings yet

- TDS ARGO HYTOS PRM6 10 Proportional Directional Control Valves EngDocument20 pagesTDS ARGO HYTOS PRM6 10 Proportional Directional Control Valves EngRamu PamuruNo ratings yet

- Pressure Shut-Off Valve, Pilot Operated Types DA and DAWDocument12 pagesPressure Shut-Off Valve, Pilot Operated Types DA and DAWÂnderson Silva BrasilNo ratings yet

- 150 MW Reheat LP-A1Document4 pages150 MW Reheat LP-A1DeepikaNo ratings yet

- Valvula de Freio L50Document4 pagesValvula de Freio L50adelmomouraNo ratings yet

- Rexroth Relief ValveDocument10 pagesRexroth Relief ValveAdnanNo ratings yet

- Using The ASME VIII-1 Nozzle F Factor (UG-37)Document8 pagesUsing The ASME VIII-1 Nozzle F Factor (UG-37)Liu YangtzeNo ratings yet

- Proportional Pressure Reducing Cartridge M22 X 1,5Document4 pagesProportional Pressure Reducing Cartridge M22 X 1,5Евгений ШкарупеловNo ratings yet

- HTTP WWW - Documentation.emer... Bulletins 0029en VSFL BulDocument8 pagesHTTP WWW - Documentation.emer... Bulletins 0029en VSFL BulRktBatamNo ratings yet

- Válvula Limitadora Proporcional Kcg-KacgDocument14 pagesVálvula Limitadora Proporcional Kcg-KacgNíkolas BorgesNo ratings yet

- Level Transmitter - DP TypeDocument1 pageLevel Transmitter - DP TypeSreejesh SundaresanNo ratings yet

- DVP - Special RegisterDocument12 pagesDVP - Special RegisterthiagoNo ratings yet

- F5C UkDocument4 pagesF5C UkJas SumNo ratings yet

- RE27551 Ckeck-Q-meterDocument10 pagesRE27551 Ckeck-Q-meterEmrah BinayNo ratings yet

- D D D D D D D D D D: LP211, LP311 Low-Power Differential Comparators With StrobesDocument13 pagesD D D D D D D D D D: LP211, LP311 Low-Power Differential Comparators With Strobesyassine yassineNo ratings yet

- MRU-Domestic 22437775 Issue 04Document92 pagesMRU-Domestic 22437775 Issue 04jorge luisNo ratings yet

- R900564519 Valvula Retencion Rexroth Z2SRK6Document4 pagesR900564519 Valvula Retencion Rexroth Z2SRK6soniamargarita22021995No ratings yet

- Van Nap LT06Document3 pagesVan Nap LT06hoiNo ratings yet

- Final End User Data Sheets 15 Valves Tor Deshy Rev1Document15 pagesFinal End User Data Sheets 15 Valves Tor Deshy Rev1Ghofrane HNo ratings yet

- FST Service Info DPS1-8 - EN-20190801-TT - pdf-2Document10 pagesFST Service Info DPS1-8 - EN-20190801-TT - pdf-2odie.bonifacioNo ratings yet

- PSR170 DiagramaDocument1 pagePSR170 DiagramaAyala KarlNo ratings yet

- Re64623 2006-6Document12 pagesRe64623 2006-6kny geNo ratings yet

- Solution Manual for an Introduction to Equilibrium ThermodynamicsFrom EverandSolution Manual for an Introduction to Equilibrium ThermodynamicsNo ratings yet

- Barbour IndexDocument5 pagesBarbour IndexchuckfestNo ratings yet

- Ic 7410Document108 pagesIc 7410Luciano HoraNo ratings yet

- Web Service Description Language (WSDL)Document29 pagesWeb Service Description Language (WSDL)Pradeep GurunathanNo ratings yet

- Technical Catalogue: June JuneDocument9 pagesTechnical Catalogue: June JunehaggNo ratings yet

- Burj Khalifa Case StudyDocument10 pagesBurj Khalifa Case StudyVishwajeet PatilNo ratings yet

- Prof. G.Ram Reddy Marg, Road No.46. Jubilee Hills, Hyderabad - 500 033 AssignmentsDocument16 pagesProf. G.Ram Reddy Marg, Road No.46. Jubilee Hills, Hyderabad - 500 033 Assignmentskesava_vinilaNo ratings yet

- TH Solutions Feedback Oscillators October 2019.PDF Version 1Document2 pagesTH Solutions Feedback Oscillators October 2019.PDF Version 1Nida Bagoyboy NatichoNo ratings yet

- 18 Hole Golf Course Planned For San Cristobal, GalapagosDocument2 pages18 Hole Golf Course Planned For San Cristobal, GalapagosSalvaGalapagosNo ratings yet

- Level Transmitter CalibrationDocument6 pagesLevel Transmitter CalibrationrichadNo ratings yet

- SY-365 SANSY365KEE100208 - 14SY036B07888 - enDocument356 pagesSY-365 SANSY365KEE100208 - 14SY036B07888 - enSodalita Mineração71% (7)

- Corporate Responsibility: Using Our Expertise To Build A Stronger and Safer SocietyDocument52 pagesCorporate Responsibility: Using Our Expertise To Build A Stronger and Safer SocietyHuening KaiNo ratings yet

- HCPL-7800A: Isolation AmplifierDocument9 pagesHCPL-7800A: Isolation AmplifierkarkonNo ratings yet

- MGT One Minute Manager SummaryDocument5 pagesMGT One Minute Manager SummaryJitendra SinghNo ratings yet

- 2wh Electro Mechanical 1st Circular - Nov'22Document2 pages2wh Electro Mechanical 1st Circular - Nov'22Anish KumarNo ratings yet

- Blinding Concrete Works Contents Revised 19-04-16RDocument3 pagesBlinding Concrete Works Contents Revised 19-04-16RJoel Alcantara100% (1)

- Induction Motor BasicsDocument19 pagesInduction Motor BasicsPUSHPAN DAHARWALNo ratings yet

- D' FCK B Fyk D: Example1) Determine The Ultimate Moment Carried by The Beam Section Shown BelowDocument3 pagesD' FCK B Fyk D: Example1) Determine The Ultimate Moment Carried by The Beam Section Shown BelowMuaz HararNo ratings yet

- Virginia D. Nazarea, Robert E. Rhoades, Jenna E. Andrews-Swann-Seeds of Resistance, Seeds of Hope - Place and Agency in The Conservation of Biodiversity-University of Arizona Press (2013) PDFDocument313 pagesVirginia D. Nazarea, Robert E. Rhoades, Jenna E. Andrews-Swann-Seeds of Resistance, Seeds of Hope - Place and Agency in The Conservation of Biodiversity-University of Arizona Press (2013) PDFBarbaraBartl100% (1)

- Appendix R Global GPDS AcronymsDocument1 pageAppendix R Global GPDS AcronymscaioltbgNo ratings yet

- People Soft Bundle Release Note 9 Bundle18Document24 pagesPeople Soft Bundle Release Note 9 Bundle18rajiv_xguysNo ratings yet

- วิชามาร ใน GoogleDocument2 pagesวิชามาร ใน Googleนู๋ตริน สบายใจNo ratings yet

- 0417 w14 Ms 2Document11 pages0417 w14 Ms 2murtaza123No ratings yet

- Sensors and Software GPR Manual PDFDocument286 pagesSensors and Software GPR Manual PDFLuis Alberto Aliaga Vásquez0% (1)

- Installing Moodle On Windows Server 2008 R2 x64Document17 pagesInstalling Moodle On Windows Server 2008 R2 x64alex_pearceNo ratings yet

- Spero Split AC Option - 1 QuoteDocument18 pagesSpero Split AC Option - 1 QuotesperoNo ratings yet

- TICOM Vol. 2 - Notes On German High Level CryptographyDocument103 pagesTICOM Vol. 2 - Notes On German High Level CryptographyRobert ValeNo ratings yet

- Dipti ProjDocument43 pagesDipti ProjAnkita TolasariaNo ratings yet

- 5p60 Chassis Multi Norma ChinoDocument1 page5p60 Chassis Multi Norma ChinoRicardo Chaman ChavezNo ratings yet

- Asus P4pe2Document64 pagesAsus P4pe2Agsa MandiriNo ratings yet

- Sikadur Injectokit LV - MSDSDocument7 pagesSikadur Injectokit LV - MSDSMani SainiNo ratings yet