Professional Documents

Culture Documents

CG Unified

Uploaded by

Don BruwerCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

CG Unified

Uploaded by

Don BruwerCopyright:

Available Formats

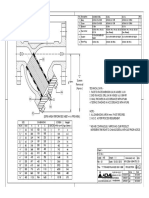

UNIFIED PLUG, RING

AND CALIPER THREAD GAUGES The types of gauges used are

COVENTRY GAUGE

COVENTRY GAUGE

SCREW PLUGS SCREW RINGS CALIPERS

the same as for ISO threads,

described on page 156.

Gauges for testing Unified SCREW PLUGS SCREW RINGS CALIPERS Gauges can be supplied to

threads to BS 1580:Parts comply with the

1&2:1962, requirements of the

BS 1580:Part 3: 1965; and American National Standards

BS 919:Part 1:1960. Institution specification

BS 1580: Pts 1&2:1962 ANSI/ASME B1.1 1989 for

specifies details of product product threads, and B1.2 GO NOGO ‘E’ GO NOGO ROLLER KNIFE

threads. (The basic profile is 1983 for gauges. Class of fit Class of fit Class of fit Class of fit

the same as that for ISO The designated SIZE 2B 2B 2B 2A 2A ANY ANY

threads as illustrated on GO NOGO ‘E’ GO NOGO ROLLER KNIFE diameter/pitch combinations N°0-80 UNF 0001 0002 0001B 0800 0801 1800 2000

page 156). The standard Class of fit Class of fit Class of fit Class of fit are similar to those in N°1-72 UNF 0003 0004 0003B 0802 0803 1801 2001

includes nominal sizes and SIZE 2B 2B 2B 2A 2A ANY ANY

limits of size for standard BS 1580, with similar N°2-64 UNF 0006 0007 0006B 0804 0805 1802 2002

threads for 1A, 2A and 3A N°1-64 UNC 0070 0071 0070B 0860 0861 1830 2030 allowances and classes of fit. N°3-56 UNF 0008 0009 0008B 0806 0807 1803 2003

for external threads, and 1B, N°2-56 UNC 0072 0073 0072B 0862 0863 1831 2031 The gauging philosophy N°4-48 UNF 0010 0011 0010B 0808 0809 1804 2004

2B, and 3B for internal N°3-48 UNC 0074 0075 0074B 0864 0865 1832 2032 however in B1.2 differs from N°5-44 UNF 0013 0014 0013B 0810 0811 1805 2005

threads in the following N°4-40 UNC 0076 0077 0076B 0866 0867 1833 2033 the British system. In the N°6-40 UNF 0015 0016 0015B 0812 0813 1806 2006

sizes:- N°5-40 UNC 0079 0080 0079B 0868 0869 1834 2034 ANSI system generally the N°8-36 UNF 0017 0018 0017B 0814 0815 1807 2007

N°6-32 UNC 0081 0082 0081B 0870 0871 1835 2035 gauging limits are contained N°10-32 UNF 0019 0020 0019B 0816 0817 1808 2008

UNC N°8-32 UNC 0084 0085 0084B 0872 0873 1836 2036 within the product tolerance, N°12-28 UNF 0022 0023 0022B 0818 0819 1809 2009

1/4”-28

(coarse pitch) N°10-24 UNC 0087 0088 0087B 0874 0875 1837 2037 whereas in the British system UNF 0024 0025 0024B 0820 0821 1810 2010

5/16”-24

from 1/4” to 4” dia. N°12-24 UNC 0090 0091 0090B 0876 0877 1838 2038 the gauging limits may UNF 0027 0028 0027B 0822 0823 1811 2011

3/8”-24

1/4”-20 UNC 0092 0093 0092B 0878 0879 1839 2039 transgress the minimum UNF 0030 0031 0030B 0824 0825 1812 2012

UNF 5/16”-18 UNC 0095 0096 0095B 0880 0881 1840 2040 material limit. Further, the 7/16”-20 UNF 0033 0034 0033B 0827 0828 1813 2013

1/2”-20

(fine pitch) 3/8”-16 UNC 0098 0099 0098B 0882 0883 1841 2041 ANSI standard specifies that UNF 0035 0036 0035B 0829 0830 1814 2014

9/16”-18

from 1/4” to 11/2” dia. 7/16”-14 UNC 0100 0101 0010B 0884 0885 1842 2042 the major diameter of the UNF 0038 0039 0038B 0831 0832 1815 2015

5/8”-18

1/2”-13 UNC 0103 0104 0103B 0886 0887 1843 2043 Not Go plug gauge is UNF 0041 0042 0041B 0833 0834 1816 2016

UNEF 3/4”-16

9/16”-12 UNC 0106 0107 0106B 0888 0889 1844 2044 truncated to high UNF 0044 0045 0044B 0835 0836 1817 2017

(extra fine pitch) 5/8”-11 UNC 0109 0110 0109B 0890 0891 1845 2045 addendum, whilst the British 7/8”-14 UNF 0047 0048 0047B 0838 0839 1818 2018

from 1/4” to 111/16” dia. 3/4”-10 UNC 0111 0112 0111B 0892 0893 1846 2046 standard specifies low 1”-12 UNF 0050 0051 0050B 0841 0842 1819 2019

7/8”-9 UNC 0113 0114 0113B 0895 0896 1847 2047 addendum truncation. 11/8”-12 UNF 0052 0053 0052B 0844 0845 1820 2020

UN

1”-8 UNC 0116 0117 0116B 0898 0899 1848 2048 11/4”-12 UNF 0055 0056 0055B 0847 0848 1821 2021

(constant pitch) for The regular checking of 13/8”-12 UNF 0058 0059 0058B 0850 0851 1822 2022

11/8”-7 UNC 0119 0120 0119B 0901 0902 1849 2049

4,6,8,12,16,20,28, gauges in constant use is 11/2”-12 UNF 0060 0061 0060B 0853 0855 1823 2023

11/4”-7 UNC 0122 0123 0122B 0904 0905 1850 2050

and 32 tpi for various important, and should be

13/8”-6 UNC 0125 0126 0125B 0907 0908 1851 2051

diameters as specified. carried out as for ISO

11/2”-6 UNC 0128 0129 0128B 0910 0911 1852 2052

gauges.

Allowances

N°12-32 UNEF 2232 2233 2233B - - - -

(deviation from basic size) 1/4”-32 UNEF 2200 2201 2200B 2300 - - -

1A and 2A provide allowances of 30% of the Classes of fit 5/16”-32 UNEF 0130 0131 0130B 0913 - - -

effective diameter tolerances of 2A external threads. 1A/lB are used where easy assembly is required. 3/8”-32 UNEF 0132 0133 0132B 0914 - - -

3A is basic (no allowance). 2AG is 0.001” smaller on 2A/2B are the classes used for the majority of 7/16”-28 UNEF 0134 0135 0134B 0915 - - -

diameter to provide for plating to finish at 2A. general engineering purposes. 3A/3B apply to 1/2”-28 UNEF 0136 0137 0136B 0916 - - -

(0.001” on diameter will allow for an average deposit threads requiring a closer fit, and are only used 9/16”-24 UNEF 0138 0139 0138B 0917 - - -

of 0.00025”). 1B, 2B and 3B for internal threads are when a close accuracy of form and pitch are 5/8”-24 UNEF 2202 2203 2202B 2302 2303 - -

all basic. Before plating threads are not designated. required. 1/16”-24 UNEF 2204 2205 2204B 2304 - - -

They are referred to as before plating, and are 0.001” 3/4”-20 UNEF 2206 2207 2206B 2306 2307 - -

larger on diameter than basic size. BS 1580:Pt 3:1965 specifies nominal sizes and 13/16”-20 UNEF 2208 2209 2208B 2308 - - -

limits of size for standard threads for 2A and 3A 7/8”-20 UNEF 2210 2211 2210B 2310 2311 - -

for external threads, and 2B and 3B for internal 15/16”-20 UNEF 2212 2213 2212B 2312 - - -

threads for UNC, UNF, and UNEF for threads 1”-20 UNEF 2214 2215 2214B 2314 2315 - -

below 1/4” diameter. The allowances and classes

158 1B of fit are the same as above.

11/16”-18

11/8”-18

UNEF

UNEF

2216

2218

2217

2219

2216B

2218B

2316

2318

-

2319

-

-

-

-

159

NUT 2B

3B BS 919:Pt 1:1960 specifies the limits for gauges 13/16”-18 UNEF 2220 2221 2220B 2320 - - -

for testing the product thread. The basis for 11/4”-18 UNEF 2222 2223 2222B 2322 - - -

O ➤ O determining the gauge limits is the 15/16”-18 UNEF 2224 2225 2224B 2324 - - -

3A

Allowance 1A 2A diameter/pitch. Generally, the larger the 13/8”-18 UNEF 2226 2227 2226B 2326 - - -

2AG

BOLT

diameter, and coarser the pitch, the larger the 17/16”-18 UNEF 2228 2229 2228B 2328 - - -

gauge limits within defined diameter/pitch 11/2”-18 UNEF 2230 2231 2230B 2330 - - -

bands. 19/16”-18 UNEF 2238 - - - - - -

Allowances for 1A and 2A are the same 15/8”-18 UNEF 2236 2237 2236B - - - -

Product tolerance: 1 > 2 > 3 111/16”-18 UNEF 2234 2235 2234B - - - -

For more information visit www.coventrygauge.co.uk Tel: 08708 50 90 50 Fax: 08708 50 90 60

You might also like

- BMI Division ... : Iso Metric Screw ThreadsDocument10 pagesBMI Division ... : Iso Metric Screw ThreadsAbdul Qadir TambeNo ratings yet

- Is 554Document3 pagesIs 554Nisarg PandyaNo ratings yet

- Eds G 1101Document6 pagesEds G 1101aldairlopesNo ratings yet

- Identification of Hy-Lok Metric Tube Fittings From FractionalDocument3 pagesIdentification of Hy-Lok Metric Tube Fittings From FractionalJit BNo ratings yet

- BS Iso 21358-2007Document12 pagesBS Iso 21358-2007m 418No ratings yet

- MAM STD - B3 - 02 - 17 - 04 - Arc WeldingDocument3 pagesMAM STD - B3 - 02 - 17 - 04 - Arc WeldingMohanrajMJNo ratings yet

- Indian Standard: Hexagon Head Bolts, Screws and Nuts of Product Grade CDocument12 pagesIndian Standard: Hexagon Head Bolts, Screws and Nuts of Product Grade CPrasenjit DeyNo ratings yet

- Repairs and Maintenance: Service ManualDocument152 pagesRepairs and Maintenance: Service ManualCarlosNo ratings yet

- Indian Standard: Hexagon Head Bolts, Screws and Nuts of Product Grades A and BDocument6 pagesIndian Standard: Hexagon Head Bolts, Screws and Nuts of Product Grades A and BJignesh TrivediNo ratings yet

- Tee and Strap Hinges - Spectftcation: (Fourth Revision)Document11 pagesTee and Strap Hinges - Spectftcation: (Fourth Revision)kamlesh kumarNo ratings yet

- BS 1936-2 1991Document16 pagesBS 1936-2 1991Jonicus-DextoreNo ratings yet

- Design StandardsDocument14 pagesDesign StandardsS SathiyarubanNo ratings yet

- Length Standards EngDocument2 pagesLength Standards EngGerhard VNo ratings yet

- Figure 740 GRINNELL Rapid Installation Pivot-Bolt (GRIP) Rigid CouplingDocument4 pagesFigure 740 GRINNELL Rapid Installation Pivot-Bolt (GRIP) Rigid CouplingСергей КолесниковNo ratings yet

- Specification FOR Sprockets For Sugar Industry .: Indian StandardDocument2 pagesSpecification FOR Sprockets For Sugar Industry .: Indian StandardShrinivas BartakkeNo ratings yet

- Nuts & Bolts CEB SpecDocument12 pagesNuts & Bolts CEB SpecHemantha BalasuriyaNo ratings yet

- Is 10685-1983 (R.a. 2019)Document3 pagesIs 10685-1983 (R.a. 2019)HARIOM INSTRU-LABSNo ratings yet

- Notes:: FV-01A FV-01BDocument1 pageNotes:: FV-01A FV-01BomarNo ratings yet

- Is 1364 PDFDocument12 pagesIs 1364 PDFpRAVIN0% (1)

- Ijdc 621.88 211: Bureau OF Indian StandardsDocument11 pagesIjdc 621.88 211: Bureau OF Indian StandardsJignesh TrivediNo ratings yet

- WC - Is 12817Document10 pagesWC - Is 12817SanthoshKumarSharmaCHNo ratings yet

- Is 903-1993Document12 pagesIs 903-1993dinesh399000No ratings yet

- Aust Steel Cat - 04 Pipe Fittings 11 - WEB PDFDocument52 pagesAust Steel Cat - 04 Pipe Fittings 11 - WEB PDFspamalstublieft1832No ratings yet

- 02-Pipe Fittings PDFDocument12 pages02-Pipe Fittings PDFSaid Ahmed SalemNo ratings yet

- Iso 6361 2 1990 en PDFDocument8 pagesIso 6361 2 1990 en PDFganmoses0% (1)

- PIPE THREADS Japanese PDFDocument2 pagesPIPE THREADS Japanese PDFOMAR CECEÑASNo ratings yet

- Bolt and Nut TableDocument6 pagesBolt and Nut TableSteve John PolandNo ratings yet

- AirlinerMagazine 1960-09Document12 pagesAirlinerMagazine 1960-09Alejandro Vigar100% (1)

- 5290 Landing ValveDocument11 pages5290 Landing ValveSachin KumarNo ratings yet

- Indian Standard: Hexagon Head Bolts, Screws and Nuts Of: Product Grade CDocument6 pagesIndian Standard: Hexagon Head Bolts, Screws and Nuts Of: Product Grade CJignesh TrivediNo ratings yet

- Pipe Threads (R) - 50Document2 pagesPipe Threads (R) - 50Karthik RajanNo ratings yet

- ASTM F.722 Rev 1982Document12 pagesASTM F.722 Rev 1982rendy simanjuntakNo ratings yet

- S131 en 13 ABS Red Stripe Inclinometric CasingDocument5 pagesS131 en 13 ABS Red Stripe Inclinometric CasingJuan PerezNo ratings yet

- Specification 23404Document3 pagesSpecification 23404Anandhu Mohan MNo ratings yet

- 1900 Series Safety Relief Valve Spec Data Gea20256dDocument100 pages1900 Series Safety Relief Valve Spec Data Gea20256dUmar SaeedNo ratings yet

- CG ISO MetricDocument1 pageCG ISO MetricDon BruwerNo ratings yet

- Tpping Screws - Chapter 4Document13 pagesTpping Screws - Chapter 4Miguel QueirosNo ratings yet

- Ancon MBT Couplers International VersionDocument14 pagesAncon MBT Couplers International VersionCarlotaGomesNo ratings yet

- Suction Hose Couplings For Fire Fighting Purposes - SpecificationDocument9 pagesSuction Hose Couplings For Fire Fighting Purposes - SpecificationRakesh SiempuNo ratings yet

- Information For StandardDocument4 pagesInformation For StandardMuhammad Alief OthmanNo ratings yet

- CPM FMR 22 002Document1 pageCPM FMR 22 002Mark Darrel AranasNo ratings yet

- Iso 4759Document63 pagesIso 4759NatashaAggarwal50% (2)

- Drill String StandardsDocument27 pagesDrill String StandardsMuhammad Shahrukh100% (2)

- GLV-Catalogue - Botil IndiaDocument18 pagesGLV-Catalogue - Botil IndiaHamza LamamraNo ratings yet

- Indian Standard: (Reaffirmed 2017)Document8 pagesIndian Standard: (Reaffirmed 2017)Anirban DasNo ratings yet

- Ball Valve: Two-Piece Floating Ball Valves Class 150 1/2" To 8"Document1 pageBall Valve: Two-Piece Floating Ball Valves Class 150 1/2" To 8"kapsarcNo ratings yet

- Jis B 0101 - 2013Document59 pagesJis B 0101 - 2013igormetaldataNo ratings yet

- Y STRAINER FLANGED END 150 Model PDFDocument1 pageY STRAINER FLANGED END 150 Model PDFsajanchaudhariNo ratings yet

- 150121013-1501 Multi Sera CalibratorDocument4 pages150121013-1501 Multi Sera CalibratorLab RSTiaraNo ratings yet

- Sae J78 PDFDocument15 pagesSae J78 PDFGabriel Macedo100% (2)

- Pc3 Clamp DrawingDocument4 pagesPc3 Clamp DrawingSujin SujiNo ratings yet

- Pc3 Clamp DrawingDocument4 pagesPc3 Clamp DrawingSujin SujiNo ratings yet

- Bare Strapare PDFDocument8 pagesBare Strapare PDFStanuta GheorgheNo ratings yet

- Bar Lock CouplerDocument2 pagesBar Lock CouplerlimyutNo ratings yet

- Is 206Document13 pagesIs 206inder palNo ratings yet

- IS - 730 (1978) - J, L, U Bolts StandardsDocument8 pagesIS - 730 (1978) - J, L, U Bolts StandardsbccharanNo ratings yet

- Steel and Its Heat Treatment: Bofors HandbookFrom EverandSteel and Its Heat Treatment: Bofors HandbookRating: 2.5 out of 5 stars2.5/5 (3)

- Pocket Guide to Flanges, Fittings, and Piping DataFrom EverandPocket Guide to Flanges, Fittings, and Piping DataRating: 3.5 out of 5 stars3.5/5 (22)

- HOBSON - Low Tensile Bolts and NutsDocument2 pagesHOBSON - Low Tensile Bolts and NutsJJ FloresNo ratings yet

- User Manual Itnc 530 670 - 388-22Document525 pagesUser Manual Itnc 530 670 - 388-22JAMES JUDYNo ratings yet

- 940-713-030.10 1224 Threading Machine ManDocument87 pages940-713-030.10 1224 Threading Machine ManOliver GhalebiNo ratings yet

- Parts Catalogue For Professional Embroidery Machine PR600 PR600 CDocument43 pagesParts Catalogue For Professional Embroidery Machine PR600 PR600 CcinthiaNo ratings yet

- Valvulas Alta Pressão MhaDocument4 pagesValvulas Alta Pressão MhaAna Carolina AlvesNo ratings yet

- Chapter 7 - MachiningDocument96 pagesChapter 7 - MachiningTejkumarigurungNo ratings yet

- WHAT ID FOUNDRY-WPS OfficeDocument17 pagesWHAT ID FOUNDRY-WPS OfficeGift NkwochaNo ratings yet

- Learjet 45 Illustrated Parts CatalogDocument4 pagesLearjet 45 Illustrated Parts CatalogJosueFerreiraNo ratings yet

- SolidCAM 2009 Turning Training CourseDocument156 pagesSolidCAM 2009 Turning Training Coursesiddik.s2582100% (1)

- Metric (ISO) Fasteners Metric (ISO) Nuts and Bolts: Torque SpecificationsDocument5 pagesMetric (ISO) Fasteners Metric (ISO) Nuts and Bolts: Torque SpecificationsSergeyNo ratings yet

- Design and Development of In-Pipe Inspection Robot ForDocument12 pagesDesign and Development of In-Pipe Inspection Robot ForJeziel SunielNo ratings yet

- Asme-B18 2 2Document38 pagesAsme-B18 2 2Ross HartwigNo ratings yet

- Makita 1050D Spare PartsDocument3 pagesMakita 1050D Spare PartsNunoNo ratings yet

- 7000X Grain HeaderDocument71 pages7000X Grain HeaderArmorNo ratings yet

- Bollhoff HeliCoil Plus Thread Repair KitsDocument40 pagesBollhoff HeliCoil Plus Thread Repair KitsAce Industrial SuppliesNo ratings yet

- Jis B-1186Document21 pagesJis B-1186nate anantathatNo ratings yet

- Hydraulic Fitting Thread Chart - Hydraulics DirectDocument23 pagesHydraulic Fitting Thread Chart - Hydraulics Directbass305No ratings yet

- Asme B18.2.6 2003Document11 pagesAsme B18.2.6 2003Jesse ChenNo ratings yet

- Cirrus: Illustrated Parts Catalog Models Sr22 and Sr22TDocument4 pagesCirrus: Illustrated Parts Catalog Models Sr22 and Sr22Thector joel lizarragaNo ratings yet

- Bellows X OverDocument3 pagesBellows X OverMichael AkhramovichNo ratings yet

- Gagemaker Catalog 4 2013 Spreads 62Document1 pageGagemaker Catalog 4 2013 Spreads 62Carlos Enrique Guzman CastellonNo ratings yet

- Design and Fabrication of Bolts (Full)Document26 pagesDesign and Fabrication of Bolts (Full)subinNo ratings yet

- Unit 2: Bench Work & FittingDocument24 pagesUnit 2: Bench Work & FittingRajvardhan Jaideva50% (4)

- Chapter DDocument70 pagesChapter DUpin BangNo ratings yet

- Examen SPTFOrdDocument4 pagesExamen SPTFOrdIRENE PASCUAL HERANZ BRONCHALONo ratings yet

- Threading: TF SeriesDocument52 pagesThreading: TF SeriesNguyen MinhNo ratings yet

- Threading - Rolling OperationDocument20 pagesThreading - Rolling Operationsarath6725No ratings yet

- Root Dia CalculationDocument12 pagesRoot Dia CalculationGuru MoorthiNo ratings yet

- OSS Hardware SectionDocument72 pagesOSS Hardware SectionglobalindosparepartsNo ratings yet

- Piezas Polipasto Dh-325Document32 pagesPiezas Polipasto Dh-325Alejandro Rodriguez FloresNo ratings yet