Professional Documents

Culture Documents

REVIEW for TEST 1

Uploaded by

Quốc Khởi NguyễnCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

REVIEW for TEST 1

Uploaded by

Quốc Khởi NguyễnCopyright:

Available Formats

UNI.

OF TECHNOLOGY – VNUHCM Course ID ME2007

FACULTY OF MECHANICAL ENGINEERING Duration 60 minutes Q. sheet code

DIVISION OF MACHINE DESIGN

Notes: Open-book exam

Question 1) (L.O.4.1):

The transmission system of a blender is given in Figure 1. An electrical motor with power of 8 kW and

rotation speed of 1450 rpm is used to run the system. Velocity ratios of the flat-belt drive and the helical-

gear drive are 2 and 2,5 respectively. Assuming there is no power lost in the transmission system.

Motor ×

Flat-belt drive

Helical-gear drive

Shaft I

× ×

× Blender

Shaft II

Coupling

Figure 1

Calculate the torques (Nmm) and rotation speed (rpm) of shafts I and II. (1,5 mark)

Question 2) (L.O.1.3):

Some parameters of the flat-belt drive shown in Figure 1 are given as follows:

- Diameter of the drive pulley D1 = 200 mm

- Wrap angle of the belt on the drive pulley α1 = 140°

- Coefficient of friction between the belt and the pulley f = 0,25

Determine:

a) Required initial tension to prevent belt slip. Note that the tension caused by centrifugal force is

ignored. (2,0 marks)

b) Force applies on shafts. Note that the belt drive has no belt tensioner. (0,5 mark)

Student’s ID: ............................ Student’s full name: .................................................................... Page 1/2

Question 3) (L.O.1.7):

Some parameters of the helical-gear drive shown in Figure 1 are given as follows:

- Gear normal module: mn = 3 mm

- Number of teeth of the drive gear: Z1 = 30

- Helical angle: β = 10°

- Pressure angle: αn = 20°

Draw force vectors apply on the helical-gear drive and calculate their magnitudes. (2,0 marks)

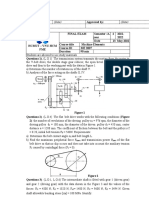

Question 4) (L.O.1.9):

A shaft contains a flat-belt pulley and a helical gear is shown in Figure 2. Note that unit of the given

dimensions is millimeter.

Magnitudes of the external forces are given as: Fb = 2000 N; Ft1 = 2500 N; Fr1 = 1000 N; Fa1 = 500 (N).

Pitch diameter of the helical gear is d1 = 100 mm.

200 250 250

Helical

Fb

gear

C

× ×

A B D

Fa1

Flat-belt pulley Ft1 Fr1

Figure 2

Determine:

a) Reaction forces at B and D positions. (1,5 mark)

b) Diagrams of bending moments (Mx, My) and torque (T) of the shaft. Note that moment/torque values

need to be shown on the diagrams. (1,5 mark)

c) Shaft diameter at critical section. Note that the allowable bending stress of the shaft’s material is

[σ] = 70 MPa. (1,0 mark)

--- END ---

You might also like

- POE EOC Review KeyDocument9 pagesPOE EOC Review KeyRyan CedergrenNo ratings yet

- General Physics II: Quarter 3Document15 pagesGeneral Physics II: Quarter 3Ashanty Cruz100% (3)

- Waves RevisionAnswersDocument50 pagesWaves RevisionAnswersOrisa THANAJARONo ratings yet

- Assignment 1Document3 pagesAssignment 1Ansuman SahooNo ratings yet

- Midterm Study GuideDocument7 pagesMidterm Study GuidejohntothepNo ratings yet

- Guide LTA Tunnel Lining Design PDFDocument176 pagesGuide LTA Tunnel Lining Design PDFMarlon50% (4)

- HK211 copyDocument5 pagesHK211 copyQuốc Khởi NguyễnNo ratings yet

- Machine Elements Gear Drive AnalysisDocument6 pagesMachine Elements Gear Drive Analysiszangue billy jamesNo ratings yet

- Problems s1Document6 pagesProblems s1zangue billy jamesNo ratings yet

- Kfupm 162 Me308 HW#1Document3 pagesKfupm 162 Me308 HW#1Ahmed Al-AwamiNo ratings yet

- Kinematics of MachinesDocument2 pagesKinematics of Machinessameer_m_daniNo ratings yet

- Apr May 2019Document6 pagesApr May 2019VenkadeshNo ratings yet

- 2010 - May - June-06ME44Document2 pages2010 - May - June-06ME44nitte5768No ratings yet

- Theory of Machines I 14 Dec. 2013Document3 pagesTheory of Machines I 14 Dec. 2013Rohit GarateNo ratings yet

- Gear Problem 1Document3 pagesGear Problem 1Ali EbNo ratings yet

- Design of Transmission ShaftsDocument5 pagesDesign of Transmission ShaftsHadidNo ratings yet

- 2012 Exam - PaperDocument7 pages2012 Exam - PaperKynaston StuddNo ratings yet

- Kinematics of Machinery May2004 Rr222105 Nr220304Document9 pagesKinematics of Machinery May2004 Rr222105 Nr220304Nizam Institute of Engineering and Technology LibraryNo ratings yet

- Gear TrainsDocument27 pagesGear TrainsThahir ShahNo ratings yet

- Kinematics Exam QuestionsDocument3 pagesKinematics Exam QuestionsShyloo GsaNo ratings yet

- Cycloidal GearboxDocument5 pagesCycloidal GearboxjohnjoviedoNo ratings yet

- King Fahd University of Petroleum & Minerals: College of Engineering Sciences Mechanical Engineering DepartmentDocument2 pagesKing Fahd University of Petroleum & Minerals: College of Engineering Sciences Mechanical Engineering DepartmentOmar RefeNo ratings yet

- ForcesDocument2 pagesForcesSpammerNo ratings yet

- DME2 Assignment 1 QDocument2 pagesDME2 Assignment 1 QAbhishek KulkarniNo ratings yet

- Kinematics of MachinesDocument2 pagesKinematics of Machinessameer_m_daniNo ratings yet

- Design of ShaftDocument5 pagesDesign of ShaftAnonymous oTrMzaNo ratings yet

- Design of Shaft PDFDocument5 pagesDesign of Shaft PDFAnonymous oTrMzaNo ratings yet

- Homework Project 23-24Document24 pagesHomework Project 23-24xdff5png8zNo ratings yet

- 5051 Apr 20Document3 pages5051 Apr 20Rithik Raj RanjuNo ratings yet

- Mechanics of Deformable BodiesDocument19 pagesMechanics of Deformable BodiesRAMKUMARNo ratings yet

- 18mec201t CT 2 QP and Ak Batch 1Document6 pages18mec201t CT 2 QP and Ak Batch 1SREEJAUN T J (RA2111025010015)No ratings yet

- r05310304 Kinematics of MachineryDocument10 pagesr05310304 Kinematics of MachinerySRINIVASA RAO GANTANo ratings yet

- 15A03402 Kinematics of MachinesDocument2 pages15A03402 Kinematics of Machinesrammohan reddyNo ratings yet

- Ebrahim I 2000Document13 pagesEbrahim I 2000namNo ratings yet

- ME 3227 Shaft ProjectDocument31 pagesME 3227 Shaft ProjectNeel NadparaNo ratings yet

- Mechatronics exam with questions on control systems and PLC applicationsDocument62 pagesMechatronics exam with questions on control systems and PLC applicationshaptooorNo ratings yet

- Machine Design Homework Due Jan 7Document2 pagesMachine Design Homework Due Jan 7Bryam CabreraNo ratings yet

- Ball Bearing FundamentalsDocument44 pagesBall Bearing Fundamentalssing_rNo ratings yet

- R15-MayJune 2015 Kinematics of MachineryDocument2 pagesR15-MayJune 2015 Kinematics of MachineryPraveen KumarNo ratings yet

- Mechanics Ii Time Allowed: 2 HoursDocument9 pagesMechanics Ii Time Allowed: 2 HourssubipuruNo ratings yet

- B57eb2 1ed LuDocument7 pagesB57eb2 1ed LuRashid AzadliNo ratings yet

- WWW - Manaresults.Co - In: Code: 13A01101 B.Tech I Year (R13) Regular & Supplementary Examinations May/June 2015Document3 pagesWWW - Manaresults.Co - In: Code: 13A01101 B.Tech I Year (R13) Regular & Supplementary Examinations May/June 2015Noor IslamNo ratings yet

- MSM Lecture 05Document36 pagesMSM Lecture 05RafaelNo ratings yet

- Btech 1 Sem Basics of Civil Engineering pbc1b102 2020Document2 pagesBtech 1 Sem Basics of Civil Engineering pbc1b102 2020bhaktiranjandas649No ratings yet

- Drive Fundamentals and DC Motor CharacteristicsDocument6 pagesDrive Fundamentals and DC Motor CharacteristicsKawooya CharlesNo ratings yet

- Modeling Vibration and Noise in A Gearbox: Created in COMSOL Multiphysics 5.6Document48 pagesModeling Vibration and Noise in A Gearbox: Created in COMSOL Multiphysics 5.6Soumya ChaphaleNo ratings yet

- Design of Machine Elements-IiDocument2 pagesDesign of Machine Elements-IiAmal GangadharanNo ratings yet

- EjercicioS RESISTENCIADocument7 pagesEjercicioS RESISTENCIAsalvadorNo ratings yet

- Shi 2013Document6 pagesShi 2013amirbakhtiary97No ratings yet

- Civil Services Examination 2013 Mechanical Engineering Paper 1Document9 pagesCivil Services Examination 2013 Mechanical Engineering Paper 1Navish KotwalNo ratings yet

- (Gatepsu - In) CE Paper 1 MAINS 2018 PDFDocument8 pages(Gatepsu - In) CE Paper 1 MAINS 2018 PDFAbhinavNo ratings yet

- IES Conventional Mechanical Engineering 2017 PAPER 2 PDFDocument12 pagesIES Conventional Mechanical Engineering 2017 PAPER 2 PDFravi khannaNo ratings yet

- ME 452 Machine Design II Midterm Exam SolutionsDocument20 pagesME 452 Machine Design II Midterm Exam SolutionsPotatoes123No ratings yet

- Design Shafts ModuleDocument37 pagesDesign Shafts ModuleJithin KNo ratings yet

- Verificación de Base de Chimenea de CLAUSDocument15 pagesVerificación de Base de Chimenea de CLAUSRoberto ChapadoNo ratings yet

- Me2220 Mkup Suppl 2017Document4 pagesMe2220 Mkup Suppl 2017Harish KrishnanNo ratings yet

- HK212Document7 pagesHK212Minh HuyNo ratings yet

- Proj 2021-2Document5 pagesProj 2021-2RAUL J COLON-OLIVERASNo ratings yet

- Attachment 1638181293Document5 pagesAttachment 1638181293Faizan AlyNo ratings yet

- Model Question Paper Design of Automotive Components: TED (21) - 5051 Revision 2021Document4 pagesModel Question Paper Design of Automotive Components: TED (21) - 5051 Revision 2021ashifsha930No ratings yet

- Icems 2019 8921951Document5 pagesIcems 2019 8921951Amir NazirNo ratings yet

- 142100008Document31 pages142100008Sumit PhadtareNo ratings yet

- Time: 3 Hours Total Marks: 70: Printed Pages: Sub Code: Paper Id: Roll NoDocument3 pagesTime: 3 Hours Total Marks: 70: Printed Pages: Sub Code: Paper Id: Roll NoAwanish SinghNo ratings yet

- 2021 TDDocument16 pages2021 TDhapop59109No ratings yet

- Internal Combustion Engine Bearings Lubrication in Hydrodynamic BearingsFrom EverandInternal Combustion Engine Bearings Lubrication in Hydrodynamic BearingsNo ratings yet

- OHVDocument2 pagesOHVQuốc Khởi NguyễnNo ratings yet

- System Linear EquationDocument123 pagesSystem Linear EquationQuốc Khởi NguyễnNo ratings yet

- DE2221Document3 pagesDE2221Khánh Tôn Thất PhúcNo ratings yet

- Chapter 2 Doolittle MethodDocument2 pagesChapter 2 Doolittle MethodQuốc Khởi NguyễnNo ratings yet

- System Linear EquationDocument123 pagesSystem Linear EquationQuốc Khởi NguyễnNo ratings yet

- Earthquake Resistant Design PhilosophyDocument55 pagesEarthquake Resistant Design PhilosophyShubham GuptaNo ratings yet

- Rheology Measurements of A Biomass Slurry: An Inter-Laboratory StudyDocument12 pagesRheology Measurements of A Biomass Slurry: An Inter-Laboratory StudyNicolaus AnelkaNo ratings yet

- SCI8 Q1M3 Lolomboy NHSDocument32 pagesSCI8 Q1M3 Lolomboy NHSAivie PastranaNo ratings yet

- Geodesy Flashcards - QuizletDocument11 pagesGeodesy Flashcards - QuizletTJ CabatinganNo ratings yet

- Introduction To ThermodynamicsDocument66 pagesIntroduction To ThermodynamicsMikaela Dela Cruz0% (1)

- Awg Ls-Dyna Modeling Guidelings Document v13-1 PDFDocument163 pagesAwg Ls-Dyna Modeling Guidelings Document v13-1 PDFManoj KumarNo ratings yet

- Physics 72 EEE RecitationDocument2 pagesPhysics 72 EEE RecitationRalph EvidenteNo ratings yet

- Impact TestingDocument27 pagesImpact Testingravi00098No ratings yet

- Erdenet Concentrate Desliming - Alternate gMAX4 Simulation PDFDocument1 pageErdenet Concentrate Desliming - Alternate gMAX4 Simulation PDFolziitulga batboldNo ratings yet

- Thesaurus of MechanismDocument26 pagesThesaurus of MechanismphopphoNo ratings yet

- DEm Lab ManualDocument59 pagesDEm Lab ManualO.p. BrarNo ratings yet

- Structural ConceptualizationDocument32 pagesStructural ConceptualizationNico Jalando-onNo ratings yet

- Objective: Activity1. Let's Make Waves! What Happens When Waves Pass By?Document4 pagesObjective: Activity1. Let's Make Waves! What Happens When Waves Pass By?Nina Angela Cate100% (1)

- Conduction Convection Radiation ReadingDocument5 pagesConduction Convection Radiation ReadingAnonymous vVsidh3nNo ratings yet

- 1974 - Impedance Functions For A Rigid Foundation On A Layered MediumDocument14 pages1974 - Impedance Functions For A Rigid Foundation On A Layered MediumdisotiriNo ratings yet

- Discussion: (Ahmad Izzuddin Bin Mohamad) (2018224724)Document2 pagesDiscussion: (Ahmad Izzuddin Bin Mohamad) (2018224724)Ahmad IzzuddinNo ratings yet

- Test En2 Website ExampleDocument5 pagesTest En2 Website Exampleahmad khanNo ratings yet

- SSC CGL Trigonometric TricksDocument3 pagesSSC CGL Trigonometric TricksAbhimanyu GuptaNo ratings yet

- 1.answers To Physics Question BankDocument18 pages1.answers To Physics Question BankMuhammad YousafNo ratings yet

- ANSYS DampingDocument8 pagesANSYS Dampingsuresh_501No ratings yet

- Metal Matrix Composites Focus On Alloys and Lattice Dynamics - Suzanne N. FitzgeraldDocument140 pagesMetal Matrix Composites Focus On Alloys and Lattice Dynamics - Suzanne N. FitzgeraldMahmood KhanNo ratings yet

- Anchor Bolts Interaction of Shear and Tension Loads PDFDocument4 pagesAnchor Bolts Interaction of Shear and Tension Loads PDFhriveroll2100% (1)

- Classical Mechanics (NETGATE) PDFDocument30 pagesClassical Mechanics (NETGATE) PDFSaley SaeedNo ratings yet

- DOM Model QuestionDocument2 pagesDOM Model QuestionSenthilkumar SubbiahNo ratings yet