Professional Documents

Culture Documents

Rumus Untuk Well Control

Uploaded by

nawar mhlwOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Rumus Untuk Well Control

Uploaded by

nawar mhlwCopyright:

Available Formats

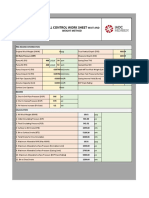

RUMUS UNTUK WELL CONTROL

Rounding Rules

1. Kill Mud Density = Round up to one decimal place (example: round up 12.21

ppg to 12.3 ppg, round up 11.67 ppg to 11.7 ppg)

2. Leak Off Test (LOT) = Round down to one decimal place (example: round

down 12.21 ppg to 12.2 ppg, round down 11.67 ppg to 11.6 ppg)

Once any of the above numbers have been calculated the rounded value must be

used in subsequent calculations.

Well Control Course Equations

1. Pressure P psi

Force(lb)

P

Area(in 2)

2. Pressure Gradient G psi/ft

G 0.052 MW(ppg)

3. Hydrostatic Pressure HP psi

HP MW(ppg) 0.052 TVD(ft)

Rev for UNPROK

RUMUS UNTUK WELL CONTROL

If you want to solve for

MW or TVD, fill in the

known information and

the equation is written

for you.

Pressure (psi)

MW(ppg)

0.052 Vetical Ht (ft)

Pressurepsi Pressure (psi)

Vertical Ht(ft)

0.052 MW(ppg)

MWppg X 0.052 X TVDft

5. Bottom Hole Pressure BHP psi

BHP HP SP under static conditions

BHP HP SP FrP while circulatin g

6. Formation Pressure FP psi

FP HP SIDPP

Assuming shut - in well and BHP equalized with formation pressure

7. Equivalent Circulating Density ECD ppg

Friction Pressure ann (psi)

ECD(PPG)

0.052 TVD bit (ft)

8. Leak-off Test Equivalent Mud Weight LOT ppg

Leak Off Pressure (psi)

LOT Leak off Test MW(ppg)

0.052 TVDshoe (ft)

RUMUS UNTUK WELL CONTROL

9. Maximum Initial Shut-In Casing Pressure MISICP psi

Upon initial shut-in only—Based on shoe fracture pressure, FR.

MISICP(psi) LOT(ppg) - Current MW(ppg) 0.052 TVD shoe (ft)

10. Kill Mud Weight to Balance Formation KMW ppg

SIDPP(psi)

KMW(ppg) Original MW(ppg)

0.052 TVD(ft)

11. Initial Circulating Pressure ICP psi

ICP(psi) SCR Pressure(p si) SIDPP(psi)

12. Final Circulating Pressure FCP psi

KMW(ppg)

FCP(psi) SCR Pressure(p si)

Original MW(ppg)

13. Surface To Bit Strokes strokes

Drill String Capacity(bbls)

Strokes

Pump Output(bbl stk)

14. Circulating Time min

Volume(bbls)

Minutes

Pump Output(bbl stk) SPM

15. Capacity Factor bbl/ft

Capacity(bbl/ft) Diameter 2(in) 1029.4

Rev for UNPROK

RUMUS UNTUK WELL CONTROL

16. Annulus Capacity Factor ACF bbl/ft

Casing/Open hole ID 2 (in) Work String OD2 (in)

ACF(bbl/ft)

1029.4

17. Pipe Displacement (Tube Only) bbl/ft

Pipe OD 2 (in) Pipe ID 2 (in)

Displaceme nt(bbl/ft)

1029.4

18. Steel Displacement bbl/ft

Steel Displacement = 0.00036 X Weight (lbs/ft)

19. Closed end pipe displacement bbl/ft

Pipe OD 2 (in)

Displacement(bbl/ft)

1029.4

20. Height of Influx ft

Influx volume(bbl )

Height(ft)

ACF(bbl/ft)

21. Approximate rate of gas migration ft/hr

Change in SICP(psi)

Rate(ft/hr)

MW(ppg) 0.052 Time for change(hr)

22. Weight Indicator reading when hung off lb

=Top drive / blocks

+Compensator

+Drill string air weight (RKB-ML)

+10,000 to 20,000lbs (approximate recommended tension)

RUMUS UNTUK WELL CONTROL

23. Approximate Barite Requirement For Weight-up 100 lb sx

15 Increase in MW(ppg)

Barite(sx) Volume to weight up(bbls)

35.0 - KWM(ppg)

24. Volume Gain From Slug bbl

Slug wt(ppg) current MW(ppg)

Gain(bbl) Volume of Slug(bbl)

current MW(ppg)

25. Triplex Pump Output (volume) bbl/stroke

Output(bbl/stk) 0.000243 Liner ID 2 (in) Stroke Length(in) Efficiency%

26. Pump Output bbl/min

Output(bbl/min) Output Volume(bb l/stk) Pump Speed(spm)

27. New Pump Pressure With New Pump Strokes psi

New Rate(spm)

2

New Pressure(p si) Original Pressure(p si)

Old Rate(spm)

28. Gas Pressure and Volume Relationship — Boyle’s Law

P 1 V 1 = P2 V 2 The Pressure (psi) of a gas bubble times its Volume (bbl) in

one part of the hole equals its Pressure times its Volume in another.

Disregards effects of Temperature (T) and gas compressibility (z)

P1V1 P1V1

P2 = V2 =

V2 or P2

Rev for UNPROK

RUMUS UNTUK WELL CONTROL

Accumulator sizing

29. Bottle Capacity Required (gals)

Bottle Volume(ga ls)

Volume Fluid Required(g als)

Precharge Pressure(p si) Precharge Pressure(p si)

Minimum Operating Presure(ps i) Maximum Operating Pressure(p si)

30. Volume Useable Fluid Available (gals)

Volume Useable Fluid(gals)

Precharge Pressure Precharge Pressure

Bottle Volume(ga ls)

Minimum Operating Pressure Maximum Operating Pressure

VOLUMETRIC METHOD CONSIDERATIONS

31. Mud Increment MI bbl

PI(psi) ACF(bbl/ft)

MI(bbl)

0.052 MW(ppg)

LUBRICATE AND BLEED METHOD

32. Lube Increment LI bbl

PI(psi) ACF(bbl/ft)

LI(bbl)

0.052 MW(ppg)

SNUBBING

33. Area in2

Area (in 2 ) Diameter 2 (in) .7854

RUMUS UNTUK WELL CONTROL

34. Pressure-Area Force Fp lb

π OD(in)2

Fp Well Head Pressure(psi)

4

Or

Fp Pipe OD 2 (in) .7854 Well Head Pressure(psi)

35. Snub Force SF lb

SF Fp Friction Force - W

b

Wb = Bouyed weight of string

36. Buoyed Weight of Tubulars Wb lb (open ended)

65.4 MW(ppg)

W (lb/ft) W (lb/ft)

b air 65.4

37. Buoyed Weight of Tubulars Wb lb (closed ended)

(no fluid in pipe)

2

Pipe OD (in)

Wb (lb/ft) Weight air (lb/ft) MW(ppg)

24.5

38. After filling the pipe, the Effective String Weight will be: Wb (closed ended)

(different fluids in pipe and annulus)

2 2

OD(in) Fluid Wt well (ppg) ID(in) Fluid Wt pipe (ppg)

W Air Wt(lb/ft) - -

b 24.5 24.5

NOTE: This is the GENERAL EQUATION for the Effective Buoyed Weight of the

String. It works regardless of the fluid that is inside or outside the pipe. If

the fluid is gas at fairly low pressure, use 0 lbs/gal for the fluid wt.

Rev for UNPROK

RUMUS UNTUK WELL CONTROL

39. The Balance Point occurs in unfilled pipe when the length of pipe run into the

well is:

Fp(lb)

L(ft)

OD(in)2 Fluid Wt well (ppg)

Air Wt(lb/ft) -

24.5

40. The Balance Point occurs in unfilled pipe when the length of pipe run into the

well is:

Fp (lb)

L(ft)

2

OD(in) Fluid Wt well (ppg) ID(in)2 Fluid Wt pipe (ppg)

Air Wt(lb/ft) -

24.5 24.5

41. Maximum Down Force on Jacks

Maximum Down Force(lb) .7 Critical Buckling Load(lb) from pipe data

42. Effective Area of Snubbing Jacks

Effective Area Number of Jacks .7854 ID 2cylinder - OD 2rod

(2 or 4)

43. Hydraulic Pressure to Snub psi

Hydraulic Pressure to Snub(psi)

Maximum Down Force(lb) EQ 41

Effective Areain) EQ 42

RUMUS UNTUK WELL CONTROL

Useful Equations

44. Mud weight from oAPI

Mud Weight(pp g) 1178.7/ API 131.5

45. Cutting Back or Weighting Up One Fluid with Another to Obtain Desired Fluid

Density

Volume of mixing fluid to add(bbl)

Starting MW(ppg) Desired MW(ppg

Volume of starting fluid(bbl)

Desired MW(ppg) Mixing Fluid(ppg)

46. Final Density of a Mixture of Fluids ppg

Final Fluid Wt(ppg)

Fluid Wt 1(ppg) Volume Fluid 1(gals) Fluid Wt 2(ppg) Volume Fluid 2(gals)

Volume Fluid 1(gals) Volume Fluid 2(gals)

Rev for UNPROK

You might also like

- Well Control EquationsDocument13 pagesWell Control EquationsMarkus LandingtonNo ratings yet

- Well Control EquationsDocument13 pagesWell Control EquationsCheaib HakkoumNo ratings yet

- Well Control EquationsDocument12 pagesWell Control EquationsMuhammad SaiedNo ratings yet

- Rumus Dasar Well ControlDocument2 pagesRumus Dasar Well Controlwindaru kusumaNo ratings yet

- Pre Record Information: Driller Method Well Control Work SheetDocument1 pagePre Record Information: Driller Method Well Control Work SheetTriana Priyo SunjoyoNo ratings yet

- HYDPRO - Drilling Hydraulics Model: Fluid PropertiesDocument2 pagesHYDPRO - Drilling Hydraulics Model: Fluid PropertiesjesusNo ratings yet

- Mekflu Lect4B Pumping System and Good PracticeDocument74 pagesMekflu Lect4B Pumping System and Good Practicebima0407No ratings yet

- LOT & Kill SheetDocument1 pageLOT & Kill SheetBaniNo ratings yet

- CV and Line Sizing For Steam CalculatorDocument2 pagesCV and Line Sizing For Steam CalculatorHiranthaNo ratings yet

- Plate Heat Exchanger Data SheetDocument2 pagesPlate Heat Exchanger Data SheetZUCEL ARLLETTE MAJUS CASTANEDANo ratings yet

- Well Control FormulasDocument5 pagesWell Control FormulasAugustin DumitriuNo ratings yet

- IWCF Formula Sheet - APIDocument4 pagesIWCF Formula Sheet - APIAwani Kester100% (1)

- Rumus Dasar Well Control-DikonversiDocument6 pagesRumus Dasar Well Control-Dikonversiwindaru kusumaNo ratings yet

- WorkBook - CalculationsDocument30 pagesWorkBook - CalculationsHunterNo ratings yet

- DEWALT HVACR Professional Reference Master EditionDocument24 pagesDEWALT HVACR Professional Reference Master EditionmatgarNo ratings yet

- IADC Formula Sheet: X X X + + ÷ X + X - ÷ XDocument5 pagesIADC Formula Sheet: X X X + + ÷ X + X - ÷ XMarwa ElghifaryNo ratings yet

- Kill SheetDocument4 pagesKill SheetAnwar FauzenNo ratings yet

- Spreadsheet - Gas Blanketed Tanks - Outbreathing Process CalculationsDocument12 pagesSpreadsheet - Gas Blanketed Tanks - Outbreathing Process Calculationsselva_maniaNo ratings yet

- QA-RD7A Formula Sheet Rev 3 - 2006Document4 pagesQA-RD7A Formula Sheet Rev 3 - 2006wandersaquaNo ratings yet

- LPBFP - Sizing Calculation LP HRSG Feed Pump - Doc PG DC 292 100 d603 - R 1Document8 pagesLPBFP - Sizing Calculation LP HRSG Feed Pump - Doc PG DC 292 100 d603 - R 1anbesivam87_49857255No ratings yet

- QA-RD7AE-V8 English API Formula SheetDocument4 pagesQA-RD7AE-V8 English API Formula Sheetadvantage025No ratings yet

- Centrifugal Comp Calc Without ImpellerDocument8 pagesCentrifugal Comp Calc Without Impellersohail1985100% (1)

- III. Basic CalculationDocument14 pagesIII. Basic Calculationdidin kenyalNo ratings yet

- Well Control EquationsDocument13 pagesWell Control EquationsShaho Abdulqader Mohamedali100% (1)

- Material Stream: A TGI: ConditionsDocument2 pagesMaterial Stream: A TGI: Conditionswilmar valeroNo ratings yet

- Refrigeration Formulas PDFDocument3 pagesRefrigeration Formulas PDFArif PurwadanaNo ratings yet

- Upstream-Downstream PCV 215 MMSCFD CaseDocument3 pagesUpstream-Downstream PCV 215 MMSCFD CaseerwinfsNo ratings yet

- Well Control Kill Sheet: (A) Well Data (C) Calculation (E) Drillpipe Pressure ScheduleDocument4 pagesWell Control Kill Sheet: (A) Well Data (C) Calculation (E) Drillpipe Pressure SchedulezhaoNo ratings yet

- Simulator Proficiency GuidelinesDocument4 pagesSimulator Proficiency GuidelinesBoedi SyafiqNo ratings yet

- Heat Exchanger Rating SheetDocument2 pagesHeat Exchanger Rating SheetZUCEL ARLLETTE MAJUS CASTANEDANo ratings yet

- Master Planning of Utility Compound and Preliminary Engineering Design (30% Design Level) (30% Design Level)Document4 pagesMaster Planning of Utility Compound and Preliminary Engineering Design (30% Design Level) (30% Design Level)bubbles82No ratings yet

- Pipeline Case 2 HydraulicDocument23 pagesPipeline Case 2 Hydraulicbimo wahyuNo ratings yet

- Mekanika Fluida 04 - Pumping System CurveDocument77 pagesMekanika Fluida 04 - Pumping System CurveAtha GrizzlyNo ratings yet

- EX-0035 Drilling - English API Formula Sheet THDocument4 pagesEX-0035 Drilling - English API Formula Sheet THPavin PiromNo ratings yet

- Data Sheet of Filtered WaterCentrifugal PumpDocument2 pagesData Sheet of Filtered WaterCentrifugal Pumpsajeesh5113699No ratings yet

- Enform Formulas Acronyms and Well Control FormsDocument22 pagesEnform Formulas Acronyms and Well Control FormsLuqman HadiNo ratings yet

- Project No. 16279S Project Name Bapco - JVTST: Calculation of Emissivity of Process GasDocument11 pagesProject No. 16279S Project Name Bapco - JVTST: Calculation of Emissivity of Process GasrajachemNo ratings yet

- Performance Galileo Mx521Document1 pagePerformance Galileo Mx521Juan AlarconNo ratings yet

- Pump Fit/Lot Weight Up Equivalent Circulating DensityDocument109 pagesPump Fit/Lot Weight Up Equivalent Circulating DensitynurmhNo ratings yet

- Pump Fit/Lot Weight Up Equivalent Circulating DensityDocument100 pagesPump Fit/Lot Weight Up Equivalent Circulating DensityGustavo Javier FloresNo ratings yet

- FGM Mud Log Book Jan 2022Document61 pagesFGM Mud Log Book Jan 2022ongcchemist gd chitraNo ratings yet

- Mud Log Book Jan 2022Document59 pagesMud Log Book Jan 2022ongcchemist gd chitraNo ratings yet

- Material Stream: Inlet Gas: ConditionsDocument51 pagesMaterial Stream: Inlet Gas: Conditionskuno pernicoNo ratings yet

- Pipeline Case 1 HydraulicDocument9 pagesPipeline Case 1 Hydraulicbimo wahyuNo ratings yet

- Well Control Work Sheet: Pre-Record InformationDocument4 pagesWell Control Work Sheet: Pre-Record InformationWilliam SumendapNo ratings yet

- Volume and StrokeDocument39 pagesVolume and StrokeHarpreetSinghNo ratings yet

- Steam Calculation On Basis of Flow-Temperature (1) 2222Document5 pagesSteam Calculation On Basis of Flow-Temperature (1) 2222hmaza shakeelNo ratings yet

- Formula Sheet - MetricDocument4 pagesFormula Sheet - MetricAlexander KlmNo ratings yet

- Foundation LoadingsDocument1 pageFoundation Loadingsmanish318No ratings yet

- Formulas For Wait and Weight Well Control MethodDocument5 pagesFormulas For Wait and Weight Well Control MethodHenry Brito100% (1)

- PR20140005 Daily Drilling ReportDocument60 pagesPR20140005 Daily Drilling ReportMakui Juralli Giménez LandínezNo ratings yet

- Venteo API 2000 (Amine)Document8 pagesVenteo API 2000 (Amine)Produccion VegetalNo ratings yet

- EX 0039 Well Intervention English API Formula SheetDocument2 pagesEX 0039 Well Intervention English API Formula SheetSauver la terreNo ratings yet

- Practical Class 1Document26 pagesPractical Class 1asel.muratttNo ratings yet

- UAS TekprodDocument17 pagesUAS TekprodMas RochmatanNo ratings yet

- Gate in Petroleum - Important Formulas: Abbreviations Used in This DocumentDocument4 pagesGate in Petroleum - Important Formulas: Abbreviations Used in This DocumentSHUBHAM SINGHNo ratings yet

- Technical Data Sheet For GIS 18-2-2022Document14 pagesTechnical Data Sheet For GIS 18-2-2022sami ul haqNo ratings yet

- Tarea 8 Bombas Damian A61610 Minor B06661Document7 pagesTarea 8 Bombas Damian A61610 Minor B06661Orlando Porras MoraNo ratings yet

- Cast Iron: Physical and Engineering PropertiesFrom EverandCast Iron: Physical and Engineering PropertiesRating: 5 out of 5 stars5/5 (1)

- Handbook of Heating, Ventilating and Air ConditioningFrom EverandHandbook of Heating, Ventilating and Air ConditioningRating: 4 out of 5 stars4/5 (6)

- Tugas BHS Inggris Explanation TextDocument4 pagesTugas BHS Inggris Explanation TextAnisyaf7No ratings yet

- Yongnuo 560 EX II Flash User ManualDocument1 pageYongnuo 560 EX II Flash User ManualEj CoombsNo ratings yet

- Termoformadora de Bandeja SunWell M1370L-HTPF PainelDocument40 pagesTermoformadora de Bandeja SunWell M1370L-HTPF PainelGleicianeLimaGomesNo ratings yet

- LC and Crystal Oscillator: Prepared By: Mrs. Nisha G R Asst. Professor Dept of ECE VCET, PutturDocument29 pagesLC and Crystal Oscillator: Prepared By: Mrs. Nisha G R Asst. Professor Dept of ECE VCET, PutturNisha Kotyan G RNo ratings yet

- Search by Xrays Applied Technology-CollimatorDocument10 pagesSearch by Xrays Applied Technology-CollimatorHashir SaeedNo ratings yet

- Q4 Science 9 - Module 1Document23 pagesQ4 Science 9 - Module 1Danilo Saliog67% (6)

- Iec 60038Document4 pagesIec 60038ZAHID IQBALNo ratings yet

- 01 - ED Technical Training Part 1Document76 pages01 - ED Technical Training Part 1Калин АнгеловNo ratings yet

- Energy Reports: Mostefa GhassoulDocument8 pagesEnergy Reports: Mostefa GhassoulEduardo DíazNo ratings yet

- Kinematics of CM 04 Material Time Derivatives PDFDocument4 pagesKinematics of CM 04 Material Time Derivatives PDFOgunfuye Samuel AbimbolaNo ratings yet

- Gough, Clenshaw, Pollard - Some Experiments On The Resistance of Metals To Fatigue Under Combined Stresses PDFDocument155 pagesGough, Clenshaw, Pollard - Some Experiments On The Resistance of Metals To Fatigue Under Combined Stresses PDFDavid C HouserNo ratings yet

- Chapter 3 (Laplace Transform)Document14 pagesChapter 3 (Laplace Transform)EmmanuelNo ratings yet

- Solar Swimming Pool HeatingDocument9 pagesSolar Swimming Pool HeatingAtmesh PoudyalNo ratings yet

- A Periodic Table of The Elements at Los Alamos National LaboratoryDocument3 pagesA Periodic Table of The Elements at Los Alamos National Laboratoryروشان فاطمة روشانNo ratings yet

- PR Calc Ellipse WKSHT - 00001Document4 pagesPR Calc Ellipse WKSHT - 00001Jose VillonaNo ratings yet

- Mechanics: Harmonic Oscillation of A String PendulumDocument4 pagesMechanics: Harmonic Oscillation of A String Pendulumfatjonmusli2016100% (1)

- AcousticsDocument6 pagesAcousticsShanisse AballaNo ratings yet

- Reflexw Manual A4 booklet-TRSDocument11 pagesReflexw Manual A4 booklet-TRSrichard.meinteilNo ratings yet

- CP1b Distance Time GraphsDocument22 pagesCP1b Distance Time GraphsMysticalNo ratings yet

- Satellite Comm. McqsDocument68 pagesSatellite Comm. McqsZephNo ratings yet

- Lesson Plan 3 ChemistryDocument10 pagesLesson Plan 3 ChemistryLeslayy CelizNo ratings yet

- EarthworksDocument26 pagesEarthworksRufa May Auingan YbiasNo ratings yet

- Naca Report 824Document265 pagesNaca Report 824Ivan FonsecaNo ratings yet

- Verderflex Rapide R5000 Pumps DatasheetDocument4 pagesVerderflex Rapide R5000 Pumps Datasheetprasadi.ariyadasaNo ratings yet

- 1 Sheet Fundamentals of Heat TransferDocument3 pages1 Sheet Fundamentals of Heat TransferManju MuruhanNo ratings yet

- This Study Resource Was: Introduction To Static ElectricityDocument3 pagesThis Study Resource Was: Introduction To Static Electricitykatelyn ibarraNo ratings yet

- CHAPTER 3 - Crystalline Structure of SolidsDocument63 pagesCHAPTER 3 - Crystalline Structure of SolidsAlex HunterNo ratings yet

- Cambridge International General Certificate of Secondary Education (9-1)Document20 pagesCambridge International General Certificate of Secondary Education (9-1)Pranav BISUMBHERNo ratings yet

- Compressive Strength and Deformation Capacity of Concrete Under Sustained Loading and Low Stress RatesDocument21 pagesCompressive Strength and Deformation Capacity of Concrete Under Sustained Loading and Low Stress RatesCamila HernandezNo ratings yet

- 4-Discovery of The Subatomic ParticlesDocument35 pages4-Discovery of The Subatomic ParticlesEdchel Espeña100% (1)