Professional Documents

Culture Documents

Tutorial Worm Gear

Uploaded by

pshretankCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Tutorial Worm Gear

Uploaded by

pshretankCopyright:

Available Formats

Tutorial Worm Gear

Q.1. A 2-start wormset has d = 50 mm, px = 10mm, mG = 22:1. Find the lead, lead angle,

worm-gear diameter, and centre distance. Will it self-lock? The input speed is 2200 rpm.

Determine the power transmitted and torques and forces in the mesh for the if it runs at

1000 worm rpm. Tw = 22.4 Nm, Tg = 492 Nm rated, Wt = 7028 N, Friction = 215 N

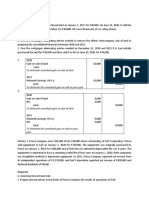

Q.2. A right-hand single-tooth hardened-steel (hardness not specified) worm as shown in

Figure 1 has a catalog rating of 2000 W at 600 rev/min when meshed with a 48-tooth

cast-iron gear. The axial pitch of the worm is 25 mm, the normal pressure angle is 14o,

the pitch diameter of the worm is 100 mm, and the face widths of the worm and gear are,

respectively, 100 mm and 50 mm. The figure shows bearings A and B on the worm shaft

symmetrically located with respect to the worm and 200 mm apart. Determine which

should be the thrust bearing, and find the magnitudes and directions of the forces exerted

by both bearings.

Q.3. The hub diameter and projection for the gear of Prob. 1 are 100 and 37.5 mm,

respectively. The face width of the gear is 50 mm. Locate bearings C and D on opposite

sides, spacing C 10 mm from the gear on the hidden face (see figure) and D 10 mm from

the hub face. Find the output torque and the magnitudes and directions of the forces

exerted by the bearings on the gearshaft.

Q.4. An ratio worm gear reducer is to be designed using a hardened-steel worm and a chill-

cast bronze gear. Center distance should be approximately 150 mm. The worm will be

driven by a 1200-rpm motor. Determine appropriate values of dw, dg, Zw, Zg, p, λ, and

φn. Estimate the power capacity and efficiency of the reducer. Can the worm be bored

for mounting on a separate shaft?

Q.5. Design a 7.0 kW 11:1 worm-gear speed-reducer mesh for a lumber mill planer feed drive

for 3- to 10-h daily use. A 1720-rev/min squirrel-cage induction motor drives the planer

feed (Ka = 1.25), and the ambient temperature is 21oC.

Q.6. A single-thread steel worm rotates at 1800 rev/min, meshing with a 24-tooth worm gear

transmitting 2.0 kW to the output shaft. The worm pitch diameter is 72 mm and the

tangential module of the gear is 6 mm. The normal pressure angle is 14.5o. The ambient

temperature is 21oC. The application factor is 1.25 and the design factor is 1; gear face

width is 50 mm, lateral case area 0.387 m2, and the gear is chill-cast bronze.

(a) Find the gear geometry.

(b) Find the transmitted gear forces and the mesh efficiency.

(c) Is the mesh sufficient to handle the loading?

(d) Estimate the lubricant sump temperature.

Q.7 Estimate the allowable gear wear load (WtG)all for the gearset of Q.5 using Buckingham’s

wear equation.

You might also like

- Tutorial Sheet-II MEC3110/317 (Machine Design II)Document4 pagesTutorial Sheet-II MEC3110/317 (Machine Design II)Prateeksha ShakyaNo ratings yet

- MD2 Model QuestionsDocument2 pagesMD2 Model Questionsmanish sharmaNo ratings yet

- Bevel and Worm GearsDocument1 pageBevel and Worm GearsDevansh ChhajlaniNo ratings yet

- MDDocument5 pagesMDYogesh DanekarNo ratings yet

- Machine Designe - IIDocument2 pagesMachine Designe - IIAndrea DouglasNo ratings yet

- Shaft Diameter Determination for Bending, Torque & Fatigue LoadsDocument1 pageShaft Diameter Determination for Bending, Torque & Fatigue LoadsMurali Krishnan NairNo ratings yet

- Me511 AssDocument2 pagesMe511 AssridwanmuhammadtajudeenNo ratings yet

- MD II Machine Design AssignmentsDocument5 pagesMD II Machine Design Assignmentsrishabhk28995No ratings yet

- Design of Machine Elements - IIDocument8 pagesDesign of Machine Elements - IIprasaad26No ratings yet

- Assignment No 1 NME 602 MD 2Document2 pagesAssignment No 1 NME 602 MD 2nitin_johri0% (1)

- 2017 AS (Summer) Sem VII Mech Engg Machine Design N Drawing IIDocument4 pages2017 AS (Summer) Sem VII Mech Engg Machine Design N Drawing IIMayur DhanokarNo ratings yet

- ME 331 - DESIGN OF MACHINE ELEMENTS EXAMDocument5 pagesME 331 - DESIGN OF MACHINE ELEMENTS EXAMarumugam_rNo ratings yet

- DMM Question BankDocument2 pagesDMM Question Bankzubair ahmedNo ratings yet

- Design of Spur Gear Tutorial No: - DateDocument18 pagesDesign of Spur Gear Tutorial No: - DateAkhilesh NavikNo ratings yet

- Machine Design-II EME602 2012-13Document4 pagesMachine Design-II EME602 2012-13nitin_johriNo ratings yet

- Design of Mechanical Drives w17Document4 pagesDesign of Mechanical Drives w17aniket ingle100% (1)

- Met401 Design of Machine Elements, December 2022Document4 pagesMet401 Design of Machine Elements, December 2022malluboy1729No ratings yet

- Iat-I QPDocument2 pagesIat-I QPBalaChandarNo ratings yet

- MDDocument2 pagesMDAbhijeet PramanikNo ratings yet

- DMM Ii (2015)Document35 pagesDMM Ii (2015)gorijalaNo ratings yet

- 01 Helical Gear ONLY ProblemsDocument2 pages01 Helical Gear ONLY Problemskamal0% (1)

- Question Bank - DMEDocument6 pagesQuestion Bank - DMEBdhdhshNo ratings yet

- DME - Assignment - IDocument3 pagesDME - Assignment - ISathis KumarNo ratings yet

- 353 35435 ME357 2011 4 2 1 Sheet MD2Document10 pages353 35435 ME357 2011 4 2 1 Sheet MD2adel nabhanNo ratings yet

- 13 ME AssignmentDocument2 pages13 ME AssignmentMuhammad Sharif JamaliNo ratings yet

- Btech Auto 5 Sem Design of Machine Components Pau5i101 2020Document2 pagesBtech Auto 5 Sem Design of Machine Components Pau5i101 2020Pagal KutaNo ratings yet

- Me 7 Sem Subject Design of Mechanical Drives Jun 2017Document2 pagesMe 7 Sem Subject Design of Mechanical Drives Jun 2017djniksthehearteditorNo ratings yet

- Me-1352 Design of Transmission SystemDocument7 pagesMe-1352 Design of Transmission Systemshujai cruise100% (1)

- Problems s4Document4 pagesProblems s4zangue billy jamesNo ratings yet

- WWW - Manaresults.Co - In: (Common To Ame, Me)Document3 pagesWWW - Manaresults.Co - In: (Common To Ame, Me)Vikranth DeepakNo ratings yet

- Time Allowed: 1.5 Hours Full Marks: 70: 604 (S) August 2021Document3 pagesTime Allowed: 1.5 Hours Full Marks: 70: 604 (S) August 2021Sourav BhowmikNo ratings yet

- MGM College of Engineering Assignment on Machine Design ProblemsDocument1 pageMGM College of Engineering Assignment on Machine Design ProblemsmrinalsinghrawatNo ratings yet

- Dme Question BankDocument4 pagesDme Question BankRavi Patil100% (1)

- Theoretical QuestionsDocument17 pagesTheoretical Questionsanbamech50% (2)

- MD-II Question BankDocument3 pagesMD-II Question BankAnonymous Pfi1bgrYNo ratings yet

- ME 308: Machine Design II: Second Semester (141) Problem Set # 1Document2 pagesME 308: Machine Design II: Second Semester (141) Problem Set # 1Ahmad S. BesailyNo ratings yet

- 15ME641Document3 pages15ME641Anmol NairNo ratings yet

- No of Pages: 4 Course Code: 12M502: Fig.1 Fig 2Document4 pagesNo of Pages: 4 Course Code: 12M502: Fig.1 Fig 2CRAZY PIANO PLAYERNo ratings yet

- Me 7 Sem Design of Mechanical Drives Winter 2017Document2 pagesMe 7 Sem Design of Mechanical Drives Winter 2017djniksthehearteditorNo ratings yet

- TUTORIAL 3 Design of Shaft Key and CouplingDocument2 pagesTUTORIAL 3 Design of Shaft Key and Couplingrip111176100% (1)

- Design of Transmission System QuestionsDocument4 pagesDesign of Transmission System QuestionsMangesh SNo ratings yet

- QB Unit-3,4,5Document7 pagesQB Unit-3,4,5Agranshu BhardwajNo ratings yet

- Common Subject Code: Shivaji University, KolhapurDocument10 pagesCommon Subject Code: Shivaji University, Kolhapursatyamchgl2010No ratings yet

- Design Problems CoachingDocument31 pagesDesign Problems CoachingsedexxNo ratings yet

- Assignment QuestionDocument15 pagesAssignment QuestionPratik WalimbeNo ratings yet

- Design of Transmission Systems Model ExamDocument3 pagesDesign of Transmission Systems Model ExamrajkumardotcomNo ratings yet

- DME Question Bank unit (3-4-5)Document7 pagesDME Question Bank unit (3-4-5)PrathamNo ratings yet

- ASSIGNMENTS OF MD II New FormatDocument15 pagesASSIGNMENTS OF MD II New Formatsushant vermaNo ratings yet

- Machine Design & Industrial Drafting SUBJECT CODE:-2141907 Tutorial - 01Document10 pagesMachine Design & Industrial Drafting SUBJECT CODE:-2141907 Tutorial - 01The AIRS CreationsNo ratings yet

- Design1 SheetsDocument9 pagesDesign1 SheetsYou channelNo ratings yet

- 15A03602 Design of Machine Members - IIDocument2 pages15A03602 Design of Machine Members - IIJagannath CherkuNo ratings yet

- Gearing - ProblemsDocument7 pagesGearing - ProblemsmanuNo ratings yet

- Tutorial Sheet No 1 On Spur GearDocument3 pagesTutorial Sheet No 1 On Spur GearChirayuNo ratings yet

- Dme-2 2017-18 Ist AssignmentDocument1 pageDme-2 2017-18 Ist Assignmentmallesh mendaNo ratings yet

- Advanced Electric Drives: Analysis, Control, and Modeling Using MATLAB / SimulinkFrom EverandAdvanced Electric Drives: Analysis, Control, and Modeling Using MATLAB / SimulinkNo ratings yet

- How to Run a Lathe - Volume I (Edition 43) The Care and Operation of a Screw-Cutting LatheFrom EverandHow to Run a Lathe - Volume I (Edition 43) The Care and Operation of a Screw-Cutting LatheRating: 4.5 out of 5 stars4.5/5 (2)

- O level Physics Questions And Answer Practice Papers 1From EverandO level Physics Questions And Answer Practice Papers 1Rating: 3.5 out of 5 stars3.5/5 (4)

- Dowell's Price List 18.3.2022Document26 pagesDowell's Price List 18.3.2022Sunil WadekarNo ratings yet

- Implementation of Swachh Bharat in MysoreDocument13 pagesImplementation of Swachh Bharat in MysoreDipyaman ChoudhuryNo ratings yet

- D754te3 VMDocument37 pagesD754te3 VMGurpreet SinghNo ratings yet

- Dahong PalayDocument2 pagesDahong PalayAngela MontenegroNo ratings yet

- Fujitsu GeneralDocument51 pagesFujitsu GeneralZubair DarNo ratings yet

- Nursing Care of The Patient Undergoing Lumbar Spinal Fusion: ReviewsDocument10 pagesNursing Care of The Patient Undergoing Lumbar Spinal Fusion: ReviewsMuammar100% (1)

- The Role of Technology in AgricultureDocument35 pagesThe Role of Technology in AgricultureDivyesh ThumarNo ratings yet

- Chemistry in Everyday LifeDocument33 pagesChemistry in Everyday LifeArya StarkNo ratings yet

- Let's Check: To Eliminate Unrealized Gain On Sale of LandDocument4 pagesLet's Check: To Eliminate Unrealized Gain On Sale of Landalmira garciaNo ratings yet

- Color Me VeganDocument272 pagesColor Me VeganBela Luísa Novo100% (1)

- Scope Management Plan TemplateDocument10 pagesScope Management Plan TemplateAlessandro Rota100% (1)

- Folder Hexa EngDocument8 pagesFolder Hexa EngMuresan MVNo ratings yet

- ป 6Document43 pagesป 6MoLo Kanyarat ChenpitaksombatNo ratings yet

- Pearly Co Cleared Funds ForecastDocument8 pagesPearly Co Cleared Funds ForecastPutin Phy0% (1)

- Automated Hematology Cell Counters 12-09-2023Document161 pagesAutomated Hematology Cell Counters 12-09-2023Tom JohnathanNo ratings yet

- Main Receiving Station PDFDocument8 pagesMain Receiving Station PDFPrakash Kumar0% (1)

- Ats, TT, Tig: Anti Tetanus Serum, Tetanus Toxoid, Tetanus Immuno-GlobulinDocument15 pagesAts, TT, Tig: Anti Tetanus Serum, Tetanus Toxoid, Tetanus Immuno-Globulinjisoo100% (2)

- Order - Judgement Query Coram WiseDocument13 pagesOrder - Judgement Query Coram Wisesatish_CJNo ratings yet

- Alpine Valley Liability ReleaseDocument1 pageAlpine Valley Liability ReleaseChristina Nakazaki0% (1)

- 2018 Ibc Seaoc Structural Seismic Design Manual Volume 2 Examplespdf CompressDocument385 pages2018 Ibc Seaoc Structural Seismic Design Manual Volume 2 Examplespdf Compressvkch saipavan100% (3)

- Trilon C Types TI enDocument11 pagesTrilon C Types TI enjuanfelipehincapieNo ratings yet

- Understanding the Relationship Between Place and HealthDocument14 pagesUnderstanding the Relationship Between Place and HealtheNo ratings yet

- Perineal Care Procedure GuideDocument2 pagesPerineal Care Procedure GuideAlhadzra AlihNo ratings yet

- Symbol High Low R5 R4 R3 R2: DailyDocument8 pagesSymbol High Low R5 R4 R3 R2: Daily257597 rmp.mech.16No ratings yet

- IRC Girl Shine Part 4 DigitalDocument124 pagesIRC Girl Shine Part 4 DigitalMónica SalesNo ratings yet

- S# Isin CFI Code (As Per New ISO) Security Name Security Symbol Sector Name Security Type StatusDocument25 pagesS# Isin CFI Code (As Per New ISO) Security Name Security Symbol Sector Name Security Type StatusahmedalishNo ratings yet

- Aiesha Edward Resume2Document2 pagesAiesha Edward Resume2api-491571342No ratings yet

- Chap 24 Econ 40Document4 pagesChap 24 Econ 40Racel DelacruzNo ratings yet

- 01 Well Head ComponentsDocument46 pages01 Well Head ComponentsKhanh Pham Minh100% (7)

- Aire Acondicionado Mazda 3 2006Document2 pagesAire Acondicionado Mazda 3 2006Jhon ConnorNo ratings yet