Professional Documents

Culture Documents

DCS16 1 - 4 - 6MM A

Uploaded by

tugcebender90Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

DCS16 1 - 4 - 6MM A

Uploaded by

tugcebender90Copyright:

Available Formats

DCS16-1/4"-6MM-A

Ruland DCS16-1/4"-6MM-A, 1/4" x 6mm Single Disc Coupling, Aluminum,

Clamp Style, 1.000" (25.4mm) OD, 1.031" (26.2mm) Length

Description

Ruland DCS16-1/4"-6MM-A is a clamp single disc coupling with 0.2500" x 6mm bores, 1.000" (25.4mm) OD, and 1.031" (26.2mm) length. It is

zero-backlash and has a balanced design for reduced vibration at high speeds. The single disc design is comprised of two anodized aluminum

hubs and two sets of thin stainless steel disc springs which can accommodate angular misalignment and axial motion, however does not allow for

any parallel misalignment. DCS16-1/4"-6MM-A is lightweight and has low inertia making it well suited for applications with speeds up to 10,000

RPM. Hardware is metric and tests beyond DIN 912 12.9 standards for maximum torque capabilities. Ruland manufactures DCS16-1/4"-6MM-A

to be torisionally rigid and an excellent fit for precise positioning stepper servo applications commonly found in semiconductor, solar, printing,

machine tool, and test and measurement systems. It is machined from solid bar stock that is sourced exclusively from North American mills and

RoHS3 and REACH compliant. DCS16-1/4"-6MM-A is manufactured in our Marlborough, MA factory under strict controls using proprietary

processes.

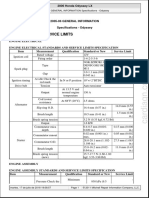

Product Specifications

Bore (B1) 0.2500 in Small Bore (B2) 6 mm

B1 Max Shaft Penetration 0.499 in (12.7 mm) B2 Max Shaft Penetration 0.499 in (12.7 mm)

Outer Diameter (OD) 1.000 in (25.4 mm) Bore Tolerance +0.001 in / -0.000 in (+0.03 mm /

-0.00 mm)

Length (L) 1.031 in (26.2 mm) Hub Width (LH) 0.467 in (11.85 mm)

Recommended Shaft Tolerance +0.0000 / -0.0005 " (+0.000 / -0.013 Forged Clamp Screw M3

mm)

Screw Material Alloy Steel Hex Wrench Size 2.5 mm

Screw Finish Black Oxide Seating Torque 2.1 Nm

Number of Screws 2 ea Dynamic Torque Reversing 12.5 lb-in (1.40 Nm)

Angular Misalignment 1.0° Dynamic Torque Non-Reversing 25 lb-in (2.80 Nm)

Parallel Misalignment 0.000 in (0.00 mm) Static Torque 50 lb-in (5.6 Nm)

Axial Motion 0.006 in (0.15 mm) Torsional Stiffness 94 lb-in/Deg (10.6 Nm/Deg)

Moment of Inertia 0.0089 lb-in2 (2.602 x 10-6 kg-m2) Maximum Speed 10,000 RPM

Full Bearing Support Required? Yes Zero-Backlash? Yes

Balanced Design Yes Torque Wrench TW:BT-1R-1/4-18.3

Recommended Hex Key Metric Hex Keys Material Specification Hubs: 2024-T351 Aluminum Bar,

Disc Springs: Type 302 Stainless

Steel

Temperature -40°F to 200°F (-40°C to 93°C) Finish Specification Sulfuric Anodized MIL-A-8625 Type

II, Class 2 and ASTM B580 Type B

Black Anodize

Manufacturer Ruland Manufacturing Country of Origin USA

Weight (lbs) 0.066900 UPC 634529130940

Tariff Code 8483.60.8000 UNSPC 31163008

Note 1 Stainless steel hubs are available upon request.

Note 2 Torque ratings are at maximum misalignment.

Note 3 Performance ratings are for guidance only. The user must determine suitability for a particular application.

Note 4 Torque ratings for the couplings are based on the physical limitations/failure point of the disc springs. Under

normal/typical conditions the hubs are capable of holding up to the rated torque of the disc springs. In some

cases, especially when the smallest standard bores are used or where shafts are undersized, slippage on the

Ruland Manufacturing Co., Inc. 1

6 Hayes Memorial Drive • Marlborough, MA 01752 • Main 508-485-1000 • Email sales@ruland.com • www.ruland.com

shaft is possible below the rated torque of the disc springs. Keyways are available to provide additional

torque capacity in the shaft/hub connection when required. Please consult technical support for more

assistance.

Prop 65 WARNING This product can expose you to chemicals including Ethylene Thiourea and Nickel (metallic),

known to the State of California to cause cancer, and Ethylene Thiourea known to the State of California to

cause birth defects or other reproductive harm. For more information go to www.P65Warnings.ca.gov.

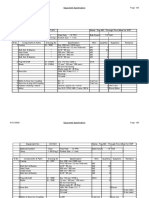

Installation Instructions

1. Align the bores of the DCS16-1/4"-6MM-A single disc coupling on the shafts that are to be joined

and determine if the misalignment parameters are within the limits of the coupling. (Angular

Misialignment: 1.0°, Parallel Misalignment: 0.00 in (0.00 mm), Axial Motion: 0.006 in (0.15 mm))

2. Fully tighten the M3 screw on the first hub to the recommended seating torque of 2.1 Nm using a 2.5

mm hex torque wrench.

3. Before tightening the screw on the second hub, rotate the coupling by hand to allow it to reach its

free length.

4. Tighten the screw on the second hub to the recommended seating torque. Make sure the coupling

remains axially relaxed and the misalignment angle remains centered along the length of the

coupling.

5. The shafts may extend into the relieved portion of the bore as long as it does not exceed the shaft

penetration length of 0.499 in (12.7 mm).

Ruland Manufacturing Co., Inc. 2

6 Hayes Memorial Drive • Marlborough, MA 01752 • Main 508-485-1000 • Email sales@ruland.com • www.ruland.com

Powered by TCPDF (www.tcpdf.org)

You might also like

- Ferguson Te20 - Tef20 Parts ListDocument48 pagesFerguson Te20 - Tef20 Parts ListEcu318se100% (1)

- Lathe Machine CZ1440G-1 ManualDocument32 pagesLathe Machine CZ1440G-1 Manualsecondharbour China100% (1)

- Especificaciones de Servicio Motor Chrysler Pentastar 3.6LDocument100 pagesEspecificaciones de Servicio Motor Chrysler Pentastar 3.6LNicolas Jesus Retamal Zuñiga100% (3)

- Melag 23 Autoclave - Maintenance ManualDocument8 pagesMelag 23 Autoclave - Maintenance Manualleopa7850% (2)

- 3.0L EngineDocument182 pages3.0L EnginewawanNo ratings yet

- Technical Report For SolidworksDocument13 pagesTechnical Report For SolidworksWesleyNo ratings yet

- Hot Work Safety Training (1122)Document15 pagesHot Work Safety Training (1122)Rosano D. Manamtam100% (1)

- PCMR32 10 10 ADocument2 pagesPCMR32 10 10 ArrNo ratings yet

- LTypeHubswithKeyway Inch (Imperial) BoresDocument4 pagesLTypeHubswithKeyway Inch (Imperial) BoresMohamed EbeidNo ratings yet

- 2Az-Fe Engine Mechanical: Service DataDocument6 pages2Az-Fe Engine Mechanical: Service DataFaisal Mohammad HassaniNo ratings yet

- Fixfast DF2 LS Stitcher Datasheet 2Document6 pagesFixfast DF2 LS Stitcher Datasheet 2Jonathan DouglasNo ratings yet

- Connecting Rod Bearing Journal - Spheroidal Graphite Iron Crankshaft PDFDocument2 pagesConnecting Rod Bearing Journal - Spheroidal Graphite Iron Crankshaft PDFjoaobargasNo ratings yet

- Perkins 4.154 Torque Specs and Assembly Information Copy.Document42 pagesPerkins 4.154 Torque Specs and Assembly Information Copy.Engine PartsNo ratings yet

- Vehicles 6 Speed PowerShift Transmission DPS6Document3 pagesVehicles 6 Speed PowerShift Transmission DPS6Carlos SerapioNo ratings yet

- Crankshaft Grinding GuidelinesDocument2 pagesCrankshaft Grinding Guidelinesиван ТрояновNo ratings yet

- RR11 Brochure PDFDocument4 pagesRR11 Brochure PDFel.runitaNo ratings yet

- SpecificationsDocument11 pagesSpecificationsTigran SHAHGALDYANNo ratings yet

- Спецификации PDFDocument1 pageСпецификации PDFиван ТрояновNo ratings yet

- 412-Cro-Ch65 Fig. 65-6Document3 pages412-Cro-Ch65 Fig. 65-6slam12125No ratings yet

- Prueba Resorte de EmbragueDocument2 pagesPrueba Resorte de Embraguejohan gomezNo ratings yet

- Fichetechnique-White-Metal Anglais Site 2Document1 pageFichetechnique-White-Metal Anglais Site 2sourajpatelNo ratings yet

- Katalog Wire Mesh SteelindonesiaDocument2 pagesKatalog Wire Mesh Steelindonesiarisiana_limuriaNo ratings yet

- DF2 SS LS DatasheetDocument4 pagesDF2 SS LS DatasheetJonathan DouglasNo ratings yet

- Makita Torque Shear Bolt For TighteningDocument2 pagesMakita Torque Shear Bolt For TighteningMeriam DacunesNo ratings yet

- Tuning Valve ClearanceDocument3 pagesTuning Valve ClearanceShimmer Crossbones100% (1)

- Rupture Disk: SKR-U Rupture Disk Partnered With A Threaded Union-Type HolderDocument4 pagesRupture Disk: SKR-U Rupture Disk Partnered With A Threaded Union-Type HolderJulio Cesar ReyesNo ratings yet

- 1a PARTE MERCURY V6Document8 pages1a PARTE MERCURY V6Antonio VillafuerteNo ratings yet

- RAS-3015T 1000W: Technical ProposalDocument15 pagesRAS-3015T 1000W: Technical ProposalAhmed ShafeekNo ratings yet

- 12.25 DT1GJMRS PDFDocument1 page12.25 DT1GJMRS PDFBelen CastroNo ratings yet

- Protable Line Boring MachineDocument13 pagesProtable Line Boring MachineMary SmithNo ratings yet

- Tyco Terminal - Product Specification PDFDocument4 pagesTyco Terminal - Product Specification PDFMohammed084No ratings yet

- 303-01 - 2.3L Ecoboost - SpecificationsDocument5 pages303-01 - 2.3L Ecoboost - SpecificationsCARLOS LIMADANo ratings yet

- Contanier QRDocument49 pagesContanier QRAxel LetonaNo ratings yet

- Eutalloy 11496Document2 pagesEutalloy 11496jorge_20120% (1)

- SKI Techl Spec - Engine - 600HOETEC (Line-Up) - Supplement mmr2017-124 enDocument3 pagesSKI Techl Spec - Engine - 600HOETEC (Line-Up) - Supplement mmr2017-124 enSkorost SkorostNo ratings yet

- 5.25 MM ROCLADocument1 page5.25 MM ROCLAemmydadNo ratings yet

- Side-Mount External Retaining Ring: 15-7 PH Stainless Steel, For 5/32" ODDocument2 pagesSide-Mount External Retaining Ring: 15-7 PH Stainless Steel, For 5/32" ODYossiNo ratings yet

- Nibbler GNA 2.0 Professional: The Handy Tool For Cut-Outs of All KindsDocument1 pageNibbler GNA 2.0 Professional: The Handy Tool For Cut-Outs of All KindsMarcus Vinicios Pantoja da SilvaNo ratings yet

- W 619 - 1 - Deep Groove Ball Bearings SKFDocument6 pagesW 619 - 1 - Deep Groove Ball Bearings SKFhairynigga1996No ratings yet

- Techincal Specifications Shop Manual 2011 REX 550 - ETEC enDocument20 pagesTechincal Specifications Shop Manual 2011 REX 550 - ETEC enSkorost SkorostNo ratings yet

- DSI Underground Systems Cable Bolts US 01Document16 pagesDSI Underground Systems Cable Bolts US 01Tato Del AguilaNo ratings yet

- Kubler - Bellows CouplingsDocument2 pagesKubler - Bellows CouplingsSayak BoseNo ratings yet

- 14 Spline NutDocument24 pages14 Spline NutCAT MINING SHOVELNo ratings yet

- Axle (Rear) - (Specifications) - 3Document4 pagesAxle (Rear) - (Specifications) - 3Ava AddamsNo ratings yet

- Hilti Drilling Screw DocumentDocument8 pagesHilti Drilling Screw DocumentGregory Alan Francisco IINo ratings yet

- AA02193C STRG Pin Wear Checks and SizesDocument8 pagesAA02193C STRG Pin Wear Checks and SizesSebastiao DuarteNo ratings yet

- Traction MotorDocument117 pagesTraction Motorbharath100% (1)

- Standards and Service Limits: 2005-06 General InformationDocument21 pagesStandards and Service Limits: 2005-06 General Informationvadim vadim100% (1)

- 084 DT4GMRSDocument1 page084 DT4GMRSigorsfaceNo ratings yet

- Welding Studs Capacitor Discharge PDFDocument24 pagesWelding Studs Capacitor Discharge PDFCesarNo ratings yet

- Analysis and Design of Tall Buildings Bungale S TaranathDocument8 pagesAnalysis and Design of Tall Buildings Bungale S TaranathPerr CortezNo ratings yet

- Burndy mrc840 SpecsheetDocument2 pagesBurndy mrc840 SpecsheetJesús Cortés SosaNo ratings yet

- Rigid Coupling 4Document9 pagesRigid Coupling 4Yosia HutasoitNo ratings yet

- Belting Correia de BorrachaDocument54 pagesBelting Correia de BorrachaFilype NascimentoNo ratings yet

- Pug MillDocument4 pagesPug Millprashant mishraNo ratings yet

- 7.2 Crusher Erection and Maintenance Data - FlsmidthDocument4 pages7.2 Crusher Erection and Maintenance Data - Flsmidthdannyjoelec99No ratings yet

- Jeep Renagade 1.3 SpecsDocument9 pagesJeep Renagade 1.3 SpecsJoão Koiti InoueNo ratings yet

- Report 2.0 DESIGN MECHY UITMDocument15 pagesReport 2.0 DESIGN MECHY UITMAliMubarakNo ratings yet

- Ranger 2007 3.0LDocument189 pagesRanger 2007 3.0LguillermoNo ratings yet

- Pamphlet On Traction Motor HS-15250ADocument4 pagesPamphlet On Traction Motor HS-15250ASathish ManoharanNo ratings yet

- Catalogue Worm Gear Sets and Customised Worm Gear SetsDocument30 pagesCatalogue Worm Gear Sets and Customised Worm Gear Setsfog900No ratings yet

- BOQ - Jay Jay Avissawella C8 (COM ROOM)Document1 pageBOQ - Jay Jay Avissawella C8 (COM ROOM)Isuru PrabodaNo ratings yet

- Motion Ina Straight LineDocument14 pagesMotion Ina Straight Linemrnandafx 004No ratings yet

- CFD Analysis On Residence TimeDocument7 pagesCFD Analysis On Residence TimeKahwai WongNo ratings yet

- Washer - ISO 7093-1-2000Document9 pagesWasher - ISO 7093-1-2000Corneliu VilcuNo ratings yet

- Eutectic Boiler Repair Single Pages PDFDocument12 pagesEutectic Boiler Repair Single Pages PDFscofiel1No ratings yet

- 1 Introduction To Quantum Mechanics Unit IDocument12 pages1 Introduction To Quantum Mechanics Unit IyomamaNo ratings yet

- Grade 5 Science Lesson 8-Force, Energy and Machines Module 1Document21 pagesGrade 5 Science Lesson 8-Force, Energy and Machines Module 1praviseNo ratings yet

- Intro To Centrifugal CompressorDocument5 pagesIntro To Centrifugal CompressorMuhammad RidhwanNo ratings yet

- Chapter 12 (Torque Converters)Document20 pagesChapter 12 (Torque Converters)ZIBA KHADIBI100% (2)

- Layout and Design: Hot Runner GuideDocument18 pagesLayout and Design: Hot Runner GuideARUN KUMAR KoterimadathilNo ratings yet

- 1991 Ford Festiva DiagramaDocument16 pages1991 Ford Festiva Diagramatransportes murrietaNo ratings yet

- CE 3111 Lecture Notes 1Document26 pagesCE 3111 Lecture Notes 1Kent Clark VillaNo ratings yet

- Effect of Localized Fire Damage On Failure Mode Shifts in Sandwich StructuresDocument1 pageEffect of Localized Fire Damage On Failure Mode Shifts in Sandwich StructuresjameswNo ratings yet

- Mait Gama Completa ForezeDocument44 pagesMait Gama Completa Forezemacielxflavio50% (4)

- Experimental Tests vs. Theoretical Modeling For FRC in CompressionDocument8 pagesExperimental Tests vs. Theoretical Modeling For FRC in CompressionandresNo ratings yet

- Structural Bolts CatalogueDocument3 pagesStructural Bolts CatalogueTom CaineNo ratings yet

- A4-P 1.0 enDocument4 pagesA4-P 1.0 enshani5573No ratings yet

- Training Courses - BETA Machinery AnalysisDocument8 pagesTraining Courses - BETA Machinery AnalysisJose BijoyNo ratings yet

- 3604 SMN-JWR PDFDocument7 pages3604 SMN-JWR PDFsaharaNo ratings yet

- Plan Scari MariteDocument1 pagePlan Scari MariteNicu PrunaNo ratings yet

- C172 ChecklistDocument1 pageC172 ChecklistsergioNo ratings yet

- iCR 3600 Flat Gear and Motor Replacement: WarningDocument13 pagesiCR 3600 Flat Gear and Motor Replacement: WarningEliana Caceres TorricoNo ratings yet

- Omni-X Tube Bending GuideDocument15 pagesOmni-X Tube Bending GuidemsppmsNo ratings yet

- GSX150 MB8NG4BF (L7)Document92 pagesGSX150 MB8NG4BF (L7)Javier LlumpoNo ratings yet

- Difrential Gear Box Final P P TDocument20 pagesDifrential Gear Box Final P P TShaik AshfakhNo ratings yet

- Verde IvecoDocument3 pagesVerde IvecoLuca RobertNo ratings yet